Author: Website editors

Publication date: 25.04.2019

Issues discussed in the material:

- What is heat recovery ventilation?

- Ventilation scheme with recovery

- What are the advantages of a ventilation system with recovery?

- Types of recuperators for ventilation

- How to choose air handling units with heat recovery

- Tips on how to install supply and exhaust ventilation with recovery

Each person, of course, has his own idea of how comfortable housing should be arranged. For one, the appearance and interior of the premises will be of paramount importance, while the other will consider the various amenities most important. But no matter what we give preference to, in any case, the majority will agree that in order for housing to be called comfortable, it is necessary that it have an optimal temperature - warm in the cold season, and cool in hot weather.

Of course, no matter how we create such conditions, they are always associated with certain costs. We can use devices like air conditioners, fans, heaters. Someone will prefer to carry out repairs in such a way as to make the premises airtight. And such a move will really help preserve the internal temperature. But we must not forget that in such cases one serious trouble cannot be avoided - the housing will stop being ventilated, so there will be no talk of any comfort. The only solution is to ventilate to ensure air movement. Some may be concerned about whether this will result in additional energy costs. But they will even decrease if your choice is ventilation with heat recovery for a private house, apartment or industrial facility. What is it, how does it work? This article will tell you about this and much more.

What is heat recovery?

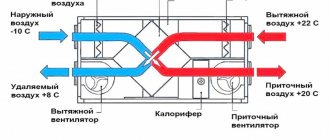

Heat recovery or heat recovery is a heat exchange process in which heat is taken from exhaust air and transferred to fresh injected air. Recovery is used using supply and exhaust units and central air conditioners with a recovery heat exchanger. The process takes place in a recovery heat exchanger in such a way that the exhaust and fresh air are completely separated from each other so that they do not mix.

In refrigerated rooms, recovery heat exchangers can also be used in the reverse way, that is, to recover cold. In this case, the cold from the exhaust air is transferred to the supplied air.

An important characteristic of recuperators is the Recuperation Efficiency Coefficient.

The heat recovery efficiency ratio expresses the ratio between the maximum possible heat recovered and the heat actually recovered. Theoretically, efficiency can vary from 30 to 90%. This characteristic depends on the cost, manufacturer and type of recuperator.

Fans

Air movement is provided by fans - supply and exhaust, although you can find systems with an integrated supply and exhaust fan that is powered by a single motor. In simple models, fans have three speed levels: normal, reduced (used for operation at night or in the absence of residents, if this is a house or apartment) and maximum (used when the highest level of air exchange is needed). Some modern fan models have many more speed levels, which allows them to better meet the needs of system users at different levels of ventilation intensity.

The fans can be controlled automatically. Control panels are usually installed indoors in places convenient for their use. Temporary programmers allow you to set fan speeds throughout the day or week. In addition, some advanced models can be integrated into a smart home system and controlled by a central computer. The operation of the recuperator can also depend on the level of humidity in the premises (this requires the installation of appropriate sensors) and even the level of carbon dioxide.

Since the ventilation system must operate around the clock, high quality fans are an extremely important feature of the air handling unit.

Design and principle of operation of supply and exhaust ventilation with heat recovery

To ensure constant air exchange in the room, clean the incoming air from dust and raise the temperature in a private house or apartment, it is necessary to install forced ventilation. Supply and exhaust ventilation with heat recovery supplies purified air. Thermal energy savings at rated power are about 6 kW. A recuperator is a device that returns heat to the house. It belongs to the category of volatile structures and requires connection to a source of electrical energy.

When designing, the following is taken into account:

- Number of rooms in the house;

- Expected number of people;

- Purpose of the premises.

The calculation of the air duct network throughout the house is made based on the pressure loss that is present in the ventilation system. In a building with a forced supply and exhaust ventilation system installed, the air flow comes from the street. When passing through the condensing unit, the air is cleaned of dust, heated to the required temperature and supplied to the room. The advantage of the system is that purified and heated air is supplied to the house in the required volume.

The process works around the clock:

- Air from the street enters through the ventilation duct through the silencer into the ventilation unit;

- In the unit, the air is cleaned of dust, heated and supplied through a silencer through the ventilation duct into the room;

- Exhaust air from bathrooms and utility rooms returns back to the ventilation unit and transfers its heat to the incoming air, which comes from the street;

- Passing through the ventilation unit, the already cooled and exhausted air exits onto the roof of the street.

