Engineering designers are faced with the most important task - creating a comfortable microclimate in the premises. Air masses and polluted air need constant cleaning and fresh supply. Supply ventilation in buildings is arranged in different ways. A large number of consumers give preference in choosing a supply and exhaust system.

Recovery – return and purification of molecules to places of reuse. For this process, a device was invented - “recuperator”.

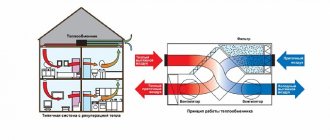

For a better understanding of what “supply” is, as well as how ventilation with heat recovery works and what it consists of, it is necessary to consider the types of modern exhaust systems and their necessity in everyday life.

Combined system

The system consists of a natural influx that circulates through the hood.

The absence of seasonal problems, as well as a low price - all this can be attributed to the advantages of the exhaust duct. The supply and exhaust circulation falls far short of a full-fledged air exchange system. The functionality is too weak.

The disadvantages include:

- Due to the stable consumption of waste ether, the load on the heating system increases. Therefore, energy efficiency is low compared to a natural ventilation system.

- The air exchange in the house is of poor quality, since ventilation works when the bathroom, kitchen, and bathrooms are used, and not constantly. To achieve the level of comfortable living, exhaust fans will not achieve this, not under any circumstances.

Proper organization of the ventilation system for a house and apartment.

Modern building codes require the creation of high-quality thermal insulation. In part, this requires maximum tightness of door and window openings. For this reason, without ventilation, the air in interior spaces tends to stagnate. With permanent residence, it also becomes waterlogged, depleted of oxygen, and a lot of dust accumulates. That is, you simply cannot do without an influx of fresh air, if only for the sake of health. Simple ventilation systems will have a positive effect on the climate in the house, but will increase heating costs. But systems with recovery will provide a constant flow of fresh air and will not allow heat to leave the walls of the house.

The choice of such a system for an apartment is based on three factors - performance, thickness of external walls and noise level.

Productivity is determined at approximately 30 cubic meters per hour per person. That is, when two people live in an apartment, it is worth taking a system capable of passing 60 cubic meters of air in one hour. It is important that the air supply is constant, and we only use it while we are at home. Therefore, correction factors are used during design. For example, the Russian SNIP for heating, ventilation and air conditioning recommends using a coefficient of up to 0.3. Taking into account the load in residential premises, it is recommended to install a recuperator with a capacity of 40 cubic meters per hour for rooms up to 20 sq.m., and for rooms up to 30 sq.m. — install a recuperator with a capacity of 60 cubic meters. at one o'clock. The logic of the calculation is that such devices have several levels of performance and at an average flow rate, the devices should completely replace the air in the room in less than 2 hours.

You also need to know the thickness of the walls in order to select the necessary consumables. The recuperator system is placed in a circular channel 50 cm long and consists of a motor, filters and a ceramic heat exchanger, which takes up about 30 cm.

That is, if the wall of the house is less than 30 cm, an additional cover will be required - a hood. With its help, you can install the recuperator in a wall from 18 cm thick. If the wall thickness exceeds 50 cm, an additional channel is used for installation in a wall up to 1 meter. Sometimes the outer wall of the room borders on a glazed loggia, but in this case there is a solution - the air channel can be laid through the loggia. Flat or round pipes are used.

In terms of noise, systems in the region of 20-40 decibels are suitable for an apartment. If the selected model is louder, you should install it in the living room, dining room, and not in the bedroom.

Selecting a ventilation model for a private home is, in general terms, no different from choosing ventilation for an apartment. However, for some particularly large or elongated rooms it is better to install several recuperators, although two are usually enough. Otherwise, it is recommended to equip each living space with one device .

Particular attention is paid to wet areas, which include the kitchen, bathroom and toilet. These rooms must be equipped with natural exhaust ventilation. In apartments, exhaust ventilation is organized in the form of satellites, through which air is discharged from each room into the main ventilation duct of the building. If the hood is weak, fans for the bathroom, toilet or kitchen are used.

Possible additional functionality of the recuperator.

In its simplest form, the recuperator consists of a ceramic element - a heat exchanger - and an electric motor - a fan. Modern models use a reversible fan with a double-equal impeller blade section.

It draws in air from the street and pulls it out of the house. But it can have several operating modes - only supply or exhaust, choice of recovery intensity and night mode with reduced noise. It can be controlled directly by a switch, a remote control, or from a mobile application via a Wi-Fi network. The recuperator can also be equipped with additional filters, from one to several. They can protect against dust, pollen, or be a multi-layer cartridge. The built-in noise canceling features are quite useful in noisy areas.

