SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Modern technologies that have come to our country encourage the population to also use the latest developments. Solar panels, room temperature controllers and other smart devices can not only reduce utility bills, but also maintain a comfortable room temperature. Of course, a recuperator for a private home cannot be called an innovation, however, the savings in money and heat energy are obvious.

Installation of a recuperator in a private house

What is a recuperator and why is it needed?

A recuperator is a technical device that is an element of the ventilation system, equipped with a heat exchanger, through which a reduction in thermal energy losses is achieved in the premises where it is used. The presence of a recuperator allows you to ensure the required air exchange in the room, which is achieved by the presence of supply and exhaust fans in the design, and the heat exchanger allows you to select heat from the air pumped out of the room and transfer it to air flows coming from outside. The main functions of such equipment are:

- Ensuring ventilation of the room in a year-round cycle of use.

- Reducing heat loss in winter.

- Cooling of air coming from outside in summer.

Option for placing the device in a private home

Top 6 recuperators. Reviews and ratings in 2021-2022

In winter, when the outside temperature is low, indoor ventilation means cool air is brought into the room. However, heat losses can be minimized with appropriate design. We have prepared a rating of recuperators that work well for air exchange and retain most of the thermal energy. Among the products we present, everyone will definitely find a suitable model for themselves.

Wall-mounted heat exchanger with Marley MENV180 heat exchanger.

An easy-to-install wall-mounted heat exchanger with Marley MENV180 heat exchanger is suitable for any home. It can be used in various rooms, from the living room to the bedroom and bathroom. A wall-mounted heat exchanger promotes proper air exchange, minimizing heat loss. It protects against the formation of mold and moisture on the walls. The heat recovery efficiency of the recuperator is about 85%, which means that less than 30% of thermal energy is lost.

The recuperator wall has three gears that determine its productivity: 16 m3/hour, 25 m3/hour and 37 m3/hour. The power consumption of each stage is respectively: 3 W, 4.5 W and 7 W. The heat exchanger can be mounted on walls with a thickness of 280 to 500 mm - above this value an extension will be required. The diameter of the hole for installing equipment is 180 mm. The Marley recuperator is controlled by remote control. It works alternately in both directions, which means that it removes air from the house and brings fresh air into the room without much heat loss.

Consumers consider the Marley wall-mounted heat exchanger to be a good buy. This helps reduce home heating costs during the heating season. It provides warmth and efficient air exchange.

Compact recuperator Awenta HRV100P + IPX4 remote control.

Fresh air and suitable indoor conditions, regardless of the season, will be provided by the compact heat exchanger Awenta HRV100P + IPX4 remote control. It is mounted in an external partition or on a wall and is designed to work in decentralized ventilation with heat recovery. The mini-recuperator can operate continuously in two modes: supply and exhaust. They both work in two ways. The recuperator productivity at the first power is 35 m 3 / hour, and at the second power - 50 m 3 / hour.

The hole for the recuperator should be 100 mm in diameter. The engine speed is 2100 rpm at low power and 2500 rpm at high power. The compact recuperator is controlled by remote control. It works efficiently and helps to recover large amounts of heat during air exchange. Suitable for heating various rooms, living rooms, kitchens and bedrooms.

Users praise the good and cheap Awenta heat exchanger for its efficiency and ease of installation. The included remote control allows you to change any gear, and therefore the operating speed. The recuperator is made of good quality materials.

Vaillant Rekuperator Recovair Var 260/4 0010016046

If you are looking for a good heat exchanger for your home, you may be interested in the Vaillant Recovair Var 260/4 0010016046 model. It is equipped with a counter-current cross-flow heat exchanger, which has a high efficiency of up to 98%. This means that only a few percent of the thermal energy is lost. The Vaillant recuperator has a maximum capacity of 260 m3/h and operates under residential buildings and large premises.

