Hello, my dear interlocutor.

More than one and a half million people die from carbon monoxide poisoning every year. And in most cases this happens due to faulty geysers or poorly cleaned air ducts.

Do you know what is most dangerous? The gas in cookers is specially “flavoured”. Therefore, our sense of smell can sense a methane leak. With gas in the column, the story is a little different. With poor ventilation, combustion occurs with a lack of oxygen, resulting in the formation of dangerous carbon monoxide, after inhaling which a person loses consciousness and falls asleep. Unfortunately forever.

Therefore, a hood for a geyser is a must-have device. We’ll find out how it works and how to install it correctly from today’s article.

Why does a gas water heater need a hood?

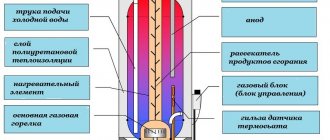

A geyser is a convenient device that allows you to provide residents of your home with hot water at any time of the year. Modern devices are equipped with temperature regulators, sensors for the operation of the water point and other convenient functions. But even the most modern unit will not protect against carbon monoxide if the chimneys in the house are not cleaned.

In addition, household gas is explosive, and if leaked, in a certain proportion with oxygen, it can provoke a disaster.

A hood will help solve the issue of removing combustion products and providing sufficiently high draft. It should be installed strictly in accordance with the requirements of regulatory documents.

The chimney of the column should not be confused with devices for other kitchen appliances that run on gas.

We will consider the advantages of built-in coal hoods for kitchen stoves in one of the following articles.

The best ways to test traction

For correct operation of geysers with an open combustion chamber, you will need good draft and proper arrangement of the chimney. Most modern models are equipped with an automatic safety system that prevents the device from starting if there is no traction.

Next, we’ll look at how you can check the draft in the chimney of a domestic gas boiler and water heater.

Method #1 - using an anemometer

A professional check of the draft in the chimney of a gas boiler and water heater is carried out using a special measuring device - an anemometer.

With its help, you can verify the presence of air traffic and determine its strength. The indicator should be 1.96-29.40 Pa.

Method #2 - using a match

If it is not possible to use an anemometer, you can check as follows:

- Prepare paper strips and secure them at the entrance to the mine channel. You must first remove the horizontal part of the chimney pipe. The movement of part of the leaf will signal the presence of traction.

- Sufficient draft can also be determined using a flame. A lit match should be directed vertically towards the viewing window on the front panel of the water heater.

The chimney should be checked before igniting the water heater. A flame brought to the inspection hole at the top of the column during operation should be drawn inward.

It is necessary to check the draft in the gas water heater every time before turning on the device. Open the window slightly for air flow

Method #3 - checking the traction sensor

The water heater has several control modules installed. Sensors for overheating, draft, ionization, and water pressure prevent emergency situations.

The draft sensor monitors the temperature of the exhaust gases, and when it increases, it reacts accordingly:

- Inside the sensor there is a bimetallic plate connected to the gas valve.

- Metal expanding as a result of overheating transmits a signal to turn off the gas supply.

- The cooled plate returns to its original dimensions, opening the valve.

It is recommended to check the serviceability of the sensor when systematically turning off the column.

You can do this in several ways:

- place a mirror next to the sensor, its surface should not sweat when the water heater is turned on;

- The serviceability of the sensor will be indicated by turning off the gas water heater when the chimney is closed 2/3 with the damper.

In some water heater models, the regulator is mounted on a plastic mount that can be easily moved out of place. This will also lead to frequent speaker shutdowns.

You can also test the serviceability of the sensor using an ohmmeter; its resistance should be equal to infinity. Otherwise, the part should be replaced.

The sensor shuts off the gas supply in the event of a gas leak or poor removal of combustion products. The serviceability of the protective element is a guarantee of safe use of the water heater

When there is a constant interruption in the fuel supply, home owners often simply turn off the sensor, after which the water heater actually starts working without interruption. But such a decision violates the safety precautions for operating gas equipment. The water heater will remain unprotected; if there is a leak, carbon monoxide will enter the room.

It is strictly prohibited to use a gas water heater if there is no vacuum in the chimney channel. Let's consider the possible reasons for the lack of traction.

Requirements for chimneys for geysers (SNIP)

Requirements for chimneys are set out in the following documents:

- SNiP 41-01-2003 in a new edition (SP 60.13330.2012);

- NPB 252-98 (fire safety standards);

- SP 42-101-2003;

- VDPO (rules for the production of pipe and furnace works).

