Home page » Articles about boiler equipment. Reviews. Comparisons. Ratings.

Instructions

Steam boiler catalog

SaveSavedDeleted 2

Editor Kotlotorg 09/25/2020

2876 Views

Instructions for boiler room personnel on servicing steam boilers operating on liquid and gaseous fuels.

Solving problems with boiler attenuation

If the flame goes out not due to malfunctions of the boiler itself, but to other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot yourself, but this is a topic for a separate article.

Restoring traction

You can figure out what is clogged - the boiler or the chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is draft in the pipe, then we solve the problem with the boiler by calling a technician. Otherwise, you will have to climb on the roof and look into the pipe. If a blockage is detected, you need to remove those foreign fragments that interfere with the passage of smoke.

Cleaning the chimney is a mandatory procedure to prevent its contamination

If ice is found on the head, it must be carefully chipped off so as not to damage the chimney itself. Be sure to check the cleaning hatches. A sign that cleaning needs to be done is a large amount of soot and soot extracted from the inside of the channel.

You can still reconcile with the blowing of the channel due to strong wind if it happens once or twice during the entire heating season. But if winds are a common occurrence in your area, you should take measures:

- First, you can try to extend the pipe. The high altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent configuration of the head can help out, which will cover the hole on the side from which the winds predominantly blow.

If the electricity goes out

A non-volatile boiler in conjunction with a circulation pump does not consume much. It can be adapted for DC power and switched to battery operation. But this is not suitable for powerful boilers. The only way out is to connect the boiler to an alternative source of electricity, for example, a gasoline or diesel generator.

If the gas pressure decreases

The first thing you need to do is check the gas pipeline at the place where it branches off from the main line. The joints where there are traces of welding, as well as valves and taps, are carefully checked. The specific odor imparted to natural gas at distribution stations will help detect leaks.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Completing a collective petition will help speed up the decision-making process for the natural gas supplier organization in your area.

Internal cleaning of hot water boilers

The operation of a hot water boiler must be accompanied by regular, at least twice a shift, removal of sludge from the boiler. To do this, open the valves on the drainage fittings and drain the water until the settled sludge stops coming out of the drainage system fittings. In this case, the system's makeup must be turned on.

Cleaning of internal heating surfaces from scale should be carried out chemically with the involvement of a specialized organization.

Clean internal surfaces between heating seasons. If the boiler operates all year round, clean the internal surfaces at least once a year.

In the boiler room, it is necessary to keep a log (statement) on water treatment and the water-chemical regime of boilers to record the results of analyzes of water, steam, condensate, reagents, on boiler purging and maintenance operations of water treatment equipment in accordance with the approved regime map and the frequency of chemical control. Each time the boiler is stopped to clean the internal surfaces of its elements, a description of the physical and mechanical properties and thickness of deposits, scale and sludge is made in the water treatment log.

Why does a gas boiler often go out?

If your parapet, floor or wall convector goes out quite often, you need to find out why this happens and what needs to be done to fix the problem. One of the main reasons for this phenomenon may be a lack of oxygen. This is especially true for boiler models that do not have a draft-increasing hood.

What else can contribute to a lack of air for the boiler:

- The chimney is clogged - in this case it needs to be cleaned;

- Installation of sealed plastic windows, significantly reducing the flow of fresh air into the room;

- Replacement of interior doors, as a result of which the gaps between the floor and the doors have become much smaller;

- Purchasing a powerful hood that takes part of the air flow for itself.

In addition to lack of air, the reason that the flame does not ignite may be a drop in gas pressure. The problem may be on the general backbone (in which case you just need to wait until specialists fix it) or specifically on your network.

To find out if this is true, you should treat all suspicious areas with a sponge and soap suds. Bubbles will appear where there is a leak. It is better to entrust the work of eliminating such a problem to professionals.

A few more reasons why the boiler may turn off:

- Malfunction of sensors - as a rule, these devices monitor the concentration of gases in the boiler and the temperature of the device. If a failure occurs, then naturally the operation of the unit will be disrupted and it will have to be turned off for repairs.

- Poor ventilation of the room - the boiler does not have enough fresh air. The easiest way to solve this problem is to open the door to the room or window. If a flame appears, then you need to think about installing additional ventilation so that the boiler does not constantly go out.

