Gas holder - the name was borrowed from English. Gas – gas and holder – holder, owner. Under the loud name there is simply a storage tank for a gaseous substance. Most often, residents of private houses pump and store natural or liquefied gas into such containers. Heating systems that include solid fuel or diesel boilers may often not suit homeowners due to labor-intensive maintenance.

An alternative in this case is a high-tech gas boiler, but what to do when the main gas pipeline is too far from your home, or is completely absent? A gas tank comes to the rescue. The use of such a device is not at all uncommon in the modern world. A correctly selected gas tank, depending on the volume and corresponding gas consumption of the boiler equipment, is capable of providing a country house with fuel, requiring replenishment only twice a year.

Types of gas tanks

In addition to differences in operating principle, natural resource storage tanks are divided depending on the configuration, installation method, and wall material.

By configuration

Cylindrical types of gas holders can be vertical and horizontal.

The vertical model looks like a large can. Its main advantage is the small area that the unit occupies. However, due to the small area of gas evaporation, such a system does not provide optimal pressure at increased gas flow rates. To increase the evaporation power in such a storage facility, you can additionally install an electric heater - an evaporator. But this increases energy costs, negating material savings during system operation. Vertical devices are relevant for small houses and limited household needs.

To provide a heating system in winter, it is better to purchase horizontal models of gas tanks. They have a large evaporation area and are able to create pressure for efficient operation of heating and heating systems.

By installation method

There are three types of gas storage facilities.

Ground ones are installed on the surface of the site, which greatly facilitates the maintenance process. However, the fire safety of the tank requires additional control. At the same time, during the cold season, the mixture cools down and stops evaporating in the required volume, which can lead to failure of the heating system. In northern regions, these models are not recommended for installation due to increased heating costs. If the area is rocky with uneven terrain, this barrel is ideal for use.

Underground ones are mounted in pre-dug pits. Due to its bulky size, excavation work takes a lot of effort and time. But due to installation below the soil freezing level, the tank does not require additional heating, since the suspension evaporates normally, ensuring uninterrupted operation of the equipment. Another advantage of underground gas storage barrels is maximum safety and minimal risk of explosion in the event of a gas leak.

Mobile – special models used for emergency or seasonal needs. They are located on a trailer with wheels, making them easy to transport. They are small in size and volume. Not suitable for stationary connection, as they require additional heating of the mixture in the frosty season.

Tank material and wall thickness

The gas tank includes a protective frame made of galvanized steel. It also has tent protection from ultraviolet radiation and a container for natural suspension.

What it is?

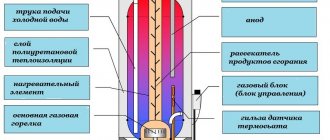

A gas holder is a large cylinder that contains liquid gas.

The device is designed to supply private homes with fuel. According to the principle of operation, gas holders are no different from an ordinary household cylinder or lighter.

The tank is buried in the ground and filled with liquid gas to 85%. It evaporates into the remaining 15% empty space. Gaseous fuel enters the house through pipes: to heating appliances, boiler, stove, water heater, etc.

Main elements of a gas tank:

| Tank | Made of steel 8-12 mm thick. Able to withstand pressure |

| Locking devices | They are responsible for supplying fuel to the house. |

| Condensate collector | A separate container in which all the condensate from the evaporated gas accumulates. |

| Evaporator | A device that helps gas evaporate at subzero temperatures |

| Gas level indicator | An electrical device that informs about the filling of the tank using a radio signal |

Installation Requirements

It is necessary to install one or another model of gas storage facility, taking into account the norms and technical rules. Underground structures should be located at a distance of 10-12 cm from any communication systems and residential premises, exclusively in stable soil.

Ground-based devices are installed in the shade at a distance of 20 m from the house and 2-3 m from the fence bordering the territory. Trees and bushes should be 10 m from the installation. A well with water is 15 m away.

If all installation rules are followed, the gas holder does not pose any danger to residents and equipment. The gas suspension is stored in a barrel without access to oxygen. In the event of depressurization, a fuel explosion will not occur.

Why can't you do the maintenance yourself?

In the gas tank, propane and butane are under pressure, so all manipulations associated with the tank are considered work with increased danger. They are performed by specially trained people. If you do maintenance yourself, you can provoke emergency situations that are dangerous to the life and health of people.

You are only allowed to carry out security checks yourself. The container and connecting elements should be periodically inspected for leaks. If defects are detected, a service company is urgently called. The owner must also monitor the level of the propane-butane mixture in order to know when to call service for refueling.

