Heating radiators built into the floor are heat-generating equipment, the installation of which is carried out in such a way that technological elements and parts are not visible. Structurally, they consist of a box made of steel with anti-corrosion properties, inside which a heat exchanger made of aluminum or copper is placed. For connection, special corrugated, moisture-resistant tubes are used.

They can be either equipped with a housing or installed without it. Either option is quite easy to install.

Appearance of the battery in the floor Source stroy-podskazka.ru

Convector leakage

If your regular radiator is leaking, you will notice it immediately because you will see a puddle underneath it.

And if the underfloor convector leaks, you will discover it only after the entire laminate gets wet and the water rises above its level.

In this case, all neighbors below are guaranteed to be flooded.

When a regular radiator has leaking connections, what do you do? Take a regular adjustable wrench and calmly tighten them.

And when the convector leaks, all connections will be covered with very hot and very opaque water. And soaking this water with a rag is very inconvenient.

Radiators have very sharp edges and when you get water out of there, you are guaranteed to get cuts on your fingers.

Also, do not forget that only convectors with a fan heat properly. A fan is an electrical device that is powered by a voltage of 220V.

And in the case of a leaking convector, the effect will be quite obvious, as if the electrical wiring had been stuck in water.

Also, dirt and dust constantly accumulate in the niche of in-floor convectors, and cleaning there, as we found out, is not very convenient.

Do you need a fan?

The presence of any type of fan in a convector affects the cost of the unit - in the direction of its increase. And for the buyer, this is a reason to think: is the ventilation option in the device really necessary and what does ventilation provide for heating the room?

A convector for heating a house will have a much higher percentage of heat transfer if the air supply to the heat exchanger and from it into the room becomes more intense. And without a fan this is a priori impossible. What kind of intensity is there if nothing “stimulates” the air and it moves on its own at normal speed?

Climate control experts have calculated that if there is a fan in a heating device, the room is heated 2-3 times faster than usual. There is nothing to comment on here, just repeat a few lessons from the school physics curriculum.

In addition to rapid heating, the fan also has the important function of cooling the heat exchanger. That is, an ordinary fan serves as a guarantor of the safety and durability of the unit itself.

It is especially important to have a fan in powerful gas and water convectors, which heat the air inside to very high levels and, without timely and high-quality cooling, risk melting and becoming unusable during one heating season. Therefore, ventilated heating convectors have received only positive reviews, despite the high price

Therefore, ventilated heating convectors have received only positive reviews, despite the high price.

Low batteries

Radiators with a small center distance have the following advantages:

- they can be placed under a low window sill;

- they have maximum heat transfer per unit area.

Cast iron radiators The dimensions of sections of heating radiators MS-140M-300-0.9 are:

- length 93 millimeters;

- depth - 140 millimeters;

- height – 388 millimeters.

heat transfer of cast iron heating radiatorspower of a cast iron radiator section

Aluminum radiators

dimensions of heating radiators

Bimetallic radiators Bimetallic low radiators, such as in the photo, have two nuances:

- among heating devices there are batteries not with solid steel cores, but with steel tubes placed between aluminum collectors. Their operating pressure, indicated by manufacturers, is usually 12 or 16 atmospheres;

- they often do not have vertically located channels and, in the case of a lateral connection, can be heated by the collectors due to the thermal conductivity of aluminum. The circulation of the coolant is ensured by the last section, since it is flow-through.

Electric convector heat without hassle

In principle, now any of the heat sources does not require much labor from its owner: gas and electric boilers can be turned on in the fall and turned off only in the spring - at the end of the heating season. Yes, and improved wood burning ones can be left unattended for 8-12 hours (this is how long the process of burning wood lasts). But if you really want to “forget” about the heat source in your home, install a couple of convectors.

The best option for the home is electric heating convectors with a thermostat that keeps the air within certain temperature limits, preventing the plates from melting.

Advantages of an electric convector:

- affordability;

- ease of installation;

- compactness;

- low noise;

- ease of use;

- high efficiency;

- no need for special maintenance.

Flaws:

- ineffective in large rooms;

- decrease in efficiency over time;

- high percentage of electricity consumption;

- not in all cases they can serve as the main source of heat.

Results

Convector heating is a very good option for heating rooms. Convectors can be recommended for installation both in small apartments and in large country houses. They have good performance and efficiency.

Homemade - this word means that the product is made with your own hands, but sometimes it is used with some kind of disparaging connotation. Yet this is far from the case. The most expensive hand-built cars in the world are created according to individual projects. What should we call them? Homemade? Everything that ensures the life of mankind is created by human hands.