- Failure of the meter, which does not allow gas to pass through in the required quantity. This is usually expressed in the fact that the boiler is very loud, banging and thumping. The numbers on the display do not change smoothly, but in jerks. Here you need to call only specialists. Doing anything with the meter yourself is prohibited.

The reason for the boiler's extinguishing may be related to the pipe. If it burns out, you will have to change it. There is no other option.

Methods for troubleshooting geysers

Geyser "Vector" is one of the most popular in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the Vector gas water heater, a spark does not appear and the burner does not ignite. The reasons for the problems are:

- Lack of draft in the chimney. It could simply be clogged and need to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this yourself, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. Very low pressure may indicate problems with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and wash it under water, and it is best to replace the membrane as it becomes damaged over time. You can do this yourself.

- The nutrient element is not working. Ignition is done using batteries, without which there will be no current to create a spark. You need to remove the panel, then take out the battery pack, pull them out and insert new ones.

What devices use bimetal?

The scope of application of the bimetallic strip is extremely wide. Almost all devices where temperature control is necessary are equipped with bimetal-based thermostats. This is explained by the design simplicity and reliability of such relay systems. In our usual technology, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electric packages there is automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- In thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from temperature overloads: transformers, electric motors, pumps, etc.

Typical causes of heating boiler breakdowns

The main reason is the destruction of electro-automatic devices, including the “safety unit” and the control unit. Flame, draft and temperature are controlled by bimetallic sensors. If the integrity of the protective fuses or the rules of use are violated, the servomotor will block gas access to the boiler and an error will appear on the information panel. To resume operation, use a multimeter to detect a break in the circuit or a burnt-out temperature sensor.

Low pressure in the expansion tank is the second reason. For correct operation, a pressure of 0.8-1 bar is required. At 0.7 bar the condensing boiler will not turn on. To increase it, remove the water from the boiler and pump up the air with a bicycle pump. The flexible hose connects to a built-in nipple, the pressure is controlled by a mechanical pressure gauge.

The electronic board of the boiler is faulty. An incorrectly selected voltage stabilizer, lack of grounding in the socket and lack of power supply protection unit increase the risk of board burnout. It is impossible to repair the electronics yourself; dismantling and diagnostics by a master electronics engineer will be required. A burnt-out circuit is difficult to restore after moisture has entered; you should order and install a new circuit board according to the model of the electric boiler.

The spark clicks and the burner does not start - the ignition electrode or the boiler ionization sensor is faulty. If the electro-automatic ignition constantly clicks, and upon completion of the start-up the red LED flashes (go into emergency mode), you should inspect the spark plug and high-voltage wires for cracks. If the insulation is broken and the spark strikes away from the main burner, the ceramic spark plug must be replaced.

Insufficient water pressure is reason number five. If the pressure in the heating system drops below 0.5 bar, the boiler will turn off. To resume operation, the system must be recharged with water. Open the feed tap until the pressure stabilizes. For control, a pressure gauge is installed on the front panel. If the fall continues, invite our technician to your home to check the tightness of the pipe welds and threaded connections of the batteries.

DHW or hot water supply does not turn on - the three-way valve of the boiler is faulty. The electric valve is dismantled, disassembled and washed from rust. Then they check the power button, visually it sticks in one position. After assembly, apply voltage to the motor to check the rod. If after repair the boiler does not start, the 3-way valve must be replaced.

Lack of annual preventive surveillance is the seventh reason. We offer qualified cleaning assistance from experienced craftsmen. Write in the chat window or submit a request by phone. An engineer will remotely diagnose a defective device and advise the owner on the cost of services. We will draw up a defective work report and provide a guarantee for equipment repairs for up to 1 year.

Heating boilers Conord

Rostovsky has a rich history and equally rich experience. Initially, the company was engaged in the repair of road equipment, but in the early 70s it was reoriented to the production of heating equipment.

At the same time, the name “Conord” appeared, which is an abbreviation for the words “Heating Boilers, Non-Standard Equipment, Rostov-on-Don.” The newly born plant began its activities with the production of the DON-16 boiler, famous throughout the USSR.

Heating equipment “Conord”

Today it is a modern enterprise, the technical equipment of which does not in any way remind of its advanced age. The production lines are equipped with the latest high-precision laser machines, imported presses and robots, which allow us to quickly and efficiently produce reliable and affordable devices. The main part of the range consists of gas water heaters, as well as heating boilers - gas, solid fuel and combined.

The range of boilers is quite diverse. First of all, the products differ in the gas burner device used (for short, they call it automatic). Three varieties are available.

