To install a heating system, you will need a source of thermal energy. This can be main or liquefied gas, firewood, electricity or liquid fuel. The most profitable option is gas. But not all settlements have mains gas. In this case, use its liquefied version. If you decide to use a gas cylinder for heating, you need to familiarize yourself in advance with the advantages and disadvantages of such systems, as well as understand the nuances of their design.

Heating a private house with gas cylinders. General description and principle of operation. Fuel consumption

Heating with gas cylinders is a good alternative for main gas supply with many advantages. When installing equipment, it is important to take care of the oxygen regulator, since according to safety standards, more air must flow into a liquefied fuel boiler than into a traditional unit. For uninterrupted and safe operation of the system, additional devices are used that come into action in emergency situations.

Unlike classic equipment, which operates solely through connection to a centralized mains, autonomous gas heating of a private house is completely independent. Moreover, it functions normally even when the fuel pressure decreases. Similar units are also distinguished by the presence of a nozzle with a reduced cross-section of holes, ensuring a stable supply of the propane-butane mixture.

In order for the device to properly heat the house, heat water and solve other plumbing and household needs of the owner, it is important to refuel it on time. For this purpose, a gas tank is placed on the site - a special underground container that contains propane-butane. Depending on the volume of the tank, the fuel can last for a whole year, and the refilling process will take no more than 20-50 minutes.

Some companies producing traditional boilers equip them with injectors. They are able to switch equipment to liquefied fuel if there are failures in the main line. In this case, the user will also need to purchase a nozzle, reconfigure the valves and change several operating parameters on the heat generator board. However, after performing such actions, the unit will work flawlessly, providing efficient heating, water heating, etc.

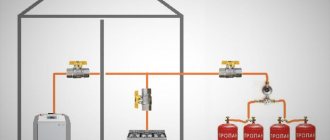

In the absence of a gas holder, fuel can be kept in gas cylinders in the amount of 2-15 units. To connect other communications, a gas reducer is used, which controls the supply of the fuel mixture and reduces its consumption.

Autonomous gas boilers have the following components as standard:

- Safety valves.

- Temperature controllers.

- Flame and pressure sensors.

If the listed elements are present, the operation of the system will be smooth and uninterrupted.

As for fuel consumption, the exact figures depend on various factors. First of all, the area of the heated room is taken into account. So, for a building of 100 m² you will need 2-3 cylinders with a volume of 50 liters per week. For a suburban building with an area of 200 m², you will need to buy 4 tanks.

Features of heating with liquefied gas

Liquefied gas in cylinders is used as a coolant for autonomous systems. It can be pure propane or a propane-butane mixture. Experts say that this type of gasification is effective in houses of 70-100 m² with good thermal insulation. At the same time, to reduce fuel consumption, they recommend combining gas boilers with electric heating systems.

When choosing this heating option, you cannot disassemble the unit in case of malfunctions or breakdowns, since it runs on high-pressure gas and is explosive.

The user also needs to constantly monitor the condition of the cylinders during the cold season, since when the temperature drops to critical levels, interruptions in the supply of the fuel mixture may be noticed. This is due to different boiling temperatures of gases.

In what case can such a system be used?

On the territory of Russia there are a large number of settlements that are isolated from the usual benefits of civilization, such as gas. However, with the help of modern autonomous systems, gasification can be implemented anywhere in the world. There are no restrictions or prohibitions on the use of such equipment, but the implementation of the project requires considerable financial investment.

To avoid unreasonable expenses, you should understand in which cases autonomous gas supply is justified. Experts are of the opinion that it will be rational if:

- Maintenance of buildings up to 100 m².

- The presence of good thermal insulation of the room.

- Low level of heat loss.

Heating with liquefied gas may also be needed for a short-term solution, since in the future it will be possible to convert the system and connect it to the central main line.

For heating country houses and country cottages, 50 liter cylinders filled with liquefied butane and propane are used.

How long will a 50 liter cylinder last? Calculation of gas consumption

Depending on the area of the room and the characteristics of the heating system of a private house with gas cylinders, the consumption can vary from 50 to 400 liters. Consumption of liquefied gas for heating a building up to 50 m². will not exceed 50 liters per week, i.e. – 1 bottle for 7 days. If the house is larger, you will need 2-3 cylinders.

