Despite its apparent simplicity, competent and correct organization of heating is quite a complex task, especially for non-professionals. If you don’t have the necessary skills, or unexpected surprises in the form of the need to redo the work in the future, contacting specialists in the installation and design of home heating systems will help. We turned to a team of professionals from the Akvahit company to learn about all the subtleties and nuances associated with the installation of a heating system. Therefore, you first need to decide whether it is worth developing a heating scheme for a private house with your own hands or turning to professionals.

Without specialized education, it is very difficult to carry out calculations and installation. Source nehomesdeaf.org

In general, in order to have high-quality heating at home, you can go in the following ways:

- Contact a specialized service that will carry out both the creation of a heating scheme for a private house by the designer and the installation work;

- Order partial execution of installation work by specialists;

- Get professional advice and install heating in a private home yourself.

Regardless of the option chosen, you should imagine the entire installation process in stages. Even if you don’t have to do anything yourself, it never hurts to monitor the progress of the work being done.

What is home heating?

This is a set of engineering components designed to receive heat, transport it and maximize its efficiency in the desired room, in order to maintain temperature conditions there at a given level. Comprises:

- Converter of stored fuel energy into heat (boiler);

- Coolant transportation systems (pipes)

- Shut-off and control valves (faucets, manifolds, etc.);

- Devices for transferring heat to air or a hard surface (battery, heated towel rail, heated floor).

Sample project for installing a heating system for a private home Source yandex.ru

What is burned in boilers

The choice of boiler is initially made according to the type of fuel from which it extracts thermal energy:

- Gas is a simple and inexpensive heating solution. The use of this type of fuel allows you to fully automate the heating process, subject to high-quality installation and configuration of the equipment;

- Solid fuel is most often used in populated areas where there is no gas pipeline. Used: firewood, briquettes, coal or pellets. These types of boilers have a disadvantage - it is impossible to fully automate the heating process. They require the combustion chamber to be filled manually every 10 hours and a separate place to store the fuel. They also need to be cleaned periodically. An intermediate solution is to use an automatic dispenser - autonomy in this case depends on the size of the bunker. In some cases, it is possible to increase the operating time of the boiler without adding fuel to 5-12 days;

- Electricity is the leader in terms of cost, and at the same time in terms of convenience and environmental friendliness of use. The main advantage of such devices is the ability to fully automate control. Also, such boilers require virtually no maintenance;

- Liquid fuel (gasoline, diesel) is most often used in places where there are no other energy sources. The efficiency of such boilers is about 80%, which makes them relatively economical.

See also: Catalog of companies that specialize in insulating country houses.

Installation work

The first stage of installing a heating system is installing and piping the boiler. According to the regulations, powerful devices (from 60 kW) are installed only in specially designated rooms - boiler rooms. But, if the power is below 60 kW, the boiler can be placed in the kitchen.

According to regulations, boilers with solid and liquid fuels cannot be installed in rooms with poor air flow. Another prerequisite is the installation of a chimney.

The heat generator must be installed taking into account the permissible parameters of the distance to other equipment and walls in the room.

Any equipment has a passport and a manual, which indicates the available distances to the nearest objects in the house. If the manual does not contain this data, then installation must be carried out according to the following rules:

- The passage between the boiler and other objects must be at least 1 meter.

- The nearest equipment should be located 70 centimeters from the boiler.

- Two boilers should be located 1 meter apart. The distance between boilers, if they are located opposite each other, must be at least 2 meters.

Video description

Comparison of fuel types in this video:

If there is no gas - pellet boilers BIODOM

If gas is supplied to the house, then it is almost guaranteed to be the optimal heating solution. But if there is no gas, even if there is a central highway nearby, then a prudent owner will consider not only the cost of heating, but will also add in the cost of connecting a gas pipeline to the house. In this case, pellet boilers look more economically profitable. Moreover, there are now innovative solutions on the market to automate their work.

