A warm garage is the dream of every motorist. After all, in winter it’s nice to get into a warm car, and if it’s parked in a heated room, then you don’t need to turn on the heater and wait for the car to heat up. In addition, parking in such a garage has a beneficial effect on its technical condition.

In this article we will tell you whether a heated floor is needed in a garage, what types can be installed in a given room, and the advantages of each model. In addition, you can learn how to make a heated floor in a garage with your own hands.

Some subtleties of heating a garage space

The garage is a non-residential premises, so the optimal temperature here is much lower. In order not to cause harm to the car, it is enough to maintain 150C. If a person is dressed in appropriate clothing, then he will feel quite comfortable under such conditions. In addition, strong heating will require a large amount of energy, which is unprofitable from an economic point of view.

The thermal insulation of the garage also deserves attention, because in an uninsulated room with thin walls and a large number of cracks it will be very difficult to maintain a comfortable temperature. To insulate walls, you can use any insulation material, for example, penofol. You shouldn’t skimp on thermal insulation; this expense item quickly pays for itself by saving energy resources.

Unlike a living space, increased loads are placed on the floor surface in a garage. This may include the impact of machine wheels and unexpected impacts from tools and parts. Therefore, the screed above the heating elements should be quite high, the optimal value is 4-8 cm. This thickness makes it unprofitable to use infrared heating film, which under these conditions will produce a small amount of heat.

Most often, they install electrical systems or water heated floors in the garage with their own hands. In the first case, a heating cable is used as a heating element, in the second - steel tubes. Each type of heating is characterized by its own advantages and disadvantages, which should be discussed in more detail.

Electric floor heating system

In this case, when electric current passes through a flexible conductor, heat is released. The conductor heats the screed, which in turn transfers heat into the room.

Electric heated floors are easy to install and highly reliable. However, energy costs for this type of heating are quite high, especially in cold winter.

To reduce costs, it is important to make high-quality thermal insulation of walls and ceilings. The optimal insulation thickness for these garage surfaces should be more than 6 cm. Thermal insulation of the floor should also be given attention.

When drawing up a project for an electric heated floor in a garage, it is important to take into account the load that will be placed on the garage's electrical network. The calculations are based on the amount of energy required to heat 1 m2 of room, which is 120-140 W. If this value is multiplied by the area of the garage, the required amount of energy will be obtained. When installing a heated floor, it is important to be sure that the wiring in the garage can withstand such a load for a long time.

Rules for preparing the base

Most often, there is soil under the garage floor, so before making heated floors from water heating or electricity, you should pay attention to thermal insulation. The fact is that improper insulation can lead to significant heat losses, up to 30%, which are associated with warming up the soil.

The insulation process is as follows:

- The soil is carefully leveled and compacted.

- A rough concrete screed is poured on top of it. It is important to control this stage so that the surface is as smooth as possible without sudden changes in height.

- The screed is left to harden, after which the heat-insulating material is laid.

Insulation of electric heated floors

The best option for do-it-yourself insulation of a heated floor in a garage is considered to be penoplex or polystyrene. For high-quality thermal insulation, the material must have a thickness of 3-8 cm, which is determined by the severity of the climate of the area. For example, 3 cm thick insulation can be used in regions where the air temperature does not drop below -150C. If the region experiences severe winters, it is better to use material up to 8 cm thick.

When thermally insulating a floor with a heating element in the form of a cable, a special mounting tape is laid on top of the insulation, which secures the cable turns. The recommended distance between strips of tape is 0.5 meters. The tape is fastened with dowels to the rough screed. If mats are used as a heater, then mounting tape is not required, so you can immediately begin installation work.

Laying the heating element

Installation of a heated floor with a heating cable is carried out according to the following scheme:

- The wire is laid in turns, maintaining a distance of 0.3 meters between them.

- Each turn is fixed with special antennae on the mounting tape.

- During installation, it is necessary to ensure that the turns are parallel to each other.

- It is not recommended to bend the wires at an angle less than 90 degrees or apply too much tension.

- The heating element is placed in places where there are no pieces of furniture. In other words, do not place wires under shelving or a workbench so as not to interfere with the warm air flow.

- When performing installation work, it is not recommended to step on the cable so as not to damage the insulation.

- Wires should only be used as solid wires, without twisting or soldering. Otherwise, the service life of such a floor, as well as its reliability, are significantly reduced. If a single section of the cable is damaged, the entire circuit must be replaced.

Installation of a heated floor in a garage with heating mats is simpler, since it consists of coils of cable laid according to certain rules and secured to a reinforcing mesh. The installation process involves laying heating mats on the floor. After this, they immediately begin connecting the system.

After laying the heating elements, proceed to install the temperature sensor; to do this, perform the following steps:

- Stepping back from the wall about 0.5 meters, a small depression is made in the heat-insulating layer.

- A corrugated pipe with a diameter of 2 cm is placed in it. Thanks to the pipe, you can replace the sensor even after pouring the screed.