In the production program of Marley Deutschland GmbH you can choose ventilation with recovery for your apartment, home or office.

| Characteristics | Marley MEnV-180 | Marley MEnV-180-II | Marley MEnV-180-PLUS-60 | Marley MEnV-180-PLUS-60-WiFi |

| Productivity in recovery mode, cubic meters/hour. | 16-25-37 | 16-25-37 | 16-25-37-60 | 16-25-37-60 |

| Recovery coefficient, % | 85 | 85 | 85 | 85 |

| Recommended area, sq.m. | 20 | 20 | 30 | 30 |

| Operating modes | 3+1 | 3+1 | 4+1 | 4+1 |

| Noise level, dB(A) | 22-29-35 | 22-29-35 | 16-25-30-37 | 16-25-30-37 |

| Energy consumption, W. | 3-4,5-7 | 3-4,5-7 | 3-4,5-7-11 | 3-4,5-7-11 |

| Control, controller | Remote control | Remote control | Remote control | Remote control + WiFi remote control |

| Insulation sleeve | EPS (2 halfpipe) | EPP (3 segments) | EPS (2 halfpipe) | EPS (2 halfpipe) |

| External visor | ASA -Plastic | ASA -Plastic | ASA -Plastic | ASA -Plastic |

| Inner panel | ABS+UV | ABS+UV Gloss | ABS+UV | ABS+UV |

| Air cleaning | G3+F5 | G3+F5 | G3+F5 | G3+F5 |

| Option, filter F8, F9 | + | + | + | + |

| Option, carbon filter | + | + | + | + |

| Warranty, years | 2 | 2 | 2 | 2 |

Classic coercive system

Given modes and volumes, air flows circulate in classical forced ventilation. Stable air in individual rooms is maintained all year round by special ventilation equipment, as well as a system of supply and exhaust air ducts.

High energy costs in winter are the only disadvantage of the air handling unit. For a comfortable temperature, cold masses from the street require constant heating.

Recuperators mounted on roofs

These ventilation units are used in facilities with large workspaces. They filter, heat and supply air to the building. The air temperature is controlled by a duct heater or cooler. Its influx is carried out partially or in full through the plate structure of the recuperator.

Characteristic

Such supply and exhaust ventilation systems are installed on the roofs of buildings through holes made in them. Recuperators extract used air collected under the ceiling and release it into the atmosphere, and its heat is transferred to a powerful incoming jet. The air supply is directed directly to the ceiling or directed into the work area. The recuperator can be a component unit in the overall ventilation scheme of the entire facility. The device is easy to use.

Design

Models of units are made of different capacities, which are measured by the volume of air passing in cubic meters per hour. The base of the device is a frame-panel structure made of aluminum profiles. The optimal thickness of the heat exchanger sheets is about 0.2 mm. For sound and thermal insulation, the walls of the housing are lined with mineral wool. Recuperators are equipped with electric, water and gas sections for heating. The achieved efficiency is about 65%. Installation of supply and exhaust ventilation does not cause any difficulties. To do this, it is necessary to make a window in the roof and strengthen the structure - a “glass” for proper load distribution. Installing a recuperator on the roof does not take up the useful volume of the building.

Recuperative ventilation

This is the most advanced system for circulating air flow. Fully implements modes and volumes. Operation of forced supply ventilation with a recuperator requires little electricity and is the most economical. The heat contained in the exhaust air is returned from the street, heated by the recuperator, and then heated additionally. Abroad, in some countries, this technical solution has adopted a legal basis and become a construction standard. A simple example of UVRK is a domestic production model. It has a small size and low energy consumption. Installed on a loggia or balcony.

Due to the growing needs of people related to the comfort of living quarters, it has become advisable to install a multifunctional forced ventilation system. Thanks to the recuperator for ventilation, exhaust air is removed outside the room, and the temperature becomes comfortable. Transfer to heat and its selection occurs from the exhaust flow.

General information and operating principle

A recuperator is a device for ventilating a room, using the heat of the exhaust air for continuous heat exchange through the dividing surface with the incoming flow.

The technology ensures the preservation and return of “internal” heat, which is intended to be blown outside simultaneously with the hood. In the process of constant circulation, flows move in two directions. Warm exhaust air is removed from the room through a heat exchanger, and the incoming cold air is heated and disinfected due to heat exchange. At the same time, the temperature regime can be adjusted with the possibility of maintaining not only heat, but also coolness.

