Autonomous heating and hot water supply turn a private home into a comfortable home that provides considerable savings and does not depend on the appetites of resource suppliers.

Installing your own boiler allows you to independently regulate the heating mode, based on need and climatic conditions, and not on the average annual coolant supply schedule.

The choice of equipment in the retail chain is extensive, but finding the most successful option is quite difficult.

The cost of European boiler models is too high; the quality of domestic models often leaves much to be desired.

Let's consider one of the most successful options, combining affordable cost and high quality.

Navien Deluxe gas boiler series

Navien gas boilers are products of the South Korean industrial concern KyungDong NAVIEN.

The company specializes in the production and design of heating equipment operating on various types of fuel - liquid, solid, gas and electricity.

Navien Deluxe is a series of double-circuit wall-mounted gas boilers that replaced the discontinued Navien Ace family.

The design and set of functions have remained virtually unchanged, although some aspects have been improved and supplemented.

The units supply coolant (HC) to the heating system and at the same time provide the home with hot water (DHW).

Korean developments were carried out taking into account Russian conditions and are specialized in working with unstable parameters in all areas - gas and water pressure, power fluctuations. The equipment fully complies with the norms and standards in force in the Russian Federation .

IMPORTANT!

Navien boilers are equipped with a special device that compensates for voltage fluctuations in the network up to 30%.

Conclusions and useful video on the topic

Detailed instructions on connecting and commissioning a wall-mounted version of a gas boiler:

Knowing the specifics of installing, connecting and configuring a gas boiler is useful both for independent home craftsmen and for owners who invite plumbers and gas workers to perform the work described above.

Possession of information will ensure the correct execution and proper control of all actions. Then the boiler will work perfectly, will not create problems and will last for an extremely long time.

What models are included in it?

The Deluxe series includes the following boiler models:

- Deluxe.

- Deluxe Plus.

- Deluxe Coaxial.

- Deluxe Atmo.

The first three models practically do not differ from each other, having only minor differences in the design of the chimney or the amount of gas supply.

The Atmo model is a boiler with an open combustion chamber, which is distinguished by the supply of air directly from the room.

All types of boilers are available in various power options:

- 13k (kW).

- 16k (kW).

- 20k (kW).

- 24k (kW).

- 30k (kW).

- 35k (kW).

- 40k (kW).

Some models are created on the basis of one standard size with software-limited functionality.

Thus, boilers with a power of 24 and 16 kW are of an identical design, but the 16 kW models have slightly reduced power. This gives the units a noticeable power reserve, allowing them to freely overcome load changes and external influences .

Competitors

Table. Comparison with competitors and analogues Photo ModelRatingPrice

| sample in the review Navien Deluxe S COAXIAL-24k | 6 | RUB 32,900 |

| Navien DELUXE 24K | 6,5 | RUB 32,081 |

| Navien DELUXE PLUS 24K | 6,8 | RUB 31,479 |

| BAXI ECO-5 Compact 1.24 | 6,4 | 31,000 rub. |

| Lemax Premium-30N | 4,8 | RUB 32,500 |

| Lemax Premium-25B | 5,1 | RUB 33,800 |

| Lemax Premium-30NB | 5,1 | RUB 35,030 |

| Lemax Premium-25NB | 5,1 | RUB 34,700 |

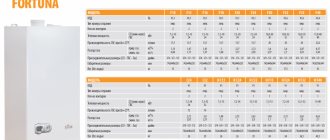

| Ferroli Fortuna Special C 24 | 6,4 | RUB 32,423 |

| Ferroli Domina Special F 28 | 5,7 | RUB 35,999 |

Specifications

Let's look at the technical characteristics of Navien Deluxe boilers:

| Parameter | Deluxe | Deluxe coaxial | Deluxe Plus | Deluxe ATMO |

| Boiler type | Gas wall-mounted double-circuit | |||

| Combustion chamber type | Closed | Open | ||

| Efficiency | 91,7 % | 86 % | ||

| Thermal power of the boiler according to the air conditioner | 9-40 kW | |||

| Primary heat exchanger material | Stainless steel | Copper | ||

| Coolant temperature in the heating system | 40°-85° | |||

| DHW temperature | 30°-65° | |||

| Control type | Electronic | |||

| Mains voltage | Single phase, 230 V, 50 Hz | |||

| Weight | 28 kg | 26 kg | ||

| Case dimensions | 440x695x265 mm | 430x720x340 mm | ||

Some changes or additions in the values of boiler parameters are possible due to improvements in the design by the manufacturer.

