At a certain stage of building a steam room or sauna in a country house, you will need to choose a heating method and equipment for heating the room. There are not many options, installing electric heating elements, building a brick stove or installing a boiler in a bathhouse with your own hands. The difference between them is quite significant, so before buying equipment, it makes sense to figure out whether the option of installing a boiler in a bathhouse is better or worse than traditional stoves.

The use of a water boiler is economically justified; in addition to a bathhouse, the device will easily provide heat for a summer kitchen and a country house

Difference between boiler and stove

And when you have found detailed information, photos and drawings of boilers for the bathhouse, how to build a stove with your own hands, you need to understand well that the brick stove that is installed in a traditional Russian bathhouse is not a cast iron boiler at all. But a metal structure welded from a barrel or pipe cannot be called a stove; it is nothing more than a boiler for a bath.

At the same time, boilers, like stoves, are necessary for one thing:

- heating steam rooms;

- heating water and stones

- as well as maintaining the desired temperature in the steam room.

Therefore, a stove is a brick structure, and a homemade boiler for a bath means a different heating device.

Combinations

Let's consider several successful combinations of boilers that can be used for a bath and made with your own hands:

Pellet and electric. The disadvantage of this solution is the cost of the equipment. Therefore, quite large initial costs are required. In this case, you will need to allocate quite a lot of space to place the devices. However, there are also advantages of this solution: the affordable cost of pellet fuel, the possibility of automating the process, reducing costs by turning on the electric boiler only at night if a two-tariff meter is installed.

Gas and electric boiler. This is a technological solution that will allow you to fully automate the process, without fiddling with solid or liquid fuel, while always being provided with heat. After all, if there is a power outage, the gas supply is unlikely to be interrupted and vice versa.

Electric-gas boiler

Coal and electric boiler. Under certain conditions, such a combination can be both beneficial and convenient. Of course, you need to be able to buy coal profitably.

Installation of a chimney in a bathhouse

There are basic recommendations for installing a chimney. The temperature of the flue gases reaches 450-550°C. An ordinary metal pipe heats up red hot.

Safety standards stipulate that it is not enough just to isolate the stove from a wooden wall; it is necessary to protect the surface in places of contact with the chimney.

Fireproof cutting is required where the chimney passes through the floor slabs and roof.

Choosing a chimney type

Ceramic and insulated stainless steel sandwich pipes are used to connect the sauna stove. Each option has its own advantages and purpose:

- Ceramic chimney is used for internal connection. The pipe passes through the floor slab and roof. The advantage of ceramics is durability, resistance to aggressive and acidic environments, and the almost complete absence of condensation.

- Sandwich chimney - both internal and external installation are provided. In the second case, the pipe is led out into the street through the side wall.

The sandwich chimney and ceramics are assembled like a construction set. Self-installation is not difficult. To facilitate installation, manufacturers provide step-by-step instructions with a detailed description of the work.

All component materials used when installing chimneys must comply with existing SNiP and PPB. It is not recommended to use galvanized and asbestos-cement pipes, and do-it-yourself fasteners.

all videos on oven installation

Heating system from the heating main

A private bathhouse can be directly connected to the central heating main. To organize a similar heating option for a bath, you will need to install an additional circuit.

The connection of the circuit to the heating main is carried out in accordance with the design documentation and permits obtained from the relevant authorities.

Choosing this option involves some difficulties:

- the likelihood of accumulation of groundwater in places where pipes are laid;

- the need for additional insulation of the heating main;

- the need to attract professional installers.

Fire safety when installing a sauna stove

Fire safety rules when installing an iron stove in a bathhouse stipulate requirements related to mandatory compliance with fire breaks and measures aimed at preventing emergency situations.

The body and chimney pipe become very hot during combustion. Over time, wood, under constant thermal stress, oxidizes, which causes ignition, even without the presence of an open fire. For this reason, fire safety requirements when installing a stove in a bathhouse require compliance with three important rules:

- Provide safe distances between the stove body and walls made of flammable materials.

