Many people associate electric heating of a home with the installation of appropriate water boilers with heating elements, convectors, or laying heated film floors. However, there are many more options. In modern private homes, electrode or ion boilers are installed, in which a pair of primitive electrodes transfer energy to the coolant without any intermediaries.

Ion-type heating boilers were first developed and implemented in the Soviet Union to heat submarine compartments. The installations did not cause additional noise, had compact dimensions, there was no need to design exhaust systems, and they effectively heated sea water, which was used as the main coolant.

The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. Ions charged with different signs begin to move chaotically and collide. Thanks to the resistance formed, the coolant heats up.

- 1 History of appearance and principle of operation

- 2 Characteristics: advantages and disadvantages

- 3 Design and technical characteristics

- 4 Video guide

- 5 Simple DIY ion boiler

- 6 Features of installation of ion boilers

- 7 Manufacturers and average cost

History of appearance and principle of operation

Within just 1 second, each of the electrodes collides with the others up to 50 times, changing its sign. Thanks to the action of alternating current, the liquid does not divide into oxygen and hydrogen, maintaining its structure. An increase in temperature entails an increase in pressure, which forces the coolant to circulate.

To achieve maximum efficiency of the electrode boiler, you will have to constantly monitor the ohmic resistance of the liquid. At classic room temperature (20-25 degrees), it should not exceed 3 thousand Ohms.

Do not pour distilled water into the heating system. It does not contain any salts in the form of impurities, which means you should not expect it to be heated in this way - there will be no environment between the electrodes to form an electrical circuit.

Read additional instructions on how to make your own electrode boiler here

Choosing an electric heating boiler

It is impossible to say for sure about the efficiency of such heating. It should not be chosen for poorly insulated rooms, especially large private houses. Such a boiler will perfectly heat an apartment or small house, while maintaining budget savings. The popularity of boilers of this type is explained by their simplicity and ease of operation; safety also plays an important role.

access to three-phase network RusNit Bosch Dacon Elbeva is required

Boilers produced in our country have already proven themselves well and have the lowest cost; companies from the countries of Slovakia and the Czech Republic do not have much difference in price, but their equipment includes additional devices. The most expensive boilers of the German company, they are famous for their excellent quality, are equipped with devices that make their operation fully automated, and can operate from a single-phase or three-phase network.

When making a choice, first of all you need to pay attention to the technical characteristics of heating boiler models. Then navigate by price category and appearance

Electric boilers are the safest and most environmentally friendly heating devices.

Characteristics: advantages and disadvantages

An ion-type electrode boiler is characterized not only by all the advantages of electric heating equipment, but also by its own characteristics. The extensive list includes the most significant:

- The efficiency of installations tends to the absolute maximum – not less than 95%

- No pollutants or ion radiation harmful to humans are released into the environment

- High power in a housing that is relatively small in size compared to other boilers

- It is possible to install several units at once to increase productivity, or separate installation of an ion-type boiler as an additional or backup heat source

- Low inertia makes it possible to quickly respond to changes in ambient temperature and fully automate the heating process through programmable automation

- There is no need to install a chimney pipe

- The equipment is not harmed by an insufficient amount of coolant inside the working tank

- Voltage surges do not affect heating performance and stability

You can find out how to choose an electric boiler for heating here

Of course, ion boilers have numerous and very significant advantages. If you do not take into account the negative aspects that arise more often during the operation of the equipment, all benefits are lost.

Among the negative aspects it is worth noting:

- To operate ion heating equipment, you cannot use DC power sources, which will cause electrolysis of the liquid

- It is necessary to constantly monitor the electrical conductivity of the liquid and take measures to regulate it

- It is necessary to ensure reliable grounding. If it breaks down, the risk of being shocked increases significantly

- It is prohibited to use heated water in a single-circuit system for other needs.

- It is very difficult to organize efficient heating with natural circulation; installation of a pump is mandatory

- The temperature of the liquid should not exceed 75 degrees, otherwise the consumption of electrical energy will increase sharply

- Electrodes wear out quickly and need to be replaced every 2-4 years

- Repair and commissioning work cannot be carried out without the involvement of an experienced technician.

Read about other methods of electric heating at home here

Heating with electric boiler

Most often, property owners prefer an electric water boiler for heating a private home. The function of coolant in autonomous systems can also be performed by other liquids, for example, antifreeze. These devices are affordable and their installation is simple.

According to the heating method, electric boilers are:

- ten;

- electrode;

- induction.

A heating element water heater is a traditional device in which the liquid is heated by a heating element that is powered by electricity. After it transfers heat to the coolant, it circulates through the system and distributes energy to radiators located in the rooms.

This boiler is easy to install. It is equipped with a thermostat designed to maintain the desired temperature. The power consumption is adjusted by turning off a certain number of heating elements.

