When choosing heating devices to supply the house with hot water and heating, the homeowner is guided, first of all, by considerations of the appropriateness of the device in a particular case. It is necessary to calculate the economic issue - how much the equipment, its installation, and maintenance will cost. It is important and technically justified to choose a boiler so that its performance is sufficient to solve the main problem, and at the same time you do not have to overpay for unnecessary options and excess power. In some cases, it is convenient to use a system where the energy carrier is natural wood. Especially in those areas where there is no gas supply line or there are power outages.

Wood boiler for home heating Source anatomycharty.com

Types of wood boilers

Do not confuse the device with a stove: it has a different operating principle. If the stove heats the air, then wood-burning boilers for the home are designed to operate a water heating system. Hence a different approach to equipment design. The heat exchanger is located in the air overheating zone. The natural or forced movement of water in the system carries it through pipes to heating devices in the home. Having given up some of the energy, the cooled water again returns to the boiler, where it is brought to the desired temperature. The fluid circulation circuit is designed based on the design of the heating device. For this reason, it is recommended to purchase a wood-burning boiler for heating a private house with batteries before installing the heating distribution.

The most important indicator of boiler performance is its efficiency, which largely depends on the design of the combustion chamber and heat exchanger. It is customary to divide equipment intended for firewood into the following types:

- Classical.

- Boiler with top ignition for long burning.

- Pyrolysis.

- Long combustion boiler with an extended firebox.

Boiler in a heating system Source msk-kamin.ru

In addition to differences in design due to the principle of operation, devices can be equipped with additional parts. For example, pellet boilers are often equipped with automatic fuel supply. Some models have sensors that inform about current processes and help install a remote control system. Today, wood-burning boilers for home heating are efficient, modern devices that successfully compete in performance with the best examples of gas and electric equipment.

Classic wood boiler

Traditional oven-like design. The main metal container or a separate device connected to a separate storage tank is used as a heat exchanger. Efficiency depends on the correct arrangement of structural elements, their sizes, regulation system and control over the combustion process. The draft damper is installed in a position where the exhaust air flow is sufficient to prevent combustion products from entering the room. Excessive speed of convection flows is undesirable, since thermal energy will not have time to transfer the required amount of heat to the heat exchanger. Strong draft will blow hot air out into the street. System efficiency decreases and fuel consumption increases significantly.

Classic wood boiler Source gorodvitebsk.by

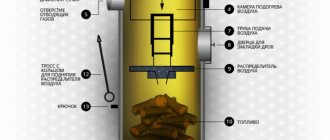

Boiler with top ignition

This design refers to long-burning devices. A characteristic feature of a boiler with top ignition is a fairly large volume of firewood and a controlled combustion process from top to bottom. The flame spreads more slowly. The dosed air supply does not allow the rapid spread of open fire; it is enough to maintain a certain level of combustion. As the top layer is consumed, the firewood located below begins to be included in the process. A high-quality top-burning boiler can operate on one load for up to two days.

See also: Contacts of companies that specialize in home insulation.

Boiler with top ignition Source tr.skopelitissa.com

Pyrolysis boiler

Modern productive system based on the principle of double combustion. When wood burns, gas is formed, which in a conventional firebox is discharged into the chimney. Moreover, under certain conditions, it also has the ability to release energy when burned. The design of the pyrolysis boiler consists of two compartments. In the first, the wood burns, in the second, the gas it produces. This design is often called a gas generator. Ensures more complete combustion of fuel. The efficiency of the device is higher than that of a traditional boiler. A more complex design will cost a little more, but will quickly pay for itself with lower fuel consumption. Such a boiler for heating a private house using wood is considered the most productive and economical.

Pyrolysis boiler Source projject.ru

Boiler with extended firebox

The operating principle is similar to a device with top ignition. The special design of the firebox allows the firewood to be placed in such a way that the horizontal spread of an open flame is difficult. A minimal air supply also contributes to this. The fire gradually moves from one edge of the firebox to the other. Unlike the traditional design, the release time of the potential energy of one bookmark is significantly longer. The simplicity of the boiler and high efficiency make it attractive for those who do not want or do not have the opportunity to constantly monitor the combustion process. Manufacturers are trying to offer models with a single daily load, which is very convenient both for a country woman with permanent residence, and for temporary housing, for example, a dacha.