Main stages:

- air collection;

- feeding it into the system using a fan;

- passing through a recuperator;

- exhaust and removal outside the ventilated room;

- supply of outside air passing through a recuperator;

- partial heat transfer from the exhaust to the incoming flow.

Types of equipment with recovery

Recuperative ventilation equipment is available in a wide range. It is divided into 2 types:

- central;

- decentralized.

A unit suitable in terms of power is selected for the premises. The main classification is based on heat transfer and design features.

There are several types of recuperators:

- lamellar;

- rotary;

- heat pipes, etc.

Rotary

In appearance, such a recuperator resembles a rotating rotor. It is mounted perpendicular to the air masses (incoming and outgoing). It is also a heat storage device. The moving sector of the rotor retains heat as air is recovered. The incoming air receives thermal energy when the device rotates, and the sector is cooled. The efficiency of rotary recuperators reaches 80%. Modest dimensions, low aerodynamic resistance, and the ability to transfer moisture are the advantages of such a device.

Heat pipes

The device consists of hermetically sealed tubes with liquid inside. It boils at 0 degrees. The upper end is connected to the incident flow, and the lower end to the output flow. When warm air gets inside, it causes the liquid to boil. The passing air heats up after water vapor enters the upper part. The process resumes after the condensate settles. The installation of such a heat exchanger is carried out at an angle or vertically.

Recuperators are made from different materials, on which properties, quality and service life directly depend.

- Aluminum. Foil is used to separate air flows. Budget is the main advantage. Periodic freezing - this drawback may make a potential client refuse to purchase such equipment. It needs additional heating, and this costs electricity.

- Plastics Plastic units have similar properties to aluminum ones, only their efficiency is higher. Plastic material is more reliable and durable.

- Cellulose. Excellent moisture absorption. Humidified air enters the premises.

- Paper. Such a heat exchanger does not freeze and does not need heating. But there is no circulation of air and water.

System installation problems

There are practically no potential problems associated with the use of such equipment. Some are resolved by the manufacturer, others become a headache for the buyer. The main problems include:

- Formation of condensation. The laws of physics determine that when high-temperature air passes through a cold closed environment, condensation occurs. If the ambient temperature is below zero, the ribs will begin to freeze. All information provided in this paragraph determines a significant decrease in the efficiency of the device.

- Energy efficiency. All ventilation systems operating in conjunction with a recuperator are energy dependent. The economic calculation carried out determines that only those models of recuperators that will save more energy than they spend will be useful.

- Payback period. As previously noted, the device is designed to save energy. An important determining factor is how many years it takes for the purchase and installation of recuperators to pay off. If the indicator in question exceeds 10 years, then there is no point in installing it, since during this time other elements of the system will require replacement. If calculations show that the payback period is 20 years, then installing the device should not be considered.

The above problems should be taken into account when choosing a heat exchanger, of which there are several dozen types.

How to choose a recuperator

- It is difficult for people who do not deal with supply ventilation and heat recovery to understand the variety of models presented. To do this, you need to know several criteria that you should pay special attention to.

- Non-existent facts about the product. For example, marketing companies use tricks in the form of non-working phrases: “Efficiency - 100%”, “Operation at - 70 degrees”, etc. This sales scheme has nothing to do with the recuperator. As you know, at 10 degrees below zero, the device operates stably. But if the temperature drops, the process efficiency (efficiency factor) also decreases. To prevent this, manufacturers use additional thermal equipment.

- Cold bridges and body material are the second criterion that you should pay special attention to. For example, 30 mm cladding does not withstand subzero conditions and needs additional insulation. The aluminum frame strongly attracts cold temperatures.

- Fan pressure. The values of this criterion are measured in Pa and in no case in m³. Any buyers pay attention to the second value, which in fact is erroneous. The result follows from operation with low fan pressure.

- Automation. The presence of this option greatly simplifies the process of using the equipment. Ideally, there should be several operating modes and optional components.

Technical characteristics that you should pay attention to when choosing

- Metal devices are effective in operation down to -10ºС. At low temperatures, performance decreases noticeably. As a result, electric pre-heating elements are used;

- When choosing, you should study the thickness of the case and the material of the cold bridges. The thickness of 3 cm is subject to additional insulation when the outside temperature drops below -5ºС. You will have to doubly use insulating material if the frame is made of aluminum;

- Particular attention should be paid to the free pressure indicators of the fans. It may happen that at 500 m3 the pressure may be completely absent. Consumers usually find out about this when the recuperator fails;

- It’s a big plus when additional functions can be connected to the automatic system. Thanks to improved automation, operating costs are reduced and the performance of the entire device is improved;

- The main indicator for deciding which recuperator to choose is ventilation pressure and power. A preliminary calculation is made of how much air should enter the house in one hour.

