Nowadays, it is not surprising when country houses have complete autonomy, that is, they do not depend on gas, water supply, sewerage and even electricity (but this is more difficult). Gone are the days when you had to collect water from a well using buckets or a well through special glasses. For heating, there was a huge Russian stove on the floor of the house, and the toilet was located exclusively on the street with a hole in the floor.

Now, in order to provide heating and hot water supply, it is enough to have electrification at home, and if there is a gas main nearby, the task is greatly simplified. To help, install a boiler room with a gas boiler in the house. Unfortunately, not all villages and settlements have a centralized gas supply. Then owners of private houses without central gas supply should consider the possibility of heating (hot water supply) using liquefied gas (LPG).

The difference between liquefied and natural gas

First, it’s worth understanding how heating with liquefied gas occurs. Unlike main gas, liquid gas consists of a mixture of propane and butane. The proportions of the composition depend on the time of year in which it is used.

Imported gas for heating a house tends to freeze in winter. To prevent this from happening, more propane is added to the LPG content, since propane itself in its pure form has no impurities and, unlike the other component, butane, does not freeze. Liquefied gas for home heating can be stored in gas cylinders or gas holders. If everything is clear with gas in cylinders, then what is a gas tank? This is a special container that is either dug into the ground on the site or installed permanently in front of the house.

There are other ways to install gas tanks; you can find out more by clicking on the following links: What is a gas tank; Mobile gas tanks.

Advantages of LPG

Liquefied gas for heating a home, unlike natural gas, does not depend on gas networks; therefore, there are no interruptions in the fuel supply or planned outages associated with the maintenance of the gas pipeline.

Another plus is an independent geolocation. This means you can install the container in any locality, even in a remote village.

The next advantage is savings on laying a gas pipeline to the site. In order to bring natural gas to your site, costs are required not only for the services of gas workers and for the purchase of materials, but also for paying for connections to neighbors, since they, in turn, pulled pipes to their site.

Stable fuel supply, therefore, stable operation of a gas boiler using liquefied gas. Any owners of private houses with centralized gas for heating can share negative experiences when the gas boiler stopped working due to a decrease in pressure in the gas main or a short-term interruption and then resumption of gas supply, threatening the entire autonomous heating system with freezing.

Disadvantages of LPG

The main disadvantage of liquefied gas over natural gas is its price.

The tariff for the cost of natural gas in Russia is 4.72 rubles. per 1 m³, LPG - on average 21 rubles. per liter If you consume an average of 842 liters of liquefied gas per month (this is an approximate calculation for a cottage of 150 m²), then the cost of heating with liquefied gas in winter will be 17,682 rubles. per month. The cost of heating with natural gas, based on the same 150 m², is 3,540 rubles.

We recommend: How to calculate the consumption of liquefied and natural gas

The price difference is almost five times. Of course, this is just an example, where the amount is taken based on possible frosts from -25 to -40 degrees Celsius. Again, you need to understand that winter, on average in the regions of Russia, lasts 3-4 months; the rest of the time, gas consumption, and, accordingly, gas payments will be much less.

Disadvantages can also be noted:

- the need for gas delivery and refilling of cylinders or a gas tank. On average, refilling gas tanks is enough once a year;

- in the case of an underground gas holder, in contrast to heating using liquefied bottled gas, special installation work will be required to prepare the pit, and these are additional costs;

- gas tanks need to be maintained. If low-quality fuel is filled, the equipment may fail. Repairing gas tanks is quite expensive.

Combustion waste: hydrocarbons do not leave soot

| Methane | Propane | Butane | |

| Chemical formula | CH4 | C3H8 | C4H10 |

| Compounds formed during combustion | H2O + CO2 | ||

During combustion, the fuel breaks down into water vapor and carbon dioxide. There is no burning, soot emission, or foreign odor.

Boilers and chimneys using diesel fuel, wood, coal and waste oil have to be constantly cleaned. The soot remains on all accessible surfaces and falls out in the form of a gray coating on snow and plants. The use of LPG eliminates such problems.