It would seem that the evolution of pellet boilers stopped in the early 2010s, when manufacturers introduced screw feeding technology, which made it possible to significantly simplify the management of the home heating system. Everything that manufacturers have come up with in recent years was more like complicating the boiler for the sake of the complication process itself, rather than helping the boilers themselves become better and more efficient.

It seemed that it was impossible to improve the efficiency of pellet combustion and simplify the process of installation, startup and operation of pellet boilers. But in 2022, the BIODOM company appeared on the Russian market with its development - pellet boilers with BIOLOGIC technology. Back in 2004, having developed and patented its invention, this European company, overcoming the difficulties of an unknown brand, brought its know-how to the masses - a pellet boiler, all interaction with which consists of adding pellets and pressing the “Start” and “Stop” buttons.

BIODOM engineers paid a lot of attention to the energy efficiency and cost-effectiveness of the boilers they produce Source biodom-ural.ru

Today, BIODOM boilers with BIOLOGIC technology are time-tested, and invariably, from year to year, they prove their uniqueness and performance. One of the main secrets is the use of solutions used in modern cars and their processing to control the combustion of solid fuel, which has become a unique novelty that has solved most of the problems in the industry.

- Boilers have become compact - space can be allocated for them in a house of any size.

- Installation has become as simple and time-consuming as installing an electric boiler.

- The chimney was reduced to the smallest possible size and became the same as that of a gas wall-mounted boiler.

- Activating a new BIODOM pellet boiler is easier than starting a microwave - after pressing the “Start” button, reliable automation will do the rest, including adjusting for pellet quality.

- The cost of installation and operation is one of the lowest compared to boilers operating on other types of fuel.

What type of fuel should I choose?

When choosing fuel, traditional options are considered. 1. Gas is a popular fuel and affordable. With a high-quality approach, all heating processes are automated.

2. You can use solid fuel if there is no gas pipeline. The choice is made between pellets, coal and firewood. The disadvantages of this type of fuel include the inability to automate the system. 3. The use of electricity is convenient and simple. The disadvantage of fuel is its high cost. 4. Liquid fuel is used. This can be fuel oil or diesel fuel. This method is characterized by efficiency and high efficiency.

Coolant transfer devices

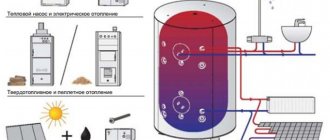

For use as a coolant, a universal solution in terms of price and efficiency would be to use ordinary water. True, such heating systems in private homes will require the installation of additional equipment. It includes the following elements:

- Capacity to compensate for the expansion of liquid when heated (open or membrane type);

- Circulation pump;

- Hydroarrow;

- Buffer tank;

- Collector. Needed if a beam distribution system is used;

- Container for indirect heating;

- Sensors and devices for taking their readings (if automation is used).

Note. The expansion tank is an integral part of the water heating system. It must be installed without fail.

When water is heated, it increases in volume, which in a confined space increases the pressure in the pipes and often provokes their rupture. An expansion tank into which excess water is forced out helps to avoid such consequences.

This is what the expansion tank looks like in the system Source infourok.ru

The circulation pump ensures the movement of coolant through a network of pipes. The use of several pumping units for a large number of circuits is possible due to the installation of a separating hydraulic arrow or a buffer tank, which simultaneously serves as a heat storage tank. The use of such equipment is especially indicated for multi-storey private houses.

Distribution collectors, such as the Gibax G-Collector, are most often installed to power underfloor heating or when connecting radiators using a radial circuit. As for the tank for indirect heating, it is a container with a coil that heats water for hot water supply needs.

Measuring instruments are installed for visual monitoring of temperature and pressure in pipes. To ensure automation of the heating process, pressure sensors, temperature regulators and controllers are installed.

The basis of everything is a plan

Without knowing it, we completed the first point of the work plan - we calculated the required thermal power for heating. The general plan also includes determining the location and number of radiators, selecting pipes and necessary accessories (fittings, taps, manifold distributors, filters and other necessary parts of the heating system). The plan, usually drawn in enlarged form, marks the location of all the elements that a homemade heating system provides, and in addition, it allows you to select heating devices.