The recuperator operates silently, so it can be used even in rooms intended for work. It is also equipped with the recoVAIR system, which constantly monitors air quality. As a result, the recuperator traps and filters dust particles and impurities, purifying the air. So this is a good solution for people suffering from allergies. By removing moisture and carbon dioxide, the recuperator protects against mold growth. The power consumption of the Vaillant model ranges from 15 W to 170 W depending on the operating mode.

You might like the ranking of the TOP 10 best coffee machines of 2021-2022 - which one to choose?

User reviews of Vaillant recuperators are usually positive. Consumers are satisfied with the air quality and minimal heat loss. The recuperator is easy to use.

Air handling unit Dospel Luna 200 Recuperator 012-1480

It is worth thinking about purchasing a ventilation unit, a recuperator Dospel Luna 200 012-1480, because it works well in both commercial and residential premises. Heat recovery efficiency can reach 95%. The Luna recuperator has a capacity of 200 m3/hour. The kit includes a 3-step switch to regulate the operation of the equipment. The engine speed in the recuperator is 2400 rpm.

The recuperator is equipped with a hybrid countercurrent cross-flow heat exchanger, which not only provides high efficiency. This also extends the life of all equipment and reduces freezing temperatures during adverse weather conditions. The Luna model is a good heat exchanger for an apartment, which also serves to cool rooms in the summer. The maximum power consumption in the recuperator is 120 W. The diameter of the ventilation pipes of the Luna model should be 150 mm.

People who have installed the Luna recuperator at home and at work are satisfied with its performance. Provides effective air exchange without large heat losses. Consumers describe the model as a functional and good heat exchanger, since it also allows additional cooling of the room in the summer.

Recuperator Aeris Aerisnext 450 R VV Standard ST

We recommend that you consider purchasing the Aeris Aerisnext 450 RW Standard ST heat exchanger as it is efficient and easy to use. It is equipped with a counterflow heat exchanger, which ensures the efficiency of the entire system at 93%. In addition, the recuperator has a built-in bypass for exhausting air outside the heat exchanger and special energy-saving fans. The kit includes two G4 class filters, and a special system informs about the need to replace them.

The Aeris recuperator is easy to use and can be controlled wirelessly or using the display located on the body. The outer part is protected from accidental opening of the damper, for example by a child. The internal part of the recuperator is insulated with polypropylene, which ensures silent operation of the entire system. The Aeris model is additionally equipped with a pressure, temperature and humidity sensor. The recuperator has a capacity of 450 m3/hour and operates under large living spaces and vehicles.

Consumers have tested Aeris recuperators and left positive reviews. Users love the ease of use and efficient operation of the entire system in the device. The heat exchanger works well in large spaces and, in addition to minimizing heat loss, also protects against mold growth.

Oxy Rekuperator, air handling unit Wanas 350V/2

The Wanas 350V/2 ventilation unit and the Oxy heat exchanger will work well in every home. Operates effectively in rooms up to 230 m3. The heat exchanger is equipped with an aluminum counter-current cross-flow heat exchanger, which ensures good system efficiency. Equipment productivity is about 350 m 3 / hour. The Wanas heat exchanger can be installed on plaster or flush-mounted. Its operation is simple and convenient since it is equipped with touch controls.

The recuperator has an automatic bypass, which protects against accidental activation of the device. Effective frost protection uses 3 algorithms that can be individually adapted to your needs and home conditions. The Wanas model is a universal recuperator. The dimensions of the equipment are: 840 mm x 634 mm, so it will work well in both large houses and small apartments. The recuperator can work with the control panel, the entire heating system and external sensors. Three additional functions: “Holiday”, “Vacation” and “Fireplace” increase the comfort of use, allowing you to customize the operating mode of the system to suit your needs.

Most users speak positively about the Wanas recuperator. Consumers are happy with it because it is effective, easy to use and functional. Works well in private houses and apartments.

