Register Login

Publication date: December 13, 2013

One of the most important components of a solar system is the charge controller. It can be supplied separately or complete with an inverter. As the name implies, this device is designed to control battery charge, that is, charge controllers for solar batteries monitor the voltage level on the battery and serve to prevent complete discharge or overcharging of the battery.

The age of global accessibility, when you can find absolutely any product and information, allows you not only to purchase controllers in any specialized store, but also to assemble it yourself. To do this, you will need a diagram of the device that you plan to manufacture, in our case it is a charging controller, and the ability to understand electronics. We will try to provide you with both.

Charging controllers for solar power: a brief description

There are several varieties of the described device. The simplest of them perform only one function: turns the batteries on and off depending on their charge. More “advanced” models are equipped with a function for tracking the maximum power point, which provides a higher output current compared to the current of the solar battery. And this, in turn, increases the efficiency of the entire installation as a whole.

More advanced models are capable of reducing the voltage on the solar panel and maintaining it at the required level. The presence of this function helps to charge the battery more fully.

Any controller, including homemade ones, must meet certain requirements:

- 1.2P ≤ I×U, where P is the total power of solar panels of the entire system; I – controller output current; U – system voltage with discharged batteries.

- 1.2 Uin = Ux.x, where Uin is the maximum permissible input voltage, Ux.x is the total open-circuit voltage of all solar panels in the system.

What are battery charge controllers for?

If the battery is connected directly to the terminals of the solar panels, it will be charged continuously. Eventually, a battery that is already fully charged will continue to receive current, causing the voltage to increase by several volts. As a result, the battery is recharged, the temperature of the electrolyte rises, and this temperature reaches such values that the electrolyte boils, and a sharp release of vapors occurs from the battery cans. As a result, complete evaporation of the electrolyte and drying out of the cans may occur. Naturally, this does not add “health” to the battery and sharply reduces its service life.

Controller in a solar battery charging system

So, in order to prevent such phenomena, in order to optimize the charge/discharge processes, controllers are needed.

Necessity

When the battery is at maximum charge, the controller will regulate the current supply to it, reducing it to the required amount to compensate for the self-discharge of the device. If the battery is completely discharged, the controller will turn off any incoming load to the device.

The need for this device can be reduced to the following points:

- Multi-stage battery charging;

- Adjusting the battery on/off when charging/discharging the device;

- Connecting the battery at maximum charge;

- Connecting charging from photocells in automatic mode.

A battery charge controller for solar devices is important because the performance of all its functions in proper mode greatly increases the service life of the built-in battery.

Device diagram

These boards do get very hot, so we'll solder them a little bit above the PCB. For this we will use hard copper wire to make the legs for the PCB. We will have 4 pieces of copper wire to make 4 legs for the circuit board. For this you can also use - pin connectors instead of copper wire.

The solar cell is connected to the IN+ and IN terminals of the TP4056 charging board, respectively. A diode is inserted into the positive end to protect against reverse voltage. The BAT+ and BAT- boards are then connected to the +ve and -ve ends of the battery. This is all we need to charge the battery.

Now to power the Arduino board we need to increase the output to 5V. So we add a 5V voltage amplifier to this circuit. Connect the -ve batteries to the amplifier's IN- and the ve+ to IN+, adding a switch between them. We connected the booster board directly to the charger, but we recommend installing an SPDT switch there. Therefore, when the device charges the battery, it is charged and not used.

The solar cells are connected to the input of a lithium battery charger (TP4056), the output of which is connected to a 18560 lithium battery. A 5V voltage amplifier is also connected to the battery and is used to convert from 3.7VDC to 5VDC.

The charging voltage is typically around 4.2 V. The voltage amplifier's input ranges from 0.9 to 5.0 V. So it will see about 3.7 V at its input when the battery is discharging, and 4.2 V when it is charging. The amplifier's output to the rest of the circuit will maintain its value at 5V.

This project will be very useful for powering a remote data logger. As we know, power supply is always a problem for a remote recorder and in most cases there is no power outlet available.

This kind of situation forces you to use some batteries to power your circuit. But eventually, the battery will die. Our low cost solar charger project is a great solution for such a situation.

