Today our story will be devoted to the elements of the heating system, with which many tragic incidents are associated, and first of all we are talking about chimneys. If you have a bathhouse, cottage or residential building where an autonomous boiler is used, then you can potentially suffer from poor draft, which does not remove combustion products outside.

The accumulation of CO in the body can lead to “silent” death. If you want to know how to protect yourself and your loved ones, read the article to the end.

Ventilation and chimneys in a private metal house

Requirements for laying ventilation and smoke ducts when building a house

Today our story will be devoted to the elements of the heating system, with which many tragic incidents are associated, and first of all we are talking about chimneys.

If you have a bathhouse, cottage or residential building where an autonomous boiler is used, then you can potentially suffer from poor draft, which does not remove combustion products outside. The accumulation of CO in the body can lead to “silent” death. If you want to know how to protect yourself and your loved ones, read the article to the end.

Ventilation and chimneys in a private metal house

Ventilation duct for a gas boiler. Ventilation in a boiler room with a gas boiler

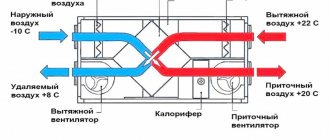

For gas equipment, regulatory documents indicate the minimum air exchange rate of 3 times in 1 hour. But in fact, the design, structure and characteristics of the model are taken into account. If the burner is open, calculate the volume of oxygen consumed. To generate 1 kW of thermal energy, 0.12 m³ of gas is required. For equipment with a power of 24 kW, this figure will be 2.88 m³. The average oxygen consumption is 10 times higher, 28.8 m³ per hour.

Effective ventilation of a gas boiler room is done according to the following rules:

- The supply inlet pipe is installed at the bottom of the wall opposite the heating device.

- The exhaust is mounted above the combustion chamber.

- A check valve is installed in the supply air to prevent changes in the direction of the air flow.

- The hood for a gas boiler in a private house has a larger diameter than the ducts.

The latter is necessary to distribute the flow from the supply ventilation duct between the exhaust vent and the chimney of the heating installation. Otherwise, less pressure will be created in the combustion chamber, which will lead to a decrease in power. Read all about smoke removal systems here.

Layout of ventilation elements and windows in the boiler room

Nikonorov Vladimir Alekseevich

Our expert. Specialist in the field of air conditioning and ventilation with 10 years of experience.

The air flow is equal to the incoming volume. This is important for forced convection. Otherwise, excess or reduced pressure will be created in the room.

For solid fuel boiler

The peculiarity of the operation of solid fuel heating is the periodic entry of combustion products into the room. This happens during fuel loading and ash removal. Therefore, for heating with a solid fuel boiler, the air exchange rate is increased by 10-15% compared to one operating on gas.

Things to consider:

- The outlet circulation channel is installed vertically in the ceiling above the soot formation zone.

- The minimum distance between it and the chimney is 0.5 m.

- Backdraft protection in the chimney. It is necessary to periodically clean it from soot and check its integrity.

For artificial air convection, standard fans are installed. Their power provides an inflow equal to the sum of the flow rates of the exhaust duct and the chimney.

The length of the vertical element for the convection movement of air masses must be at least 3 meters. The inlet pipe is located above the firebox and ash pan.

The need to arrange smoke and ventilation ducts

The laying of ventilation and chimney must be done at the stage of wall construction.

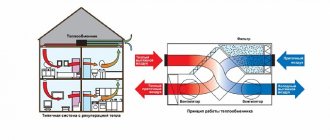

Full ventilation is air circulation, in which enough fresh air enters the room and waste materials are removed.

In modern homes it is becoming more and more complex. This is due to the equipment of apartments with plastic windows. Sealed structures reduce heat loss and protect against noise, but prevent microcirculation. As a result, natural exhaust cannot cope with air exchange. The dwelling must be equipped with additional ventilation ducts or forced ventilation.

For stove or boiler heating, separate chimney ducts are needed to serve only the heating unit. To burn 1 cubic meter of natural gas, 10 cubic meters of oxygen are required. It is impossible to take such a mass of air from a room. The supply of oxygen and the removal of combustion products is provided by chimneys.

Checking act

What does a chimney or ventilation duct inspection report include? Let's list its points:

We recommend that you read: Industrial ventilation

When might this act be required? Many organizations, including the Gas Authority, Home Inspectorate and the State Border Service, may want to look at this document during one of their inspections. Its absence will entail legal consequences that any of us would like to avoid.

For such cases, you should prepare a special package of documents, including:

Requirements and standards

Vertical ducts are mainly used for ventilation.

A number of documents regulate the construction of ventilation and chimney ducts: SNiP “Heating, Ventilation and Air Conditioning”, SNiP “Gas Supply”, “Safety Rules in the Gas Industry” and many others.