VIEW OTHER RECOVERY UNITS IN THE STORE

Advantages and disadvantages of air recovery systems for a private house and apartment

Air recovery systems are gradually beginning to “win” their consumers and the reason for this is their advantages, which include indicators such as:

- ensuring the required level of ventilation indoors without compromising the tightness of building structures and their elements (windows, doors, etc.);

- protection of the internal space from external contaminants present in the air (dust, suspended impurities, etc.);

- reduction of thermal energy losses through the ventilation system;

- the likelihood of mold and mildew appearing on elements of building structures is reduced;

- long service life;

- simple and inexpensive maintenance;

- installation does not require various permits and approvals.

Scheme of a ventilation system with recovery of a country house. The disadvantages of using such systems include:

- the complexity of installation work, especially in ventilation systems of large facilities;

- significant overall dimensions require free space to accommodate the device itself and air ducts that ensure air circulation and condensate removal;

- high price.

Rotary

This type of model has a rotating heat exchanger inside the structure. This design consists of several petals. The only drawback of such an installation is the penetration of external odors into the enclosed space.

The advantage of the model is the minimal amount of condensate during operation. Rotary models are easy to maintain and use. Where can I buy such an air recuperator? You can purchase this design in specialized ventilation departments in hardware stores.

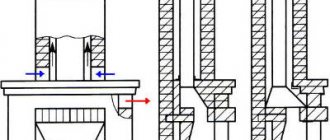

Operating principle of air handling unit with recovery

The operation of the supply and exhaust ventilation system with a heat recovery device is carried out as follows:

- air is taken from the interior of a house, apartment or other permanent structure equipped with a heating system, the temperature of which is higher than outside;

- at the same time, cold air from the street is also sucked into the ventilation system of the building;

- warm and cold air meets in the heat exchanger of the recuperator, where heat is transferred from one air flow to another;

- cold and clean air from the street is heated and only then supplied to the interior of the building;

- Air intakes equipped with fans are used for air intake.

Schematic diagram of the recuperator operation

Recuperator for a country house: main types and subtleties of choice

From the point of view of design and operating principle, air recuperators come in several types:

- roof units;

- rotary devices;

- plate type devices.

Each type of device has both pronounced disadvantages and obvious advantages. Obviously, they are designed for different operating conditions.

Plate units

We are talking about the most popular and sought-after heat exchangers. They are distinguished by a simple design, which ensures high reliability. Plate installations for country houses provide an efficiency of 78% if they are plastic models. And cellulose solutions – up to 92%. The latter ensure the return of both heat and moisture due to their greater heat capacity.

Advice! All types of equipment, with the exception of cellulose equipment, require drainage to remove excess moisture.

"Advantages" of plate devices:

- work without energy consumption;

- operational reliability;

- high efficiency.

“Disadvantages” of exhaust mechanisms:

- moisture does not return;

- with the onset of frost, heat exchangers freeze;

- Installation is only possible if there are hoods and a supply of fresh air.

Air exchangers for roofs

Energy recovery in ventilation systems can be organized in the form of specialized rooftop units. Installation of massive systems is advisable only for large premises, warehouse complexes, retail outlets, hangars and garages. Characterized by high efficiency.

Roof systems are not suitable for apartments, private houses and cottages.

Rotary devices

The air rotary air exchanger is no less popular among consumers than plate solutions.

The body is made of aluminum. The main operating element of the unit is a small electric motor. The zigzag and flat elements are driven by a drive belt. Each element of recovery ventilation transfers part of the heat from the hood to the underwater air flow. Advantages of the rotor circuit:

- air currents maintain humidity;

- high efficiency;

- the recuperator for a private home is small in size, thanks to which it fits even in compact ventilation systems;

- rotors are not afraid of harsh winters and severe frosts.

Disadvantages of the system:

- The devices operate on electricity.

Types of recuperators for forced ventilation

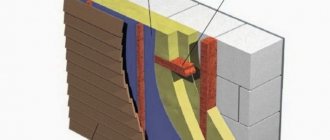

Recuperators differ in design, technical characteristics and materials used in manufacturing, which ultimately determines the scope of use of a particular model and the method of its installation. Installation of such systems can be done inside a wall, outside or inside an apartment (country house).