Automation AGU-T-M (Russia)

- is cheap;

- does not require power supply (a bimetallic plate is used as a temperature sensor);

- does not impose special requirements on operating conditions and is inexpensive to repair (replacing the bimetallic plate - the only “weak link” - costs only 50 rubles).

This type of automation is quite common in our country and its use is not limited to the Conord brand. You can also see it in such Russian boilers as Mimax and some others.

There is no ignition system in the AGU-T-M, so the boiler has to be started using a lighter or a match.

Automation Euro SIT (Italy)

A boiler with such automation will be more expensive, but it simplifies setting the operating mode and ensures a higher level of safety. It contains:

- igniter with safety device (thermocouple);

- sectional burner with Polidoro tubes;

- gas valve SIT;

- temperature sensor;

- traction sensor

Unlike AGU-T-M, this automation reacts not only to gas shutdown, but also to deterioration of draft in the chimney.

The coolant temperature is set using a thermostat and is maintained automatically by a gas valve.

A piezoelectric spark gap is used to ignite the boiler.

Honeywell (USA)

The automation is of the same type as Euro SIT, only other materials are used for the manufacture of some elements.

An economy mode function has been added, to enter which the ignition knob must be turned all the way.

Conord boilers are also divided into single-circuit and double-circuit.

The former are intended for connection only to the heating system, the latter can additionally perform the function of an instantaneous gas water heater.

Unlike many other boilers with two circuits, Conord does not turn off the heating while using hot water. The 2nd circuit heat exchanger is heated by the smoke pipes. But still, the amount of heat supplied to the heating circuit decreases at this time.

Navien boilers from the largest Korean manufacturer, as a rule, work properly. But it is still a technique, and sometimes it can fail. Let's look at the types of malfunctions of the Navien boiler, as well as ways to troubleshoot problems.

We’ll talk about the functions of an inverter for a heating boiler in this topic.

Do you know why double-circuit gas boilers are purchased more often than single-circuit ones? Using this link https://microklimat.pro/otopitelnoe-oborudovanie/kotly/dvuxkonturnye-gazovye-kotly-dlya-otopleniya-chastnogo-doma.html we will consider the advantages of this type of equipment, as well as installation and selection features.

Diagnostics at the service center

Repair of electric ignition of a gas boiler is included in the list of services of many service centers specializing in the maintenance of household appliances and heating equipment. By contacting qualified specialists, you can count on the fact that device malfunctions will be eliminated as quickly as possible. Reliable service centers that value their own reputation provide customers with a long-term guarantee for equipment repairs.

To determine the cause of a malfunction in the electric ignition of a gas boiler, technicians use modern diagnostic devices. During repairs, specialists use only high-quality original components. In addition, the service center offers to call a technician to your home. This service eliminates the need to deliver a large unit to the workshop yourself.

Repairing a gas boiler may involve replacing the ignition unit, restoring the control unit, eliminating leaks, or installing a new tap. An experienced specialist will be happy to answer all the client’s questions regarding the rules for operating the equipment, and will also tell you how to avoid breakdowns in the future. Service centers offer advice or order a particular service at any time of the day. This can be done by phone or through the website.

Hello, dear readers. What to do if the piezoelectric element in the gas water heater does not work? In what situations can you solve a dilemma with your own efforts? When is it necessary to contact specialists? And how to fix the problem in Amina, Zanussi cash advance businesses and other brands?

This material examines the reasons for the failure of a piezoelectric element in a gas apparatus. Cases with models of different brands are reflected. Methods for solving this problem are provided.

What models are there?

The main types of Lemax gas boilers are:

- Floor-standing models with steel or cast iron heat exchanger.

- Wall mounted solid fuel.

The solid fuel type of equipment is represented by two models:

- Wood stoves.

- Coal boilers.

Wall-mounted boilers are produced only as double-circuit boilers: they are capable of operating at pressures up to 3 bar. In all cases, Italian automation and circulation pumps are used. Wall-mounted models include a 6-liter expansion tank. This equipment is guaranteed for 2 years. Floor-mounted modifications equipped with steel heat exchangers are also in high demand. For their manufacture, high-strength metal with a thickness of 2 mm is used.

There are 5 models of steel boilers with different capacities:

- Lemax premium.

- Premium nova.

- Gazovik.

- Clever.

- Patriot.