Heating equipment for heating with liquefied gas

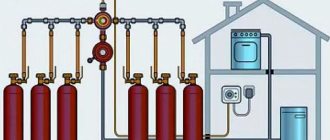

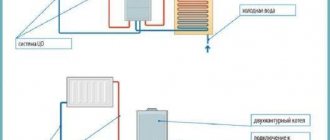

For heating with liquefied gas, as mentioned above, two options are used - bottled gas or a gas holder. This applies to sources of autonomous gasification. The main equipment is a gas boiler, which is built into the heating system.

The system also includes a gas meter, a system for converting liquefied gas into a gaseous state (sometimes it is built into a gas tank) or a boiler for liquefied gas is used, distribution of gas pipes and pipelines for circulating coolant in a private home, expansion tank, pressure pump, boiler, water filter for cleaning hard water, ventilation and exhaust gas discharge system.

Choosing a boiler

So, first we decide whether there will be one boiler or two boilers operating on different types of fuel. One will be the main one, and the second will be auxiliary, duplicating, it all depends on the financial capabilities of the owner of the house.

Boilers differ in a number of parameters:

- design features (single-circuit only for heating or additionally double-circuit for hot water supply);

- type of fuel used (gas, solid, liquid fuel, electric and combined);

- by placement method (wall-mounted, floor-mounted);

- functional purpose, power and a number of other parameters.

For more information about choosing boilers, read the article “Selecting a heating boiler.”

Features of heating with liquefied gas

The main feature of heating a private house with liquefied gas from a gas holder or using cylinders is the need to monitor the presence of residual amounts of blue fuel and timely refueling.

Use of gas cylinders in heating

This is the simplest method of gas heating, but at the same time not entirely convenient. Gas cylinders are usually used to heat small residential or country houses.

Since installation and commissioning can be done independently. The only condition is that the number of connected cylinders with a volume of up to 50 liters does not exceed 3 pieces. Otherwise, the services of gas workers and drawing up a project will be required. A metal cabinet is used for gas cylinders. I mount the cabinet itself to the wall of the house from the outside. To prevent the cylinders from freezing (condensation may form inside in winter), heaters are sometimes used.

Gas holder for home heating

The peculiarity of heating with a gas holder is the possibility of installation almost anywhere, regardless of the gasification of a particular area, village, etc. Unlike cylinder units, large gas tanks can be used to heat even a small enterprise. Lately, gas tanks have become increasingly popular.

Competition in the market is growing, therefore, the price begins to decrease. It is especially worth thinking and calculating everything if there is an alternative to electric or autonomous gas heating.

Safety precautions when working with gas cylinders

Propane heating requires strict safety precautions. In addition to not placing the cylinders closer than 2 meters from the boiler, avoid direct rays and overheating. Still unacceptable:

- In case of freezing, use an open flame to warm the cylinders. In general, fire and gas containers are an explosive combination, so if an accidental fire occurs, the fuel container should be removed first.

- When arranging a room for cylinders, it is necessary to ensure that there is no cellar or basement next to the room. The gas is odorless, but has the physical property of sinking. Thus, a person who goes down into the cellar may become poisoned. Also, if there is an unnoticed gas leak, large accumulations of fuel in the cellar will lead to an explosion.

- To minimize the risk of fire, a gas leak meter must be installed in the system.

- Storing empty cylinders in the house is strictly prohibited. A warehouse with full containers should be located no closer than 10 meters from a residential building.

Calculation of costs for an autonomous gas supply device

Costs can be divided into three components:

- initial costs for equipment purchase and installation;

- costs of operating liquid blue fuel;

- cost of service.

Initial costs for equipment purchase and installation

Of course, it is impossible to write down unambiguously how much a gas tank and auxiliary equipment cost. Since this depends not only on the requirements for the installation volume, but also on the regions of the Russian Federation. The cost of gas tanks starts from approximately 150 thousand rubles and above. To this must be added the cost of a gas boiler (about 50 thousand rubles) and other equipment.

Since installation of an autonomous system will require a project, it will be necessary to pay the cost of design work, as well as the cost of installation and gas workers’ services when connecting the equipment.