Advantages and disadvantages of balloon heating

Propane heating has both pros and cons.

If we talk about the positive aspects, then these are:

- Environmental safety of the fuel: during the combustion process, propane does not leave behind ash or slag.

- Complete independence from the centralized highway.

- Stable work.

- Easy to use and configure.

- Relatively low costs for purchasing the fuel mixture.

- High efficiency indicators.

- Easy to convert the boiler to connect to the main gas supply.

- Long service life.

- Such boilers are widespread on the secondary market, so selling them after several months or years of operation will not be difficult.

The disadvantages include the need to refill the tanks and provide special conditions for uninterrupted operation. The owner of the house will also need to carefully study the connection diagram so as not to freeze in the winter due to breakdowns or malfunctions in the equipment.

How to calculate gas consumption?

To calculate fuel consumption, you need to know the power of the heating equipment. When determining it, they use the rule that for every 10 square meters of heated area, a boiler power of 1 kW is required.

Autonomous heating system for a private house with a gas boiler

Thus, to heat a house with an area of 100 square meters, you need a boiler with a power of 10 kW. To generate 1 kW of thermal energy, approximately 0.12 cubic meters of gas per hour are consumed. To heat such a house for one hour you will need 1.2 m³ of fuel. Knowing this number, it is easy to calculate the daily fuel consumption. It will be 28.8 cubic meters.

At first glance, it seems that gas consumption is quite high. But these values are valid only for continuous operation of the boiler during the first warm-up of the system immediately after its startup. In the future, the equipment will operate in automatic mode and fuel consumption will decrease.

As a rule, to maintain the temperature in a house with an area of 100 square meters within 22°C at sub-zero temperatures outside, you will need about three cylinders of fuel per week. If at night the temperature is maintained 4-6 degrees below daytime, then fuel consumption will be reduced by a whole cylinder.

If the containers are used to heat a summer cottage for seasonal residence, then the operation of the boiler can be adjusted so that during the absence of the owners in the building the temperature is maintained within +5°C. This will ensure economical fuel consumption. As a result, to heat a small house for 7-10 days you will need only one cylinder of liquefied fuel.

Types of propane boilers

When choosing a propane boiler, you need to understand the main types of such units, their operating principles and characteristics.

LPG gas boilers available on the secondary market are of 3 types:

- Single-circuit.

- Dual-circuit.

- Condensation.

In terms of purpose, they are practically no different from each other, but the principle of operation, design and design features look different.

Features of single-circuit devices

Single-circuit units are used only for heating purposes, so they are in demand in buildings where water heating tasks are solved in other ways. Such models cost much less than their dual-circuit counterparts, which is due to their limited functionality.

The main module is equipped with a closed combustion chamber, and when a flame occurs, it is enriched with oxygen from the outside. Combustion products are discharged to the street using a specially equipped chimney.

Nuances of double-circuit products

Installations with 2 circuits are used for efficient heating of residential buildings of any size, as well as for heating water. The fuel mixture is heated through 2 burners, which are ignited by an igniter.

After a fire, a temperature sensor is activated, transmitting all the necessary information to automated units. If the temperature exceeds the permissible values, access to the chamber is closed.

If there is a closed combustion chamber, it is additionally equipped with a coaxial chimney with forced draft. This is necessary to organize a uniform flow of oxygen and stable combustion. Waste products enter the ventilation or chimney ducts and exit outside.

How condensing units work

Condensing units are designed to supply hot water and heat the building, but the principle of their operation differs from the 2 previous options. After entering the heat exchanger, the cold liquid warms up and enters a closed circuit.

Units of this type are high-tech equipment with economical consumption of the fuel mixture. The exhaust gas warms up to +40°C, and efficiency indicators reach 97%. Heat loss values are minimal - up to 0.5%. After this, half of the water is sent to communication channels, and the rest is sent to taps for washing, laundry and other household needs. Having completed the full cycle, the liquid from the radiator is returned to the heat exchanger.