The Premium nova model is considered the most advanced today. Thanks to automatic settings, the device can independently both start a Lemax gas boiler and set optimal operating parameters in the system. The Patriot series devices are characterized by the presence of a closed combustion chamber. They are produced exclusively as single-circuit ones, without the need for electrical power and a chimney. The presence of a 4 mm thick cast iron heat exchanger for the Leader and Wise units extends the service life by approximately 2 years. They are not afraid of various contaminants and the effects of corrosion.

General Information

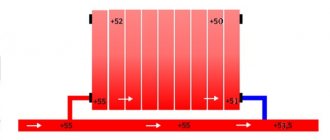

… and hints on saving energy: When the regulator settings are altered the regulator reacts with a time lag. Every 20 sec- onds the processor compares all desired and actual values and carries out all necessary corrections with the necessary speed. The room in which the room temperature regulator is mounted (control room) determines the temperature for all other rooms. Ie the room temperature in the control room acts as a control input for the entire heating network. For this reason all thermostat regulated radiators located in the control room must be opened completely at all times. Otherwise the thermostat valves would reduce the heat sup- ply although the regulator constantly requires more heat (see also chapter 4.1). If in the adjoining rooms a lower temperature is wanted or if the radiator should be turned off completely, the (thermostatic) radiator valves must be set accordingly. Since the room where the room temperature regulator is mounted acts as a control room, any external heating sources (eg insolation, tiled stove, etc.) can result in insufficient heating of the remaining rooms (the radiators stay cold). In order to avoid this the room temperature sensor RF 1 can be used according to the notes in chapter 2.2, chapter 5.1 and chapter 6.7. When the room temperature is reduced during the day or during the night a lot of energy can be saved. If the room temperature is reduced by 1 K (°C) this can save up to 5% of energy. It is not recommended to let the temperature of daily heated rooms drop below +15°C. When the room is heated up again the comfort is diminished by the walls which are cooled down. So if one wants a real comfortable room temperature the regulator must be turned up and so a lot more energy is used up than is in case of an even heat supply. If the building has good thermal insulation it is possible that the set economic temperature is not reached. But even in this case energy is saved since the heating system is not activated. In this case the starting time for economical operating mode can be set earlier. Do not let windows stand ajar for airing the rooms since this would constantly withdraw heat from the room without improving the air in the room considerably. Do avoid continuous airing! It is better to air the room briefly but properly (open the windows completely). Set the temperature regulator to a lower value during airing. 15

Types of gas boilers

Based on the type of installation, boilers are divided into wall-mounted and floor-mounted units.

Floor-standing gas boilers are characterized by greater power, which means the ability to heat large areas of premises, and longer service lives due to the fact that the heat exchangers for such heat generators are made of steel or cast iron. Floor-standing boilers require a separate room - a furnace room.

Floor standing gas boiler

Wall-mounted boilers are more compact and lighter, which allows them to be installed on the walls of rooms. This type of heat generator is characterized by limited power, shorter service life, and increased requirements for the quality of purification of the coolant and heated water. Gas boiler malfunctions may vary depending on the type of installation.

Wall-mounted gas boiler

By design, boilers are divided into single-circuit, used only for space heating, and double-circuit, intended, in addition to heating, to heat hot water.

Depending on the type of removal of combustion products, heat generators are equipped with systems with natural or forced draft. In the first case, the units are connected to a traditional chimney, which is discharged to the roof of the building, and exhaust gases are released due to natural draft. To ensure this, ventilation ducts are arranged according to certain rules. One of them is that the upper level of the chimney must be located above the roof ridge by at least 500 mm, or at the same level with it at certain distances from the ridge. The reason why the gas boiler blows out may be failure to meet these conditions. Boiler units with natural draft are equipped with open combustion chambers or atmospheric burners, the air for the burner is taken from inside the room.

In the second case, the boilers are equipped with a coaxial chimney, which is a “pipe-in-pipe” design, which is discharged outside through the wall of the room. The air necessary to support combustion comes from the outside pipe through the outer pipe, and combustion products are discharged through the inner pipe. Forced draft boilers have closed combustion chambers.

Traditional and coaxial gas removal systems

And finally, according to the method of ensuring coolant circulation, boiler units are divided into volatile and non-volatile. Volatile boilers have circulation pumps that operate from the electrical network and create pressure in the heating system. In addition, volatile boilers are equipped with sophisticated automation that controls and maintains established operating modes, including an electronic ignition system. Non-volatile heat generators do not require connection to electrical networks, and the movement of the coolant occurs due to natural pressure drops as a result of its heating. Non-volatile boilers can be ignited using a piezoelectric element by pressing a button.