The main provisions regarding the direct removal of smoke from household water heaters are collected in the following paragraphs:

- The cross-sectional area of the chimney pipe must be greater than or equal to the cross-section of the outlet pipe of the column;

- Laying gas pipes through living rooms is prohibited;

- The chimney system must be completely sealed, resistant to corrosion and temperatures up to 200°C;

- The vertical section of the chimney at the outlet of the column should not be shorter than 500mm. Only in some cases this figure is reduced to 250mm;

- The length of connecting pipes should not be more than 3 m in designed houses and no more than 6 m in existing ones;

- The design allows for no more than 3 turns with a radius of at least the pipe diameter;

- If the wall of the building is made of non-combustible materials, the distance from it to the exhaust pipe must be at least 5 cm, if the wall material is flammable - at least 25 cm. If the fire protection requirements of SP 42-101-2003 are met, the distance can be reduced to 10 cm;

- If the connecting pipe passes through an unheated room, it must be protected with thermal insulation;

- The slope of the exhaust pipe towards the column must be more than 0.01;

- You cannot use one hood for a gas water heater and a gas stove;

- The ceiling height in the room with a water heater and chimney should not be less than 2 m. Area – at least 7.5 m for one device, at least 13.5 for 2 devices.

Calculation of hood parameters

Before starting work on installing a chimney for a geyser in an apartment or private house, it is necessary to calculate the parameters of the exhaust channel. These parameters determine the required amount of air removed from the room.

When calculating, the following indicators should be taken into account:

- power of heating devices;

- volume of exhaust gases;

- difference in temperatures of outside air and combustion products;

- the height of the chimney pipe (for gas installations at least 2 m).

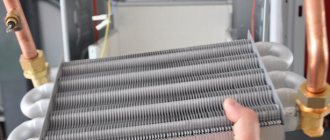

There are many types of pipelines for geysers, of different diameters, shapes, and lengths. Standard chimney diameters are 110-130 mm. For dispenser power up to 19 kW, a pipe with a diameter of 11 cm is used, above – 13 cm.

What material should I choose for a kitchen with a gas stove?

No housewife is immune from food burning, so smoke and soot when cooking are common. However, those who have to use a gas stove are well aware that an open flame can smoke on its own. The reason for the formation of soot is incomplete combustion of gas in the presence of various types of malfunctions: clogged injectors, deformation of the divider.

The answer to the question of what kind of ceiling to make in a kitchen with a gas stove is simple. The finishing material should be easy to clean from dirt. Otherwise, the choice depends on the parameters of the room. For low ceilings, painting is the right solution. If conditions permit, a tensile structure can be installed.

What kind of corrugation is used for chimneys

Combustion products in an apartment building are discharged into the ventilation duct, in a private apartment - to the street. Depending on where the gases are discharged, the pipes are divided as follows:

- Coaxial - the pipe exits through the wall or roof of the house to the street;

It is a structure of two pipes, the larger of which is put on the smaller one. Oxygen from the street is supplied to the fire through the free space between the pipes.

- Chimney - with connection to the ventilation duct.

Chimney pipes, in turn, can be smooth steel or corrugated.

- Smooth steel pipelines. Covered with white heat-resistant enamel or galvanized. Maximum length -1.5m. Made from sheet steel with a minimum thickness of 0.6mm. Due to temperature differences, condensation forms in the pipes and freezes in winter. Therefore, the structure must be carefully insulated.

- Flexible corrugated air ducts. Corrugated pipes are the best choice for removing waste gases from the column. They are convenient, reliable, and inexpensive. Due to their low weight and flexibility, they are easy to install.

The standard diameter of corrugated pipes is 11 and 13 cm. Maximum length – up to 3m. If you need to mount a longer section, the parts are connected with metallized tape. It can also be used when repairing corrugation.

When choosing a pipe for exhaust, it is necessary to take into account the temperature of the exhaust gases. Usually in the column it reaches 200-300°C, so the operating temperature of the corrugation should be at least 350°C.

Corrugated chimneys are made from stainless steel or aluminum.

In the case of gases venting through the wall, a special hole is prepared in it with an installed passage pipe, isolating the wall and the pipe from each other.

Let's look at the features of each material.

Stainless steel chimney:

- Withstands heating up to 900°C.

- Stainless steel is a durable and corrosion-resistant material;

- The corrugation bends in any direction and does not require additional fittings.

Aluminum:

- The multilayer structure made of aluminum foil and reinforcing wire is not inferior in flexibility to stainless corrugation;

- The temperature of the exhaust gases should not exceed 400° C;

- Aluminum is lighter than stainless steel and has better stretchability;

- These products are inferior to their stainless steel counterparts in strength.

The use of aluminum pipes is not prohibited, but, as practice shows, inspectors in most cases require replacing aluminum with another material.

In any case, you should purchase only certified products.

Glossy or matte?

Stretch ceilings come in three varieties, which differ in surface structure. The film can be glossy, matte or with a convex, structural pattern. The latter are used extremely rarely in the kitchen, since it is the most difficult to remove dirt from them.

As for the two remaining options, experts unanimously say: there is no noticeable difference between them. When cleaning, in order to restore the gloss to the coating, you have to wipe the surface of the ceiling in several steps. The matte finish does not need polishing, but due to the presence of roughness, it is more difficult to clean.