The amount is not small, so you need to carefully check and calculate everything. The initial investment may well pay off. It is worth noting that connecting natural gas from a central gas supply system may not be cheaper, but even more expensive. Some owners prefer installing gas tanks, even if they have a central gas network in close proximity.

Expenses for operating liquid blue fuel

Liquefied petroleum gas costs depend on many factors:

- climate zone. In a temperate climate, costs can be much lower than, for example, in the latitudes of the far north.

- insulation of the heated room. Well-insulated walls and roof will help save fuel.

- serviceability of equipment. Equipment must be maintained in good condition.

- competent calculations when designing a heating system.

- the use of automated systems that will help regulate the gas supply, including GSM modules. They will avoid problems in the event of a decrease in gas pressure or room temperature, notifying the owner in real time using an application on a mobile phone.

From the experience of heating a room of 145 m² with bottled gas, including hot water supply, it is clear that at an outside temperature of -10 to -27 ºC, the consumer consumed 10 cylinders with a volume of 50 liters and a weight of 20 kg per month. At temperatures from -5 to -20 ºС – 8 pieces. At the same time, the room temperature was set to +23 ºС. You can do a simple monetary calculation. One cylinder is 50 liters, filling to 80-85% according to safety requirements is 40 liters. 10 cylinders of 40 liters - 400 liters. With a gas price of 21 rubles per liter, we get 8,400 rubles. To this amount you need to add the transportation of cylinders for refilling.

We recommend: Heating with bottled gas, consumption and other nuances

When using gas tanks, the monthly consumption is approximately 842 liters (with a house area of 150 m² and a moderate climate). If you use a gas container with a volume of 5 m³, then, in principle, one refill can be enough for an entire heating season.

The volume of the gas tank may be sufficient to operate the heating system throughout the entire season.

Gas heating system maintenance

Servicing heating systems with liquefied gas, like natural gas, requires the presence of a specialist in gas work who has a special permit for this.

The specialist’s responsibilities include checking the gas boiler and supply pipe or hose. This is an inspection of the condition of the burner, combustion chamber, locking devices, connectors, automation, cleaning of soot and carbon deposits. The technician also makes adjustments to the equipment if necessary.

Inspections are carried out at least 1-2 times a year.

Heating device for a heating system - what can you do with your own hands?

Experts allow you to install boilers that are very simple in design with your own hands. They have only one heating circuit, an open combustion chamber and naturally remove gas oxidation products. In this case, there is nothing complicated in the process of work - connect the heating system pipes, organize a chimney, supply gas. You can independently install a fully automated, double-circuit boiler with a closed combustion chamber, forced circulation and a gas leakage control system. Such a device is so “smart” that it simply will not work in case of any violations.

To install a gas boiler, you need to organize a place.

However, in any case, first of all, you need to organize a place in your house or apartment for proper installation of the unit, and only a representative of the gas service can put it into operation. He also gives permission to use the device. Otherwise, impressive fines are the least a person can get away with when installing a gas heating device on their own.

It is strictly prohibited to connect any other heating boiler to the gas pipeline yourself. This should only be done by an experienced person. It is better to invite him from the state gas service. This will solve problems with paperwork and will cost several times less than the services of an employee of a commercial company.

However, no one has yet prohibited the owner of heating equipment from independently connecting his purchase to the water supply and heating system. These measures can be carried out with your own hands if the technical design of the boiler room is approved by the gas service and all conditions for the subsequent operation of the device are met.

Types of gas tanks

Before considering the rating of the best models, let's look at the types of gas holders in order to understand the features of the equipment and the advantages of the configurations. Gas tanks of all types are designed for:

- storage and supply of blue fuel;

- distribution of gas between consumers;

- measuring the volume consumed;

- maintaining the required pressure in the tank.

But individual equipment differs in operating principle, position in space and type of installation.

Volume parameters

There are gas holders with variable volume inside and constant volume. The first allow you to collect a small amount of gas (pressure close to atmospheric), and as it is consumed, the internal chamber decreases due to the lowering lid. To do this, a large piston or water dome is used instead of a rigid top of the tank. Vessels with a constant volume have rigid walls up to 12 mm thick, which allows you to pump large amounts of propane-butane or other mixtures into them.