Basic safety rules when lighting burners.

— before igniting the burners, it is necessary to double check the closure of the gas fittings and the opening of the safety plugs - before and after ventilating the firebox;

— before ignition, it is necessary to thoroughly ventilate the firebox and flues at maximum blast and draft, after which reduce the draft and draft. and conduct an air analysis - the gas content should be no more than 1/5 of the LEL, i.e. 1%;

— when igniting, you must wear overalls with the sleeves down, safety glasses, gloves, and stand to the side of the ignition hole;

— supply gas to the burner only if there is a stable pilot flame;

— if the burner does not ignite in a timely manner or goes out during operation, make an emergency stop followed by ventilation of the firebox and flue ducts;

— carry out an emergency stop in other situations specified in the topic “Rules for servicing the gas-air path”;

— during operation, carefully monitor the presence and quality of the flame and parameters

work, recording them in the logbook;

— gas supply to furnaces equipped with automated burner units operating according to a program is determined by the instructions of the unit manufacturer. (II paragraph art. 4.6.16).

Gas hazardous work.

Gas-hazardous work is considered to be work performed in a gas-contaminated environment or during which gas may escape.

These include: -connection of new gas pipelines to existing ones; - gas start-up, commissioning work; - commissioning of hydraulic fracturing, gas filling stations, LPG tanks; - maintenance and repair of existing external and internal gas pipelines, gas-using installations, hydraulic fracturing equipment, household gas-using equipment; — work on the hydraulic fracturing bypass; — installation and removal of plugs on existing gas pipelines, disconnection of equipment; — disconnection from existing gas pipelines, conservation and re-preservation of gas pipelines and seasonal equipment; — performing draining and loading operations on tank installations; -repair and inspection of wells, pumping water and condensate from gas pipelines and condensate collectors; — preparation and carrying out technical inspection of LPG tanks and cylinders; — opening the soil in places of gas leaks until they are eliminated; — all types of welding and hot work on operating gas equipment.

Basic rules of conduct. Civil defense work must be performed under the guidance of a specialist (and some types of work - under the guidance of the most qualified employee).

The work must be carried out by a team consisting of at least 2 workers (some types of work - commissioning of gas pumping units, maintenance of gas equipment in residential and public buildings, technical inspection of gas distribution units, power distribution units and technical inspection of gas distribution units located in individual buildings according to instructions containing additional safety measures - 1 employee).

Repair work in wells, tunnels, trenches and pits with a depth of more than 1 m, collectors and tanks must be carried out by a team of at least 3 workers.

To perform gas-hazardous work, a permit is issued, accompanied by instructions on safety measures. Persons who have the right to issue orders are determined by order of the SPGH or the enterprise operating the gas supply system with its own gas service.

Periodically repeating gas-hazardous work performed in similar conditions, as a rule, by a constant staff of workers, can be carried out without issuing a work permit in accordance with production instructions and instructions on safe work methods approved for each type of work.

Such work includes work on gas-using installations, boilers, units, maintenance of gas pipelines, shut-off valves and gas equipment without shutting off the gas, draining LPG from tanks, filling LPG tanks and cylinders. Each enterprise must develop a list of gas hazardous work performed without the guidance of a specialist. The initial execution of these works is carried out with the issuance of a work permit.

Work to localize and eliminate accidents is carried out without a permit until the direct threat to human life and damage to material assets is eliminated. After eliminating the threat, work to bring the equipment into a technically sound condition must be carried out in accordance with the permit.

In the case where accidents are eliminated from start to finish by the emergency service, drawing up a work permit is not required.

Gas-hazardous work is usually carried out during the daytime. Work to localize accidents - at any time of the day in the presence and under the guidance of a manager or specialist.

When performing work in wells and pits with an open gas pipeline, no more than 2 people are allowed to be present at the same time, and the work must be carried out in rescue belts and gas masks. On the ground surface on the windward side (as well as at the tank hatch) there must be 2 workers who are required to hold the ends of the ropes from the workers’ life belts and continuously monitor the working and air intake pipes of the hose gas masks. Do not allow unauthorized persons to the place of work. Pits and wells must be fenced when work is carried out in them. Warning signs should be installed nearby.