As a rule, any radiators will work in a heating system; the only question is how much they cost and what they look like. They are usually located under window openings to provide a thermal curtain. When choosing radiators, you can be guided by a rough estimate - if the coolant temperature is seventy degrees, then one section is used to heat an area of three square meters. m.

After the power of the boiler and radiators has been selected, it is time to choose pipes. The most popular and affordable are polypropylene and metal-plastic. Of course, if you decide to do the heating yourself no matter what, you can use other types of pipes, but the rest of their types are either outdated, require welding and additional operating costs (steel), or very expensive (copper).

Types of batteries by shape and material

There are various types of heating devices on the market, each of which has its own design features and characteristics. When installing heating in a private home, an important condition for the correct operation of the entire installation is the competent selection of the heating unit.

Properly selected batteries are the key to uniform heating of the room Source zerocreation.ru

The following types are distinguished:

- Sectional batteries made of cast iron. Their disadvantages are bulkiness, unsightly appearance, possible violation of the integrity of the joints between sections, as well as a low degree of heat transfer; In return, they are resistant to pressure changes and have an impressive service life.

- Sectional batteries made of bimetallic materials. The radiator sections are made of light alloy metal, and their inner part is lined with stainless steel. They are distinguished by durability, practicality and aesthetic appearance. Unlike cast iron radiators, bimetallic ones can withstand higher pressure;

- Sectional batteries made of aluminum are made of light alloy metals without the use of steel. They have high thermal conductivity, and the operating pressure is comparable to that of cast iron radiators;

- Panel batteries made of steel. They are non-separable welding structures with decorative cladding and have high heat transfer rates. The disadvantages include low operating pressure, which limits the scope of application.

- A convector is a pipe with fins designed for the same pressure as in the main pipelines.

Important! The use of steel pipes for hidden installation of liners is strongly discouraged. It is also prohibited to join different materials together - a common mistake is connecting copper pipes to aluminum radiators.

The pipelines through which the coolant enters the heating devices can be made of polymer and combined materials, copper or steel. For example, you should pay attention to Gibax metal-plastic pipes. In addition to resistance to pressure and temperature, these pipes are resistant to chemicals, have a 10-year warranty from the manufacturer, and a service life of more than 50 years.

Pipelines and splitters made of various materials Source kvadro72.ru

Calculation of the heating system and selection of boiler power

It is impossible to select equipment without knowing the amount of thermal energy required to heat the building. It can be determined in two ways: simple approximate and calculated. All sellers of heating equipment like to use the first method, since it is quite simple and gives a more or less correct result. This is a calculation of thermal power based on the area of heated premises.

They take a separate room, measure its area and multiply the resulting value by 100 W. The energy required for the entire country house is determined by summing up the indicators for all rooms. We suggest a more accurate method:

- by 100 W, multiply the area of those premises where only 1 wall, on which there is 1 window, is in contact with the street;

- if the room is a corner one with one window, then its area must be multiplied by 120 W;

- when a room has 2 external walls with 2 or more windows, its area is multiplied by 130 W.

If we consider power as an approximate method, then residents of the northern regions of the Russian Federation may not receive enough heat, and residents of the south of Ukraine may overpay for equipment that is too powerful. Using the second, calculation method, heating design is carried out by specialists. It is more accurate, as it gives a clear understanding of how much heat is lost through the building structures of any building.

Before you begin the calculations, you need to measure the house, finding out the area of the walls, windows and doors. Then you need to determine the thickness of the layer of each building material from which the walls, floors and roofs are built. For all materials in the reference literature or on the Internet, you should find the value of thermal conductivity λ, expressed in units of W/(m ºС). We substitute it into the formula for calculating the thermal resistance R (m2 ºС / W):

R = δ / λ, here δ is the thickness of the wall material in meters.