Among the disadvantages of such boilers, one should note the formation of scale on the heating elements, which usually leads to breakdown of the unit, especially when the water is hard. It is necessary to use special means against lime deposits.

Instead of a heating element, an electrode electric boiler has an electrode that acts on water ions, resulting in the release of thermal energy. This electric water heater is safe because it is immune to coolant leakage. If there is no water, then the device stops working.

This method of heating the coolant does not lead to the appearance of limescale, but the electrodes begin to deteriorate over time and need to be replaced. Non-freezing liquid cannot be used in such boilers - only electric water heating of a private house is allowed. In this case, water must have a specific resistance of a certain value.

An electric induction boiler consists of a radiator and a pipeline through which a coolant liquid circulates. It does not have a heating element. The emitter creates an electromagnetic field that interacts with the metal. Electricity creates vortex flows, which in turn release heat to the liquid.

The induction unit is easy to install and maintain, it has no wearing parts, it is effective for heating large rooms, and practically no scale accumulates in it. The coolant can be not only water, but also antifreeze.

It is not difficult to make such a boiler with your own hands, and it will cost much less than one made in a factory. Its significant disadvantage is the large parameters of the device and the high price when compared with heating element and electrode units.

In addition, if the integrity of the circuit is mechanically damaged, the induction boiler will not be able to operate due to dangerous temperature increases. To prevent damage to the device, it should be equipped with a sensor that will turn it off if there is no water in it.

All methods of heating suburban real estate with electric heating devices have many advantages: safety, no need to stockpile fuel, noiselessness, environmental friendliness, simple operation. But currently electricity is expensive and therefore many owners do not use this heating option.

Device and technical characteristics

The design of the ion boiler, at first glance, is complex, but it is simple and not forced. Externally, it is a seamless steel pipe, which is covered with a polyamide electrical insulating layer. Manufacturers have tried to protect people as much as possible from electric shock and leaks of expensive energy.

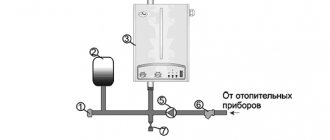

In addition to the tubular body, the electrode boiler contains:

- The working electrode, which is made of special alloys and is held in place by protected polyamide nuts (in models operating from a 3-phase network, three electrodes are provided at once)

- Coolant inlet and outlet pipes

- Ground terminals

- Terminals supplying power to the chassis

- Rubber insulating pads

The shape of the outer body of ion heating boilers is cylindrical. Most common household models meet the following characteristics:

- Length – up to 60 cm

- Diameter – up to 32 cm

- Weight - about 10-12 kg

- Equipment power – from 2 to 50 kW

For domestic needs, compact single-phase models with a power of no more than 6 kW are used. There are enough of them to fully provide heat to a cottage with an area of 80-150 sq. m. For large industrial areas, 3-phase equipment is used. A 50 kW installation is capable of heating a room up to 1600 sq. m.

However, the electrode boiler works most efficiently in conjunction with control automation, which includes the following elements:

- Starter block

- Surge protection

- Controller

Additionally, GSM control modules can be installed for remote activation or deactivation. Low inertia allows you to quickly respond to temperature fluctuations in the environment.

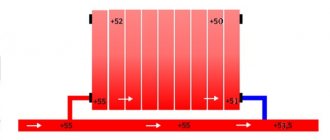

Due attention should be paid to the quality and temperature of the coolant. The optimal liquid in a heating system with an ion boiler is considered to be heated to 75 degrees. In this case, power consumption will correspond to that specified in the documents. Otherwise, two situations are possible:

- Temperature below 75 degrees - electricity consumption decreases along with the efficiency of the installation

- Temperature above 75 degrees - electricity consumption will increase, however, the already high efficiency indicators will remain at the same level

Questions - answers

What is the difference between an electrode and a heating element boiler?

In a heating element boiler, a heating element - a tubular electric heater - is heated using electricity, which then transfers its heat to the coolant. An electrode boiler works by passing current through a coolant (water or non-freezing coolant “-20 C”). The passage of alternating current cannot be called electrolysis, since only ionization of the liquid occurs. An electrode boiler is a simple and very reliable water (liquid) heater, in ideal cases it can operate without replacing elements for many years (tens of years).

What affects the performance and service life of electrode boilers?

For an electrode boiler to operate, it is necessary that the coolant has the required resistivity (conductivity). An electrode boiler is part of a heating system. To ensure reliable, long-term, trouble-free operation of the boiler, the heating system must comply with the recommended parameters in the boiler passport.

Why are heating systems based on electrode boilers usually more economical and reliable than heating elements?