The specialist who supervises gas-hazardous work (or the person assigned the task) is responsible for providing workers with personal protective equipment and the serviceability of these equipment.

Each person working with a work permit must be issued a life belt complete with a safety rope and a hose or insulating gas mask. The use of filter gas masks is not permitted. The need to use gas masks is determined by the work manager.

Permission to use insulating gas masks in each case must be issued by the work manager to persons who have undergone a medical examination and special instructions.

The duration of work in a gas mask without a break should not exceed 30 minutes.

In the absence of “forced” air supply by a fan, the length of the hose should not exceed 10 m.

During operation, the air intake pipes of hose gas masks should be located and secured on the windward side of the gas emission point. The hose should not have sharp bends or be pinched by anything. Gas masks are checked for leaks before performing any gas-hazardous work. When wearing a gas mask, the end of the corrugated tube is tightly clamped with your hand. If it is impossible to breathe in this position, the gas mask is working properly.

Lifebelts must have shoulder straps with a ring on the back at their intersection for attaching a rope. The belt should be adjusted so that the ring is located no lower than the shoulder blades. The use of belts without shoulder straps is prohibited. Rescue belts with rings are tested as follows: a load weighing 200 kg is attached to the ring of the belt, fastened with both buckles, and remains suspended for 5 minutes. After removing the load, there should be no signs of damage on the belt. Carbines are also tested for 5 minutes. with open shutter load 200kg. After removing the load, the carbine bolt should snap into place correctly and freely. The ropes are tested for 15 minutes. weighing 200 kg - there should be no damage on it as a whole and on its individual threads.

Tests of lifebelts, carabiners and ropes must be carried out at least once every 6 months. under the leadership of a responsible person appointed by order for the enterprise. In addition, they are checked before being issued for work. Each belt and rope must have an inventory tag , which indicates the dates of the tests performed and subsequent tests.

When performing repair work in a gas-filled environment, tools made of non-ferrous metal should be used to prevent the possibility of sparking. Tools and fixtures made of ferrous metal must be copper-plated or generously lubricated with grease.

Automatic Flame

Designed for the safe operation of heating boiler houses with no more than 10 hot water boilers, with a heating capacity of up to 1 Gcal/hour each; automatic regulation of boiler loads in accordance with the heating schedule, issuing signals about the operation of the boiler room to the control panel, and emergency shutdowns of boilers.

It has automatic regulation of AR and automatic safety of AB.

Consists of: 1. control panel: a) general boiler unit BUO;

b) boiler block for each BUK boiler;

2. burner block;

3. heat regulator (may be missing).

The gas boiler goes out, what to do and how to fix it

If you have a turbine boiler and the flame does not ignite in it, it is worth listening to how it works. If sounds are heard stronger than usual or vice versa, silence - the problem is most likely in the built-in fan, which will have to be repaired or bought a new one.

There are usually 3 options when the boiler does not work:

- The device is completely turned off;

- The device is turned on, the display is on and the indicator is on, but the flame does not ignite;

- The flame ignites but quickly goes out.

First you need to check whether power is supplied to the convector. The reason for its absence may be not only a power outage, but also the operation of a machine on the distribution panel.

If the voltage is OK, you can begin repairs. To do this, unscrew the front panel of the boiler with a screwdriver and remove it or fold it back. Then find the fuse box and check each of them. If a burnt-out one is found, it must be replaced with the same rating. If after these steps the unit starts working, great, but if not, you will have to call a specialist.

If any error is displayed on the convector display, you can read what it means in the technical data sheet of the device.

Some problems that cause the device to turn off can be resolved yourself:

- A clogged sump can be cleaned by first turning off the taps of the device;

- Correct the circulation pump by unscrewing the screw in the center of the pump and releasing the air;

- Add air if the pressure in the tank is too low;

- Repair existing leaks and add water to the system.

This is how you can try to resume the operation of a gas heating boiler of various brands with your own hands, for example, AOGV, Dani, Weber, Aton, AGV.

Cleaning convective heating surfaces from soot deposits

When burning organic fuel (coal) in boiler plants of any capacity, issues inevitably arise in cleaning heating surfaces from external ash and soot deposits.