Advantages and disadvantages

The advantages of Navien Deluxe boilers include::

- The ability to provide hot water supply along with the organization of heating of the home.

- Environmental safety of equipment.

- Adaptation to Russian technological and climatic conditions.

- Simple and reliable control, presence of a remote control.

- The presence of a self-diagnosis system through a group of sensors that monitor all systems and components of the unit.

The disadvantages of the units are:

- Dependence on the availability of electricity, gas and water.

- High noise level.

- Possibility of using only standard components.

All features of Navien Deluxe boilers, in fact, are specific design features and can be fully compensated for by proper operation and maintenance.

Device

The Navien gas double-circuit boiler heats the coolant and ensures its circulation in the system.

A gas burner combined with a primary tubular heat exchanger heats the OM flow, which passes through a three-way valve at the outlet.

To obtain a given temperature, a certain amount of cooled return water is mixed in, after which the coolant is sent into the system.

The combustion mode is regulated by the supply of fresh air, which is provided by the fan.

Hot water is heated by a secondary heat exchanger (plate). The operation of all devices is monitored by a system of sensors that signal to the control board about the occurrence of certain problems.

Installation and connection procedure

Let us immediately note that the installation and connection of any model of Navien gas boiler, as well as its first start-up, must be carried out by a specialist from an authorized service structure.

Otherwise, the manufacturer will not fulfill warranty obligations. However, the owner should know how the process is carried out in order to control the work of the hired contractor.

Providing conditions for installation

South Korean equipment for heating coolant and hot water can process both main gas and liquefied gas mixtures. The blue fuel options available for use are indicated on the plate. It is attached to the right side of the body.

Information about what type of gas can be processed in the Navien boiler can be found in the table on the right panel of the housing. Using gas that does not correspond to the declared one may lead to failure of the unit or an accident.

To connect the boiler, you will need to connect a power supply line to the location. The device cannot be connected to the electrical network through adapters or extension cords.

Requirements for the electrical line for the boiler:

- The power supply source for operating a boiler of this brand must have the following parameters: 220V, 50Hz. Deviations from these standards may result in either fire or loss of performance.

- It is prohibited to connect any electrical equipment parallel to the boiler to the source. Failure to comply may result in a short circuit.

- The socket should be located 30 cm from the heater body.

- The unit must be located at least 60 cm away from electrical appliances of all types.

- The boiler body must be grounded.

In the room intended for the location of gas equipment, a flawlessly functioning exhaust and supply ventilation system must be organized.

The window should have a transom that can be easily opened for ventilation. The door should have a ventilation gap or grille at the bottom.

Image gallery

Photo from

Processing multiple contours

Trouble-free ventilation

Installation of a floor-standing unit in a boiler room

Wall model in the kitchen of a private house

It is not allowed to locate gas equipment in rooms with a characteristic high level of humidity: in bathrooms, in swimming pools, in showers and bathhouses. Dampness and insufficient air flow interfere with the normal operation of the boiler. In addition, its operational life is reduced.

Boilers cannot be installed in open areas. They are not intended for contact with atmospheric negativity. It is prohibited to place where explosive and flammable substances, as well as bulk building materials, are stored.

Choosing a location

In most cases, wall-mounted gas boilers are located in kitchens or hallways that have a window or only a vent for ventilation.

To install floor-standing models, boiler rooms are installed, separated from residential and functional spaces in the house. In any case, sufficient space should be provided for convenient maintenance and repair of the unit.