Note. When a wall or roof is made of different materials, it is necessary to calculate the R value for each layer and then sum the results.

Now you can find out the amount of heat lost through the external building structure using the formula:

- QTP = 1/R x (tв – tн) x S, where:

- QТП – lost amount of heat, W;

- S is the previously measured area of the building structure, m2;

- tв – here you need to substitute the value of the desired internal temperature, ºС;

- tн – street temperature in the coldest period, ºС.

Important! The calculation should be made for each room separately, alternately substituting into the formula the values of thermal resistance and area for the external wall, window, door, floors and roof. Then all these results must be summed up, this will be the heat loss of the given room. The area of internal partitions does not need to be taken into account!

Video description

In our video we’ll talk about heating in a private country house.

Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov: Safety is an absolute advantage of a water heating system. But besides the positive aspects, it has disadvantages:

- The difficulty of heating large rooms due to significant heat loss during the circulation of coolant through the pipes;

- Additional costs for hiding an extensive network of pipes and heating devices under the cladding to preserve the aesthetics of the appearance of the rooms;

- Large battery dimensions;

- Possible problems may arise after draining the coolant from the pipes, in the form of air plugs.

What a thermal imager shows if there is air in the sections Source zerocreation.ru

Calculation of heat losses for ventilation

It is worth considering that any house has certain heat losses. Each room has a specific loss. The ventilation air also heats up, this must be taken into account. The calculation formula is:

To determine the amount of heat required by the house, you need to add Q heat and Q air.

The boiler must be chosen with reserve. The preferred efficiency is 1.3–1.5. It is necessary to increase the power if the boiler will be used for other purposes.

Fluid circulation methods

The coolant moves through the pipes by gravity (convection and expansion), or by forced means. In the first case, the liquid heated in the boiler, due to convection, moves through a network of pipes to the radiators. This movement of water is called direct current. Next, the coolant cooled in the batteries moves back to the heating boiler, after which the cycle is repeated. This segment is the reverse current.

To increase the circulation rate of the heat carrier through the pipes, specialized pumping units are used that are installed between the return flow pipes. There are models of heating boilers with built-in pumps.

Natural way of circulation

The coolant moves here naturally, without the application of extraneous forces. It uses the simplest physical principle, thanks to which water is heated in a kettle, and this happens because its hot layers are lighter than cold ones and rise to the top.

An example of natural coolant circulation Source santehnika-nk.ru

This is how the whole process happens - the water heated in the boiler rises to the highest point of distribution and then moves by gravity under the influence of its own weight (the pipes are at a slope of 3-4 degrees). Passing through the batteries, the water cools, its density increases, and when it enters the heating boiler, it displaces the already heated layers to the top.

Heating systems based on this type of circulation are quite simple and do not require the installation of additional equipment, which simplifies the installation process. But they are only suitable for houses with a small area due to restrictions on the contour length of 30 meters. Also, the disadvantages include the need to install pipes with a large diameter and low pressure levels.

Where does the heat come from?

The main source of heat is the heating boiler. Perhaps, in many ways, its correct choice ensures future comfort on cold winter days and nights, and therefore it must be taken with all possible responsibility. You have to give an answer to yourself - what are we going to heat this boiler with? Despite all the conveniences that homemade heating provides, do not forget that it must work, and for this the stove must be heated.

It’s easier to heat an ordinary stove than to choose the most wonderful boiler, designed for inaccessible or exotic types of fuel; it will be cheaper and less hassle. Therefore, it is necessary to use a boiler that uses cheap local fuel, this will reduce heating costs.

Now there are products aimed at any flammable substances, including universal ones that can work on several of them - coal, wood, diesel fuel, gas, etc.

The next, no less important task will be to determine the power of the boiler. The fact is that if its power is not enough to heat the house, then you risk, at a minimum, catching a cold in the winter, and if it is excessive, then it is simply wasted money. Therefore, when creating a heating system with your own hands, when choosing a boiler, you need to take into account factors such as:

- presence and number of windows;

- geographical location of the house;

- the material from which the house is made and the thickness of the walls;

- presence of insulation, etc.