Contamination of the external heating surfaces leads to: an increase in the temperature of the flue gases, the aerodynamic resistance of the gas path and, as a consequence,

- to a decrease in the productivity and efficiency of the boiler unit;

- to excessive fuel consumption,

- increasing costs for own needs,

- deterioration of environmental indicators due to overestimation of thermal emissions and nitrogen and sulfur oxides, in the latter case due to a violation of the aerodynamics of the combustion space.

- After 3000 hours but not later than 6000 hours of operation of the hot water boiler, monitor the operation of the gas-air duct of the boiler installation according to the readings of the control and measuring instruments. In the event of a decrease in the vacuum in the combustion chamber or loss of the developed pressure of the smoke exhauster, the boiler should be stopped to carry out work to clean the boiler flues and chimney from settled ash and soot.

Clean the convective part of the boiler by washing with cold water or blowing with compressed air using a compressor until the heating surfaces are completely clean.

Operation of hot water boilers after washing with water begins only after the thermal insulation of the convective part has completely dried.

What is a bimetallic plate

An element that has the property of deforming (bending) in one direction under the influence of elevated temperature is called a bimetallic plate. From the name you can guess that the plate contains two metals. Each of them has its own coefficient of thermal expansion. As a result, when such a plate is heated, one component expands by a certain amount, and the second by another.

This leads to a bend, the shape of which depends on the difference in temperature coefficients. The rate of deformation is directly proportional to the change in temperature. When the plate cools, it returns to its original position. The plate is a monolithic compound and can work indefinitely.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

Review of manufacturers

Gas services, as well as experts in this field, recommend using boilers from the company.

The units are presented in several versions and differ in functional features. Boilers are produced only of floor type. The main difference from other analogues is the affordable price and the lack of electricity required for operation.

Keber boilers are also popular; they are equipped with an automatic safety and regulation system, which ensures precise gas supply and temperature stabilization.

Gas boilers of the AOGV series are quite in demand and are used to heat rooms that have a water heating system with natural or artificial circulation.

(Termotechnik) presents a large selection of boilers and offers floor-mounted, parapet-type, gas and solid fuel units. Many years of experience ensures excellent quality and guarantees product reliability and long service life.

Eliminating problems associated with blowing out the boiler requires special care and responsibility. It is necessary to check all components of the boiler to determine and eliminate the cause of the malfunction. If the recommendations presented do not bring results, it is worth calling the gas service specialists. Remember that quickly getting rid of problems will prevent additional breakdowns and protect not only the entire system, but also the residents of the house.

Watch the video in which a specialist examines one of the most common reasons: why a gas boiler goes out in the wind, what needs to be done, what work needs to be done to improve draft in the boiler:

Gas boilers are the most economical type of heat generators, easy to install and subsequently operate, used in autonomous heating systems. However, like any engineering equipment, gas boilers can sometimes fail, and the most common type of failure is self-extinguishing burner. To understand why a gas boiler goes out or find out the cause of other problems, you need to know about the types of boilers and the principles of their operation.

Great Encyclopedia of Oil and Gas

Page 3 Switching devices must be provided on branches to devices. To ignite gas burners and monitor their operation, inspection hatches are installed in the combustion doors or front stoves. If there is no draft, it is necessary to warm up the chimney, for which the brick wall at its base is dismantled and a fire is laid on a sheet of steel (baking sheet).

Before igniting the gas burners, the baking sheet with the remaining coals and ash is removed from the chimney, filled with water, and the hole in the wall is filled with bricks.

These works are carried out under the direction of the person in charge of the boiler room.

Explosions and pops in the combustion chamber and gas ducts of the boiler unit are a consequence of gas contamination of the firebox or its unsatisfactory ventilation.

Most often, explosions occur when gas burners are ignited due to violation of safety rules and current instructions by operating personnel. It should be remembered that in all cases, if the burner does not ignite, re-igniting it is permissible only after thorough ventilation of the combustion chamber and boiler flues.

We recommend reading: Eurovision 2022 semi-final results

Ignition of gas fuel units is carried out after checking the condition of the explosion safety valves.

On industrial furnaces that do not have explosion valves, when igniting gas burners, open the loading and tilting doors or remove their latches.

The main feature that distinguishes the Promenergo-gaz igniter from other electric ignition devices is the refusal to use a spark plug or a pair of electrodes operating from high-voltage transformers, cars or motorized reels. For ignition, an electrical device for igniting the EUR (Fig. 52), developed on the basis of commercially produced electric igniters (for igniting household gas burners), is used, designed to operate at a voltage of 220 V.