Image gallery

Photo from

Wall model on a permanent structure

Recommended types of contact materials

Insulating gasket between wall and boiler

Space for blowing the boiler body

Let's consider the rules for choosing a location for a wall-mounted gas appliance as the most common solution for our compatriots:

- Hanging is allowed on a wall made of non-flammable building material. If the wall material is capable of igniting and sustaining combustion, the surface must be lined with a non-combustible finish.

- The unit must not be located near emergency exits or staircases.

- There must be at least 0.6 m between the opposite wall and the front panel of the gas equipment. A similar distance must be maintained between the boiler and any electrical appliances.

- Between the side panel of the case and the nearest structure or piece of furniture you need to leave 0.2 m.

- There should be 0.8 - 1.1 m between the floor plane and the lower edge of the unit hung on the wall.

To mount the wall-mounted model, it is advisable to find a place on a load-bearing wall. If the strength of the wall is in doubt, it should be strengthened. The boiler is fixed with anchor bolts.

Image gallery

Photo from

Distance between the boiler and heating devices

Violation of installation rules

Indentation from all types of electrical appliances

Rules for socket location

If there is a suspicion that the heater will make excessive noise during operation, it is recommended to use buffer substrates on the wall made of non-flammable material.

Connecting the speaker to communications

For the gas heater of coolant and sanitary water to operate, the dual-circuit heating device must be connected to communications. We have already talked about laying a separate power line. Everything must be done in accordance with the PUE regulations.

In order to understand the nuances of connecting a gas boiler, you should carefully study its structural structure. Due to the fact that an inexperienced contractor confuses a gas pipe with a water supply branch, a serious emergency situation may result.

Now you need to connect branches from cold water supply systems, gas supply and heating return pipes to the boiler. And you have to remove from it the heated coolant supply line, the hot water supply pipe to the mixers and the chimney.

All stages of connecting a Navien brand gas boiler must be performed according to a diagram drawn up in advance by the gas service with which the contract was concluded and by the plumbers servicing the house. It takes into account the technical features of a particular room and the recommendations of the equipment manufacturer.

Connecting the gas boiler to communications must be carried out by a representative of the organization with which an agreement has been concluded for the supply of blue fuel, inspection and maintenance of gas-using equipment

After installation, all connections of pipes transporting water must be checked for leaks. Both heating and water supply lines need to be tested. Gas pipelines also require inspections, which are simply covered with a soap solution at the connection points to detect leaks.

It is recommended to insulate pipes that are not involved in the heating process. These are partially heating routes and all water supply branches. As thermal insulation, it is better to use foam insulation that follows the shape of the pipe.

All pipelines connected to the boiler must be equipped with taps to shut off the device in the event of a threat or breakdown. The boiler should be connected to a source of liquefied gas through a reducer, and to a group of cylinders - through a gas manifold.

All communications entering and exiting the boiler must be equipped with taps, which are required to shut off the flow of medium in the event of repair or replacement of equipment, as well as in the event of a threatening situation.

Upon completion of the installation operations, the boiler is started for the first time, which must be performed by a representative of the organization supplying you with gas. Then adjustments are made according to your personal preferences and requirements for the indoor microclimate, as well as in accordance with the time of year.

Features of the first launch

The first start-up and adjustment operations are carried out by representatives of the service center, who installed the boiler and connected it to communications. All actions are documented.

The owner of the equipment needs to keep these papers, because they constitute written confirmation for the subsequent fulfillment of warranty obligations.

Before carrying out installation work, a diagram must be drawn up. The contractor must provide the customer with an estimate of the materials he will have to purchase.

For the first launch you need:

- Fill the boiler and the circuits connected to it with water . This is done through a make-up unit located on the bottom of the boiler, equipped with its own tap. They are also used if for some reason the pressure in the gas boiler drops during operation.

- Monitor the pressure during filling . When the pressure gauge shows 2 atm, the tap should be turned off.

- Remove air pockets manually . Next, excess air will be removed from the unit automatically, but for the first time after filling the heating circuit with coolant, they must be eliminated using a Mayevsky tap from each device, starting from the furthest one.

- Replenish the water in the heating circuit so that the coolant takes up the space that was previously occupied by air that had not been removed.