SHUFT NOVA – 600 EC

The unit with a recuperator is designed for cleaning, heating and supplying clean air to small spaces: apartments, offices, shops. The process is as follows: the device removes dirty air, purifies it, extracts heat and adds it to clean air.

Advantages:

Temperature operation – from – 35 to + 60°С.

- Efficiency – 94%.

- Additional heating of the housing block from freezing.

- Economical energy consumption - no need to heat to -10°C.

- Silent fan SHUFT.

- The PTC heater is made of ceramic and does not burn oxygen.

- Filters on external and internal hoods with a quick-release system.

- Air degreasing and odor elimination occurs due to the provision of a carbon option and a combined filter.

Cost: from 83,500 rub.

ECO-FRESH 01 LUX

The recuperator of the Bulgarian manufacturer is designed specifically for industrial and polluted cities. The principle of operation is as follows: activated carbon takes part in the system, which easily copes with the task. Exhaust gases, soot, dust are cleaned thanks to the filter. Bacteria and viruses are destroyed due to air ionization. The system is controlled using a remote control (RC). There are 5 speeds and 6 modes. The air is heated in supply mode. One such device can replace two other representatives with a guarantee.

Advantages:

- Excellent air circulation in the room.

- Purification and ionization of incoming ether.

- Removing dirty atmospheres.

- Creates superpressure by providing the device with the removal of gases and their combustion.

- Sets humidity at the desired level.

- Heat loss is reduced thanks to the “Recovery” mode.

Cost: from 26,000 rub.

Who is the recuperator suitable for?

The supply and exhaust unit with heat recovery is designed for the mass consumer: it does not have any restrictions on the number of users. This device provides effective protection from dust, street noise and drafts. Thanks to the recuperator, the windows can be kept closed at all times, while the air in the house will remain clean and fresh.

An air handling unit with heat recovery will help allergy sufferers reduce the burden on the immune system thanks to a system of air filters that retain pollen, lint and dust. Clean, fresh air without toxins, exhausts and fumes, and optimal humidity levels help preserve the health of children, the elderly, and also improve the condition of those who suffer from asthma and other respiratory diseases.

The result of the recuperator is clean and fresh air, optimal humidity, that is, a comfortable microclimate that has a beneficial effect on sleep, quality of rest and human performance.

Below is a rating of the most popular recuperator models in 2022.

Blauberg Winzel Expert: a new level of comfort

Expert is one of the models in the line of recuperators from the Winzel company (part of the Blauberg concern, Germany). It is an improved version of the basic Winzel Comfo model. The Blauberg Winzel Expert recuperator has a modern design and is more functional than earlier models.

Recovery efficiency. Winzel Expert is equipped with a highly efficient ceramic heat exchanger: thanks to its high heat capacity, the efficiency of the recuperator reaches 97%. For example, at an outside temperature of -20°C, the device will provide heating of the cold flow from the street to +22.7°C without the use of electricity, only by recovering the “internal” heat of the room.

Technical specifications. The device has ultra-low power consumption (4.2 W) and operates with minimal noise (30 dBa when supplying 50 m³ of air per hour). When operating in night mode, the recuperator is practically inaudible (no more than 11 dBa). The device does not require special care and is controlled using a remote control. Equipped with a humidity level sensor.

This model is distinguished by its compactness and aesthetic design - these two advantages are key for many buyers.

Air cleaning. The filter system, which is provided in Winzel Expert, ensures the purification of street air from a variety of contaminants (industrial emissions, dust, fluff, fumes, pollen and others).

In their reviews, buyers note the laconic and stylish design of the device, recovery efficiency, and ease of operation. The disadvantages of this model include the relatively high price and the risk of ice formation on the body at temperatures below -25°C.

Winzel Comfo: the essentials

Comfo is the “oldest” model in the line of recuperators from Winzel (Germany). This is the basic version of the device, which has all the necessary set of functions. The model is suitable for walls with a thickness of at least 500 mm. It features a high level of automation: preset settings ensure optimal operation of the device without user control.