Manufacturing a furnace with a water jacket

Transforming an ordinary “Bubafonya” into a solid fuel hot water boiler is a task for a professional welder. The boiler jacket must withstand emergency coolant pressure - at least 2 Bar, optimally - 3 Bar. The joints must be welded clearly and tightly.

The design of the Bubafonya stove with a water jacket is shown in the drawing. Your goal is to wrap the firebox with 3 mm sheet metal, leaving an opening for water at least 3 cm wide. To connect to the heating network, you need to install 2 pipes with an internal diameter of 40 or 50 mm.

Drawing of a Bubafoni boiler with a water circuit, which is connected to the heating system through a buffer tank or directly

Comment. It would seem that the simplest solution suggests itself is to put a second pipe on the cylinder and weld a sheet of iron on top. Why is it difficult to implement: firstly, it is difficult to find a thin-walled pipe Ø350...400 mm, and secondly, the boiler will be heavy and will take a long time to warm up.

We immediately discard the idea of forming a cylinder from sheet metal; 3 mm thick steel cannot be bent without industrial rollers. We offer 4 options on how to make a water jacket for “Bubafoni”:

- Use thinner metal - 1.5...2 mm, bend the cylinder manually. The process will speed up if you heat the sheet with a gas burner or cutter. Such a boiler will not withstand high pressure, but it is quite suitable for working with an open heating system.

- Take 2 sheet blanks, divide each into 3 equal parts and bend along the lines, maintaining an angle of 60°. We will get 2 halves of a hexagon, which we will place on the firebox and weld together. The problem is finding a sheet metal bending machine.

- Cut 6 edges out of metal separately, then butt weld them at an angle of 60°. The disadvantage of this method is that there are too many seams.

- Make a rectangular box. In this case, the volume of the boiler tank and the heating time will increase significantly.

In the drawing, the water circuit is shown at the full height of the firebox. We recommend shortening the shirt slightly to the level of the grate. The ash chamber practically does not heat up; it makes no sense to surround it with coolant. The outside of the boiler tank must be insulated with non-flammable material - basalt fiber.

Since there is no top cover on the Bubafon boiler, the piston is welded inside the firebox forever. To load firewood, a side door should be provided, which will “eat up” part of the useful volume of the combustion chamber. Watch the video for details:

Types of products by location

A gas boiler using liquefied gas can be floor-standing or hanging. Depending on the installation method, it may have specific properties that increase its practicality and attractiveness. Based on the information received, home owners can determine which option will be most optimal for their home.

Floor equipment

Floor-standing models are especially popular because they are characterized by high power and comfort. Such units are capable of serving not only small country houses, but also large-sized cottages and hotels. The main working element is a gas burner with highly efficient heat transfer.

The device is stable even during pressure surges, and its service life reaches 25 years if the operating rules are followed.

The units are equipped with heat exchangers made of steel or cast iron. The first option has reduced weight, but is quite fragile and sensitive to shock; it can last a short period of time. Cast iron elements are heavier, but durable.

Advanced modules are equipped with auxiliary elements that make them safer and more reliable. Such components include temperature sensors, draft, gas, pressure level controllers, thermostats, shut-off valves and other parts.

Depending on the design features, the unit can be equipped with electronic or piezo ignition systems. Representatives of the first group are activated automatically, and fuel consumption is minimized, since the system does not have an igniter with a flame.

Wall devices

Devices designed for wall mounting are characterized by compact dimensions and ergonomic design. They take up little space and can be installed in rooms with limited space and complex layouts.

For error-free installation of the system, you should use professional help. Devices must be installed taking into account the safety standards specified in SNiP standards.

In terms of their set of functions, wall-mounted models are practically no different from floor-mounted ones, but their power is much lower. Because of this, the use of installations in large-sized cottages is not justified. However, in terms of efficiency and operating comfort, they are superior to the floor-standing type.

Advantages

Numerous reviews from owners of private houses, cottages, and garages explain the growing popularity of bottled gas heating by the following factors:

- environmental friendliness and compliance with all state standards and regulations;

- autonomy and safety of heating;

- stability of operation and pressure level;

- economical fuel consumption and ease of control;

- possibility to heat water for household needs

Reasons for high performance

Heating from a gas cylinder has high efficiency due to the fact that the energy carrier easily passes from a liquid aggregate to a gaseous state. Therefore, the heating system is completely independent, which gives the owners of a private house or cottage the opportunity to use it at their own discretion and in any conditions.