Plate recuperators

This type of device is highly efficient and affordable. The basis of this type of recuperator is a plate heat exchanger made of copper, aluminum or galvanized steel. The plates are fixed rigidly, warm and cold air do not mix, the process of heat transfer occurs simultaneously in both directions.

Appearance and direction of air flow in a plate recuperator Among the disadvantages of this type of device, it should be noted the formation of condensate on the heat exchanger plates when used in winter, which requires a drainage device or a defrosting system.

Rotary models

The basis of the design of such models is a heat exchanger rotating around its axis, made in the form of a rotor (rotors) equipped with petals. This is an open system, the disadvantage of which is the possibility of penetration of odors from the external environment into the internal space of the premises. The advantages of rotary recuperators are the following:

- low probability of condensation forming on the surface of the heat exchanger;

- high work efficiency;

- ease of maintenance and use.

FOR YOUR INFORMATION!

The performance of rotary models is achieved by changing the rotation speed of the heat exchanger.

Diagram and appearance of a rotary recuperator

Models with intermediate coolant

The designs of this type of recuperator include two heat exchangers through which water or glycol solution circulates. One of the heat exchangers is located in the exhaust duct of the ventilation system, and the second is located in the supply duct. Accordingly, the warm air transfers its heat to the coolant in the heat exchanger of the exhaust duct, and on the heat exchanger in the supply duct the coolant transfers it to the air coming from outside.

FOR YOUR INFORMATION!

The temperature regime is regulated by changing the circulation rate of the coolant.

The advantage of this type of device is the absence of contact between air flows, eliminating the possibility of transferring contaminants from one to another. Disadvantages are: low efficiency and the need for fairly frequent maintenance.

Diagram of a recuperator with an intermediate coolant

Other types of recuperators

In addition to the types of devices of this type discussed above, which are the most common, there are several more:

- roof - designed for external installation, used in ventilation systems at industrial facilities;

- chamber - the basis of the design is a working chamber, divided by a damper, through which the direction of air flow changes;

- Heat pipes are a closed system of tubes filled with freon and serving as a heat exchanger.

Scheme of operation of a chamber recuperator These types of devices have the following distinctive features:

- for roof models - high efficiency and cost;

- for chamber models - high efficiency and the ability to transfer odors and suspended particles from one type of air flow to another;

- for heat pipes – low efficiency and the impossibility of penetration of contaminants from one air flow to another.

Scheme of operation of models operating on the principle of heat pipes

Some tips when buying a device

Before making a choice in favor of one model or another, you should remember:

- Recuperators produce operating noise. Some manufacturers offer silent devices.

A small device will fit into any interior

- The power consumption of heat recovery ventilation is important since the device operates around the clock.

- Some devices require consumables - filters.

- The performance must be indicated on the device.

Some craftsmen equip finished devices with special filters made of plastic or fibrous materials for additional air purification. But it is worth remembering that these filters need to be closely monitored and promptly replaced with new ones.

Filters for air exchangers

Helpful information! To prevent ice from forming in the device, you need to turn off the fan from time to time. The plates will thaw from the heat of the escaping air.

Leading manufacturers of recuperators

The production of technical equipment intended for supply and exhaust ventilation systems for domestic and industrial purposes is carried out by Russian and foreign enterprises specializing in climate control equipment and energy saving systems. In our country, the most popular models are from companies such as:

- Electrolux, Systemair and Ostberg (Sweden);

- Remak (Czech Republic);

- Royal Clima (China);

- Mitsubishi Electric (Japan);

- Vaillant and Blauberg (Germany);

- Ventmachine (Russia).