It is located outside the boiler outside the zone of high temperatures and the main flow of the gas-air mixture moving through the ignition burner mixer. If boilers operating on different types

Gas boiler Conord technical characteristics and features

The thickness of the steel sheets used to make the Conord boiler firebox is 3 mm. The material has a fire-resistant powder coating, thanks to which the service life of the boiler, as the manufacturer assures, is 15 years.

The warranty is valid for 3 years.

The efficiency of boilers of this brand is 90%.

Such a high indicator was achieved due to the installation of turbulators in smoke pipes.

The connections to the pipelines are located on the rear panel of the heat generator.

Their diameters are 50 mm or 2 inches (heating circuit connection) and 15 mm or ½ inch (for the DHW line).

The lowest-power model provides heat generation of 8 kW. The oldest representative of the line has a power of 30 kW. Intermediate values: 10, 12, 16, 20 and 25 kW.

The diameter of the chimney depends on the power of the device. For boilers with a heat output of up to 12 kW inclusive, it is 115 mm, for more powerful ones - 150 mm.

Heat generators of this brand have built-in expansion tanks with a volume of 8.5 liters. The maximum permissible coolant pressure is 6 atm.

An important feature of Conord boilers is the ability to operate at a gas pressure in the main line of only 0.6 kPa (usually the pressure in the distribution gas pipeline is maintained at 1.3 kPa)

STARTING THE BOILER INTO OPERATION (MAIN STEAM PIPELINE)

4.1. Before putting the boiler into operation, the following operations must be carried out:

- Check the serviceability of the pressure gauge, safety valve (by forced opening), water indicating devices (by blowing them), with an entry in the logbook;

- Check and enable automatic safety and regulation;

- Blow out the lower points of the boiler.

4.2. The boiler must be connected to the steam line slowly, after thoroughly warming up and purging the steam line. When warming up, it is necessary to monitor the serviceability of the steam pipeline, its compensators, supports and hangers. If water hammer occurs, stop warming up and find out the cause.

4.3. Switching on is carried out at a pressure equal to the main steam line or lower by 0.5 atm.

4.4. Record the start time of lighting and turning on the boiler in the logbook.

The boiler blows out in a strong wind, what to do in this case

Mechanical heating boilers can go out due to being blown by strong winds. Any atmospheric phenomena - rain, high humidity, low atmospheric pressure, wind can affect draft, causing its excess or deficiency, and also cause reverse draft. Result: the boiler went out. What to do in this case?

The solution to the problem is as follows:

- You can install a special mushroom-umbrella on the edge of the pipe, which will protect the chimney from unwanted influences;

- Or you can increase the pipe itself if its length is not enough.

By the way, this is not the only problem that can arise with the chimney. In addition to blowing smoke, ice may form on the pipe. The reason for this phenomenon is condensation.

The fact is that moisture tends to accumulate and freeze over time, and then become so thick that it simply blocks the access to oxygen and the flame goes out and the boiler turns off.

However, it happens that it is very difficult to knock off ice build-ups and then you have to defrost them. You can purchase a disposable burner with a small can. To melt the ice, you need to light the burner and insert it into the cleaning hatch. When the pipe warms up, the boiler can be put into operation.

How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

Boiler bimetallic plate

Natural gas heating systems are high-risk devices and therefore include various condition monitoring sensors. So, the main safety element is the traction sensor. It determines the correct direction of exit of combustion products, that is, from the combustion chamber towards the chimney. This prevents carbon monoxide from entering the room and poisoning people.

The main component of the draft sensor is a bimetallic plate for a gas boiler. Its operating principle is similar to any bimetal, and the dimensions and parameters of the material are calculated in such a way that exceeding the temperature of 75 degrees in the channel leads to deformation of the plate and operation of the gas valve.

The principle of operation of piezo ignition

The principle of operation of piezo elements in a lighter is known to many of us, so it will be easy to imagine how piezo ignition functions in a column. Gas enters the combustion chamber, and a spark is struck at the outlet, which creates ignition and starts the unit. The set temperature is maintained constantly. When it reaches the set level, the fuel supply to the main burner is suspended and the column is turned off. Note that the auxiliary burner continues to support the operation of the coolant. The main burner resumes operation automatically when the water temperature drops. The work cycle repeats.

The ease of operation of piezo ignition is not the only bonus. To this you can add energy independence, ease of use and affordable cost. The disadvantage of the models is the costly fuel consumption.