Boiler with an extended firebox Source aquatools.com.ua

Stropuva

This company specializes in the production of heating boilers with a top combustion system. The history of such technology dates back to 2000. At this time, an engineer from Lithuania first created a heating device with a similar system. Subsequently, it became the most economical and was able to win the title of the best heating system running on solid fuel. Thanks to a special type of ignition, firewood burns many times longer and produces maximum heat. Stropuva are boilers with the highest efficiency.

S20U

[gallery2 link=”file” size=”full” ids=”13964,13962,13963"]

| Min./Max. Coolant temperature, degrees Celsius | Maximum water pressure in the circuit | Additional functions | Fuel types | Dimensions, mm | Weight, kg | Price, rubles | grade |

| 60/95 | 1,5 | Built-in heating fan, safety valve. | Wood briquettes, coal, | 2120*557*557 | 236 | 98 920 | 4 |

S20P

[g[gallery2 link="file" size="full" ids="13965,13966,13967"]/p>

| Min./Max. Coolant temperature, degrees Celsius | Maximum water pressure in the circuit | Additional functions | Fuel types | Dimensions, mm | Weight, kg | Price, rubles | grade |

| 60/95 | 1,5 | Built-in heating fan, safety valve. | Wood briquettes | 2120*557*557 | 236 | 83 620 | 4 |

S20

[gal[gallery2 link=»file» size=»full» ids=»13967,13965,13966"]>

| Min./Max. Coolant temperature, degrees Celsius | Maximum water pressure in the circuit | Additional functions | Fuel types | Dimensions, mm | Weight, kg | Price, rubles | grade |

| 60/95 | 1,5 | Built-in heating fan, safety valve. | Wood briquettes, | 2120*560*560 | 231 | 79 410 | 5 |

How to choose the right model

When purchasing, you should be guided by all the information about the features of the models that will be important during operation. From the ability to install in a prepared room to the quality of the wood burned. The choice of a specific model is determined by the following economic and technical characteristics:

- Price. The cheapest are classic designs. They are 2-4 times cheaper than pyrolysis analogues.

- Boiler weight. Steel construction is lighter than cast iron. The heaviest models are some types of pyrolysis boilers. Weight can reach 500 kg. This factor should be taken into account when purchasing. The floor in the boiler room must be sufficiently reinforced.

- Power. It is generally accepted that 1 kilowatt is needed per 10 m2 of area with average energy efficiency of housing. In regions with harsh climates, a correction factor is used. Sometimes it can be up to 2 units. A high level of thermal protection, on the contrary, will reduce the average value. For a “smart home” you can apply a coefficient of 0.5-0.7.

- Material of manufacture. Steel boilers are noticeably cheaper. The metal burns out faster, and the service life of such a device is about 20 years. Cast iron is more resistant to high temperatures and will withstand 35 years of regular use, and it is also more inertial. It warms up slower, but cools down longer, which in some cases is very beneficial.

Domestic wood boilers Source criptopia.ru

Galmet

A large Polish company for the production of heating devices, founded in 1982. For many years, the engineers of this company have been busy developing and improving technology for the production of equipment. Currently, Galmet is a popular company in Europe and Russia. Equipment is supplied to almost three dozen countries around the world. The production process is constantly being automated, which helps eliminate as many human errors as possible and reduce the cost of manufacturing heating equipment.

GT KWuZ 20

[galle[gallery2 link=»file» size=»full» ids=»13969,13970,13971"]

| Min./Max. Coolant temperature, degrees Celsius | Maximum water pressure in the circuit | Additional functions | Fuel types | Dimensions, mm | Weight, kg | Price, rubles | grade |

| 50/90 | 2 | Pressure gauge. | Wood briquettes, coke, peat, peat briquettes, coal, | 1120*465*960 | 272 | 20 490 | 4 |

Top 20

[gallery[gallery2 link=»file» size=»full» ids=»13954,13956,13955"]able>

Min./Max. Coolant temperature, degrees CelsiusMaximum water pressure in the circuitAdditional functionsTypes of fuelDimensions, mmWeight, kgPrice, rublesestimate 50/852Overheat protection, underfloor heating connection, pressure gauge.Wood briquettes, coal,1120*465*960272102 3005Wood 20