The topic of this article is homemade products for heating a house, but its goal is not to teach, but to give an overview of those homemade options that talented people implement. Of course, self-production requires certain knowledge, experience, tools and materials for the job. Only in this case is it possible to produce a high-quality and safe heating device no worse, and in many cases even better, than industrially produced boilers.

Most often, craftsmen begin creating a heating system by determining the type of boiler, creating drawings and then constructing the boiler. This work is not easy, therefore, without good knowledge of the structure and operating principle of the selected type of boiler, experience, availability of the necessary tools and materials for its installation, it is difficult to complete it.

Most often, the following types of boilers are manufactured independently:

Gas boilers are difficult to make on your own, since this is high-risk equipment and is subject to special technical requirements. Attempts to make a homemade one are limited by the need to obtain a quality certificate and permits from supervisory authorities. It is problematic to pass all the required checks for compliance with quality parameters. But repairing a convector with your own hands is acceptable. Most often, the central pipe of the coaxial output burns out and it can and should be replaced.

Electric boilers

Boilers of this type are characterized by extreme simplicity and low safety requirements during installation. An electric boiler can be compared to conventional electrical appliances that are used in the house. The only drawback is the high and constantly increasing price of electricity. But for a garage or cottage, if it turns on occasionally, it will be quite suitable.

Liquid fuel boilers

Boilers using liquid fuel are also easy to manufacture. An obstacle to production can be the high price of injectors.

Solid fuel boilers

This class of boilers, and they are divided into wood, pyrolysis and pellet, is the most popular for self-production. A do-it-yourself wood heating boiler is one of the simplest and cheapest, but its efficiency is quite low. There are many drawings and practical tips on the Internet for making a boiler of this type. A wood-burning boiler can operate on any type of solid fuel.

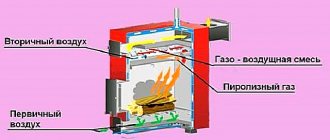

Pyrolysis boilers

Two-chamber pyrolysis boilers are quite expensive to manufacture on your own. They have two combustion chambers. In one, fuel burns with minimal access to oxygen. That is, the process of pyrolysis or dry distillation of wood occurs. The gas released from the wood burns in the second chamber, releasing a large amount of energy. A pyrolysis boiler can operate on wood, coal and peat.

Craftsmen have learned how to make a pyrolysis boiler from a gas cylinder with their own hands, which is economical and works great.

The easiest way to make a boiler is from a gas cylinder with a capacity of 50 liters. (no votes yet)

Kinds

There are two types:

- Electrical. They are equipped with closed-type heating elements in which plates are installed. Can be steel or copper. They are produced in accordance with all safety requirements. They have special fuses to provide protection against network failures. Their installation is carried out in those facilities where there is no central heating.

- From central water heating. The structure can be steel, aluminum or copper.

Installation features

To install batteries in the floor, you need to prepare a place for future batteries and provide free access to the structures for their further maintenance. It is better to entrust such work to professionals, since the slightest mistake can cost a new floor covering.

In this regard, both the built-in batteries and the “warm floor” system are, in principle, the same in terms of the volume of work performed and complexity. Therefore, it is worth focusing on the personal preferences of residents: if they want more heat, localized in one place, it is better to make batteries under the grille. If you need heat that is not so intense, but diffused throughout the room, it is worth installing a “warm floor”.

By the way, the latter can be not only electric. Some home owners, even before rough finishing the floor, connect thin pipes to the water heating system and install them throughout the floor. Next comes screed and finishing.

Battery built into the floor near the windows Source carrera.in.ua

Where can underfloor radiators be installed?

Unlike wall-mounted ones, in-floor radiators are universal. Installation can be carried out in any room, regardless of its purpose - office, residential, commercial, etc. Can be installed in houses with French windows.

Built-in batteries in the bathroom Source batareya.com.ua/

They can be used to organize heating of greenhouses, shops, art galleries, halls, hallways, corridors, even in rooms with a special artificially created microclimate - in museums, houses where panoramic windows are installed.

Built-in batteries in a children's room Source konvektors.in.ua

About the design

The idea of installing radiators in the floor is used in modern private homes, in rooms with low window sills (for example, in new buildings), in office and shopping centers, and in gyms. In such conditions, the installation of conventional radiators is irrational, both from the point of view of aesthetics and for reasons of thermal efficiency. Therefore, choose a device that is placed in the screed at the level of the floor covering; the disguised unit consists of the following elements:

- Frame . For quality equipment, it is made of stainless steel, which is resistant to corrosion. You need to find out about the material of the case before purchasing: if it is made of technical steel, the service life will not be long.

