When building a country house, heating organization becomes an important point. If there is no main gas pipeline, a diesel heating boiler for a private home will help solve the problem.

Diesel boiler - an alternative to gas heating Source nehomesdeaf.org

Features of using liquid fuel boilers

A diesel boiler installed to heat a private home has many advantages compared to other heating systems. The obvious advantages include the following factors:

- the boiler functioning process is automated, it is regulated based on the temperature of the coolant;

- high efficiency of up to 85-95%;

- direct connection of diesel equipment does not require complex approvals from various authorities;

- installation of diesel equipment is quick;

- supplying fuel for the boiler is not difficult;

- smoke exhaust can be organized through the wall;

- affordable price for equipment.

The disadvantages include:

- high fuel consumption and a significant price for it;

- for a constant supply of diesel fuel, a storage system must be organized and connected to the boiler;

- energy dependence;

- the need to place the boiler in a boiler room, a dedicated separate room;

- the need to organize a backup source of power supply.

Organizing diesel heating will require more costs Source strojdvor.ru

How to decide on the manufacturer?

Another important point is the manufacturer. The fact is that there is high-quality equipment, and there is not so much. So, at first glance it is quite difficult to understand what exactly you are dealing with. In most cases, you need to look at the company's notoriety. For example, the Kiturami diesel heating boiler, regardless of the model, is in good demand. At the same time, the number of positive reviews reaches 95%. This suggests that this company produces quality products. The same applies to Germany, which supplies Logano diesel boilers to our market. Although they have a high cost, they are distinguished by a long service life, high reliability and efficiency. In general, it makes sense to take a closer look at domestic manufacturers, since our companies make very high-quality equipment. At the same time, its price is significantly lower than European models.

Equipment classification

Depending on the requirements for the equipment, a specific boiler model is selected. Characteristics that are important when selecting a heating boiler:

- power;

- combustion type;

- heat exchanger material;

- fuel consumption;

- additional possibility of heating water.

Inside view of an oil-fuel boiler Source stroyfora.ru

See also: Catalog of companies that specialize in insulating houses.

Power

The efficiency of diesel fuel consumption and the operating efficiency of the unit depend on the power consumption. The generally accepted unit of power measurement is kilowatt. This characteristic must be reflected in the documentation supplied with the boiler.

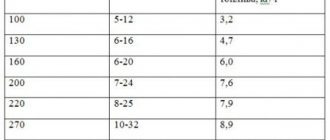

The selection of a model based on power must be made based on the area of the heated room of the house. Calculating the required power is quite simple: sum up the area of all rooms, and the resulting amount must be divided by 10. This formula is used to determine the power of a boiler for a house located in a temperate climate.

This calculation method is suitable for rooms in which the ceiling height is no more than 3 m. If the building is located in an area with a cold climate, then the calculated power of the unit must be increased in the range from 20 to 30%.

Comparison of the power of boilers of different types in the table Source pechilux.ru

Determination of fuel consumption

Diesel heating of a private home requires significant consumption of diesel fuel. This indicator depends on the power of the boiler equipment. The amount of fuel can be calculated using the formula: divide the boiler power by 10. The resulting quotient is the hourly fuel consumption (in kilograms) during heating.

In temperature maintenance mode, fuel consumption is significantly reduced. How economically diesel fuel will be consumed depends on the quality of the building’s thermal insulation. If it is weak, the flow rate will decrease by a third; if it is good, it will decrease by up to 70%. The average fuel consumption for a private home is usually from 500 to 900 grams.

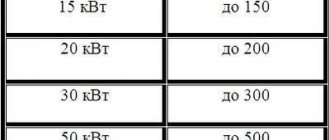

Boilers for heating and heating

Diesel boilers can be used not only to heat a house, but also to heat water. Devices that combine both of these functions are called dual-circuit.

If this is the option you need, the calculated power must be increased by a fifth. This factor must be taken into account immediately. Otherwise, the power of the diesel boiler may not be enough for both water heating and heating.

Heating system for heating a house and heating water Source teplotehnika.msk.ru

Heat exchanger: choice of material of manufacture

The boiler heat exchanger material is one of the important parameters. During fuel combustion, soot is formed, which, when combined with condensate, leads to corrosion and failure of the unit. Each heat exchanger material has its own strengths and weaknesses, including resistance to corrosion and temperature changes.

Cast iron

A heat exchanger made of cast iron has higher corrosion resistance compared to steel. But at the same time it can crack due to temperature changes. Cast iron is heavier than steel and its price is higher.

Steel

The steel body is lighter and cheaper than cast iron, it is resistant to temperature changes, but is susceptible to corrosion. Stainless steel has the best performance qualities. But such a boiler will cost more.

When choosing a diesel boiler, you can start from financial capabilities, but do not forget about the quality and duration of operation Source happymodern.ru

How to choose a diesel fuel heating boiler?

A little later we will talk about the technical characteristics of the equipment, but now it is worth considering the issue of choice a little. The fact is that currently the manufacturer offers a large selection, and it is very easy for a beginner to make a mistake. In this case, a lot of money will be spent, but the benefit from this will be minimal. The first step is to look at the material of the heat exchanger. Today they are made either steel or cast iron. The latter are distinguished by durability and heavy weight, while the former are economical and light in weight. In general, a cast iron option is suitable for a private home, especially if you take into account that such boilers are in most cases floor-standing.