Despite some difficulties when starting heating systems based on electrode boilers, electrode boilers are at least 20 - 30% more economical than heating elements. The efficiency of electrode boilers has been tested by installation and operation practice for more than 15 years. Reliability and efficiency are ensured by a simpler, more reliable design. In a heating element boiler, the heating elements are first heated, and then the heating elements release heat to the liquid. In an electrode boiler, the liquid itself plays the role of a heater. When current passes, the liquid is heated by the entire volume in the boiler. Using electrode heating of liquid, it is possible to reduce the volume of the boiler several times compared to a heating element of the same power. With a correctly assembled system, the boiler starts with low (less than 50%) of the rated power, and as it warms up it gradually gains power. Modern automation allows you to maintain a comfortable room temperature with an accuracy of +/- 0.2 degrees. C. When heating country houses, it is possible to use a weekly mode to control the heating system. Thus, efficiency in the operation of electrode boilers is achieved due to: - Less heating inertia (several times); — Smooth start; — Application of modern automation; Reliability and durability are ensured by the simplicity of the design and the use of modern materials.

How much electricity will the boiler consume?

The boiler will consume exactly that much electricity. energy, how much is the heat loss of the building. Under normal operating conditions, under normal heat losses, with the correct choice of boiler, under maximum winter conditions (when it is -23 outside for Kiev, with normal assembly of the heating system, the boiler operates for about 8 hours a day (in the mode: on - heating, off - cooling) Next, we take the boiler power and multiply it by an average of 8 hours and get the electricity consumption per day.

How to choose the right boiler?

The “ION” electrode boiler is selected according to the following parameters: - 1 kW of electrode boiler power can heat a room with an area of up to 20 sq/m, a volume of up to 60 cubic meters and 40 liters of water in the heating system. For example, a 5 kW boiler can heat a room with an area of 100 sq/m, a volume of 300 cubic meters and with the amount of water in the heating system up to 240 liters.

What pipes and radiators can be used in a heating system with an ION electrode boiler?

For heating systems, any pipes that are certified for this purpose can be used. We recommend using polypropylene.

The use of metal-plastic pipes is undesirable; connecting fittings significantly narrow the flow area; A metal-plastic pipe is often subject to deformation and delamination when the temperature of the liquid fluctuates.

You can use any modern radiators (cast iron, bimetallic), but it is best to use steel batteries. It is not advisable to use cast iron radiators, as they have a significant volume of liquid, a porous structure and contain dirt inside.

To ensure the durability and reliability of the boiler, the internal diameter of the inlet and outlet pipes and pipe fittings should not be less than the internal diameter of the inlet and outlet pipes of the boiler itself.

What are the advantages of ION electrode boilers?

The working chamber of ION boilers is made of thick special pipe material, which is very important for ionization boilers in terms of their reliability and durability.

The working chamber of almost all such boilers is made of thin-walled ordinary pipe material. The electrodes of “ION” boilers with a larger diameter are made of a special alloy, which increases their durability and reliability during the ion exchange process, and also makes it possible to generate a heat flow inside the boiler chamber at a higher speed, unlike boilers of the same boilers from other manufacturers.

“ION” boilers are presented in a wider range of models, unlike other brands of boilers, which allows expanding customer demand.

does not bind the buyer to its coolant, and ION electric boilers can be operated, unlike some boilers, with ordinary water or with a self-prepared solution in the heating system.

Can antifreeze be used as a coolant?

It is necessary to understand that antifreeze is not intended for use in heating systems. He's poisonous! It is better to use special non-freezing liquids. But since the manufacturers of these liquids do not take into account its electrical conductivity, it is possible that after pumping it into the heating system, you will still have to make preparations - set the electric boiler to the required current (this is described in detail in the operating manual). From practice I can say that usually when using non-freezing liquids, the current in the electric boiler phase is too high - and it is necessary to dilute with distilled water (approximately to the freezing temperature of -5-10 degrees).

And of course, don’t forget about the properties of antifreeze:

- The physical properties of antifreeze differ significantly from the physical properties of water. The heat capacity of antifreeze is 15-20% less than that of water, viscosity is 2-3 times higher, volumetric expansion is 40-60% greater. The values of thermal conductivity, boiling point, and other physical characteristics also differ. This means that when using antifreeze in the heating system, it will be necessary to increase the thermal power of the radiators by 40-50%, increase the volume of the expansion tank by 40-50%, increase the pressure of the circulation pump by 60%, change a number of other parameters of the heating system, including and boiler power.

- If the temperature of the antifreeze in the system, even at any one point (and most often this happens inside the heating element of the boiler), exceeds a critical value for a given brand of antifreeze, thermal decomposition of ethylene glycol and anti-corrosion additives occurs with the formation of acids and solid precipitation. Precipitation impairs the flow of coolant through the system. Acids cause corrosion of heating system metals. Also, overheating of antifreeze causes increased foaming, which leads to airing of the system, and in some cases until the foam thickens, and the formation of solid foam-like deposits. The decomposition of additives leads to the fact that antifreeze enters into a chemical reaction with sealing materials - rubber, paronite, etc., which causes leaks at the joints. In addition, the use of pipelines with an internal zinc coating is unacceptable.