Using the built-in control panel you can configure:

- Incoming air temperature;

- Fan speed required for air exchange;

- The filter replacement interval is adjustable by week.

If it is necessary that there be less air exchange at night or on certain days of the week, appropriate settings are made. For example,

- The temperature of the incoming air into the supply unit is -9◦C;

- Air temperature supplied to the room +15◦C;

- The temperature of the exhaust air leaving the unit is -3◦C.

In this mode, the air heater (heater) inside the supply column is turned off—electricity is not wasted to heat the air. This ensures thermal energy savings.

A detailed look at the problem

Let's take a closer look at the situation. We have a residential building in which a family of 4 lives. An air exchange network operates throughout the facility year-round, thereby maintaining healthy conditions inside. But then winter comes and 2 phenomena arise:

- The supply system pumps cold inside, constantly;

- The hood removes heat, also on a regular basis.

The result is low temperature in the house. The problem can be solved by installing air heaters directly in the shafts - you will get heated ventilation, which can easily replace radiators. However, they are powered by electricity or a water heating system - resources are wasted. Know that 40-70% of the energy leaving a building can be saved thanks to a heat exchanger.

Design features

Recovery in ventilation is a fairly new technology. Its action is based on the ability to use the removed heat to heat the room. This happens thanks to separate channels, so the air flows do not mix with each other. The design of recuperative units can be different; some types avoid the formation of condensation during the heat transfer process. The performance level of the system as a whole also depends on this.

Ventilation with heat recovery can produce high efficiency during operation, which depends on the type of heat recovery unit, the speed of air flow through the heat exchanger and how large the difference between the temperature outside and inside the room is. The efficiency value in some cases, when the ventilation system is designed taking into account all factors and has high performance, can reach 96%. But even taking into account the presence of errors in the operation of the system, the minimum efficiency limit is 30%.

The purpose of the recuperative unit is the most efficient use of ventilation resources to further ensure sufficient air exchange in the room, as well as energy savings. Taking into account the fact that supply and exhaust ventilation with recovery operates most of the day, and also taking into account that ensuring a sufficient air exchange rate requires considerable equipment power, the use of a ventilation system with a built-in recovery unit will help save up to 30% of energy.

The disadvantage of this technique is its rather low efficiency when installed over large areas. In this case, electricity consumption will be high, and the performance of the system aimed at heat exchange between air flows may be noticeably lower than the expected limit. This is explained by the fact that air exchange occurs much faster in small areas than in large objects.

Operating principle of the PVU

The operating principle of an air handling unit with heat recovery is as follows. Heated air is taken in through air intakes in the most humid rooms (kitchen, bathroom, toilet, utility room, etc.) and removed to the outside of the building through air ducts. However, before leaving the building, it passes through the heat exchanger of the recuperator, where it leaves some of the heat. This heat heats the cold air taken from outside (it also passes through the same heat exchanger, but in a different direction) and is supplied inside (living room, bedrooms, offices, etc.). Thus, there is constant air circulation inside the room.

Operating principle of an air handling unit with heat recovery

A supply and exhaust unit with a recuperator can be of various capacities and sizes - this depends on the volume of the ventilated premises and their functional purpose. The simplest installation is a thermally and acoustically insulated set of interconnected elements enclosed in a steel case: a heat exchanger, two fans, filters, sometimes a heating element, a condensate removal system (the automation unit, electrical circuit elements and air ducts are not considered in this context).

Organization of air exchange in the premises of a residential cottage

During operation of the installation, two air flows pass through the heat exchanger - internal and external, which do not mix. Depending on the design of the heat exchanger, recuperators come in several types.

The most far-sighted homeowners design two ventilation systems in their buildings at once: gravity (natural) and mechanical with heat recovery (forced). The natural ventilation system in this case is emergency and serves in case of malfunctions in the operation of the air handling unit and is used mainly during the unheated period. It should be remembered that during operation of the mechanical ventilation system, the gravity air ducts must be tightly closed. Otherwise, the effectiveness of forced ventilation will be lost.

Types of recuperators

1. Plate recuperators

Exhaust and supply air pass through both sides of a series of plates. In plate heat exchangers, a certain amount of condensate may form on the plates, which is why they are equipped with condensate drains. Condensate collectors have a water seal that prevents the fan from capturing and delivering water into the channel. Due to condensation, there is a serious risk of ice formation during the cold season. Plate recuperators are characterized by high efficiency (50-80%), are the most common and relatively cheap, and are widely used in small enterprises and small buildings, cottages, and shops.