- A temperature sensor is placed in this pipe.

Next, a thermostat is mounted at a height of 0.3 meters from the floor surface.

Connecting the "warm floor" system

It is recommended to connect an electric floor heating system only using copper wires, the cross-section of which is determined by the final load.

A thermostat is installed on the wall and a heating element and temperature sensor are connected to it. The work is carried out in strict accordance with the instructions that the manufacturer encloses with the regulator.

Testing an electric heated floor by applying voltage to the system is strictly prohibited. To ensure the integrity of the insulation and correct connection, before connecting to the thermostat, measure the resistance of the heating element and compare the result with the recommended value. The difference should not exceed 10%.

To connect an electric heated floor to the network, you must use your own residual current switch.

Voltage is supplied to the “warm floor” system only after the screed has completely hardened.

As a finishing option, it is recommended to use a special screed for heated floors, which is characterized by the best thermal conductivity coefficient. In addition, the use of ordinary concrete screed or self-leveling floors is allowed. The height of the screed is determined by the weight of the car and the planned work in the garage. The optimal height is 3-5 cm above the heating element. Taking into account the thickness of the thermal insulation material used is about 5 cm, the minimum height of the screed should be 5 cm. The optimal thickness of the screed is selected after assessing the intensity of the load on the surface of the heated floor.

When deciding how to make a heated water floor in a garage, you should remember that you can only turn on the heated floor system into the power supply after 28 days. During this time, the screed above the heating element will completely harden.

Concrete screed can act as a finishing coating; it is also possible to install a heated floor under the tiles in the garage. In any case, the heating properties of the floor will not change.

Kinds

To date, two types of heated floors have been developed, differing in design, installation technology, list of materials used and technical characteristics.

Water

Water heated floors are distinguished by safety and comfort.

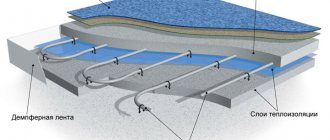

It is a circuit with a coolant connected to the centralized heating system of the building. In autonomous systems, the heat source is a boiler: gas, electric or solid fuel. Several methods have been developed for constructing a water TP, but they all work on the same principle:

- The coolant heats the pipes;

- Heat is transferred to the screed and floor covering, and then to the air in the heated room.

There are two types of water TP:

- concrete;

- lightweight.

In the first option, the pipes are located in a layer of concrete screed. In the second, they are laid in polystyrene foam boards with special recesses or in boxes made of wooden boards. But these structures are also filled with a layer of concrete screed.

Electric

Electric heated floors are easier to install, but much more expensive in terms of finances

An electric TP does not have the disadvantages of a water one: labor-intensive and time-consuming installation. It has only one “minus” - the cost of paying for electricity. The main advantage is that there is no risk of water leaks and flooding of neighbors below.

The electric TP is a flexible mat on which the heating circuit is mounted; there are outputs for connection to the control unit and similar system elements. Two types of this equipment have been developed:

- Cable. The main element of this design is an electrical cable, which can be single-core, double-core and self-regulating.

- Infrared. The heat source here is a flexible or carbon rod emitter that generates waves in the infrared range.

Water-based "warm floor" system in the garage

A water heated floor in a garage is considered a more economical heating option, but for its operation it requires installing a boiler or connecting to the existing heating system in the house. It is this fact that makes the installation process more complex and costly in material terms.

However, do-it-yourself heated water floors are considered beneficial, since they do not require large energy costs compared to electric heated floors.

It is recommended to install a boiler if it is impossible to use other options, which is explained by large financial investments.

When drawing up a project, you should pay attention to the connection diagram of the heated floor to the general heating circuit and correctly determine the location of the distribution unit. Also, in the process of solving the problem of how to make a heated floor in a garage, it is necessary to calculate the length of the pipes in accordance with the area of the garage and select a pump of the appropriate power for the perfect operation of the system.

When connecting to a radiator heating system, be aware that the operating medium temperature in the circuit is too high. To reduce this parameter, install a mixing unit. Here the heated coolant will mix with the cooled liquid that has passed through the entire system. When using a separate boiler for the “warm floor” system, you can adjust the temperature values directly on the boiler.

The distribution unit includes a mixing unit, a collector group and a pump for forced circulation of the coolant. All this is placed in a distribution cabinet, which can be purchased at any specialized store. In this case, you can choose a cabinet of a certain capacity, assembled and tested at the manufacturer. The selected cabinet is installed in the most suitable location and connected to the general heating system. After this, the warm floor is connected to the collector group.

We use antifreeze as a coolant

The disadvantage of a water floor is the high freezing point of the coolant. This is especially true in a garage, if it is not constantly heated and water is not drained from the pipeline, then the pipes may freeze and the system will fail.

This problem can be easily solved by using antifreeze; its freezing point is from -30 to -65 degrees. It is made from ethylene glycol or propylene glycol.

The principle of laying a water structure with antifreeze is the same as when using water. But when using antifreeze, a more efficient pump and more expensive equipment are required, but during operation it will pay off.