Boiler room organization

When installing diesel heating, it is necessary to provide for the organization of a boiler room in a separate room. This is necessary due to the noise and unpleasant odor created during operation of the boiler.

A separate ventilated room is the first thing you need for a home heating system Source strhouse.ru

Boiler room parameters

The size of the boiler room should allow the installation of the boiler itself and a container for diesel fuel. The area allocated for the boiler room must be at least 4 m², the ceiling height must be from 220 cm. The door opening must be from 80 cm, and windows must also be present.

A prerequisite is the organization of grounding of the boiler body and automatic connection to the electrical network. In case of unstable power supply, it is advisable to provide an alternative option for supplying electricity.

Diesel tank

The diesel fuel tank in the boiler room should be no more than 0.8 m³. For these purposes, special tanks made of polymer resistant to aggressive liquids are most often used.

The fuel tank must have the following elements:

- float level gauge;

- valve for removing fuel vapors;

- fastening fittings;

- a fuel intake that allows you to take fuel away from the bottom, where sediment forms.

Design of a diesel tank in a diesel boiler system Source remontzhilya.ru

Note! If the boiler burner does not have a filter, then it must be on the container.

Additional fuel containers

The capacity of the established volume for heating a country house during the heating season is not enough. An external tank solves the problem. This can be one container or several connected to each other. Most often, the volume selected is from 2,000 to 4,000 liters.

Tank material:

- metal;

- plastic;

- fiberglass.

What determines fuel consumption?

Some people complain that, despite assurances about the low fuel consumption of diesel equipment, the diesel fuel in their boiler tank quickly runs out and requires frequent refilling.

This may happen:

- due to incorrectly selected equipment:

- in case of breakdown;

- for other reasons.

If a unit of the wrong power is purchased, then it will take more time to warm up the room, which will lead to increased fuel consumption. For example, heating a house of 300 m² with a 20 kW boiler will require 1.5-2 times more fuel than when operating a 30 kW unit.

Fuel consumption increases due to incorrectly selected equipment.

Hardware faults are as follows:

- equipment is not configured;

- burnout or breakage of parts;

- poor pipe insulation.

Complete combustion of fuel and lubricants occurs only when the proportions of air and diesel fuel are correctly set. Incorrect burner adjustment leads to ignition of the fuel-air mixture, and not the substance itself. Due to constant under-burning, there will be an overconsumption of fuel and lubricants.

When a diesel unit is operating, fuel enters the chamber through a nozzle, and air through another channel, and the mixture is ignited. If the settings are not made correctly, the flame temperature will increase and this will lead to burnout of the nozzle.

If you do not take care of the thermal insulation of the fuel supply system in time (for example, when the boiler is outside the house), frostbite will occur in some area.

This will cause the pipes to clog.

General recommendations for selection

Diesel heating of a country house has a fairly high price due to the cost of diesel fuel. And when selecting equipment, you should adhere to the following principles:

- When planning to convert heating to gas in the future

If in the future you plan to switch to gas heating, then it is better to purchase a boiler model that is designed to replace the burner.

- Street tanks

For tanks installed outdoors, insulation must be provided during the cold season. In the absence of good insulation of the pipeline and tank, the viscosity of the fuel increases, which disrupts its supply through the pipeline, increases the load on the pump and reduces the efficiency of the boiler.

To prevent failures in the heating system, the diesel fuel tank needs to be insulated Source centr-tmt.ru

- Chimney organization

The chimney for boilers running on diesel fuel does not require complex equipment. This is due to the almost complete combustion of diesel fuel, as well as the relatively low temperature of the released gas. Most often, a coaxial chimney is used, which has built-in ventilation and outlet through the wall.

Important! The diameter of the chimney must be no less than that at the boiler outlet.

- Equipment prevention

For long-term good operation of the equipment, periodic maintenance must be provided. At least once a season, equipment maintenance should be carried out with cleaning of elements, replacement of worn parts and repair of individual engineering components.

Cleaning the elements will allow the boiler to operate smoothly and with greater efficiency. When soot accumulates in a layer of 10 mm, the power of the unit can be reduced by a third with an increase in diesel fuel consumption.

Some technical characteristics

It is not so difficult to guess that the cost of equipment increases with the improvement of operational and technical characteristics. In particular, you need to take into account power. Usually 1 kW is enough to heat a room measuring 10 square meters. Therefore, if you have a house of 100 square meters, then you need to buy a 10 kW boiler; such equipment will consume about 1 kilogram of diesel per hour.

As for weight, this parameter in most cases is not so important. Almost all models are placed on the floor. True, it is worth looking at the dimensions, since sometimes there is no room to install a wide or, conversely, tall boiler. If we talk about the power/weight ratio, then it is difficult to find any pattern. Much depends on the manufacturer and the materials used during assembly. So, boilers of 10-20 kW weigh approximately 100-160 kg, 25-30 kW – 170-200 kg and so on.