2. Rotary recuperators

Heat is transferred by a rotor rotating between the exhaust and supply channels. This is an open system, and therefore there is a high risk that dirt and odors can move from the exhaust air to the supply air, however, some manufacturers claim that mixing is eliminated in their recuperators. The level of heat recovery can be adjusted by the rotor speed. They have the highest efficiency (75-90%), and accordingly the price. Mainly used in large industrial enterprises, workshops, and large buildings.

3. Recuperators with intermediate coolant

Water or a water-glycol solution circulates between two heat exchangers, one of which is located in the exhaust duct and the other in the supply duct. The coolant is heated by the exhaust air and then transfers heat to the supply air. The coolant circulates in a closed system and there is no risk of transfer of contaminants from the exhaust air to the supply air. Heat transfer can be regulated by changing the circulation rate of the coolant. These recuperators have low efficiency (45-60%). Possessing low efficiency, they are used when the removed air is heavily polluted or toxic, when mixing is unacceptable.

4. Chamber recuperators

The chamber is divided into two parts by a shutter. The exhaust air heats one part of the chamber, then the damper changes the direction of the air flow so that the supply air is heated by the heated walls of the chamber. Contamination and odors can be transferred from the exhaust air to the supply air. Characterized by high efficiency (70-80%).

5. Heat pipes

This recuperator consists of a closed system of tubes filled with freon, which evaporates when heated by the removed air. When the supply air passes along the tubes, the vapor condenses and turns back into liquid. Has low efficiency (50-70%).

Heat exchangers with intermediate media

The operating principle of this device is almost similar to the operation of a plate recuperator.

Here the heat exchanger is a closed loop of a tube. There is a constant circulation of water or a water-glycol solution in it. The efficiency of heat exchange processes directly depends on the circulation rate in a closed fluid circuit. In such a device, mixing of air flows is completely eliminated. The only downside is the lack of efficiency. Such a device is capable of returning approximately 50% of the heat taken from the room.

Technical characteristics that you should pay attention to when choosing

- Metal devices are effective in operation down to -10ºС. At low temperatures, performance decreases noticeably. As a result, electric pre-heating elements are used;

- When choosing, you should study the thickness of the case and the material of the cold bridges. The thickness of 3 cm is subject to additional insulation when the outside temperature drops below -5ºС. You will have to doubly use insulating material if the frame is made of aluminum;

- Particular attention should be paid to the free pressure indicators of the fans. It may happen that at 500 m3 the pressure may be completely absent. Consumers usually find out about this when the recuperator fails;

- It’s a big plus when additional functions can be connected to the automatic system. Thanks to improved automation, operating costs are reduced and the performance of the entire device is improved;

- The main indicator for deciding which recuperator to choose is ventilation pressure and power. A preliminary calculation is made of how much air should enter the house in one hour.

Air ducts

As we have already noted, installation of supply and exhaust ventilation is much easier to perform in a building under construction than in one already in use . Therefore, its design should be an element of the entire construction project. Typically, the installation is located in unused attics (this makes it easier to ensure the intake of cleaner air), in basements, boiler rooms, utility and utility rooms. It is important that it is a dry room with positive temperatures. Air ducts into unheated rooms must be thermally insulated. Indoors they are usually installed behind suspended ceilings.

Aluminum or plastic flexible air ducts

In practice, various types of air ducts are used. The most convenient to install are aluminum or plastic flexible air ducts in the form of a pipe , reinforced with steel wire. Pipes can also be insulated with mineral wool. Air ducts of rectangular or square cross-section are also used. Ventilation grilles are usually mounted in walls or ceilings. Experts recommend using adjustable flow anemostats for air flow as the most convenient option, although conventional grilles are most often used for these purposes. Supply air should be taken in places where it is least susceptible to contamination.

In conclusion, several videos on the use of air handling units with heat recovery:

Design and principle of operation of a plate air recuperator.

Using an air recuperator as the main means to combat the formation of mold and mildew in a residential area.

These articles may also be of interest to you:

- Types of air conditioning and ventilation systems

- Exhaust Fan Installation

- Replacing the siphon and sink drain

- How to build a wooden toilet in the country

What are the advantages of a ventilation system with recovery?