Based on these documents, a ventilation project for the building is developed. Calculations are made taking into account the amount of required air exchange. For a living room, 3 cubic meters of air per 1 hour per 1 square meter is sufficient. m area. For bathrooms, this value is much higher - up to 25 cubic meters. For the kitchen, at least 60 cubic meters are required. m. per hour, and if a gas stove is working - 100. Cooking in a kitchen with metal-plastic windows is only possible with a hood, since it is very difficult to arrange such powerful natural ventilation.

Requirements for ventilation ducts:

The chimney must be sealed and withstand high temperatures

Additional requirements apply to chimney ducts. The combustion temperature of fuel varies greatly. In addition, firewood, coal, even gas often burn incompletely, releasing aggressive acidic residues. This is taken into account when choosing.

Ventilation and chimney ducts must be cleaned periodically; this requirement is taken into account when developing the project.

Useful tips

If, after reading the information described above, you decide to organize an air exchange system yourself, then you probably want to receive useful instructions.

We understand this and present to your attention some important recommendations.

An example of a shaft laying (a – for a one-and-a-half row, b – for a double row)

- The laying of brick ventilation ducts should be made from solid samples. At the same time, we must not forget about the dressing rules. It is best to design this element in advance.

- As a rule, the dimensions of brickwork ventilation ducts are 14x14 cm, while chimneys should be slightly larger - 27x14 cm. In this case, the thickness of the walls between them should be at least half a brick.

- If you want to achieve the correct shape and prevent clogging of the shafts, insert special inventory buoys into them. Essentially it is a hollow box made of plywood.

- To create channels, you can use a regular solution of cement and sand. Before application, it is recommended to moisten the brick with water to improve its adhesion.

- It is recommended to make the channels smooth, that is, without any roughness. It is also not advisable to have protrusions or depressions, as they interfere with normal air circulation.

Take care to cut the brick to create the holes. As a rule, this operation causes difficulties for many people.

If there is a need to create a branch, then its length should be no more than 100 cm, and the angle of inclination should be at least 60 degrees relative to the horizon.

In this case, the cross-section in both parts of the channel must be equal, otherwise a decrease in traction efficiency will be observed. To lay sloping areas, you need to use hewn bricks at the desired angle.

In places in close proximity to wooden structures, it is necessary to create a cutting made of non-combustible materials. Asbestos is perfect for this.

It is also necessary to increase the thickness of the channel walls: up to 40 cm if the structure is not protected, and up to 25 cm otherwise.

For masonry, it is best to use double silicate brick m 150, as it has the required coefficient of frost resistance and thermal conductivity. However, other samples can also be used.

License

Much has already been said about licensing workers who want to engage in such a business, but now let’s talk in more detail. If someone wants to inspect chimneys and ventilation, then he will need a certain set of documents depending on whether he needs a license to inspect only residential buildings or industrial enterprises.

In the first case, the documents listed at the beginning of the article will be enough for him. Exactly:

Registration of a license if these documents are available takes forty-five days.

In the second case, the requirements are more stringent. Inspections at industrial enterprises are carried out only by legal entities. The license must contain information that there is permission to conduct inspections in such organizations. The requirements are essentially the same as for private entrepreneurs (availability of equipment and professional staff), but they are much higher.

System Design Options

Ventilation ducts in a private brick house can have different designs. The design is chosen taking into account the characteristics of the rooms and one feature common to the hood. Along with the exhaust air, heat is also removed. To prevent cooling, a bend in the form of a brick staircase will be included in the ventilation system. It creates a barrier and prevents premature removal of heated air: after being delayed, the air flow has time to partially transfer heat into the room.

Conclusions from the premises

This design is used for arranging complex ventilation. In the upper part of the building, all the channels are combined into a common shaft and discharged through the roof, like a chimney. Its height and diameter depend on the volume of the premises and the distance to the roof ridge.

Wall pipe

A brick chimney is installed in the internal walls.

The air duct is installed directly in the internal wall. Installing ventilation ducts, and even more so chimney wall pipes, in external walls is allowed only in exceptional cases. The wall is in contact with cold outside air. In this case, the exhaust gas, passing through the air duct, cools faster and does not warm the room properly. For the same reason, condensation quickly forms inside the chimney or ventilation duct itself. This reduces traction and accelerates wear, as acid anhydrides are deposited on the walls of the shaft. The wall pipe in the outer wall must be additionally insulated.

A separate chimney is installed for each stove. In exceptional cases, 1 chimney outlet is installed for 2 stoves. A ventilation duct is installed on every 2 chimneys.

The chimney riser ends at the top floor and turns into a regular chimney. The height of the chimney and the head of the ventilation duct depends on the exit location.

Root pipe

A brick chimney on its own foundation

is usually installed in wooden buildings. A brick chimney is erected on its own foundation, and the latter is not adjacent to the foundation of the building. The thickness of the walls is equal to half a brick.