- Antifreezes have the property of increased permeability or fluidity. The more threaded connections, gaskets, and seals, the higher the likelihood of a leak. Basically, leakage often occurs when the heating is turned off and the system has cooled down. Due to cooling, the volume of metal compounds decreases and, as a result, microchannels appear through which antifreeze escapes. For this reason, all connections in the heating system must be accessible for inspection and repair, which means that hidden installation of the heating system is unacceptable. Ethylene glycol-based antifreezes are toxic (single lethal dose 100-300 ml), so they cannot be used to heat water in hot water systems, since if the heat exchangers are leaking, they can get into hot water distribution points. Antifreeze vapors are also toxic and should not enter residential areas.

- If you have no other choice and you decide to use non-freezing liquid as a coolant, then you should opt for non-freezing liquid for electrode boilers "POTOK-40", but you should take into account that for this it is necessary to replace all rubber gaskets in the system heating with paronite!

Is it possible to use an ION electrode boiler in conjunction with a circulation pump?

The electrode boiler is a flow-type heater and for the correct operation of the boiler and heating system using a circulation pump, it is necessary to ensure the flow of coolant through the boiler with the following indicators:

Are pipes of any diameter used when installing an electrode boiler?

In the heating system, it is recommended to install pipes at the inlet and outlet of the electric boiler with a diameter of at least 1 inch in the heating system. After the comb, you can switch to pipes of a smaller diameter, provided that the total cross-section of the smaller diameter pipes is at least 1 inch.

How to heat a house with an area of more than 750 kW/m? What should I do if the area of my premises is 2800 kW/m?

For an area of 2800 kW/m it is necessary to install a mini-boiler room consisting of 4 “ION” 3/36 electrode boilers connected in parallel to each other. When two or more electric electrode boilers “ION” (of the same power) are connected in parallel into one water heating system, the area (volume) of the heated room increases by 2 or more times. For example: two modifications 3/36 heat an area of 1500 sq/m, with a volume of 4500 cubic meters, three modifications 3/36 heat an area of 2250 kV/m, with a volume of 6750 cubic meters, etc.

Can an electrode boiler work without a circulation pump?

The ionization chamber, where the heating process takes place, is small in size, so the coolant heats up sharply and, as a result, its pressure increases (at the maximum power of the device - up to 2 atmospheres). Thus, the ION electrode boiler can operate in heating systems without a circulation pump, if the heating system is assembled according to a natural circulation scheme.

Is it possible to connect in parallel with other boilers?

An electrode boiler can be installed in parallel with other boilers (gas, solid fuel, etc.), and used at a time convenient for you.

Do you need an ammeter or clamp meter to start an electrode boiler?

After connecting the boiler to the heating system and turning on the power, the current consumption is measured with an ammeter. If the current strength is more than that specified in the boiler passport, it is necessary to add distilled (melt or rain) water to the heating system. If the current strength is less than required, it is necessary to add caustic (baking) soda to the heating system at the rate of 30 grams per 100 liters of water, stirring the soda in warm water.

Is it possible to use the ION electrode boiler in heating systems with aluminum radiators?

Yes, this is possible, the only caveat is that instead of a soda solution, to increase the electrical conductivity of water, you need to use ASO-1 (a special product for aluminum radiators)

What liquid is used in the heating system when operating the ION electrode boiler?

When operating the ION electrode boiler, a specially prepared coolant is not required. It uses ordinary water with a specific electrical resistance of no more than 1300 Ohm cm. Since water is an element of an electrical circuit that generates heat, it needs some preparation to obtain the required electrical resistance (for example, attempts to heat distilled water will not be successful because it does not conduct electric current). Preparation is carried out experimentally - the electrical resistance of water is reduced by adding a solution of caustic (baking) soda, or increased by mixing distilled (rain, melt) water. All this is described in detail in the passport for electric boilers.

Is it possible to use the ION electrode boiler to produce hot water?

“ION” electrode boilers can work together with indirect heating boilers to produce hot water supply, for example, the “ION” 3/9 electric boiler can heat a room with an area of up to 180 m2, a ceiling height of up to 3 meters and a volume of water in the heating system of up to 360 liters, with When connecting an indirect heating boiler, you need to add power to it for hot water supply (DHW) based on the passport data of your boiler, for example 3/6 kW, in total for heating the house and DHW, you will need a boiler with a total capacity of 3/9 kW + 3/6 kW = 3 / 15 kW

Is it possible to use an ION electric electrode boiler in conjunction with a heated floor system?

A water heated floor is a closed system of pipes located in the floor screed and connected to the heating system. Metal-plastic pipes are usually used due to ease of installation. Warm floors can be used as primary or additional heating. When using a heated floor together with an ION electric electrode boiler, a greater economic effect can be achieved. A warm water floor has a number of advantages. Thanks to the large surface, the amount of radiated heat increases and is immediately transferred to surrounding objects. Thus, the warm floor ensures uniform horizontal and vertical distribution of heat over the entire area of the room.