- Bleed air from the circulation pump built into the boiler.

After the above steps, you need to start the equipment by pressing the “Power” button. Then you need to start setting the priority temperature regime for the owners.

If, after filling the communication systems and bleeding the air, error code 02 appears on the display, you need to use the make-up tap to replenish the water. It is also needed to relieve water pressure in the circuits

Specifics of the setup

Navien boilers come with a remote control panel. It is with its help that the settings are made. All commands and modes on the panel are written in Russian, buttons for all functions are accompanied by extremely clear graphic icons.

In the lower right corner of the remote panel there is a button that is used to turn the unit on/off. One press activates the boiler in the mode set by the owner. Pressing again will stop the heater.

To control the boiler and select the appropriate operating program, gas processing equipment from Navien is equipped with remote controls

You can turn on the heating with temperature control of the coolant as follows:

- We find a button on the panel with an icon resembling a battery. Press until a similar symbol appears on the display.

- We select our priority temperature using the buttons with the “+” and “-” icons located in the center of the bottom of the panel. We increase and decrease from 40º to 80ºС in the most familiar way.

- We similarly designate the period during which the coolant will heat up.

Everything is extremely simple. If the “battery” icon on the display is pulsating, then it shows the parameters that we have just set. If it stops blinking, it means it displays the actual temperature at the moment.

In order to set the heating mode with the optimal temperature, you need to find the desired function on the remote control and set the priority temperature

To set the mode according to which the boiler will start/shut down, focusing on the temperature background in the room, perform the following steps:

- We find a button on the panel with an icon resembling a battery. However, now we wait until an exaggerated image of a house with a “thermometer” inside appears.

- We return again to the “+” and “-” buttons to select our priority temperature background in the room. It varies in the range from 10º to 40ºС.

- A flashing house will show us the selected temperature, a non-blinking house will show us the actual temperature parameter at that moment.

Upon completion of all the actions performed, there is no need to press any buttons to save; the settings we selected are automatically saved.

To select the desired water temperature, you need to find the function indicated by the shower head on the remote control and set the desired value. Note! It is prohibited for another person to change the temperature during hygiene procedures.

You need to choose the optimal temperature for preparing sanitary water as follows:

- We find the button for controlling the “Hot water” mode. Press it and wait for a pulsating image of a working shower head to appear in the upper right corner of the display.

- Again we use the “+” and “-” buttons to find the optimal temperature for us. It can be set in the range +30 – (+60)ºС.

- We are waiting for the shower to finish flashing. This means that the boiler automatically saved the set level and switched to operating mode in accordance with it.

If the unit is to be used only in the summer or was purchased for the preparation of hot water, the “Hot water priority” function comes into play. The procedure for selecting it is slightly different from the method described above. The difference is that a double symbol will appear: a shower and a circle of three arrows.

Selecting this mode will force the boiler to heat sanitary water even when it is not in use. Those. the heater activates and prepares water, and after 10 minutes it turns off if no one opened the taps during this period.

If the heated water is consumed, as indicated by an open tap and a drop in pressure, the boiler will always prepare water at the set temperature. It works to heat water only when there is a need for it. If you switch the equipment to another mode, this one automatically stops working.

Navien boilers can only operate to heat hot water. To do this, they need to be switched to the “Priority of hot water” mode (scheme of 3 points at the top) or “Away from home” (scheme of two points below)

You can switch the Navien boiler to a mode that only heats water by using another function. Our compatriots know it under the name “Winter-Summer”. However, it is correct to call it “Outside the Home”. The button to select it is located in the lower left corner.

There is a timer to set the period of continuous operation of the gas unit and turn it off when it is not particularly necessary. It is controlled according to the absolutely simple scheme described above. The range of capabilities of the timer device is designed for an interval from 0 to 12 hours.

Where is it used?

Navien Deluxe gas double-circuit boilers are designed for heating and supplying hot water supply in private homes.

The boiler power corresponds to the area being served, which makes it easier to select the right device.