The simplest homemade controller

When making any controller yourself, it is necessary to comply with certain conditions. Firstly, the maximum input voltage must be equal to the battery voltage without load. Secondly, the ratio must be maintained: 1.2P

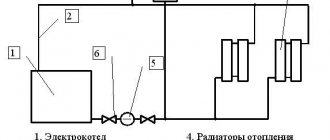

Circuit of the simplest controller

This device is designed to operate as part of a low-power solar power plant. The principle of operation of the controller is extremely simple. When the voltage at the battery terminals reaches the specified value, the charge stops. Subsequently, only the so-called drop charge is produced.

PCB mounted controller

When the voltage drops below the set level, the supply of energy to the batteries is resumed. If, when operating a load in the absence of a charge, the battery voltage is below 11 volts, the controller will turn off the load. This prevents the batteries from discharging when there is no sun.

Module connection diagram

Click to enlarge diagram

After removing the back wall, you can access the device's circuit board.

A 12 V battery with a capacity of 1.2 A/h was chosen as a battery because the author had one. In fact, on a clear sunny day, the panel will be able to charge 2-3 of these batteries. To reduce the risk of short circuit, a fuse is included in the battery circuit. To prevent the battery from discharging through the solar panel in low light conditions, a Schottky diode of type IN5817 is connected in series with the panel. When the battery is fully charged, the current drawn from the solar panel is about 50 mA, at a voltage of 19 V.

As a test load, we used a homemade LED phytolamp with 4 1 W phyto-LEDs connected in series; an MLT-2 type resistor with a resistance of 30 Ohms was connected in series with the LEDs. At a voltage of 12.6 V, the current consumed by the lamp will be about 60 mA. Thus, a 1.2 Ah battery allows you to power this lamp for about 20 hours.

In general, the assembled autonomous structure turned out to be quite functional from a technical point of view. But from an economic point of view, taking into account the cost of the solar battery, battery and control unit, the picture is bleak. A solar battery costs 2,700 rubles, a 12 V 1.2 Ah battery costs about 500 rubles, a control unit costs 400 rubles. The author also tried to use two 6 V 12 A/h batteries connected in series (they will cost about 3000 rubles), the author charges such a battery in 3-4 sunny days, and the charging current reaches 270 mA.

The total cost of the equipment used in the minimum configuration is 3600 rubles. As is easy to see, this phytolamp consumes about 0.8 W. At a tariff of 3.5 rubles per 1 kW/h, the lamp must operate from the network with a power source efficiency of 50%, about 640,000 hours or 73 years, just to justify the cost of the equipment. At the same time, during such a period of time, it will undoubtedly be necessary to completely change the equipment several times; the degradation of the battery and photocells has not been canceled.

Which is better to choose?

The choice of controller type is made based on the power and performance of the system . If they are small, you can limit yourself to installing a PWM controller. It's cheaper and easier.

However, if the kit produces significant power and supplies power to sensitive consumer devices, the best solution would be to use an MPPT controller. It is much more expensive, but is capable of setting up the most efficient operation of a set of equipment. In any case, the final choice is determined by the capabilities of the owner and the features of the existing solar complex.

Price

A solar power supply system is assembled primarily to save money, so the price of individual parts is a very important point. The proposed options have stood the test of time and are the optimal combination of price/quality:

- Solar controller 20a – cost $20.75 – simple controls, bright LCD display, clear interface. Does an excellent job of charging the battery. PWM technology. It is possible to connect via USB to a computer for setup.

- MPPT Tracer 2210RN Solar Charge Controller Regulator, price $75 – 20A MTTP controller – high-quality and reliable, certified, recognizes day/night. High efficiency – 97%

Sources used:

sovet-ingenera.com, energo.house, electric-220.ru, alter220.ru, masterclub.online, electricadom.com

Types

On/Off

This type of device is considered the simplest and cheapest. Its only and main task is to turn off the charge supply to the battery when the maximum voltage is reached to prevent overheating.

However, this type has a certain disadvantage, which is that it switches off too early. After reaching the maximum current, you need to maintain the charging process for a couple more hours, and this controller will immediately turn it off.