Calculation of volume and how long it lasts

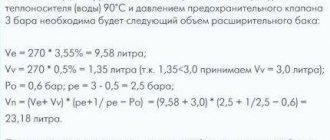

Tank volume is one of the most important parameters of an autonomous gas system. It must be calculated at the first planning stage. It is better to entrust the work to gas engineers and do the calculations yourself to check.

The calculation is easy to do using an online calculator, which can be found on building materials websites. Approximate data can be calculated, taking into account that a square meter of housing requires 30 liters of liquefied gas for the entire heating season with normal heating.

Conclusions and useful video on the topic

Briefly and succinctly about autonomous gas supply to private households:

Judging by the description of the design and installation process, it is quite possible to provide a private home with an autonomous gas station with little effort and at a cost acceptable to the family budget. And quite a few owners of suburban real estate, remote from centralized gas communications, use this opportunity. The result is obvious - convenience and increased living comfort.

Do you have practical experience in using and installing gas tanks? Or would you like an article on the topic? Please leave comments, ask questions, and share your experience in the block below the article.

Site preparation

The installation of the gas tank itself is not particularly difficult.

More problems arise with its connection and commissioning. Therefore, it is important to find professionals who specialize in installing such systems and have the necessary knowledge. If the installation of the storage facility is carried out independently, the algorithm of actions looks like this: preparatory work, arrangement of the pit, direct installation of the container, connection. First you need to dig a pit of suitable size . Before installing the gas pipeline system, a warning tape on which an increased gas hazard is reported. Next, a gravel layer , which is laid out at the bottom of the pit. Lay a concrete base on top - pour or install a slab.

Advantages of completing a turnkey project

Owners of private housing, wanting to save money, sometimes try to do some of the work themselves. And this is advisable if you have experience in installation or connection and there are no legal barriers.

However, just in the case of organizing an independent gas supply, there are practically no “loopholes” left for independent intervention:

- all installation work, equipping with additional equipment, connection, commissioning must be carried out by an organization that has a special license;

- The development of specifications and the preparation of the project are also carried out by companies with permission;

- Before concluding an agreement with the installers, the owner collects a package of documents (specifications for gasification of the house, title documents for the land, site plan, approvals from many authorities, etc.), which takes a lot of time.

If a home owner is faced with the design and installation of an autonomous gas system for the first time and is a busy person, it is better to immediately contact a private company that has long been successfully engaged in the installation of turnkey gas tanks and maintenance of gas systems.

The company, which has 10-15 years of experience in autonomous gasification, is provided with a staff of qualified workers who thoroughly know all the rules and regulations for equipment installation

Representatives of a private company, as a rule, have the necessary connections in various related authorities, so the process of approving documentation will go much faster.

The advantages of the “full package” also include prompt installation of a gas tank, including excavation work, transportation and installation, connection and pressure testing.

The company’s specialists bear full responsibility for all installation work, which is carried out in accordance with the standards of industrial safety regulations, SNiP, GOST and SP, and upon completion of the work they provide a guarantee

If errors occur during the installation process, they are corrected free of charge. Concluding a service agreement (prevention, gas injection) with the company installing the gas tank facilitates repair or replacement of equipment. You can read more about the cost of installing a gas tank in a private house in this material.

Installation procedure

As soon as the hole is ready, the tank is lowered to the bottom . It must be secured with cables made of heavy-duty metal. Then they dig a trench from the storage facility to the house. Pipes are laid in it, through which fuel will be delivered to the heating and heating systems.

One of the most critical moments is the installation of a gas supply system . In this case, it will not be possible to do without the help of a knowledgeable specialist. If there are any shortcomings or omissions, the system will not be allowed to be put into operation, and re-equipment may take a lot of money and time.

As soon as all elements of the system are installed, the technician checks the tightness of the system using a special mixture. Next, all devices are connected, and the operation of the system is checked. If no problems arise, the pit is covered with sand .

In the future, the system is serviced once a year . Thanks to simple preventive measures, you don’t have to worry about a possible leak of suspended gas. Technical inspection of the entire system is carried out by specialists, since gas is not an absolutely harmless type of fuel, such as coal or firewood.

How many gas cylinders can a private owner carry in a car?

This is perhaps one of the main questions when it comes to homemade products from gas cylinders. Let's turn to the laws.

The transportation of dangerous goods in the Russian Federation is regulated by the following documents:

- “Rules for the transportation of dangerous goods by road”

- "European Agreement concerning the International Carriage of Dangerous Goods by Road"

- "Traffic Laws"

- “Code of the Russian Federation on Administrative Offenses”, Article 12.21 Part 2 of which provides for liability for violation of the rules for transporting dangerous goods in the form of “an administrative fine for drivers in the amount of one to three times the minimum wage or deprivation of the right to drive vehicles for a period of one to three times the minimum wage.” three months; for officials responsible for transportation - from ten to twenty minimum wages.”