The use of the Navien Deluxe series is not recommended for heating industrial or public buildings, since the specific capabilities of the equipment in such conditions will not be adequately revealed.

Often such equipment is installed in apartments, if their size allows the installation of equipment of similar power.

How does this model differ from other representatives of the series?

The series includes the following models:

- Navien Deluxe Coaxial 24k.

- Navien Deluxe Plus 24k.

- Navien Deluxe 24k.

The differences between the models are small. The “Coaxial” model is designed for the use of a horizontal coaxial chimney (pipe-in-pipe type), which is convenient for installation in an already inhabited house.

It does not require complex organization of the passage of the chimney through the ceilings and roof. The “Plus” model has a control panel built directly into the body, which is convenient when installing the unit in the kitchen .

The basic Navien Deluxe model has two pipes for removing combustion products and supplying fresh air, separate for each line.

They can be connected either to vertical pipelines or through the wall.

What's included

The Navien boiler package includes::

- Primary and secondary heat exchangers.

- Expansion tank 8 l.

- Gas heating pad of closed or open type.

- Three-way valve with electric motor.

- Fan for organizing turbocharging.

- Circulation pump.

- A sensor system connected to a control board.

- Built-in voltage stabilizer.

- Remote control.

- Housing with external connecting pipes.

Depending on the model and series, some additional components may be present. Constant development and improvement of the design contributes to the complication of old and the emergence of new elements .

Starting the boiler

After all installation work has been completed and pressure testing has been carried out, the first commissioning start-up of the boiler equipment is carried out. All work is carried out by service center workers with the preparation of appropriate documents, which in the future will preserve the manufacturer’s warranty obligations.

When starting the Navien boiler, the instructions must be followed impeccably. Sequence of work:

- The circuits are filled with water through the unit’s make-up unit, built into the structure, with a special tap at the bottom next to the tap water inlet.

- Monitor the pressure gauge; when the pressure rises to 2.0 atm, close the tap.

- Remove air pockets. At the first start, it is performed in manual mode, and at subsequent starts, through an automatic system. They start the process from the most distant battery, opening the Mayevsky tap, and alternately go through all the points of the heating circuit.

- After etching the air plug, the pressure in the circuit will drop, so re-filling will be required.

- Discharge the air mixture from the circulation pump.

- To turn on the unit, press the “Power” button.

- The electric ignition will work and the unit will start, after which it is necessary to adjust the temperature regime.

User manual

Navien boilers operate automatically and require virtually no human intervention.

The only thing that is required from the owner is to set a comfortable heating temperature . If liquefied gas is used as fuel, it is necessary to ensure timely replacement of cylinders.

Download instructions

You can download the instructions here.

The possibility of long-term operation without specialized service checks is a feature of Navien equipment, which is convenient for users and relieves them of concern about the condition of the unit.

If any malfunctions occur, the corresponding error code appears on the display, the water pressure is shown by a pressure gauge, which allows you to timely detect a leak in the system.

The owner may be required to purchase and install a special filter or water softener, which will extend the life of most boiler components - heat exchanger , pump or three-way valve . If the water supply is from your own well, installing a softener becomes a necessity.

How to pay for an order

When placing an order, you DO NOT NEED TO PAY ANYTHING.

We receive the order, call you back, clarify all the details, and then send a link to payment or an invoice (for legal entities).

You will find out exact information about payment for your order when you call our manager.

You can pay for your order by credit card.

Payment is made through Yandex Cashier or the payment gateway of Sberbank of Russia.

We will send you a link to payment, where all the necessary information will be indicated: product, quantity, delivery cost.

WE DO NOT COLLECT OR STORE YOUR PAYMENT INFORMATION.

All payments are made through services of maximum reliability (Yandex Cashier and Sberbank) - therefore, your money is safe.

Payment by bank card is made without commission.

Setting up the device yourself

To configure the boiler, set the debugging mode. Then you should adjust the gas pressure limits - minimum and maximum.

It is necessary to bleed air from the circulation pump by unscrewing the plug. This is done after the pressure has built up during the circulation of the heating agent .

The boiler operation is configured using DIP switches.