As a result, the battery charge will be around 70% of the maximum. This has a negative impact on the battery.

PWM

This type is an improved On/Off. The modernization lies in the fact that it has a built-in pulse width modulation (PWM) system. This function allowed the controller, when the maximum voltage was reached, not to turn off the current supply, but to reduce its strength.

Because of this, it became possible to charge the device almost 100%.

MRRT

This type is considered the most advanced at present. The essence of its work is based on the fact that it is able to determine the exact value of the maximum voltage for a given battery. It continuously monitors the current and voltage in the system. Due to the constant acquisition of these parameters, the processor is able to maintain the most optimal current and voltage values, which allows it to create maximum power.

If we compare the MPPT and PWN controllers, the efficiency of the former is approximately 20-35% higher.

The best stationary solar panels

Stationary devices are characterized by large dimensions and increased power. They are installed in large numbers on the roofs of buildings and other free areas. Designed for year-round use.

Sunways FSM-370M

4.9

★★★★★ editorial assessment

98% of buyers recommend this product

The model is made using PERC technology, which makes it stable in adverse weather conditions. The anodized aluminum frame is not afraid of sharp impacts and deformation. High-strength tempered glass with low ultraviolet absorption guarantees the safety of the panel.

The rated power is 370 W, voltage is 24 V. The battery can operate at outdoor temperatures from -40 to +85 ° C. The diode assembly protects it from overloads and reverse currents, reduces efficiency losses when the surface is partially shaded.

Advantages:

- durable, corrosion-resistant frame;

- thick protective glass;

- stable operation in any conditions;

- long service life.

Flaws:

heavy weight.

Sunways FSM-370M is recommended for continuous power supply of large facilities. An excellent choice for placement on the roof of a residential building or office building.

Delta BST 200-24 M

4.9

★★★★★ editorial assessment

96% of buyers recommend this product

A special feature of Delta BST is the heterogeneous structure of monocrystalline modules. This has improved the panel's ability to absorb diffuse solar radiation and ensures its efficient operation even in cloudy conditions.

The peak power of the battery is 200 watts with dimensions of 1580x808x35 mm. The rigid design is resistant to difficult conditions, and the reinforced frame with drainage holes ensures stable operation of the panel during bad weather. The protective layer is made of tempered coated glass with a thickness of 3.2 mm.

Advantages:

- stable operation in difficult weather conditions;

- reinforced design;

- heat resistance;

- stainless frame.

Flaws:

complex installation.

Delta BST provides stable power generation year-round and will reliably produce electricity for many years to come.

Feron PS0301

4.8

★★★★★ editorial assessment

90% of buyers recommend this product

The Feron solar panel is not afraid of difficult conditions and operates stably at temperatures of -40..+85 °C. The metal body is resistant to damage and is not subject to corrosion. The battery power is 60 W, the dimensions in ready-to-use form are 35x1680x664 millimeters.

If necessary, the structure can be easily folded for transportation. For convenient and safe carrying, a special case made of durable synthetic material is provided. The kit also includes two supports, a cable with clamps and a controller, which allows you to immediately put the panel into operation.

Advantages:

- heat resistance;

- stable operation in any weather conditions;

- durable body;

- quick installation;

- convenient folding design.

Flaws:

high price.

Feron can be used in any weather. A good choice for installation in a private home, but several of these panels will be required to obtain sufficient power.

Woodland Sun House 120W

4.7

★★★★★ editorial assessment

85% of buyers recommend this product

The model is made of silicon polycrystalline wafers. Photocells are covered with a thick layer of tempered glass, which eliminates the risk of mechanical damage and exposure to external factors. Their service life is about 25 years.

Battery power is 120 W, dimensions in a ready-to-use state are 128x4x67 centimeters. The kit includes a practical bag made of wear-resistant material that simplifies storage and transportation of the panel. For ease of installation on a flat surface, special feet are provided.

Advantages:

- protective covering;

- quick installation;

- compact size and easy to carry;

- long service life;

- durable bag included.

Flaws:

The frame is flimsy.

Woodland Sun House is capable of charging 12-volt batteries. An excellent solution for installation in a country house, hunting base and other places remote from civilization.