As we have noted more than once, the main advantage of such a system is the ability to control the interaction of air inflow and outlet. Due to this, we significantly reduce ventilation heat loss, although we continue to saturate the room with fresh air.

Now let's talk in more detail about each of the advantages of ventilation systems with recovery.

Efficiency . Natural air removal is not always a convenient solution, because we become dependent on circumstances, environmental conditions, and temperature differences. In this regard, it is much easier to use a ventilation system with recovery, which can force air. A simple example of forced ventilation is a kitchen hood. More complex devices are capable, among other things, of getting rid of excess moisture. But this is simple exhaust equipment. In our case, we are talking about supply and exhaust systems that are capable of organizing the movement of air flows in both directions at once, mixing them and forming the necessary temperatures for a comfortable stay of a person in the room, that is, recuperating air.

Profitability . It should be noted that recuperation systems can recoup their cost through savings on heating and electricity. Costs are significantly reduced, sometimes by 5 times, that is, you are already paying 80% less than usual. Ask your friends how much it costs them to heat a country house if you don’t have one. The numbers will be impressive. Imagine how much money recovery ventilation can save. If inexpensive elements wear out, they can be replaced without negative consequences. During the warm season, you can save on climate control equipment, while simultaneously reducing emissions of harmful substances into the atmosphere. Yes, even from an environmental point of view, you are causing significantly less damage to the environment, because, among other things, you are reducing the load on the network. And don’t let it seem to you that one person is too little. Firstly, these are quite serious amounts of energy. Secondly, more and more people are switching to ventilation with recovery over the years.

Practicality . Ventilation systems with recovery are usually small in size, which means they are easy to install. Such equipment can be located in the bathroom, in the closet, and built into the ceiling. Today there are a huge variety of models to suit all tastes. So you don't have to worry about the interior.

Heating elements

Of course, a situation where the supply air is heated by the heat removed would be ideal. But in some cases this cannot be achieved. For example, if it is -25°C outside the window, then the temperature of the exhaust air, no matter what the efficiency of the heat exchanger, will not be enough to warm the supply air to a comfortable temperature. In this regard, recuperators are equipped with an electrical system for additional heating of the air supplied to the premises. As practice shows, heating the supply air is needed even if the outside temperature is less than -10'C.

The heating element is also controlled automatically and turns on depending on the program if the selected heat is not enough to heat the supply air in accordance with the set parameters. It is usually mounted together with a heat exchanger. The power and dimensions of the heating elements depend on the power of the entire installation.

It happens that with high air humidity and severe frost, condensation forms on the heat exchanger, which can freeze . To avoid this phenomenon, there are several technical solutions.

For example, the supply fan can work intermittently (turn on every half hour for five minutes), and then the exhaust fan works, and warm air, passing through the heat exchanger, protects it from the formation of ice.

The second, fairly common solution, is to direct part of the cold air flow past the heat exchanger. There are a number of other methods, including the use of an electric heater, which partially heats the air coming from outside in front of the heat exchanger. The resulting condensate should not be collected inside the unit, but removed through the pipeline system either directly into the sewer system or to another place provided by the design.

When building individual houses, it is possible to use a design scheme for a forced ventilation system with air intake at a certain distance from the house and delivering it to the air handling unit through air ducts located in the ground, below the soil freezing level. During the passage through such a channel, the air temperature will increase, which reduces the risk of condensation and ice formation on the heat exchanger and generally increases the efficiency of the recuperator.

How to choose ventilation units with heat recovery

What should you remember when choosing ventilation with recovery? You need to buy such equipment so as not to regret it, so ask the seller about the following nuances:

First of all, ask the seller the following questions:

Question 1 . Who is the manufacturer of this air recovery ventilation? How long has this company been in business, what reputation does it have, what else does it produce?

Question 2 . How productive is this ventilation with air recovery?

Here you will need a specialist who can make a detailed calculation based on the characteristics of your premises. It is clear that buying supply and exhaust ventilation with heat recovery for an apartment and a three-story house is not the same thing.

Question 3 . What will be the resistance of the system to air flows after installing this equipment?

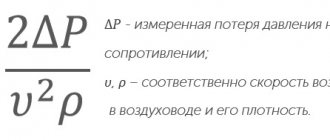

Here again you will need specialist advice. It is important not to just limit yourself to some general characteristics indicated in the table from the Internet, but to make a detailed calculation, for example, taking into account the number of bends in the air duct and many other nuances. The ratio of air flow to system resistance is one of the most important selection factors.