- Heat exchanger . This is a metal circuit through which the working fluid circulates. The central part is a copper tube, plates are attached to it, and there is no gap between them. The finned heater has high heat transfer rates. During operation, heat from the tube is transferred to the plates; heat exchange with air occurs through them.

Source kztoradiator.ru

- Floor grate . The panel, which covers the structure and protects it from accidental damage, is mounted level with the finishing coating. The grille can be removable or attached to the body, plastic, metal (aluminum) or wood. The grate, even a metal one, heats up no higher than 30°C and is completely safe to use in everyday life.

- Fan . Helps to obtain more heat and better distribute it throughout the room. To reduce noise from a running fan, vibration mounts are used.

- Auxiliary elements . These include a relief valve, which is necessary to eliminate airing, and regulators that help select the appropriate temperature during operation.

Briefly about the main thing

Radiators recessed into the floor are increasingly used for heating country houses and new buildings. Convectors are placed under windows, where they not only heat cold air, but also protect the glass from condensation. The models offered on the market are divided into electric and water. They heat the air using natural or forced convection; in the latter case, the battery is supplemented with a fan.

Question

Write in the comments what you think - is it worth installing a convector in the gap between the room and the former balcony (if the space was combined)?

Electric models

There is no news here: a closed-type heating element is used - a heating element. There are plates attached to it to increase the area of contact with air. Most often, the plates are made of aluminum - this is a relatively inexpensive metal with good heat transfer. Low-cost models may use steel, sometimes galvanized steel, and expensive ones may use copper.

Built-in convectors can be powered by electricity

The material from which the heating element is made is no less important. It is its durability that determines the life of the equipment. European manufacturers often install stainless steel heaters. They have the longest service life.

Since these are household appliances, they have a high protection class for both current and voltage. There are various types of fuses and circuits that turn off the devices in case of failure. These devices are safe under any conditions.

How to install?

Proceed with installation only if you are fully confident that you have the required knowledge, skills and tools. In this case, the best option would be to turn to professionals. Often, stores that sell floor-mounted batteries offer their installation services. Thus, they bear full responsibility for the operation of the system and assume all warranty obligations.

But if you still decide to do it yourself, study the procedure for performing the work:

- coolant or electrical cable supply;

- installation of a niche;

- floor filling;

- radiator installation;

- adjustment of its height using bolts;

- fixation of the entire structure in a niche, insulation, sealing of gaps between the walls and the metal box;

- arrangement of the final finished floor;

- connection to the electrical network or centralized heating;

- sealing cracks using silicone sealant;

- installation of a protective grill.

How to select correctly?

When purchasing, first of all, pay attention to the power of one section in order to calculate the required amount to heat a certain area. You should also take into account the type of radiator with and without forced convection.

The following factors should also be taken into account:

- The required pressure in the heating system so that the water circulates well and distributes heat relatively evenly throughout all rooms. This is especially true for housing in apartment buildings. You should look at the water pressure in the pipes supplying it to your apartment. Taking this into account, decide whether such pressure will be enough or not. Information about this can be obtained from the Housing Office. And only after making sure that the pressure is sufficient, you can begin to select a specific model of heating radiators. Often, a radiator that can withstand pressure of up to 15 atmospheres is suitable for heating an apartment.

- Type of energy carrier with certain parameters. For this type of radiator installed in a private home, any type of coolant can be used. This is because the owners independently monitor its condition and temperature level. For people living in apartments, the type of energy carrier is important. For this reason, you need to pay special attention to the design and quality of the device that will be installed in your home. It is also necessary to take into account the Ph level of the liquid with which the battery built into the floor can work, its characteristics, and temperature conditions.

- Size of pipes, their number (1 or 2).

Advantages and disadvantages

Heating radiators built into the floor have both a lot of pros and cons. They must be taken into account when selecting a specific type of heating for a house, apartment or other objects.

In particular, their advantages include:

- long period of use, providing the opportunity not to think about repairs or modernization of heating for a long time;

- high efficiency and productivity at low comparative costs for space heating;

Semicircular batteries built into the floor Source konvektor.in.ua

- environmental friendliness, reliability and reliability;

- they do not negatively affect the interior of the room, since they are hidden from prying eyes. In addition, they do not steal territory in the room without interfering with the installation of furniture.

- provide the ability to install panoramic windows.

Built-in batteries in the bathroom Source batareya.com.ua

Disadvantages:

- installation of radiators requires a certain ceiling height, otherwise they will not work efficiently;

- they are more expensive than conventional wall or floor radiators;

- their installation is much more difficult and expensive;

- with forced convection they spread dust throughout the room, in addition, energy costs will be higher.