Nuances of use

It will be possible to use gas cylinders for space heating even at the stage of building a house - this is convenient in case of construction in the cold season. To ensure safe use of the energy carrier, it is recommended to follow certain operating rules. For example, during sleep it is recommended to turn off the gas supply or at least reduce it.

Additionally, this will reduce energy consumption

Gas cylinders require periodic refilling: special attention must be paid to its quality. Some station employees do not fill the cylinders completely, which is why owners are forced to overpay - be careful if you use the services of such stations

Advantages and disadvantages of units

Gas equipment for heating a private home has the following advantages:

- Autonomy and independence from the central highway, changing prices and emergency situations.

- High efficiency rates - 92-95%. Sometimes the values reach 97%.

- Quiet operation.

- Ease of maintenance and repair in case of failures. The system is easy to maintain, since all maintenance consists of replacing fuel filters, injectors and cleaning the coolant.

- Possibility of converting the system to work with centralized gas supply. If you want to connect it to the highway, you will not have to buy additional equipment.

- Long service life. For some models it reaches 25 years.

- Work safety. The fuel remains non-flammable even at high temperatures inside the chamber.

Non-volatile units are available on the market, guaranteeing complete autonomy in remote communities.

The disadvantages of the equipment include the following points:

- The need for simultaneous use of 3-4 cylinders. In this case, a gas reducer is used to connect the cylinders to the boiler.

- Fuel tanks should not be installed near the boiler - it is better to place them in adjacent rooms with a working ventilation system.

- When performing installation work, it is important to be careful and careful.

- The desire to re-equip the system will require considerable financial investments. Sometimes they reach 30-50% of the cost of the unit.

The nuances of using cylinders in winter

If bottled gas is used to heat a country house, then in winter you need to take care to protect the fuel from freezing.

This is especially true for buildings for seasonal use, for example, dachas, when the owners come to the house only on weekends. If fuel containers are stored outside the house, then at sub-zero temperatures the pressure in them decreases. If the pressure drops significantly, heating equipment may stop working. To avoid this situation, containers with fuel during cold weather are installed in a special cabinet with a built-in ventilation system. Non-flammable insulation is used to insulate the cabinet.

If there is no such cabinet, then it is better to store containers with fuel in an extension to the house, in which there is no heating, but a positive temperature is constantly maintained due to good insulation. Do not forget about other safety requirements when choosing a suitable place to install cylinders for the winter.

Connection diagram to the boiler

The connection of the working elements of the system is carried out according to a special scheme using a gearbox. The device converts liquid fuel into a gaseous mixture and supplies it to the boiler chamber. If the gas supply is provided by several tanks, you will need to purchase reducers for each tank.

Components for balloon heating systems

The main components of the system are:

- Boiler with burner.

- Tanks 50 l.

- Gearboxes.

- Locking mechanisms.

- Rubber fabric sleeve.

- Ramp.

The installation diagram is simple and understandable even for a beginner.

Features of a long-burning stove

The first step is to understand what happens when wood burns. For a flame to appear, the temperature of the wood must be brought to approximately +150 degrees, using an external heating source. Usually, a piece of paper lit from an ordinary match is enough for this. After this, the process of slow charring of the material begins, which, after reaching +250 degrees, begins to decompose into simple chemical elements. The white smoke that appears when a flame is ignited includes gas and water vapor: they are emitted by heated wood. Ignition of the released gaseous components is observed when heating reaches +300 degrees: as a result of this, the thermochemical reaction is significantly accelerated.

The breakdown of organic matter into simple elements is called pyrolysis. Practice shows that during the combustion of wood, part of the energy potential inherent in it remains unused. This is reflected in a significant amount of waste remaining after the flame goes out. In pyrolysis furnaces, fuel is used much more efficiently, which is achieved by separate combustion of gases released during fuel combustion. At the same time, the rate of smoldering of the wood itself is very low, which helps to increase the operating time of the stove on one stack. The Bubafonya stove, which is a type of pyrolysis heater, guarantees almost complete combustion of all fuel.