Question 4 . How expensive will it be to maintain ventilation with this recuperator? What is its energy class? What are the savings when using this device?

Question 5 . What are the Efficiency Coefficients of this recuperator for ventilation? Note that we say “coefficients” and not “coefficient”. Why? Is he really not alone? Not really. There is a declared one - this is some average value. And there is real efficiency, which is an objective indicator. What does it depend on? There are many factors. Here is the humidity and air, and how the system is organized, and the temperatures inside and outside.

Here are some recommendations for calculating the efficiency of a recuperator:

- If there is a paper heat exchanger, the efficiency will be from 60 to 70 percent. What does this mean for us? Is it good or bad? This means that ventilation with air recovery is resistant to freezing, although not one hundred percent.

- If there is an aluminum heat exchanger, the efficiency will be no more than 63%, while the efficiency of the air recuperator will be from 42 to 45% percent. Thus, you will have to use a significant amount of electricity to get rid of the frost.

- A rotary air recuperator has excellent efficiency indicators, but provided that it is controlled automatically, based on the readings of special sensors. However, these recuperators can freeze in the same way as aluminum ones, which reduces efficiency.

What else should you consider when choosing a recuperator for ventilation?

First . You are unlikely to find a supply and exhaust air recuperator that can effectively cope with work at temperatures below minus ten degrees Celsius. Don't trust the promises on labels and the assurances of sellers. The best option is a metal recuperator for ventilation, capable of coping with its task at that same -10 ºС. At lower temperatures, the recuperator simply stops working effectively. And if advertising promises you that this device is capable of functioning at -50 ºС, then, quite possibly, it is so, but with one caveat - this is more of an appearance of activity than real recovery. In any case, the efficiency will decrease, the air recuperator will freeze, so do not believe the promises of 100% efficiency and efficiency up to 99% - this is all just an advertising gimmick and deception that has nothing to do with reality.

Second . Look at the thickness of the case and the material. The fact is that thin cases freeze very quickly. For example, 3 centimeters is an insignificant obstacle to the cold. It's more about the name of the case than any effectiveness. It's the same with the material. The same aluminum - the coating is useless unless an additional layer of insulation is applied on top of it, or better yet, more than one. Otherwise, you just get an effective conductor for cold, which will very quickly freeze the equipment, and ventilation with recovery will stop working or begin to demonstrate very low efficiency.

Third . Pay attention to such an indicator as the free pressure of the fans. The fact is that the characteristic “500 m³” means nothing when “0 Pa” is indicated next to it. You may be deceived by large figures, which are actually incredible under the operating conditions that are typical for an ordinary residential building in Russia. In other words, they are writing to you about how ventilation with recovery can work in some ideal circumstances that you will never physically be able to provide for it. Thus, we are talking about a hypothetical ability, and not the real capabilities of the system.

Fourth . Switching modes and options is a useful thing, because it allows you to achieve significant savings in energy resources. Of course, you can monitor the temperatures yourself and quickly adjust the equipment to suit them, but sensitive sensors and automation will do this much better.

Fifth . The main parameter when choosing equipment for ventilation with recovery is the volume of air that enters the room in one hour. The optimal amount is at least 60 cubic meters per person. If there are two of you in the apartment - there are no less than 120, etc. Make sure that the equipment you are thinking of purchasing can actually provide this amount of air flow. If not, then don’t waste your money or time on purchasing it and find something suitable for your conditions. In addition to the performance itself, it is worth paying attention to the pressure that the fans have.

Filters

Air taken from outside must be supplied to the room only after passing through a filter. Typically, recuperators are equipped with filters that retain particles up to 0.5 microns in size. This filter corresponds to class EU7 according to DIN or F7, according to European standards. Thus, the filter traps dust, fungal spores, pollen, and soot.

This feature of the air handling unit should be appreciated by allergy sufferers. At the same time, a filter is also installed in the exhaust system in front of the heat exchanger. True, its class is slightly lower - EU3 (G3). It protects the heat exchanger from contaminants that are removed from the premises along with the air. Filters are made from synthetic materials and can be either disposable or reusable. The material of the latter should be easy to clean. These filters can be shaken out and washed. Some models of recovery units have filter contamination sensors, which at a certain moment signal the need to replace or clean the filter.