Features and technical parameters. An important feature of the Winzel Comfo recuperator is the optimal combination of device capabilities and its price. The device can be used to provide air exchange in a cottage, apartment or office. There are three operating modes: exhaust only, supply only or recovery.

The performance of Winzel Comfo is up to 50 m³ of air per hour in air supply mode and 25 m³/hour in recovery mode. The device provides heating of the incoming air flow without the use of electric heaters, which allows minimizing energy consumption (no more than 7.06 W/hour). Recovery efficiency – up to 88%. During operation, the device creates virtually no noise (13 dB in night mode).

Air cleaning. The device is equipped with two G3-class air filters that provide effective protection against pollen, dust, microparticles of debris and fluff. An F8 class filter is optionally available, providing fine air purification.

Customer reviews of the Winzel Comfo recuperator indicate a favorable ratio of functionality and cost of the device. If you need an air handling unit without additional functions that you will need to pay for, then this model is the best choice.

Winzel Expert WIFI: a convenient solution for a smart home

Expert WIFI is the most technologically advanced model from the entire line of Winzel recuperators (Germany). It is an updated version of Expert, which has a built-in WiFi module. It is wall-mounted and equipped with two economical reversible fans, which together consume no more than 18 W per hour.

Management capabilities. The presence of a WiFi module expands the control capabilities of the recuperator: thanks to this innovation, the device can be controlled from anywhere using an application on a smartphone. The module also allows you to create a wireless connection between several devices: for example, to combine all heat exchangers in a building into one network, which makes the use of signal cables unnecessary.

Two EC fans: double performance. Compared to earlier models, the performance of Winzel Expert WIFI is two times higher and amounts to 108 m³ of air per hour, while the noise level during operation is only slightly higher than that of the Winzel Expert model.

The Expert WIFI recuperator from Winzel is a good choice for those who use or plan to use a smart home system in the future. Control via a smartphone will allow the user to create an optimal microclimate in the house at the right time, regulate the operation of the device from anywhere and save energy by reducing its performance in his absence.

What do experts say about Winzel Expert WIFI?

“An advantageous combination of advanced functionality and ease of management. Quiet (from 11 dBa) and energy efficient (from 5.2 W) recuperator, which will be an excellent choice for connoisseurs of high technology. Can be controlled from anywhere in the world, from a smartphone, desktop PC, laptop or tablet.”

ELECTROLUX STAR EPVS-450

The efficient device is made of galvanized steel and has soundproofing properties, thanks to internal and external sound and heat insulation. The supply air is humidified and heated thanks to an innovative type of recuperator. Contaminants remain on the device membrane.

Advantages:

Automatic embedded system.

Recovery of heat and moisture in the room.

Thermal insulation inside and outside the device.

- Efficiency – up to 90%.

- Liquid crystal display with remote control.

- Works without noise.

- Errors are self-diagnosed.

- There are work settings for the week ahead.

- Does not require a drainage system.

- Setting parameters for monitoring the status of filters.

- Works smoothly at -15 degrees.

At -15C there are 2 operating modes - defrosting the recuperator and turning on the external heater.

Cost: from 73,500 rub.

Selection of supply and exhaust ventilation unit

There are special programs for selecting ventilation units . Using a computer, and in accordance with the requirements, equipment is selected taking into account productivity, air consumption, and suitable configuration. The program will simulate the installation with the necessary dimensions and characteristics. In reality, it is possible to analyze the optimal connection of nodes and constituent elements. Implementation of the program does not require special training. The selection of a supply and exhaust ventilation unit is made easier by demonstrating the selection result on the monitor. They indicate only its composition, including the necessary information from the proposed options. The selection is made automatically, according to the data entered by the customer. Then, as in a game constructor, the required nodes are removed or added. For example, add a water heating section, specifying its parameters. Or include other adjustment elements and automation kits.

Briefly about the installation of the recuperator

Before installing the supply and exhaust ventilation system, a primary installation project is carried out. Approximately estimate the cost of future work. Having studied all the features of the object, the customer’s conditions and the contractor’s capabilities, they set the exact price. Then they draw up a detailed project with an agreed final price.

Recuperators are mounted on walls, ceilings, roofs and floors. They are placed in any position and on the outside of the building. The installation opening in the wall is made with a diameter of up to 250 mm using a diamond tool. The working module of the device is located in the wall. Ventilation grilles are placed at the end. The hole in the wall is placed at an angle of about 3 degrees to the foundation of the building. The external pipe must extend beyond the wall surface by at least 5 cm.