Sectional view of a recuperator for an apartment

Marley MEnV 180 PLUS

German quality, classic design and reliability always find their consumers. Marley MEnV 180 is a device that was one of the first to enter the Russian market and for 8 years has shown itself only on the positive side

Marley MEnV 180 Plus

Advantages of Marley MEnV 180 devices

- Made in Germany (virtually no warranty cases)

- Two years warranty

- Radio remote control (breaks through walls)

- Possibility of synchronizing several devices via radio channel (option included in the basic package)

Disadvantages of Marley MEnV 180 devices

- Lack of inflow mode at 2 and 3 speeds

- You can’t turn it on in winter only for inflow

- Labor-intensive filter replacement process

- Labor-intensive process of switching the device to inflow mode

- The model has not been updated for a long time

The best models of household recuperators

The following table shows the best models of recuperators from the most popular manufacturers of such equipment presented above. The cost of the devices is as of 2019.

| Model | Specifications | price, rub. |

| "Electrolux EPVS-200" |

| 25 000 |

| Model | Specifications | price, rub. |

| "Mitsubishi Electric VL-100EU5-E" |

| 33 000 |

| Model | Specifications | price, rub. |

| "Royal Clima RCS 350" |

| 34 500 |

| Model | Specifications | price, rub. |

| "Blauberg VENTO Expert A50-1 Pro" |

| 20 000 |

| Model | Specifications | price, rub. |

| "Vent Machine PVU-350 EC Zentec" |

| 150 000 |

How much does the device cost?

Today, domestic manufacturers of recuperators use imported components, so such heat exchangers are not cheap. Among the manufacturers with an impeccable reputation are Teplotex, which assembles recuperators from Danish raw materials, Mashimpex, which uses German components, and Danfoss, which assembles products from Finnish plates.

Air exchanger operation diagram in summer

| Image | Model | Operating temperature, degrees. | Productivity sq.m. | Channel diameter, mm | Noise level, dB | Average price, rub |

| UVRK 50 MK | -40 — +50 | 13 — 80 | 150 | 42 | 19900 | |

| Dantex DV-200HRE | -20 + 40 | 200 | 146 | 32 — 39 | 24444 | |

| RCS 350 | — 28 — +50 | 330 | 144 | 26 | 36058 | |

| Elicent REC Smart 100/600 | — 30 + 45 | 27 — 53 | 100 | 28 — 35 | 36875 | |

| Vents VUT 300 V mini | — 25 + 50 | 300 | 125 | 28 — 47 | 42739 | |

| Mitsubishi Electric LGH-35RX5-E | — 10+46 | 350 | 150 | 31 | 95670 | |

| Electrolux STAR EPVS-1100 | — 15 +40 | 1100 | 250 | 41 | 92330 |

Calculation of recuperator power for ventilation

The power of a recuperator is determined by its ability to pass a certain volume of air through its structure per unit of time, i.e. it's his performance. Knowing the volume of rooms that should be ventilated through the recuperator, you can determine its required performance - for which these values must be added. The operating efficiency of such equipment depends on the temperature of the air flows outgoing and entering the premises where the recuperator is installed. This can be determined using the following formula:

K = (T3 – T1) / (T2 – T1) , where:

T1 – outside air temperature; T2 – air temperature in the ventilated room; T3 – air temperature at the entrance to the room in the supply air duct.

Placing a recuperator on the wall of a country house (apartment)

Recuperator with air conditioner

Large wall-mounted Mitsubishi air conditioner

There is a physical possibility of combining recuperation with air conditioning , thanks to which we will get the best characteristics of these devices. The pleasant coolness created by the installed air conditioner is especially desirable in the summer, while the recuperator will be responsible for more efficient air recirculation, which will provide additional ventilation in the rooms.

You might like it How to choose a good refrigerator based on quality, price and reliability: 10 tips for dummies

The recuperator itself should be selected from the point of view of the ventilation capabilities of our system, and the air conditioner is purchased for the kit from the point of view of the cooled surface. Recuperation combined with air conditioning allows for more efficient air recirculation through the installation of appropriate ducts. Remember that in order for the system to be properly tuned for efficiency, you must accurately assess the surface being conditioned and the ventilation efficiency, which can most effectively be done using specialized devices.

The type of installation and efficiency also depends on whether you are dealing with so-called heavy or light construction. The control of air conditioning with dampers must be adapted to the room and its heating level, as well as to the freedom of air recirculation across the entire surface on which the system is located.