- You can turn on automatic air removal using DIP switch No. 1, which will start circulation for 2 hours and gradually remove air automatically.

- Turning on switch No. 2 switches the system to maximum power, at which the maximum gas pressure can be adjusted.

- When switch No. 3 is turned on, the boiler is switched to forced operating mode at minimum power, at which the minimum gas pressure is adjusted.

All switching must be performed with the power supply turned off.

IMPORTANT!

Setting up the boiler should be entrusted to specialists from the service center. Doing the work yourself is only possible if there is an urgent need and there is no warranty agreement.

. and without construction experience

My works for 2022.

How I set up the Navien boiler, hysteresis on the burner

The boiler heats up, life goes on, but something told me that everything is not so rosy, first of all, a mistake was found among many buyers of gas boilers, they all buy with a reserve of power “just in case,” well, I, like everyone else, I took it with a reserve, with a reserve for hot water supply and frosts, i.e. It turned out that in warm weather outside, the Navien boiler continues to cycle , which is very unfortunate for it, and can lead to breakdown, first of all, there may be a breakdown of the ignition system , since it constantly lights the boiler, and most often wears out, this is not for me I want to.

As an inquisitive researcher, with a stopwatch in my hands, I studied the cycles of the boiler in different modes of its operation, in warm weather, in cold weather, and decided to test the capabilities of the boiler at work depending on the temperature in the room, for this I selected the room mode in the boiler settings.

At first everything was happy, the boiler obediently stood up, waiting for the set temperature to drop, but the joy was short-lived, cold was already creeping across the floor (the heat from the radiators, which cut off the cold air from my many windows, disappeared, and the house became not very comfortable, in the upper part the room where the remote control for the boiler, in which the temperature sensor is located, hung. It was in a warmer zone, we immediately understood that this was not suitable for us, at first there were thoughts of hanging the remote control down, closer to the floor, but, firstly, this is inconvenient for control, secondly, it can be ruined by domestic cats, thirdly, the boiler may not turn off at all, trying to catch up with the temperature below, when it is already hot in the middle part of the room in height.

The room temperature test did not pass and was not suitable for me, at the same time I remembered the person who connected the gas, who advised that the boiler should not be turned on in this mode.

Time passed, but the cycles did not give me peace, and one day it occurred to me, while regularly observing the boiler, that the hysteresis (delta) in the turn-on-switch-off segment of the gas boiler was probably too small, and I would like the boiler to drive the coolant longer to a higher level. low CO temperature, but it was unclear how to do this, I certainly know how to program, but programming languages for this boiler are inappropriate, and I don’t have equipment to connect to the “brains” of the boiler, and one day, purely by chance, I came across one well-known forum for a person who knows how to do this, and with the help of only one remote control, by entering the engineering menu of the Navien boiler!

This is literally what needs to be done. to change the delta between boiler start-stop.

1. With the Navien boiler remote control turned off, press the + and - buttons for 5 seconds

2. The number 8 or 9 or 10 will appear on the remote control display (for me)

3. Again, use the + or - buttons to change the value (this is delta) in the range from 2 to 20 (I set it to 12)

4. We wait 5 seconds, after which the boiler remote control goes out

5. Turn off the boiler by removing the plug from the socket for at least 10 seconds

Basic malfunctions and their solutions

Any faults that occur are shown on the display as a numeric code. Each of them corresponds to a specific error, i.e. a signal from a specific sensor about the failure of the corresponding node.

Let's take a closer look at them:

- E 01. Exceeding the heating temperature. Indicates a failure of the circulation pump or a clogged coolant filter.

- E 02. Exhaust circulation error. Possibility of coolant leaks.

- E 03. Gas does not burn. Check whether the gas supply valve is open.

- E 04. Parasitic flame. The sensor may spark and perceive it as an open fire.

- E 05, E06. Exhaust temperature sensor short circuit. Occurs due to the appearance of condensation on the board with the sensor.

- E 07. DHW temperature sensor failure. Check sensor contact.

- E 08. Short circuit of the DHW heating sensor. Replacing the sensor.