The roof heat exchanger is installed according to a special design on the load-bearing part of the ceiling. It is installed in a round or square structure made of galvanized steel. Or in a reinforced concrete glass placed during the construction of a building. Its diameter size is 700-1450 mm. Before installing the recuperator, a casing is first secured to protect against foreign objects getting into the channels.

To move air, two air ducts are laid. The first one is the main one, the supply one. It has a larger diameter. Serves for intake and separation of air flows for each consumer. The second is of a smaller diameter to remove the used atmosphere. In order to operate silently and prevent condensation, the pipelines are completely insulated. By strengthening the pipes behind the suspended ceiling, they “eat up” the height of the room by 20 cm. The large length of the air ducts creates increased resistance to air flow. In this case, the device is equipped with additional fans that maintain the required pressure.

Recuperator ELECTROLUX STAR EPVS-200

Compact model, the best among devices of this type. Copes with the supply of fresh ozone and elimination of dirty air. The recuperator has membranes located inside that utilize heat and regulate the humidity of the supply and exhaust air. Heating and humidification do not require additional electricity. The installation is carried out in the inter-ceiling space, in the utility room.

Advantages:

- Automation system in control.

- Balancing heat and moisture in the air.

- Thermal insulation inside and outside the device.

- Efficiency – up to 90%.

- Self-diagnosis.

- Programmed ventilation installation of planned work.

- Air filtration – at least F5.

- Operates without heating up to -15 degrees.

Cost: from 41,000 rub.

ECO-FRESH 01 COMFORT

The supply and exhaust recuperator is designed for operation in large rooms and houses with heating systems that run on solid fuel. The devices are equipped with a built-in sensor. This allows users to avoid poisoning during the operation of heating installations. Such incidents are possible if there is an error in construction and design. Filters also work to clean the air from exhaust gases, dust, bacteria, etc. The air is humidified and purified thanks to the performance of the components. The fan operates at 2 speeds in three modes.

When fuel burns, carbon monoxide is released. If you inhale it, a person can die. The solution to this problem is not always solved by opening the windows or ventilating the room. For this purpose, the Eco-Fresh 01 Comfort recuperator was developed. The device will automatically remove used ether from the room and replace it with fresh one.

Advantages:

- Controls the level of carbon monoxide in the room.

- Ensures complete combustion and removal of carbon monoxide.

- Accelerates the removal of flue gas.

- Cleans the ether from impurities, unpleasant odors and bacteria.

- Prevents the appearance of fungi and mold by controlling humidity levels.

- Keeps the room warm thanks to a well-thought-out system for regulating air masses in the room.

- The ceramic housing block heater helps save energy.

- Installation can be carried out inside the wall due to its compact size.

Cost: from 17,500 rub.

About recovery in the supply and exhaust ventilation system

This process determines the return of some heat to reheat the air entering the room. The return is carried out through the heat exchanger of the recuperator, when part of the heat is transferred from the exhaust air to the incoming fresh flow. And during the hot summer period, the heat exchanger reduces the penetration of high ambient temperatures into the room along with the supply air.

In heat exchangers , exhaust and supply air flow separately, having different temperatures. Cold air in contact with the warm surface of the wall heats up. An air flow with an elevated temperature, in contact with a cold surface, is cooled.

Main characteristics of recuperators

Supply and exhaust ventilation with recovery is used in industrial and public facilities, as well as in residential buildings. The indicators by which ventilation units with recovery are distinguished are as follows:

- according to available power.

- according to the design of the coolant.

- existing types can be tubular, plate and ribbed.

- according to the material used to transfer heat. This function is performed by air or liquid.

- along the direction of movement of the energy carrier, the direction of which can be straight, transverse or countercurrent.

- from the installation location on site. If the recuperator serves the premises of the entire building, it is called central. Decentralized devices include those that are installed to serve individual rooms or offices.

The main components of the recuperator design are:

- housing for securing the component parts of the unit, ensuring their safety and performance.

- a heat exchanger that exchanges heat between different energy carriers.

- fan unit - to move the flow of air masses through the exhaust and supply.

- heating elements that maintain the required temperature.

- multi-stage filters with varying degrees of air purification, trapping contaminants, impurities, and odors.

- automation unit with programmable control elements for recovery processes.

- controller with a panel displaying the real operating mode using a timer with a diagnostic function for components and sensors.

- air dampers of various shapes with manual or electric drive, regulating the throughput of the air duct.

- valves with rubber seals, having the same function as air dampers.

- noise suppressors to absorb outgoing sound from a working device.