But “The Rules do not apply to the transportation of a limited amount of dangerous substances in one vehicle, the transportation of which can be considered as the transportation of non-dangerous cargo.”

From here, we look in the table to see how many gas cylinders are not dangerous for transportation by private individuals and intended for personal use .

It turns out that 15 pieces are allowed to be transported without permission. gas cylinders of 50 l.

Procedure for refilling the storage

Modern gas tanks require refueling 1-3 times a year, depending on the volume of the tank and fuel consumption. The process of replenishing the resource itself is as follows:

- The season is selected. It is better to do this in the spring and summer, when gas consumption decreases, which significantly affects the price of fuel and its delivery.

- Preparatory stage. It is optimal to fill the tank when 25-30% of the gas mixture remains in it. Before performing the procedure, you need to record the meter readings. The duration of the entire process is 30-60 minutes. However, this period may increase depending on the size of the tank. During refueling, it is prohibited to use open flames (smoking, burning fires, etc.), flagrantly violating fire safety rules.

When refueling, you must follow the rules, neglect of which can lead to emergency situations and breakdown of expensive equipment:

- The container is filled to no more than 85% , the remaining volume is given as compensation for the expansion of the gas suspension.

- Refueling can only be done in the morning or afternoon.

- At least two specialists must take part in the process.

- Before filling the tank, the tanker must be secured with a parking brake and wooden stops, and the engine must be turned off.

- Before starting to supply fuel, be sure to check how well the drain hose is secured. To do this, use clamps, which should be available from the tanker. Other available means are unsuitable for these purposes and are prohibited for use.

- Persons performing refueling must wear special clothing and additional protective equipment.

The owner must monitor the progress of the procedure; if violations are detected, be sure to stop filling the tank.

Why is autonomous gasification needed?

It is difficult to do without gas. This is the most economical and convenient way to heat a country house. Alas, there are many places in the Moscow region where natural gas is not available. The best alternative to natural gas is liquefied propane-butane gas, which does not require a centralized gas pipeline network.

The AvtonomGaz company will install an underground gas tank - the so-called gas tank - on a site near a country house, cottage or dacha. This process is called “autonomous gasification” and requires only a few hours.

The gas tank is located underground at a distance of five to ten meters from the house. It does not take up space on the site - if desired, you can plant herbaceous plants and even shrubs above it.

Several thousand liters of propane-butane fit inside. This volume is enough to heat a house for several months. When the gas runs out, the AvtonomGaz gas carrier will replenish the tank. During refueling, a specialist will inspect the gas tank free of charge and carry out the necessary maintenance.

Problem 2: Flooding of the gas tank filler neck

Description of the problem: When checking the level of remaining fuel, it turns out that the filler neck and gearbox are flooded.

Detailed description and reasons: If this happens in the warm season without further frost, then most likely the fittings and other equipment will work properly. We talked about the consequences of gearbox freezing earlier. But if the water above the filling neck freezes, this makes it impossible to replenish the LPG level in the tank of the autonomous gas supply system.

Solution to the problem: The reasons and solutions are similar to the previous paragraph. In addition, to eliminate the possibility of flooding of the reinforcement as a result of melting snow, it is recommended to build an additional barrier to precipitation. For example, place it in a reinforced concrete ring with a lid.

Problem 4: Fuel overflow

Description of the problem: The maximum volume of fuel poured should not exceed 85% of the capacity of the LPG storage tank. But sometimes this happens. As a result, the gas phase of hydrocarbon evaporation is not formed, and a liquid mixture of gases enters the selection valve. The level gauge usually jams and the boiler does not light up.

Detailed description and reasons: The indicated limit of 85% is set specifically to ensure that there is free space in the container for the evaporation of hydrocarbons. In this case, boiling gas does not enter the pipelines. Therefore, such a situation cannot be allowed.

Solution to the problem: When fuel is overfilled, the solution can be quite clear. First of all, it is necessary to pump out excess fuel with a reserve. This is done through the liquid phase withdrawal valve. In addition, some of the fuel can be removed along with water through the condensate drain valve. It is not recommended to constantly bleed gas through the pressure relief valve. The container will not explode, but if there is excess LPG in the tank, this is a rather fire-hazardous procedure.

With a slight overflow (up to 3%), there is a possibility that the fuel will calm down on its own and the operation of gas equipment will normalize on its own without additional external manipulations.