- E 09. Fan failure. Replace the fan.

- E 10. Problems in the smoke removal system. The chimney may become clogged or the outlet channel may become icy.

There may be additional codes that need to be read carefully in the user manual.

Possible mistakes

The built-in fault detection system prevents serious equipment breakdowns.

Errors displayed during self-diagnosis of products from the Korean manufacturer are described using the example of the well-known Navien ACE 24 boiler model.

The built-in fault detection system prevents serious equipment breakdowns at the earliest stage of malfunctions.

If a malfunction is detected, electronic protection disconnects the gas unit from the network, blocking the entire heating process. At the same time, the error code is displayed on the screen or display of the device. Despite the fact that built-in diagnostic systems were developed for specialists, the average user is quite capable of independently understanding this issue and taking the necessary measures.

Error codes

Typical malfunctions of the Navien boiler are displayed with a specific error code.

Typical malfunctions of the Ice Navien gas boiler come down to several groups of problems, which are represented by the following error codes:

- 01E means that the equipment is experiencing overheating, detected by a temperature sensor;

- 02E indicates the appearance of leaks in the circuit controlled by the flow sensor (a decrease in the coolant level);

- 03E indicates the absence of a signal confirming the presence of a flame (even if the burner is working);

- 04E – indicates the presence of a flame in its physical absence (a short circuit in the flame sensor circuit is also detected);

- 05E - a typical error that occurs when there is a malfunction in the circuit for measuring the temperature of the medium in the heating circuit;

- 06E – temperature sensor (TD) failure code, indicating a short circuit in its circuit;

- 07E – error that appears when there is a fault in the diesel fuel line in the DHW circuit;

- 08E – problems with the same sensor, but occurring due to a short circuit in its circuit.

Error code 09E indicates a malfunction of the fan.

Error code 09E indicates improper operation of the fan, which needs careful inspection and replacement. Error 10E indicates problems with smoke removal, and 12E indicates that the flame in the burner has gone out.

The following block of ciphers that appears in the event of a malfunction:

- 13E indicates a short circuit in the flow sensor of the heating circuit;

- 14E is a code for the absence or violation of the normal gas supply from the main;

- 16E – error that occurs due to overheating of equipment components;

- 18E – violations related to the operation of the smoke removal system (overheating of the sensor, for example).

We can come to the conclusion that the most unreliable component is the control board. But in reality this is not the case, since it fails much less often than the sensors it serves.

There are no special instructions for troubleshooting problems that have arisen in the accompanying documentation. The manufacturer explains this by saying that the maintenance and repair of gas equipment from Navien is carried out by representatives of the service company. When a user decides to fix a problem on his own, he must understand that he is voiding his warranty.

Price range

In most regions of Russia, the cost of Navien Deluxe boilers is in the range of 27-32 thousand rubles. First of all, prices depend on the power of the unit.

In addition, logistics and other factors, overhead costs, etc. are actively involved in pricing. People planning to purchase a boiler should take into account that the total cost will be slightly higher than the price of the unit . This happens because delivery, installation and connection of the device are required.

All these measures should not be carried out independently, since service centers refuse warranty service if the installation was not carried out by their employees.

NOTE!

Some stores do not have the authority to draw up a warranty agreement. This point should be clarified, and if necessary, independently conclude a warranty agreement with representatives of the service center.

information about delivery

Right now - place your order!

After placing your order, our manager will contact you and will definitely clarify your wishes for delivery.

In your city, our online store has an Order Pickup Point.

Address of the Order Delivery Point in Moscow: Moscow, st. Luganskaya, 5.

Any questions can be asked by phone (during business hours).

There are about 10 more Order Delivery Points in Moscow, we will be happy to select the most convenient one for you. Also, we can deliver to any location in Russia and the CIS, to any address.

We usually deliver to the Order Pickup Point, but delivery to the door is also possible (including large-sized cargo). Most often we use the services:

Delivery time 1-5 days

. When receiving the goods, the representative of the legal entity must have a power of attorney from the paying company or a seal.

Private buyers must present a passport to receive the goods.