Taking into account all possible factors is a difficult task, but often they use an assessment approach, according to which to heat ten sq.m. area requires one kW of thermal power.

Knowing the heated area of your home, you will determine the base power of the boiler, and then it will need to be multiplied by a coefficient that takes into account the geographical location. For this, the following values per kilowatt of power are used:

- from seven to nine tenths for the southern regions;

- one and a half for regions of Central Russia;

- from one and a half to two for the Northern regions.

Mistakes made during installation

The most common mistakes when performing calculations or installing heating are:

- Incorrect determination of the required boiler power;

- Incorrect strapping;

- Illiterate choice of the heating scheme itself;

- Incorrect installation of all elements.

Insufficient boiler power is the most common error. It occurs when, during the selection of a heat generator for heating and hot water supply needs, the necessary additional power for heating water is not taken into account.

Incorrect selection of heating scheme leads to additional costs for reworking the entire structure. This mistake is made when installing a single-pipe distribution with more than 6 radiators. A large number of batteries does not allow them to warm up.

The last heating elements in the chain will always remain cold Source interistroy.ru

Also, during installation, the slopes of the pipelines are not observed, pipes of poor quality are connected, and inappropriate additional equipment is installed.

When installing heated floors, the pipes must be insulated in order to avoid heat loss on the way to the heating “snail”.

A common mistake when connecting pipelines is exceeding the exposure time of the soldering iron to the pipes required to obtain a reliable joint. As a result, their internal diameter decreases and a bottleneck is formed.

Connecting radiators and choosing power characteristics

The number of sections directly depends on the amount of heat required for the room. The batteries are located in the place of the room where heat loss is greatest. Usually these are window openings and external walls. Connection can occur in three different ways.

Lateral connection is typical for central heating. Diagonal fits perfectly into the scheme of highways laid horizontally. In both the first and second cases, the battery warms up as evenly as possible.

When installing a single-pipe type system, a versatile connection is used. So the heat transfer of the device becomes significantly less. The radiator is much warmer on top.

Some radiator models are designed in such a way that the pipes are connected to them from the bottom. The wiring in these devices is internal.

Installation algorithm

Installation of a two-pipe heating system, regardless of its characteristics, requires the use of the following tools, devices, materials and equipment

:

- tape measure, pencil/marker, building level, plumb line;

- electric drill;

- screwdriver;

- tool for pipeline installation (depending on the selected type of pipe);

- adjustable and gas wrenches;

- pipes (to choose from: metal-plastic, steel, copper, polypropylene);

- heating devices;

- air vents (manual for each battery, automatic for the entire circuit);

- expansion tank;

- boiler piping elements;

- drain valve and check valve for recharging the system, etc.

To simplify installation, an axonometry of the heating system is performed - special drawings are created for the heating circuit on each floor of the house. An axonometric diagram of a heating system implies the location of each element in the drawing along three coordinate axes, none of which is parallel to the picture plane. An axonometric heating diagram allows you to clearly see the relative position of all elements in space. An example of what a heating axonometry looks like can be seen in the figure:

The forced circulation heating system is installed in the following sequence

:

- Installation of the heating unit in a specially equipped place (separate room) with finishing made of non-combustible material.

- Installation of the boiler piping, circulation pump, connection of the distribution manifold, if several heating circuits are provided.

- Installation of heating devices (mounting on brackets to the wall or on stands to the floor). There must be a gap of at least 10 cm between the bottom edge of the radiator and the floor, as well as between the upper edge of the radiator and the window sill for air circulation.

- Laying a pipeline, connecting supply and return pipes to radiators, installing shut-off and control valves, Mayevsky taps and temperature sensors.

- System filling and pressure testing. After checking the circuit for leaks, air is bled from the radiators. Then the system is balanced.