What to consider when choosing a specific model

When choosing a recuperator, the main indicators influencing this choice are:

- The efficiency of the device determines the degree of thermal energy recovery, i.e. its economy.

- The degree of purification of air coming from outside into the interior space of the premises.

- Electric power.

- Operational characteristics (duration of operation and overhaul cycles, maintainability, etc.).

- Price.

In addition, for models intended for use in an apartment, important indicators will be: overall dimensions and noise, and for use in a country house - weight, type of placement and degree of protection.

Ventilation diagram for a country house with a recuperator located in the attic of the building

Bottom line

A recuperator for a private home is a device necessary to maintain an optimal microclimate and economical energy consumption. This device will reduce heat loss in winter and help maintain a comfortable room temperature in summer.

Factory models of household recuperators should be selected taking into account their ease of use and energy efficiency

It won’t be difficult for a home craftsman to make a simple plate exchanger with his own hands.

Save time: selected articles delivered to your inbox every week

How to make an air recuperator with your own hands

Factory-made recuperators are quite expensive, so if you know how to work with hand and electric tools, you can make such a device yourself. In this case, the main key to success will be the availability of free time and the desire to achieve your goal. All work can be divided into several stages: preparation and manufacturing, installation and performance testing.

Preparatory stage

During this period of work, it is necessary to determine the type of device and the availability of the necessary materials and tools. Once the type of recuperator has been determined, it is necessary to draw up a sketch (drawing) indicating the main dimensions, which will prevent waste of materials.

Homemade air recuperator made using polycarbonate So, to make a plate structure you will need:

- sheet metal 0.5-1.5 mm thick (aluminum, copper, galvanized, etc.) - for the manufacture of heat exchanger plates;

- other material (wood, plastic, etc.) - to create a gap between the heat exchanger plates;

- material for making the body (metal, plywood, lumber, plastic);

- glue and sealant;

- insulation;

- connecting flanges with a diameter corresponding to the ventilation system pipes;

- fans;

- metal profile (angle, profile pipe, etc.) - for the manufacture of a structure that provides fastening to a wall or ceiling;

- fastening elements (screws, self-tapping screws, etc.);

- electric jigsaw and grinder;

- screwdriver or electric drill;

- plumbing tools (screwdrivers, wrenches, hammer, etc.).

Manufacturing of a plate-type recuperator

Having drawn a sketch and prepared the necessary tools and materials, you can begin manufacturing, which is carried out as follows.

| Illustration | Description of action |

| Using the material for the manufacture of heat exchanger plates, blanks are cut to the required size and in the required quantity. | |

| The material prepared to create the gap is cut to the required size and glued to the surface of the plates. | |

| The plates are assembled into a block, and the gaps on their surface are staggered. | |

| The plates in the assembled block are carefully fastened together, the joints are sealed, with the exception of gaps intended for air flows of the ventilation system. | |

| A box is assembled from the material intended for the manufacture of the case, into which the assembled unit is placed, and 4 fans are mounted in the end walls. | |

| The inner surface of the housing is covered with a heat insulator, and the non-working surfaces of the heat exchanger are also covered with it. |

After all structural elements are placed in the housing, the outer cover is installed.

Installation of the assembled device

When the recuperator is manufactured, it must be installed in the selected location. To fasten it, a metal structure is used, made of a metal profile and mounted to the wall of a building or interfloor ceiling. The size of the structure depends on the geometric dimensions of the assembled device. To connect to the air ducts of the ventilation system, connecting flanges installed on the product body and special clamps are used.

Functionality check

After the device is installed, it must be connected to an electrical network corresponding to the voltage class of the fans used.

IMPORTANT ! Air ducts made of metal must be grounded, and the fan power line must have a third grounding wire.

Using corrugated sheet to make a heat exchanger The system is put into operation and its effectiveness is checked using a thermometer. To do this, air temperature measurements are taken at three points in space, and a calculation is performed using the formula given in this article (see section “Power calculation”).