The root pipe can be connected to two hearths. For this purpose, reversible sleeves are installed.

Mounted pipe

Constructed directly on the stove. Experts recommend placing a brick chimney not directly on the neck of the stove, but by first laying a reinforced concrete slab with holes on it. This device allows you to repair the stove in the future without disassembling the chimney.

What can you expect due to carelessness?

Alas, we so rarely pay attention to clogged chimneys and ventilation ducts that we could already find ourselves in “another world” a couple of times. This happens because of our carelessness, since we begin to at least do something when, due to the smoke in the room, we cannot see the picture on the TV.

But this is not so bad, the main danger is invisible and not felt by our receptors - it is carbon monoxide. It slowly begins to displace oxygen from below until it is completely pushed out of the room.

Advice: the chimney and ventilation are not installed in one pipe in accordance with SNiP.

Then there is very little time left in order to be able to save a person who, moreover, does not realize what is happening to him. It would seem that nothing could be more difficult than cleaning the chimney and ventilation duct in a timely manner, and then such a tragedy would never have happened.

Advice: find out the time for yourself and systematically carry out preventive maintenance of ventilation and chimneys, doing the procedure yourself or hiring experts.

Malfunctions

Below we will consider the most common circumstances of malfunctions of chimneys and ventilation ducts. Despite the fact that there are many more of them, almost all of them are associated with the simple irresponsibility of the owners:

Advice: if there is no draft immediately after connecting the fireplace or stove, file a claim with the builders who installed the ventilation or chimney on the roof.

Tips for use

The cause of most poisonings during a fire from combustion derivatives in most cases is poor ventilation and smoke removal. Based on this, rules and requirements were created that must be followed when operating these systems.

Let's define them:

- The ducts of fireplaces and stoves operating on hard fuel should be monitored and cleaned before the start and at the end of the heating season . When the furnace operates continuously, inspection must take place once every three months. Ventilation ducts and smoke exhaust pipes must be monitored quarterly, both in summer and winter.

- If important faults requiring repair are identified during the inspection, it is prohibited to use heating and gas devices until the defect is completely eliminated.

- Installation and repairs should be carried out by organizations that hold the appropriate license, since their experts in most cases have all the necessary skills for this . They should start work only after completing a ventilation and chimney inspection report.

Advice: these rules apply to both owners of private houses and institutions important for the maintenance and upkeep of apartments and ventilation systems in them.

In addition to the generally binding rules listed above, we recommend that you pay attention to the following:

- use completely dried firewood in stoves and fireplaces, which has a low percentage of resin content;

- It is prohibited to burn household waste in stoves and fireplaces, especially any plastic - bags or bottles;

- periodically clean the firebox and vent from ash, and roof hoods from dust and grease;

- buy a roof fan that will help improve draft in a duct or pipe; its price depends on the power. This should be done especially for those whose chimneys have a small internal cross-section;

- Install a protective cap with a mesh on the chimney with your own hands, which will prevent debris from entering the ventilation duct. During the winter period, systematically monitor this part of the system in order to promptly clear it of blockages and freezing.

Materials for smoke and ventilation ducts

Air ducts experience considerable load. Warm air flows out through the shaft. When it comes into contact with cold outside air, the gas inside quickly cools. Since its humidity is noticeably higher, condensation is deposited on the walls of the channel. In this case, the difference between the temperature inside the ventilation duct or chimney and the temperature outside becomes even greater.

Under-oxidized combustion products, acid anhydrides and oxides are removed with the exhaust gas. When condensation appears, they turn into acids and destroy the wall material. So the latter must be resistant to temperature and acids.

Brick

Solid ceramic bricks can withstand high temperatures.

Brick ventilation is a traditional solution. Ventilation and chimney ducts of any kind are constructed from building stone. When setting up, the following rules are followed:

The laying of brick ventilation ducts and chimneys is paid at higher prices compared to the construction of a partition.

Prefabricated single-circuit galvanized and steel systems

Steel chimney with one elbow at the exit from the boiler.

With high ceilings, outlet with wall pipes is not possible. It is also almost impossible to create an effective overall ventilation plan if the building is intended to be rented out, as each owner has his own needs. In this case, single-circuit systems are installed.

The structure is assembled from metal pipes and elbows. The connection is hermetically sealed - in a lock or with screw connections. There are round and square pipes. The former are used for the chimney, the latter for ventilation, where the draft force is not so important.

There are several restrictions:

The service life of a single-circuit system is short - up to 15 years. However, replacing the pipes is very easy.

Dual circuit systems

Option for chimney. The system includes 2 steel pipes - for air supply and for exhausting combustion products. The pipes are insulated from each other and from the outside air with mineral wool. The system is fireproof and lasts much longer. Thanks to thermal insulation, condensation forms in smaller quantities.