[gallery2 [gallery2 link=”file” size=”full” ids=”13958,13959,13960"]le>

Min./Max. Coolant temperature, degrees CelsiusMaximum water pressure in the circuitAdditional functionsTypes of fuelDimensions, mmWeight, kgPrice, rublesestimate 50/852Overheat protection, underfloor heating connection, pressure gauge.Wood briquettes,1300*465*98527094 7005Wood boiler installation

Fundamentally, the installation of the device does not differ from a similar operation with gas equipment. However, some nuances should be taken into account. The energy carrier for the gas boiler comes through a pipe from the main line and does not require any effort from the user. During combustion, combustion products are not collected. Firewood requires a separate storage place with recommended conditions. It is advisable that they be in a dry place. High humidity reduces work efficiency, since part of the energy is spent on drying the wood. Adding fuel to the boiler and removing ash is done strictly following fire safety precautions.

Particular attention is paid to the ventilation system and chimney design. When burning, a large amount of substances harmful to health is released. Their entry into residential premises is unacceptable. Modern boilers from leading manufacturers are equipped with reliable protection systems and sensors. However, wood-burning devices are not recommended to be installed in rooms combined with living space. A steel sheet is laid under the boiler within a radius of at least 1 meter. There are no conflicts when communicating with a standard heating system.

Model of a heating system based on a wood boiler Source maltavista.ru

Heating systems

Not only the models of heating devices differ, but also the heating systems.

Gravity system

Gravity system diagram

This is one of the simplest schemes for installing heating devices. The boiler pipes are connected to the supply and return pipelines. At the outlet of the heating device there must be a safety system, including a pressure gauge and a safety valve. Shut-off valves are not allowed between it and the device itself. For the system to work correctly, the tank is located at the top; in multi-storey buildings it should be in the attic, and in lower houses it should be in the furnace room. The main rule is that the tank is located above the heating system. A simple system requires the installation of an equally simple heating device. In this case, a classic boiler is suitable.

Compulsory system

The scheme of the forced system

is distinguished by the presence of a pump. In such a system, temperature changes may occur if the device is turned off. This phenomenon can negatively affect cast iron products. To avoid boiler breakdowns, the circuit must include a primary circuit.

The valve will be busy regulating the return temperature.

Maintenance and care of a wood boiler

The main problem when operating equipment is the timely removal of combustion products. Ash is removed regularly. The high organic content in natural wood leads to rapid contamination of pipelines. The chimney becomes clogged several times faster than when using a gas boiler. With certain skills and available tools, this operation can be carried out independently. If this is not possible, then specialists are called. If the chimney is operated with a gas boiler running, then a successful pipeline configuration allows the operation to be carried out every few years. Wood-burning units require more frequent intervention. Depending on the design, the chimney is cleaned 1-2 times a year. If, with such a schedule, a significant decrease in the efficiency of the system is noticed, you should contact professionals to modify the route and improve the performance characteristics of the removal of combustion products.

Over the course of a year, 10-15 m3 of wood is used to heat a house. Prepare it in advance. Care should be taken to ensure that fuel is stored in a place protected from precipitation. A canopy will be enough. Good ventilation during installation also contributes to effective drying. The type of wood is of great importance. Conifers such as pine, spruce, and cedar are not among the best types of fuel, but they are inexpensive. Deciduous species provide greater heat output - birch, beech, oak, ash. These rocks are considered valuable, and only waste and non-business materials are used as fuel.

Boiler in need of cleaning Source vsaunu777.ru

Teplodar

The history of the Russian one began quite recently, in 1997. A group of engineers from Novosibirsk did not trust the stove manufacturers. These people decided to make their own heating device for their own bathhouse. To do this, they identified the requirements for the future product, found suitable materials and got to work. Rumors about high-quality stoves soon spread throughout the area, the founders of the company began accepting orders and after some time they organized their own company for the production of climate control equipment. Teplodar inspires trust, because the company originated in Siberia, where having high-quality heating in the house is a vital necessity. If in cold Novosibirsk people trust these stoves, then in all other regions you can rely on them.