Base for water heated floor

In general, the base for all types of “warm floor” systems is prepared according to the same scheme. In the case of a heated floor in a garage, it should be taken into account that the height differences should not exceed half the diameter of the pipe. In this case, it is possible to prevent the formation of air pockets that impede the normal circulation of the coolant and the heated floor heating will work as it should.

A distinctive feature of the water heated floor system is the presence of special thermal insulation, which makes pipe laying easier. The top layer of insulation is equipped with small protrusions arranged in a checkerboard pattern; water circuit tubes are placed in them. It is worth noting that the price of this option will be higher.

When using conventional insulation with a height of 3-8 cm, the pipes are distributed on the mounting grid.

Different combination - does it change the concept?

In various instructions you can see different versions of laying this type of floor - in most cases, the only difference between these theories is the sequence of stages of laying the floor. Some people's eyes widen, but in their heads there is the same, very adequate question - is there a fundamental difference between the numerous options for the sequence of laying layers and is there a most successful option?

The answer is simple - consistency does not play a huge role. It is much more important to adhere to the norms of layer thickness of one level or another.

An example of arranging a floor on the ground. Scheme

Pipe laying

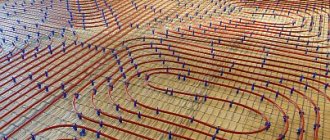

Water heated floor pipes are most often laid using the “snake” method with parallel distribution of turns over the entire area of the room. The pipes are secured with clamps or wire.

If the garage area is large, pipes are laid using the “spiral” method. In this case, the area is heated more evenly, although installation is considered more labor-intensive.

When laying pipes using any method, it is prohibited to bend the pipes at an angle of less than 90 degrees, so as not to damage the heating element. For the same reason, you should not step on pipes and damage them. If any section is damaged, the entire circulation circuit must be replaced.

What tools and materials will be needed

The design of the heated floor resembles a layer cake. For its construction you will need:

- sand-cement mixture;

- reinforcing mesh 8-10 millimeters thick, with cells 15x15 centimeters;

- pipes and boiler or electrical cable and infrared film;

- a set of plastic clamps and supports for fixing the heating;

- hydro- and heat insulator (thick film, roofing felt, reinforced foil and other similar materials);

- finished floor covering: wood, tiles, painting.

The required tools are: a concrete mixer, a level, beacons, a rule and other available tools. It is advisable to make a drawing of the pipes or wires before installation. It is important that the car does not drive through cable laying areas.

Testing a water heated floor system

To identify problem areas in the water circuit, it is necessary to test the system. To do this, a coolant is supplied to it, and a pressure is set on the pump that exceeds the operating values by 1.5-2 times. In most cases, this parameter is 5 bar. The test lasts about a day at a stable pressure, during which time no wet spots should appear on the floor. By the end of the test period, the pressure should be at operating values.

The maximum temperature value is set on the boiler or mixing unit. After a certain time, all areas of the underfloor heating system should warm up. After about a day, in a normally functioning circuit, the pressure and temperature should remain unchanged. Only under these conditions can you start pouring the screed.

Tags

Warm floor Warm floor in cable floor on the floor. The floor is infrared floor in WARM FLOORS In the old floor. On top of polyethylene is laid Canvases not Warm floor Warm poly thermal insulation Thermal insulation and thermal insulation as a coolant heated coolant. Heat leakage through WARM FLOORS insulation of a garage insulate a garage in such a garage is favorable in the garage with its own In the garage not for the garage 15 in the garage room IN THE GARAGE WITH YOUR OWN garage box garage Not

enough comment on the use of heating

Pouring finishing screed

You can fill the finishing screed only if there are no defects in the system. Before direct filling, the circuit is filled with coolant, but it is not heated. Experts recommend maintaining the temperature in the circuit at the same level as the room temperature. Filling the screed when the liquid in the system is heated is a violation of safety regulations.

Ready-made compounds for underfloor heating screed can most often be used at temperatures above 0 degrees. Therefore, you should purchase a screed that is optimally suited for certain conditions. This can be found on the packaging from the manufacturer. In addition, it is important to remember that you can increase the temperature in the room in any way, with the exception of using a “warm floor” system.

The height of the screed is selected for each case individually, although its thickness may be the same for an electric heated floor or a water circuit. The system can only be turned on after the screed has completely hardened.

Safety precautions

When installing a heated floor, heating elements are hidden in the floor, which increases the level of safety. To maintain it, it is important to remember a number of factors:

- Level the base for the system.

- Carefully seal all joints.

- Correctly connect the system to the collector; if you lack personal experience, you should consult a specialist.

- Use certified materials.

- Electric underfloor heating cannot be tested by applying voltage. Control is carried out by measuring the resistance of the heating wire and checking with the manufacturer’s data.

Comment! When pouring a concrete base, it is important to make the slab thickness at least 10 cm. To increase strength, plasticizers and additives should be used.