Can you explain in simple language how to prepare the coolant?

If you use ordinary water as a coolant in your heating system, then it must be brought into compliance with GOST R 51232 “Drinking water” (1300 Ohm per cubic cm). You cannot do this at home without special equipment. But it is possible to go the other way. When putting the ION electric boiler into operation, it is necessary to measure the starting current with an ammeter using a current clamp (or a direct-connection ammeter). If at startup the current strength does not correspond to the parameters specified in the product data sheet, then the following actions should be taken:

- The current is less - you need to add the soda solution in portions (it reduces the resistivity of the liquid). The first stage is no more than a teaspoon per hundred liters of water (coolant). If after 2 hours the current increases slightly, the first stage should be repeated.

- More current - add distilled or rain (melt) water (it increases the resistivity of the liquid).

Tell me what other materials need to be purchased and what else will have to be done to get your boiler up and running?

An approximate list of additional materials and equipment for installing and launching a single-phase heating system “ION”.

Necessarily:

- Magnetic starter (contactor) corresponding to the current characteristics of this “ION” model.

- Automatic single-pole switch (automatic) corresponding to the current characteristics of this “ION” model.

- An electrical cable (electrical wire) with a cross-section corresponding to the current characteristics of this “ION” model. Electrical cable (electrical wire) for connecting the thermostat (for example 3x0.5 (0.75) or pv 3x0.5 (0.75).)

- ASO-1 (soda substitute for aluminum radiators), if aluminum radiators are installed in the system, to increase the electrical conductivity of water

Recommended optional:

- Boxing (box) for installation of start-protective equipment.

- Direct connection ammeter (clamp meter) for monitoring the workload and, if necessary, timely adjustment of the electrical conductivity of the coolant.

- The control lamp indicates the state of the boiler (heating, interruption, absence/presence of power supply in the network).

- Weekly programmer SALUS FL09 for additional energy savings and more comfortable use of the heating system

Protective grounding is MANDATORY! Heating system:

To facilitate the operation of the ION boiler and significantly save energy, it is advisable to use a circulation pump. The heating system should be provided with additional valves for convenient maintenance, installation and dismantling of the boiler and pump.

What is better than three-phase boilers?

It all depends on what voltage you have - 220 or 380. If you have the opportunity to install the boiler on three phases 380V. , From 3/6 kW, this gives you additional benefits. Three-phase boilers have three electrodes installed, which can be turned on in stages, for example, the “ION” 3/6 kW boiler has three 2 kW electrodes installed; during off-season periods, when it’s + 10 degrees outside, you don’t need to turn on the boiler at full power, but It is enough to turn on one electrode. If you do not have three phases, then you can install a three-phase boiler on one phase. The phase is divided into three outputs and connected via automatic circuit breakers to three electrodes. It is advisable to use three-phase boilers from 100 sq.m.

What problems can arise when installing copper pipelines?

When assembling a heating system from copper piping, an important issue is the connection of copper with other metals in the same water circulation system. When copper is directly combined with steel, galvanized steel or aluminum, an electrochemical reaction occurs, causing the rapid dissolution of iron, zinc and aluminum. And also, pipes cannot be used as grounding elements for electrical equipment. To eliminate this phenomenon, it is necessary to separate these metals from the copper with an insulating gasket. Even in the absence of a metal joint, copper stimulates corrosion of the above materials. This process is the result of copper ions (Cu2+) being precipitated and penetrating into the water during the uniform corrosion of copper surfaces. Ions are deposited in places where corrosion pits have already occurred, causing accelerated destruction of the base material (steel, galvanized steel, or aluminum). The most dangerous forms of corrosion include ulcerative and erosive. Pitting corrosion is local corrosion of metal that occurs in places where the oxide protective film covering the internal surfaces of pipes in contact with water is destroyed. In cold and hot water pipes, the following factors make it difficult to form a protective film or damage an existing film:

- incorrect chemical composition of copper,

- improper preparation of the internal surfaces of pipes during their production,

- Solder leakage on the inner surface of the pipes,

- the presence of solid particles inside the pipes (for example, sand) that entered the installation during installation or during operation (hence the requirement to filter the water both supplied to the system and used to flush it).

Erosive corrosion is caused by turbulent flow of water near the walls of pipes. Thus, it is important to comply with the design water flow rate, as well as to exclude local resistances, such as narrowings, solder sagging, and improperly executed outlets.

In heating systems, the combination of steel and copper is permissible only if the oxygen content in the water does not exceed 0.1 mg/dm3, which is practically possible only in closed systems. Even in a closed circulation system, it is not recommended to use copper and aluminum radiators in the same circuit.

Simple DIY ion boiler

Having become familiar with the features and principle by which ion heating boilers operate, it is time to ask the question: how to assemble such equipment with your own hands? First you need to prepare the tools and materials:

- Steel pipe with a diameter of 5-10 cm

- Ground and neutral terminals

- Electrodes

- Wires

- Metal tee and coupling

- Persistence and desire

Before you start putting everything together, there are three very important safety rules to remember:

- Only the phase is supplied to the electrode

- Only the neutral wire is supplied to the housing

- Reliable grounding must be provided

To assemble an ion electrode boiler, just follow the following instructions:

- First, a pipe 25-30 cm long is prepared, which will act as a body

- Surfaces must be smooth and free of corrosion, nicks at the ends must be cleaned

- On the one hand, electrodes are installed using a tee

- A tee is also necessary to organize the outlet and inlet of the coolant

- On the second side they make a connection to the heating main

- Install an insulating gasket between the electrode and the tee (heat-resistant plastic is suitable)

- To achieve a tight seal, the threaded connections must be precisely adjusted to each other.

- To secure the zero terminal and grounding, 1-2 bolts are welded to the body

Having put everything together, you can embed the boiler into the heating system. Such homemade equipment is unlikely to be able to heat a private home, but for small utility areas or a garage it will be an ideal solution. You can cover the installation with a decorative casing, while trying not to restrict free access to it.

The best manufacturers

Due to their advantages, ion boilers remain very popular sources of heat supply on the Russian market.

They are produced by a number of domestic factories, and there are also models from Western manufacturers.

General overview of the most popular brands:

- "Galan", a boiler unit from a Moscow company. The company produces several basic models on a 220 V network: "Ochag", "Turbo" and "Geyser", and on a 380 V network - "Vulcan". For the devices you will need to buy a main control unit "Navigator", a circuit breaker "ABB", a thermostat "BeeRT", which controls the performance of the circulation electric pump.

- Electrode ion boilers Beryl, a Russian manufacturer, are available in 2 standard sizes for a 220/380 V network and, accordingly, with a power of 9/33 kW. It has a top-mounted power supply unit, which simplifies installation and maintenance. It is necessary to additionally purchase a “Euro” CSU unit, which allows for stepwise control of the coolant heating power every 200 W.

- Electrode boilers of the EOU brand of a domestic manufacturer, with a power range from 2 to 120 kW, in a 220/380 V network.

- "Forsazh" of the Ukrainian manufacturer are equipped with a special protective casing that increases safe operation and has a designer appearance. It is presented in 5 modifications for a 220 V network, with a power from 3.0 to 20 kW, which are equipped with an ECRT control unit.

- STAFOR, a Latvian manufacturer, complies with EU requirements. The design has a number of innovative solutions, including the use of a “Faraday cage” with distribution of safety and working zero. Together with it, it is possible to buy a branded coolant and a specialized additive STATERM POWER, which allows timely adjustments to the chemical composition of the electrolyte to regulate the efficiency of the boiler.

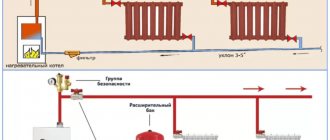

Features of installation of ion boilers

A prerequisite for installing ion heating boilers is the presence of a safety valve, pressure gauge and automatic air vent. The equipment must be placed in a vertical position (horizontal or at an angle are not allowed). At the same time, about 1.5 m of supply pipes are not galvanized steel.

The zero terminal is usually located at the bottom of the boiler. A grounding wire with a resistance of up to 4 ohms and a cross-section of over 4 mm is connected to it. You should not rely solely on RAM - it cannot help with current leakage. The resistance must also comply with the rules of the PUE.

If the heating system is completely new, there is no need to prepare the pipes - they must be clean inside. When the boiler crashes into an already operating main, it is necessary to flush it with inhibitors. The markets offer a wide range of products for removing deposits, salts and scale. However, each manufacturer of electrode boilers indicates those that it considers best for its equipment. Their opinion should be followed. By neglecting flushing, it will not be possible to establish the exact ohmic resistance.

It is very important to select heating radiators for the ion boiler. Models with a large internal volume are not suitable, since 1 kW of power will require more than 10 liters of coolant. The boiler will constantly work, wasting some of the electricity in vain. The ideal ratio of boiler power to the total volume of the heating system is 8 liters per 1 kW.

If we talk about materials, it is better to install modern aluminum and bimetallic radiators with minimal inertia. When choosing aluminum models, preference is given to primary type material (not remelted). Compared to the secondary one, it contains fewer impurities, reducing the ohmic resistance.

Cast iron radiators are the least compatible with an ion boiler, since they are the most susceptible to contamination. If it is not possible to replace them, experts recommend observing several important conditions:

- The documents must indicate compliance with the European standard

- Installation of coarse filters and sludge traps is required

- Once again, the total volume of coolant is produced and equipment suitable in terms of power is selected

The best European electrode heating boilers

It so happens that European brands deserve more trust from us. Objectively, some models are indeed an order of magnitude better than domestic ones, but lack of adaptation to our conditions makes them fail very quickly, and repairing them is not always profitable.

Buderus Logamax E213-10

A model from a famous German brand, which is traditionally distinguished by its impeccable performance, high quality, reliability and durability. Power 9.9 kW, recommended for connection to a three-phase network with a maximum current of 15 A for three phases. Wall installation. The package includes a circulation pump and an expansion tank.

Buderus Logamax E213-10

Let us highlight the main advantages of this device:

- light weight and compact dimensions.

- Easy installation - brackets included.

- steel body with excellent thermal insulation.

- Efficiency 99%.

- The kit includes a 7-liter expansion tank, a circulation pump, a safety valve, a pressure control sensor, and a blocking sensor that protects the housing from overheating.

Minus - Buderus Logamax E213-10, like all German equipment, is designed for a stable voltage in the electrical network. Therefore, for long-term operation of the device, you need to take care of purchasing a stabilizer.

The cost of the unit will cost on average 38,000 rubles.

Operating instructions Buderus Logamax E213-10

Protherm Skat 24 KR 13

One of the best electrode boilers of the Czech brand, the power of which is 24 kW. The single-circuit model for wall mounting is distinguished by functionality, safety in operation and durability. Can be connected to a “warm floor” system or a boiler for heating hot water. The package includes 4 heating elements, a circulation pump and a 7-liter expansion tank.

Protherm Skat 24 KR 13

Let's highlight a few more advantages of the unit:

- electronic control with power indicator, display and thermometer;

- 4 power levels;

- Possibility of temperature control in the range of 30-85°C;

- overheating safety system;

- high efficiency – 99%;

- soft start function;

- presence of a safety valve and air vent.

Among the minuses, it is worth noting that the boiler is too noisy and needs to be connected through a voltage stabilizer.

Cost – from 43,000 rubles.

Operating instructions for Protherm Skat 24 KR 13

Evan Warmos QX-18

One of the best domestically produced electrode boilers, which some users call a mini-boiler room - one device contains heating elements, a membrane tank, and a circulation pump.

Evan Warmos QX-18

Let us note the strengths of the device:

- LCD display at the bottom of the case;

- convenient control panel, which is hidden behind a special door;

- the operation is controlled by a microprocessor, but the boiler can also be switched to manual control;

- suitable for heating residential and industrial facilities;

- silent operation;

- emergency condition indication;

- coolant pressure and level sensor.

Like any other device, the Evan Warmos QX-18 also has disadvantages - heavy weight, large dimensions, frequent capacitor failures, mandatory connection through a voltage stabilizer.

The cost of the device is from 49,000 rubles.

Operating instructions Evan Warmos QX-18

Design Features

An electric boiler is a device consisting of several basic elements:

- a tank with water that enters and leaves after reaching a certain temperature;

- heating element (there are different types);

- thermostat (temperature sensor and adjustment device);

- a circulation pump that ensures stable movement of fluid in the system.

There are simpler models, consisting of a regular tank, two pipes for connecting the forward and return heating lines and a pipe for make-up (connection to the water supply).

There are more complex devices capable of executing programs and changing the operating mode in accordance with them.

The most common are boilers that use heating elements. As a rule, several pieces are installed so that the heating mode can be adjusted, turning on one or more heaters in turn.

These units are considered the most inefficient, since their energy consumption is high and their durability is relatively short.

Another type of heating elements are electrodes. Metal rods are simply lowered into the water, to which phase and zero are supplied. Most often, zero is supplied to the metal body, and the phase is supplied to a rod immersed in water inside the container.

Water conducts electricity, creating a potential difference. The water is heated naturally and leaves the tank. Such boilers are very reliable and durable, but their electrodes gradually dissolve and require replacement.

The newest type is the induction heater. It consists of a coil with a massive dielectric core that heats up when the coil is connected to a power source. This design has high efficiency and is the most durable device of all currently existing varieties.

When choosing one or another unit, it is necessary to take into account its operating mode and load level. If it is large, models with heating elements will not be suitable. The best option would be an induction boiler, but it is quite expensive.

It is possible to make a homemade induction heater that works no worse than a factory one and does not require too much assembly costs.

Economical electric boiler for heating: myth or reality

Some manufacturers repeat like a mantra what kind of energy-saving electric heating boilers they make. The benefits are simply colossal; it comes to the point that the efficiency of the units reaches as much as 400%. It’s incredible, you might think, it would be a shame not to take advantage of such a benefit.

What is the deception? Everything is quite simple, there are laws of physics, which, although many scientists are trying to challenge, are still to no avail. One of the laws is the law of conservation of energy. It is better to call it the principle of conservation of energy, according to which energy passes from one state to another with complete preservation of its value.

Based on this, we can conclude that even a supposedly energy-saving electric heating boiler will give out exactly as much energy as it consumes, no more, no less. In addition, when product data sheets say that the efficiency of the unit is 98% or 95%, this is all sheer nonsense. The efficiency of any heater is exactly 100%. We talked about the operating principle of electric boilers last time.

It turns out that a priori there cannot be any economical electric boilers for heating. The only difference may be the method of converting electrical energy into thermal energy and the speed of this process. A list of questions to ask when you are offered to buy the most economical electric heating boiler:

- whether errors were found in the law of conservation of energy;

- whether Noether's theorem has been refuted;

- has the mystery of Nikola Tesla been solved?

- whether the developer received the Nobel Prize.

How does everything work in practice? All electric heating boilers have exactly the same energy consumption. To heat a liter of coolant by one degree, the boiler spends 0.001 kW of energy. The device works as an intermediary. It takes energy from the network and converts it into heat, heating the water. How he does it doesn't matter. All the same, he will give back exactly as much as he took, leaving nothing for himself. Even that small part that heats not the coolant, but the body, is still ultimately transferred to the air. Why then did they come up with the term economical electric boiler for heating a private home?

Marketing and more marketing. If you have a choice between a simple unit and an economical electric heating boiler, which one will you choose? Of course, the second one. Considering the fact that this is a special device, it is natural that the latest highly complex technologies were allegedly used for its production. They are very expensive and require a lot of labor. It’s no wonder that an economical electric boiler for heating a house will cost more, but then what benefits does its owner promise. All this in order to increase sales. Oh, this wild capitalism that came to us from the West.

Superimposed on this is general illiteracy and unwillingness to understand the essence of the matter. On the contrary, it is said that this is an economical electric boiler for heating a house, which means that it is so, because no one wants to admit even to himself that he was simply cheated. People buy them, and then intensively look for benefits during operation and find them. It is only interesting what their conclusions are based on, if, most likely, the boiler purchased by the economical is the first in their practice and there is nothing to compare it with.

Therefore, do not believe advertising, be skeptical and check everything down to the smallest detail. If manufacturers really made such a breakthrough, then why are they silent about it? Let them announce their discovery to the whole world. For this they are promised not only the recognition of their colleagues, but also a significant monetary reward in the form of the Nobel Prize.

Coolant

Electrode boilers are sensitive to the composition of the coolant. In accordance with the requirements of the manufacturers, only distilled water should be used, to which table salt is added, approximately 80-100 grams for every 100 liters. The difficulty lies in the fact that the final density and conductivity of the solution must be in strict accordance with the manufacturer's requirements. It is impossible to determine the exact amount of salt, and it can give different results depending on its composition. The final preparation of the solution is carried out locally, based on the actual current values in the electronic boiler. The instructions for the device provide a table of the required values depending on the boiler power, coolant volume, etc. By adding distilled water or salt, the coolant resistance is brought to ideal.

Only compounds provided by the boiler manufacturer are used as antifreeze. When they are used, the proportion of salt in the solution also changes.

There is a mandatory requirement before using an electronic boiler in an existing heating system in parallel with another boiler. The entire system is washed, cleaned of scale and salt deposits, which can subsequently change the conductivity of the coolant.

Connecting the thermostat to the boiler

Energy saving is also affected by the accuracy of the boiler operation. By default, the boiler is configured to operate according to the coolant temperature. But you can induce the boiler to turn on and off at room temperature.

The air cools much slower than the heating system. Therefore, the boiler will turn on less often and at the same time work longer (which is quite useful for gas boilers). With this option, you can increase energy savings during heating operation by 5-15%.

Features of electronic models

Devices based on remote-type sensors and a programmable microprocessor with control buttons allow you to set the desired temperature conditions. Digital models with electronic support offer different heating modes, and the memory of programmable thermostats often features preset profiles that can be easily changed to the user's desired values.

Weather-dependent (meteo-controlled) regulators

A feature of high-tech devices is the ability to control the heating system in accordance with the external temperature conditions. The street sensor is mounted on the outside of the household, on the north side of the building, and water treatment in the system is provided by a controller (programmer). Thermal comfort and fuel economy may require installation of an additional sensor inside the heated room.

Which electric boiler to buy in Moscow for a summer house or private home

Flow-through electric boilers are of two types: electrode and heating element. The first option, with a power of 3 kilowatts, heats 50 square meters, spending about 0.5 kW per hour. A heating element boiler with the same power is capable of heating only 30 square meters and for this it requires more than 1 kW per hour. From this it can be seen that the electrode boiler is more economical in terms of electricity consumption. And the service life of electrode boilers is higher. This is explained by the fact that water is heated according to the cathode-anode principle from an electrical element. In this case, the coolant is an element of the electrical circuit.

If you don’t know which boiler to buy, how to choose an economical and at the same time reliable option, you shouldn’t rely on power. High power is not always needed; it is more important to evaluate the required heating area and, based on this, make a purchasing decision.