Cooper OVK 18 with pellet burner

[gallery2 li[gallery2 link=”file” size=”full” ids=”13929,13931,13930"]>

Cooper OK 20 with pellet burner

[gallery2 link[gallery2 link=”file” size=”full” ids=”13938,13939,13940"]tr>

Cooper PRO 22

[gallery2 link=[gallery2 link=”file” size=”full” ids=”13942,13943,13944"]>

Min./Max. Coolant temperature, degrees CelsiusMaximum water pressure in the circuitAdditional functionsTypes of fuelDimensions, mmWeight, kgPrice, rublesestimate50/952Overheat protection.Wood briquettes, pellets,855*485*67011526 9804Cooper Practice 20

[gallery2 link=»f[gallery2 link=»file» size=»full» ids=»13948,13946,13947"]td>Min./Max. Coolant temperature, degrees Celsius

Cooper OK 20

[gallery2 link=»fil[gallery2 link=»file» size=»full» ids=»13950,13951,13952"]>Min./Max. Coolant temperature, degrees Celsius

Economic benefits when using a wood boiler

It is no coincidence that many reputable manufacturers have launched the production of equipment in this category. The demand for it is high not only in Russia and the CIS countries. Today, wood-burning boilers for homes with water heating are successfully used in many regions of Europe, America and Asia. The secret is simple - high prices for gas and electricity have led to the fact that servicing the corresponding equipment is expensive. In many countries, the production of pellets from waste from the woodworking and furniture industries has been established. The granules take up little space and are highly energy efficient. Moderate prices make their use extremely attractive. The cost of heating a house of 100-150 m2 with wood at the average market price is 10,000 -15,000 rubles. This is even lower than when using gas, although it is considered the most cost-effective energy carrier. In practice, it turns out that using the latest generation high-performance wood-burning boiler is more profitable than connecting gas equipment. Electricity will cost even more.

Design project for an individual boiler room Source stroi-archive.ru

In regions where cheap wood is available, these figures are even more impressive. In some areas there is a quota for independent fuel procurement. There are many wood processing enterprises across the country, for which a constant problem is the presence of large amounts of waste. Not all enterprises in the industry have established full processing lines. If there is such a production in the neighborhood, then installing a wood-burning boiler will significantly save the family budget.

Types of electric boilers

When selecting the power of a heating boiler according to the area of the house, it is worth understanding the main types of such devices:

- Heating elements. This is the traditional and most common version of electric boilers. Multi-stage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages is low efficiency due to heat loss for heating heating elements. But the advantages include low prices for consumables (heating elements) and easy repairs.

- Induction. In such equipment, the coolant is heated at the moment water passes through the inductive coil. It is believed that induction boilers are more economical compared to heating elements, they have no heat loss and virtually no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise the boilers overheat and burn out quickly.

- Electrode. Many buyers, when they want to choose a boiler according to its parameters, choose this type of equipment the least often. Although they are considered the most economical, in most cases consumers are stopped by the need to circulate electrolyte through the pipes as a coolant, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation operates under voltage - this also somewhat frightens consumers.

Rating of the TOP 10 best solid fuel boilers for heating a private home in 2021-2022

| TOP 3 best solid fuel boilers by price/quality for 2021-2022 | ||

| 1 | Protherm Beaver 50 DLO 39 kW | Find out the price |

| 2 | Teplodar Cooper Praktik 8 | Find out the price |

| 3 | ZOTA Box 8 8 kW | Find out the price |

| TOP 3 best long-burning solid fuel boilers | ||

| 1 | ZOTA Topol-22VK 22 kW | Find out the price |

| 2 | ZOTA Topol-16VK 16 kW | Find out the price |

| 3 | ZOTA Topol-32VK 32 kW | Find out the price |

| TOP 2 best solid fuel boilers with a water circuit | ||

| 1 | ZOTA Topol M 14 14 kW | Find out the price |

| 2 | Lemax Forward-16 17 kW | Find out the price |

| TOP 2 best pyrolysis solid fuel boilers | ||

| 1 | Bourgeois-K MODERN-12 12 kW | Find out the price |

| 2 | TRAYAN T-20-1KT | Find out the price |