Position in space

Gas tanks from our rating are also divided into vertical and horizontal. In both cases, these are cylindrical containers, but when installed vertically, the vessel will take up less space on the site. The disadvantage of this form is the reduced evaporation area, as a result of which in winter the fuel will have to be heated so that it is better supplied to consumer devices. Horizontal gas tanks do not have such problems, since they have plenty of space for evaporation of the liquid contents. But to install such a vessel you will have to allocate enough space.

Installation method

The gas tanks in our rating also differ in their installation method. Underground models require more installation costs (dig a pit, pour a sand cushion, lower the container with a crane, fill it up and create a blind area). But this ensures that blue fuel remains in the liquid phase even in the most severe frosts. Another advantage is increased safety, since if there is a leak, propane, which is heavier than air, will go into the ground. Ground-based gas tanks have easier installation, but in winter in cold regions additional gas heating may be required. Such models are also considered more dangerous.

Possibility of transportation

Some gas tanks are equipped with a chassis, which allows them to be transported like a trailer by attaching them to a car. This is used by repair services. A mobile installation can easily change its location, but usually has a small capacity and needs to be heated in the cold season.

conclusions

When analyzing all the factors, we can definitely conclude that main gas will cost less than a gas tank. And first of all, this concerns the direct supply of fuel to the living space, that is, at the initial stage of gasification of the cottage. However, if the pipeline is located far from the site, and construction deadlines are running out, then liquefied autonomous gas will become a “salvation” from endless authorities and additional expenses.

A relatively common factor will be the price of energy. Here it is impossible to say which is more profitable, since the energy efficiency of the fuel is different. This indicator can be ignored, since the annual gas payment under equal conditions turns out to be almost the same.

One of the advantages of a gas holder can be highlighted - it is autonomous. If emergency breakdowns occur on the main line, the gas tank will always work. But here the price of the issue of maintenance and delivery of gas for refueling is already formed.

Weighing all the pros and cons, our review decided: if it is possible to install main gas into the house without particularly high costs, then it is worth choosing this option. In all other cases, a gas tank is the optimal solution for providing a private home with gas.

Propane-butane and fuel pellets: how to heat with them

Advantages

autonomous gasification:

- independent gas supply;

- high efficiency;

- low refueling frequency;

- a warm home at any time;

- hot water.

You will find more articles from our blog on this topic.

The advantages of LPG and gas holder cannot be denied

When wondering what is more expensive – a kilowatt of propane butane or pellets, you need to understand the specifics of using fuel pellets. For their combustion, special solid fuel boilers are used, which are capable of regulating the supply of fuel and the release of thermal energy. Of course, such equipment costs a lot (from 150,000 rubles), however, its efficiency is an order of magnitude greater than that of a conventional oven. Some models allow you to provide not only comfortable indoor conditions, but also organize hot water supply.

Selection of pellets for boiler systems

Industrial boilers are usually designed for heavy loads and are not as demanding on raw materials as their domestic counterparts

In order for a boiler to effectively heat a house using pellets, in addition to its type, you need to pay attention to the following technical indicators, which must be specified by the manufacturer:

- Product humidity - for normal ignition and maintenance of combustion should be within 8%, above 14% - the material is not suitable for use;

- Heat transfer during combustion is better if it is around 4.5 kcal/kg or higher, like wood pellets, but 4.3 kcal/kg is also acceptable;

- The ash content of the product has an upper tolerance limit of 1%; if this limit is reduced to 0.5%, then the boiler can be cleaned no more than once a month.

In addition to all of the above, you should visually inspect the pellets for cracks.

High-quality material has a shiny surface, does not crumble and is difficult to break. When the granules are lowered into water, they should eventually turn into a soggy mass; if this does not happen, a chemical adhesive component was probably used in their manufacture, which is unacceptable. The presence of coarse sediment from small stones and sand also indicates low quality of the product.