Average prices per set

The average cost of the kit primarily depends on the length of the chimney and the diameter of the selected pipe.

When purchasing, please note that aluminum corrugation stretches from the original length of 0.65cm to 3m. Stainless steel products have little stretch. Average cost of products:

- Aluminum - 200 rub/m;

- Stainless steel sleeve – 650 rub/m.

In addition, you should purchase special metal tape, sealants and the necessary fittings.

The average cost of a complete set made of aluminum is 500 rubles, from stainless steel - 1000 rubles.

How to install

The installation of gas equipment should be carried out by a specialist. If you decide to install the pipe yourself, be sure to read all the safety requirements.

Procedure:

- We accurately measure the distance required to install the chimney and apply markings to the wall;

- Purchases clamps for fastening, pipes, an adapter from the column, units for laying pipes through ceilings, a nozzle for covering the street chimney;

- We determine where the pipe will go - into the ventilation duct shaft, or to the street, and prepare the appropriate technological holes;

- We begin the installation of the lower part of the chimney - connect it to the column;

- We connect a pipe with a valve to increase traction;

- We fasten the remaining parts of the chimney with clamps installed every 1.6 m;

- All locations of passages through the floors and roof must be isolated with plugs to prevent fires;

- If the room does not have an exhaust duct inside the wall, it is recommended to use an attachment or root pipe for a gas water heater;

- If steel pipes are attached, it is necessary to provide L-shaped adapters for the ventilation duct and exhaust hood;

- All joints are connected using heat-resistant sealants;

Advice from a professional: To install a hood in a private house, it is better to use coaxial pipes or double sandwich pipes with insulation. In an apartment building, you should not install a chimney yourself at all.

Installation procedure

Installation of an exhaust pipe for a geyser made of any material begins with taking measurements and preparing all the necessary elements. In the case of corrugation, the work procedure is very simple. It is enough to take a pipeline of the required length, put it on the smoke exhaust pipe of the water heater and clamp it with a clamp. The free end is inserted into a decorative ring and fixed in the opening of the smoke channel. The main thing here is to ensure that the diameter of the corrugated pipe matches the size of the outlet hole of the column.

For all other materials, you need to prepare the required number of straight and rotary elements that will be inserted into each other, forming the desired chimney configuration according to the principle of a designer. Rotation angles are standard or made individually for specific sizes.

During assembly, ensure maximum tightness of connections. The entry of one element into another must be at least half the diameter. For better sealing, heat-resistant sealant is used. The joints are fastened with clamps and are located outside the ceilings and are freely accessible.

* When attaching an exhaust pipe for a gas water heater, you should eliminate the possibility of deflection, as well as contact with electrical wiring, gas pipes and other communications. To pass through floors and roofs, it is necessary to use additional thermal insulation or a special unit - cutting.

Due to the limitation on the number of permissible turns, the number of possible chimney configurations is quite limited. There are three main options depending on the location of the exhaust vent. Two more can be obtained by mirroring the previous ones.

All requirements and recommendations stated above apply to devices with an open combustion chamber. The standards also allow the removal of combustion products through an external wall without a vertical smoke duct from geysers with a closed combustion chamber and forced release of exhaust gases. In this case, installation is carried out according to the manufacturer's instructions in compliance with the standard distances and lengths of the coaxial chimney specified in SP 42-101-2003.

Common mistakes

Errors when installing ventilation elements can lead to disruption of the proper operation of the structure and loss of operational safety. The most common are the following:

- Combination of hoods for a water heater and a gas stove, or for a gas boiler. In this case, reverse draft may occur in the ventilation shaft and carbon monoxide will return to the room;

- Do not connect two speakers to one chimney;

- The next mistake concerns the installation of a geyser - it is often placed in the bathroom, this cannot be done. All gas appliances must be installed in rooms with a window;

- Self-taught craftsmen often confuse the ventilation duct with the riser supplying water to the column. The consequences of such an error will be the replacement of all gas equipment, not only for you, but also for your neighbors below. Gas services remove liquid. They will turn off the gas and issue a hefty fine;

Installation work

Benefits of proper installation:

- High-quality and safe smoke removal;

- Increasing the efficiency of equipment operation;

- Protection against accident and leakage.

Work process:

- The pipe is being installed into the wall. After this, the structure is connected to the column and connected to the pipe for output to the street. All cracks and connections are sealed with sealant;

- A chimney is mounted on the external wall. All connections are secured with clamps;

- To ensure that the device is level and stable, it is additionally secured with brackets while maintaining a distance of 2 meters. It is important that there are no deflections in the system;

- To avoid clogging the system, a protective umbrella is installed on top;

- At the bottom you need to organize a window to inspect the condition of the chimney.

Once the work is completed, check the traction force. To do this, you need to bring a burning match to the ventilation or chimney opening. If the flame deviates, it means there is draft.