Asbestos cement pipes

Asbestos-cement chimney pipes

are not very resistant to temperature, but are insensitive to the action of chemically aggressive substances. The cost is low. Suitable for the construction of ventilation ducts and chimneys for devices with low temperature output.

Asbestos-cement pipes are inconvenient: it is impossible to install corners or transitions, the material is fragile and difficult to work with.

Sand cement pipes

Such shafts are constructed from a special type of building blocks. Their shape is traditional - 20*20*40 cm, but they include 1,2 or 3 channels. Sizes can be large. The blocks are used in the construction of wall ventilation. They are not suitable for chimneys, as they are rarely of sufficiently high quality and do not always provide a tight seal.

Stages of making a brick chimney:

1) You will need to stock up on the tools and materials that you will need when laying out the chimney. These are bricks, sheet iron, mortar, a container for mortar and a trowel for masonry. Wear mittens for added protection.

2) Next, you need to become familiar with the structure of your chimney. It consists of a neck, riser, head, smoke valve and metal cap. A brick pipe is laid out from bricks that are connected with mortar. We use asbestos cement board to insulate the pipe from wood structures.

3) We make the brickwork tightly, do not leave any gaps. Apply a little mortar to the place where the brick is laid (bed), level it, wet the brick in water, apply a little more mortar to the end or mating edge and place the brick in place using a sliding motion with pressure towards the vertical seam. If the installation is unsuccessful, the brick is removed, there is no need to correct it by tapping, it is cleaned with a bed, wetted and re-laid. Otherwise, air leaks will occur, which will spoil the draft to the stove and the flow of gases will increase. We identify and eliminate all existing leaks. Masonry joints should be 0.5 cm horizontal and 1 cm vertical. Every 5-6 rows of masonry, the inside of the chimney is wiped with a wet rag and the seams are rubbed down.

4) Make the pipe section square or rectangular (transverse). The shape of your pipe affects the level of resistance in the chimney (hydraulic). This is also a condition for maintaining and creating the necessary traction. A round cross-sectional shape is also optimal, but it is very difficult to create such a shape using brickwork.

5) We avoid inclined chimneys during the pipe manufacturing process, because additional air resistance occurs at the turning points. But if there are no turns, then they need to be made at an angle of 60 degrees. Also, do not make a large diameter pipe, as the gases will cool faster in this pipe and the heating efficiency will be lower.

6) Above the roof, we lay out the walls of the chimney of the chimney pipe to the thickness of a single brick, but do not forget about the headband and ridge canopy. It is best to make the headrest without a cornice, because the wind should blow it well and therefore this solution will allow better removal of gases. The upper part of the brick chimney is laid with your own hands on a sand-cement mortar.

Do-it-yourself brick chimney is a very difficult and responsible moment, so you need to take this very seriously, and it is better to entrust this matter to specialists.

Source - Build a House Yourself

For what reasons do chimneys collapse?

During prolonged use, the channel is destroyed for natural reasons: temperature fluctuations, wear and tear of materials, humidity. Brick pipes lose strength under the influence of combustion products. The destruction process proceeds gradually, and the time comes to repair the chimney. In order to detect changes in a timely manner, regular preventative maintenance is necessary. This allows you to prevent unexpected situations.

A sudden violation of the integrity of the channel can be caused by the following factors:

A well-made combustion product exhaust system, during the installation of which all industry standards were observed, will last a long time. But the slightest deviations from standards during the construction process will very quickly make themselves felt. That is why you need to trust only specialists.

How to install?

Installing a fan on a fireplace is quite simple and does not require any special theoretical knowledge. The first step is to calculate the direction of air flow. This information is available on the packaging with the device or in the instructions for it.

Installation is carried out from above at the mouth of the chimney pipe. Please note that it is easier to install the device on brick chimneys than on stainless steel chimneys. You should also think about the power supply system to the smoke exhauster and correctly position the wire with the switch and speed mode switch.

Installation of smoke and ventilation ducts

The chimney should be located at the highest point of the roof.

Chimneys and ventilation ducts in brickwork work only under one condition - sufficient draft. It occurs due to the difference between air pressure at different altitudes. In a one-story house it is quite small, but this is enough to ensure that the rarer heated air is drawn out.

To ensure traction, the following requirements are met:

It is recommended to waterproof the pipe between the roof and the otter. If this is not done, the entire wall will get wet.

Source

Brief summary

A boiler with a coaxial chimney is more efficient and safe to operate compared to traditional solutions. It does not require more care than normal. In addition, its maintenance is not a complicated procedure that requires any special knowledge and tools. The device does not take up much space and is quite easy to install. It won't be difficult to find one. A wide variety of products in the retail network allows this to be done. Using a fairly simple formula, you can calculate what diameter the outlet connection hole of the product should have.

Video on the topic: