The issue of high-quality protection of apartments from noise pollution most often worries residents of newly constructed multi-storey buildings. Based on numerous reviews from residents, we can conclude: they are often bothered by noise from upstairs neighbors. As you know, they can be shock (falling heavy objects, intense walking), airborne (working TV, loud screams). The latter can be avoided with the help of ordinary ceiling soundproofing; in other cases, thorough insulation from noise will be required. This process is complex and not cheap at all. To obtain an effective result, it is important to choose the right design and purchase high-quality material.

Poor sound insulation of most modern houses is a huge problem for residents Source potolokgid.ru

Types of ceiling sound insulation

It is possible to make effective sound insulation of the ceiling covering in an apartment with or without a frame. In the first case, the procedure will be labor-intensive and financially expensive, in the second it will be simpler, but at the same time effective. But the best option to protect your home from impact noise coming from the upper apartment is to equip the latter with a soundproof floor. If the neighbors agree to the repair, then it will be financially more profitable to pay for the installation of a protective floor covering than to soundproof your ceiling.

Frameless

There are several different ways to soundproof a ceiling without creating a frame. The simplest of them is to use ZIPS. Such sandwich panels are easy to install: parts pre-coated with acoustic sealant are connected by joints (groove/tongue). Special fasteners are used for fastening to the ceiling. Ultimately, the created structure is carefully sheathed first with gypsum plasterboard, then with plasterboard sheets.

Important information! A damper tape should definitely be laid between the ZIPS panels and the wall. In addition, it is used for processing communication pipes.

Another method of soundproofing the ceiling from external impact noise is to stick mineral wool slabs onto the ceiling surface. Additionally, they should be fixed with special dowels (about five pieces per element).

It is also recommended to use a self-adhesive membrane to create frameless sound insulation for the ceiling covering. After preliminary application of the primer, it is attached to the treated surface as the first layer. Then GVL sheets are laid, and at the final stage - drywall.

The frameless method of soundproofing the ceiling in an apartment is considered less labor-intensive, since it completely eliminates the installation of complex structures Source cs10.pikabu.ru

Frame

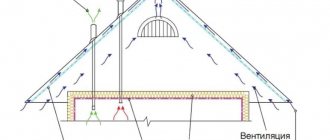

In general, frame sound insulation is an improved version of the traditional suspended ceiling, which has gained considerable popularity due to its high efficiency. In addition to significantly reducing noise levels, it is able to solve the problem of leveling the ceiling covering and changing its configuration. It is worth noting that the improved points relate to the methods of attaching the frame. The latter should not come into contact with walls or floor slabs.

To create frame ceiling sound insulation, you must perform the following steps:

- Using vibration suspensions, attach the frame to the ceiling.

- Place a vibration-isolating gasket between the latter and the wall.

- Lay mineral wool slabs.

- Cover the surface with gypsum fiber sheets.

As a rule, plasterboard sheets are used to finish the ceiling.

To create a reliable frame, a metal profile or wooden beam is most often used Source antkachev.ru

Installation of false walls on the frame

Now the owner needs to provide a basis for further fastening of decorative materials. Plasterboard panels are great for this purpose. They are attached to the frame structure using self-tapping screws. It is better to leave gaps of approximately 2–3 mm between adjacent sheets. After installing the drywall, the seams are puttied.

Having completed these activities, the owner can proceed to finishing work. Paint is applied to the frame, wallpaper or other materials are glued if they are not too heavy. As a result, the wall will turn out beautiful and reliably protected from noise penetration.

Source

Ceiling soundproofing: materials

At first it seems that for proper soundproofing of the ceiling it is possible to use many different building materials. But if you remove ineffective ones from this list, then in the end there will be a small number of them left.

Mineral wool

For high-quality ceiling protection from noise, a material with a density of more than 45 kg/m3 is suitable. It can be mounted with or without a pre-built frame. For the most part, mineral wool insulates from airborne noise. If you additionally need to get rid of shock, then it is advisable to combine cotton wool with GVL. In this case, only a frame structure will do.

Important! If the slabs are fastened with the help of fungi, then they must certainly be soundproofing.

It is possible to soundproof a ceiling with mineral wool using both frame and frameless methods Source maximuscentr.com.ua

ZIPS panels

They are made from mineral wool and gypsum fiber sheets. Such products come in different thicknesses: within 5-13 cm. Special vibration units are built into them so that noise is not subsequently transmitted through the fasteners. It is advisable to focus attention on their availability and quality even at the stage of purchasing such material.

Installing ZIPS panels does not take much time. The work can be done with your own hands, without involving specialists. The effectiveness of the design will largely depend on the thickness of the products used. Therefore, if the height of the ceilings allows, then it is better to purchase the thickest option. Drywall is used to finish the surface.

Soundproofing the ceiling with ZIPS panels does not require the installation of a frame and can be done quite quickly Source stroy-podskazka.ru

Stone wool installation options

Depending on your goals and the type of noise you want to get rid of, stone wool can be installed as follows:

- from the outer surface of the wall;

- on the inside of the walls and ceiling, well hidden under drywall;

- inside frame walls;

- insulation of pipelines and engineering structures that are a source of noise and vibration;

- under the roofing material.

Stone wool is available in the form of mats and slabs. If you consider that for sound insulation you need low-density cotton wool, then it is better to take mats - it will be easier to work with them. In addition, the slabs tend to crumble, so it is better to additionally use a layer of vapor barrier.

The article was written for the site.

Tags:Soundproofing

Sound insulation for suspended ceilings

When soundproofing the ceiling covering with special materials, it is possible to avoid the spread of dust and dirt throughout the apartment and not damage previously carried out repairs. It is easy to protect furniture items using plastic film and masking tape. In this case, things will not be damaged at all.

Attention! The installation of soundproofing materials should be carried out by professionals. The slightest violation of the technology of their fastening can lead to a decrease in the noise absorption coefficient and deteriorate the technical characteristics of the products used.

When performing sound insulation under a suspended ceiling, it is important to strictly follow the technology for performing all stages of work Source nevapotolok.ru

Any porous structure must be used correctly, special attention must be paid to fastening. The huge dimensions of the apartment do not allow beginners to cope with such a task. Before starting any work, it is necessary to clear the room as much as possible of furniture so that they do not interfere with the installation process.

Extraneous sounds enter the home from all sides, irritate its inhabitants, and do not allow them to fully rest. Even high-quality sound insulation of the ceiling from impact noise does not completely solve all problems. Achieving silence in an apartment is only possible with additional comprehensive insulation of the floors, walls, and windows. Considering the fact that most sounds penetrate through the ceiling covering, it should be provided with soundproofing materials first.

As you know, noise travels faster through a hard surface. Soft, slightly loose building materials dampen strong sound vibrations to a greater extent. In addition, the air gap present between the base and the suspended ceiling perfectly absorbs noise pollution.

Soft, slightly loose materials perfectly absorb sound vibrations, and the presence of an air gap only improves this process Source sotdelkoi.ru

It is worth noting that a layer of air also remains when creating other ceiling structures. Therefore, it is important to pay attention to the following points:

- Most modern cladding products are hard, which is why they practically do not block the penetration of sounds.

- Suspended ceilings are completely connected to the base, while suspended ceilings are most often attached to the walls and do not touch the base at all. Therefore, the quality of sound insulation of the latter is much higher.

- The stretched film web has excellent sound-absorbing characteristics.

- The design of most suspended ceilings allows layers of special soundproofing products to be placed in the interceiling space.

Today, manufacturers offer a huge range of soundproofing building materials, which differ in composition, size, and method of fixation on the surface. Therefore, it is better to entrust their choice to an experienced specialist.

Composite materials, consisting of many layers (fibrous, porous), best absorb external noise. It is also recommended to pay attention to natural high-quality products (for example, bamboo fiber), especially since the latter have an average cost.

Important! When arranging sound insulation from impact noise under a suspended ceiling, it is undesirable to use polystyrene foam or polystyrene foam. They are characterized by a low sound absorption coefficient.

When soundproofing with foam plastic, a too thick layer of material is used, which requires a lot of space for installation Source sotdelkoi.ru

Why is silence needed?

Excessive noise levels are dangerous to people. Extraneous acoustic waves surround a person on the street, at work and at home. The constant noise increases stress, increases fatigue and causes cardiovascular disease. Due to sound pollution, the population of megacities loses several years of life.

Residents of high-rise buildings especially suffer from extraneous noise. Scientists distinguish 3 types of sounds:

- Drums. Appear during movement (clatter) or mechanical actions (clatter from tools). Acoustic waves penetrate through partitions and soil.

- Structural. Noise occurs during the operation of engineering systems in a building (plumbing, pump).

- Airborne. The sound of voice, audio and video equipment.

According to sanitary standards, the volume in residential premises during the day should not exceed 65 dB, at night - 45 dB. Background noise of 120 dB is a dangerous threshold that should not be crossed. For comparison, a child’s cry is 80 dB, 100 is high-speed traffic, 120 is a rock concert.

Soundproofing walls will help eliminate negativity. Silence relieves fatigue and stress that have accumulated throughout the day and promotes healthy sleep. Without constant hum or rumble, you can focus on a specific task, which is important for schoolchildren and students.

How to make your home quiet Source di-eco.ru

After soundproofing the interior walls, sounds not only do not enter the room, but also do not leave them. Acoustic flow limitation is perfect for families with small children and music lovers. If noise is contained, there will be no problems with neighbors.

Acoustic room Source static-sl.insales.ru

How to make high-quality sound insulation under a suspended ceiling

As a result of creating the structure, a little free space remains between the stretched fabric and the ceiling. This air gap to some extent reduces the noise level inside the room. But since the air density is low, it is not possible to completely get rid of noise in this way. The best way out in such a situation is to fill the air layer with high-quality porous or multi-layer soundproofing material. It is desirable that the noise absorption coefficient be high. Many building materials have these properties.

For example, safe basalt panels weigh little, are easy to install, and last a long time. Polystyrene foam is also a fairly lightweight material; it is attached with glue and does not require additional costs.

Multidirectional basalt wool fibers with air voids effectively dissipate sound waves and convert noise energy into heat Source i2.wp.com

Minuses

It’s not in vain that we spent so much time considering the main characteristics. Without this, it is impossible to say which is better, basalt wool or mineral wool. Despite its advantages, stone slabs also have their disadvantages. This is primarily a high cost. In addition, slab basalt insulation has a large number of seams at the joints, which somewhat reduces the insulating properties. Some experts argue that the phenolic substances used in the manufacture of the material make it unsafe. There have been no tests that could confirm or refute this.

Sound insulation under plasterboard ceiling

Proper placement of a layer of soundproofing material under the drywall will reliably protect the apartment from the penetration of extraneous irritating sounds. If such building material is placed on the floor of the neighbors above, the result will be much better. But since this is not always possible to do (for various reasons), residents often have to use any available options.

Achieving the desired result is not so difficult. To do this, the empty space between the base and the drywall should be filled with highly effective noise-absorbing material, and the frame base should be made on hangers that can dampen vibrations. When installing such structures, it is necessary to strictly follow the technology and correctly select modern soundproofing products and components for plasterboard sheets.

The created metal frame hangs only on vibration suspensions; it is not attached to the walls in any way Source pikabu.ru

Noise occurs as a result of air vibrations caused by some activity. As a rule, a sound insulation system works according to the following principles: it absorbs or reflects waves. Accordingly, the components of suspended ceilings function as follows:

- The drywall itself works like a large membrane: it is placed on special hangers and reflects or dampens incoming sound vibrations.

- Any fillers (acoustic membranes, mineral wool, polystyrene foam, felt compounds) significantly improve the process of eliminating vibrations.

A successful combination of pronounced reflective and absorbing properties allows you to subsequently obtain an effective option for sound insulation of gypsum fiber board ceilings. When selecting fillers for such a design, you should carefully familiarize yourself with the different types of soundproofing materials and study their positive and negative aspects.

The seams formed after installation of drywall should be sealed with silicone sealant Source pikabu.ru

Advantages and disadvantages of stone wool

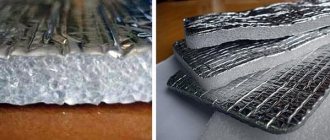

Stone mineral wool is an inorganic fibrous material, the raw materials for which are various rocks: basalt, gabbro, diabase. In English it is literally called "mountain wool". Indeed, in appearance the material is similar to tangled wool fibers.

The material production technology is as follows. The crushed stone is melted in a furnace at a temperature of 1500°C to a liquid state. Then, in a centrifuge, under the influence of air currents, the finest fibers are formed. Individual fibers are connected with a special binder, to which a water repellent is added for moisture resistance. And only after heat treatment, the resulting “carpet” is cut into pieces and packaged.

Thanks to this base, stone wool has excellent performance and strength characteristics. Among the main advantages of the material:

- reliable heat and noise insulation. The fibrous structure absorbs sound up to 50 dB or more. At the same time, stone wool is one of the most effective insulation materials, i.e. you can kill two birds with one stone;

- durability;

- non-flammability. The basis of the material is stone, which melts at very high temperatures, so cotton wool is not afraid of fire, in case of fire it does not burn or melt;

- water-repellent properties;

- high tensile strength, especially in comparison with other soundproofing materials;

- resistance to chemically active substances;

- the material is not afraid of rodents, fungi and bacteria do not appear on it. Ultraviolet rays and temperature changes do not affect it;

- cotton wool is not able to absorb moisture. At the same time, steam passes through it without any obstacles - this is a very important property. Thanks to good vapor permeability, excess moisture and condensation evaporate and are removed from surfaces for which they are harmful;

- relative ease of installation.

critical drawback - stone wool slabs are quite brittle, so you should be extremely careful when transporting them.

How to make ceiling sound insulation under plasterboard

Typically, the sequence of work on constructing a protective structure is as follows:

- Mark lines along the entire perimeter of the room (along the walls) for installation of guide profiles. When you plan to create a single-level ceiling, such markings will be its lower boundary.

- The distance from the ceiling should be sufficient for laying soundproofing materials and laying wiring for lighting design. The minimum distance between the future suspended ceiling and supporting structures is 10 cm.

- Using damper insulating tape, install guide profiles along the previously outlined lines. Fixation is carried out with nails (the step between the fastening points is 40 cm).

- Place a soundproofing membrane on the ceiling and secure it securely using umbrella dowels.

- Along the width of the room, mark lines for mounting the main frame slats, attach vibration suspensions at a distance of 80 cm from one another. There should be about 60 cm between the transverse profiles. To attach the hangers, nails are used, which are carefully driven into the base slab.

- Insert rack profiles into the guides and securely secure them with self-tapping screws. Cross slats are mounted in a similar way.

- Place mineral wool (or other similar products) into the finished sheathing, carefully cover it with a vapor barrier, then lay the wiring for future connection of lamps.

- Using standard technology, cover the frame with plasterboard. In this case, it is important to remove the wire for the purpose of further arrangement of the lighting system. The pins for attaching finishing gypsum fiber sheets should be located at a distance of about 20 cm from one another.

If the height of the room is small, it will not be possible to lower the ceiling enough. Therefore, for lighting equipment it is better to use overhead as well as suspended light sources. Spotlights installed in very tight spaces (between mineral wool and sheets of drywall) may subsequently deteriorate due to excessive overheating.

Laying soundproofing material is carried out only after the creation of a reliable frame structure is completed Source dekoriko.ru

Video description

Instructions for gluing cork wall coverings.

Polyurethane boards

The second name of the material is acoustic foam. Foamed polyurethane dampens the slightest sound waves and provides ideal acoustics in the room. The thickness of the slabs is no more than 1.5 cm, so the raw material does not take away useful centimeters in small rooms.

Soundproofing polyurethane foam is simply glued or screwed to the wall. The products are lightweight and convenient in size, so installation can be carried out without an assistant. The raw materials do not stink, and the variety of designs and colors will harmoniously fit into the interior of the room.

Polyurethane slabs Source yanashla.com

High price is the main disadvantage of polyurethane boards. Acoustic foam was developed for recording studios, so the material is suitable for musicians, film and music lovers. Due to its porosity, the raw material absorbs moisture, which limits its use in damp rooms. The foam surface is very soft, without protection it will easily tear from mechanical stress.

Mineral wool

Fibrous soundproofing material is produced in the form of sheets or plates. The general name often refers to several types of raw materials:

- basalt;

- ecowool;

- glass.

If you need cheap soundproofing of walls, then it is better to use mineral wool. The material combined with an absorbent component and drywall provides good insulation and noise reduction. The thicker the stand, the less sound will penetrate the room. Due to the frame fastening, the structure can take up to 12 cm of area, which is not suitable for tiny rooms.

Soundproofing agent Source ecoacoustic-spb.ru

Basaltine

Very thin basalt fiber of staple weaving, stitched with glass thread or basalt rope. It is resistant to temperature changes, therefore it is often used in baths and saunas for sound and heat insulation.

Photo: basaltine

Pros:

- elastic and elastic material;

- good thermophysical characteristics (l= 0.036);

- application in the temperature range from – 260°C to 700°C;

- resistant to mechanical stress;

- durable.

Minuses:

- dusty;

- considerable cost.

EcoZvukoIzol panels

Seven-layer profile made of cardboard with quartz sand, 13 mm thick and weighing 18 kg.

Photo: EcoZvukoIzol panels

Pros:

- noise insulation index up to 38 dB;

- frameless installation;

- can be cut.

Minuses:

- heavy weight;

- During installation, sand may spill out.

Cork panels

Thanks to its cellular structure, cork is an excellent natural sound-proofing material.

Photo: cork panels

Pros:

- frameless installation - panels are glued with contact adhesive to a leveled wall;

- no finishing is required - the cork has an original design and looks great in the interior;

- absolutely environmentally friendly and hypoallergenic material;

- antistatic – does not attract dust and does not electrify;

- good thermal insulation properties;

- long service life.

Minuses:

- high price;

- without special treatment – flammable;

- easy to damage if handled carelessly, subject to mechanical stress.

MaxForte ECOstove PRO

Basalt slabs made of volcanic rock have a high sound absorption coefficient αW at all frequencies. Designed for soundproofing rooms with high requirements - recording studios, theaters, etc.

Photo: MaxForte ECOstove PRO

Pros:

- maximum class “A” for sound absorption;

- sound absorption index – 0.98;

- high density;

- homogeneous structure;

- environmental friendliness;

- fire safety.

Minuses:

- vapor barrier is required in wet areas;

- risk of shedding during installation.

Craft

Kraft cardboard with wax paper and wood fibers. The thickness of 1.2 cm does not reduce the usable area of the room. Sticks to the wall, sound absorption is up to 23 dB.

Photo: Kraft cardboard with wax paper

Pros:

- frameless installation;

- high strength material;

- light weight;

- environmentally friendly;

- inexpensive.

Minuses:

- cannot be used in wet areas;

- susceptible to attack by insects and rats;

- flammable

Required Tools

Correct installation of frameless sound insulation can only be ensured if you have the necessary tools. The list of tools is small, but all elements must be present.

Photo: Sealant required. Author: Dmitry Kotov

To install sound insulation you will need the following tools:

- A stiff brush to clean the ceiling surface from dirt and peeling layers of finish.

- A tape measure is used to measure dimensions and select the most accurate material.

- An embossed spatula with which to apply the adhesive solution.

- Adhesive mixture in ready diluted form. Today in construction stores you can buy glue, which is intended specifically for the installation of soundproofing materials.

- Construction level, to achieve the most even sound insulation surface.

- Fixing dowels or as they are also called fungi.

- In case of drilling holes, you will need a hammer drill and a Pobedit drill bit with a diameter of 6 mm and a length of 16 centimeters.

- Soundproofing material selected according to requirements and characteristics.

If you have all the tools, installation work is quite simple, and if you have the skills of a builder, then all the processes can be completed independently with your own hands.

Texound

The Texaund membrane is made of pure aragonite with a complex of necessary polymers.

Photo: Texound membrane

Pros:

- high level of sound absorption;

- elasticity is maintained at temperatures down to -20 ° C;

- small thickness;

- resistance to moisture and biological damage;

- environmentally friendly material;

- low-flammability and self-extinguishing;

- universal;

- durable.

Minuses:

- the wall needs to be leveled and primed;

- significant weight;

- high price;

- sheet length – 5 m.

Isolite

Non-combustible slabs consist of basalt fibers coated with polymer compounds.

Photo: Isolite

Pros:

- high sound insulation properties;

- excellent vapor permeability;

- low thermal conductivity;

- versatility;

- tear resistance;

- light weight;

- resistance to mold and mildew;

- fire safety;

- environmental friendliness;

- durability.

Minuses:

- vulnerability to prolonged exposure to moisture;

- a vapor barrier layer is required.

Polyurethane boards

Polyurethane foam panels are widely used in recording studios and residential areas.

Photo: polyurethane boards

Pros:

- light weight;

- simple installation;

- non-flammability;

- non-toxic;

- resistant to alkalis and acids;

- not hygroscopic;

- durable.

Minuses:

- darkens during use;

- susceptible to sunlight.

Thermosound insulation

Roll material with a three-layer structure. Inside there is a pierced fiberglass fabric, on the outside there is a shell made of a polypropylene base. Provides good sound and heat insulation.

Photo: Termozvukoizol

Pros:

- excellent noise insulation and vibration insulation characteristics;

- low thermal conductivity;

- elasticity;

- environmental friendliness;

- good hygroscopicity;

- non-flammability;

- can be laid on the wiring.

Minuses:

- high price;

- heavy weight.

MaxForte SoundPRO

Rolled soundproofing material. Roll size 1.4x5, material thickness – 12 mm. Aluminosilicate fiber provides a high level of protection against airborne and impact noise.

Photo: MaxForte SoundPRO

Pros:

- universal material - suitable for walls, ceilings and floors;

- thin - will not reduce the usable area of the room;

- easy to install;

- environmentally friendly;

- fireproof;

- resistant to mold, mildew and parasites.

Minuses:

- sold only from the manufacturer;

- You cannot buy by the meter, only a whole roll;

- high price.