- Install the stove on a non-combustible base.

- Use fire-retardant material to reduce the thermal load on walls located near highly heated parts of the stove.

There are general rules that must be followed during installation:

- It is recommended that the finishing of the walls around the stove be made of non-combustible materials. If this is not possible, surfaces made of timber or logs are covered with thermal insulation and sheathed with steel sheets.

- Fire-fighting measures are mandatory: treating load-bearing structures and rafters with mastics and fire retardants to prevent the fire of wooden elements.

- PPB prescribes the use of fire insulating material for interior walls with a high degree of fire resistance. The use of mineral wool is allowed. To increase safety, basalt insulation is used as an insulating material, which can withstand a melting point of 1400°C.

Design features of fireboxes

This characteristic has a significant impact on the comfort of bathing procedures and is worth paying attention to.

- There is no combustion tunnel, the door is installed directly on the boiler wall, firewood can only be added from the steam room. The most common type of boiler, installed in most baths. Advantages - you can always increase the heating temperature of the steam room as needed; there is no need to go into other rooms to do this. Disadvantages - firewood in a steam room increases humidity and reduces the heat of combustion; part of the energy is used to dry it. In addition, firewood in the steam room is a source of dirt, and people walk around in this room without shoes.

- There is a furnace tunnel. The firebox door opens into the adjacent room. In this case, the advantages and disadvantages are reversed.

If a small number of people wash in the bathhouse, then it is advisable to buy boilers of the first modification, otherwise it is better to make the firebox in another room.

There may also be boilers without an ash pan and a grate.

An example of a sauna stove without a grate

The absence of a grate slows down the burning rate of firewood, which causes an increase in the heating time of the steam room. But it becomes possible to maintain a comfortable temperature for several hours. And here it is impossible to give unambiguous universal advice; it all depends on your specific conditions.

What do you need to know?

First you need to decide on the fuel that will be used and, therefore, on the type of boiler. It is not advisable to make electric and gas appliances yourself, but if the choice was made in favor of one of them, then it is better to buy a ready-made high-quality boiler. Otherwise, the risk of emergency situations will increase.

Solid fuel boiler for baths, diagram

It is also worth noting that an installed gas boiler must be inspected by a representative of the relevant authorities. Therefore, it is much easier to assemble and install a solid fuel unit.

Terminology

Let's start, however, with a small clarification. Strictly speaking, wood-burning boilers for saunas... are not used. If we adhere to precision in definitions, the heating equipment we are interested in is called a wood stove.

Why can’t a boiler for a wood-burning sauna be used to heat a steam room? Yes, simply because the maximum coolant temperature at the outlet of its heat exchanger is only about 90 degrees. To get the usual 80 C for a steam room under the ceiling, you would literally have to hang all the walls with radiators.

Making a boiler for a bath

Making a boiler for a bath

The iron boiler has a fairly simple design. Preparatory work consists of studying boiler drawings, as well as purchasing all the necessary equipment.

Making a boiler for a bath

Stage 1. Consumables and equipment

In most cases, boilers are made of thick-walled metal pipes. Experienced specialists use large barrels with a volume of up to 200 liters, but in our case it is recommended to use a small pipe ø50 cm with a length of 75-100 cm. This will make it possible to design a device capable of heating a room with a volume of 15 cubic meters, which approximately corresponds to an area of 9 m².

Steel pipe for boiler making

In addition, you will need the following tools:

- welding machine (electric);

- Bulgarian;

- metal circles.

Stage 2. Welding of structural supports

Boiler drawing

Cutting the pipe

After preparing everything you need, you can start working.

Step 1. The boiler body will consist of a pipe in which three supports must be formed, located parallel to the ground, at three different levels. To do this, you will need three pieces of reinforcement ø1.4 cm, 3 cm long each.

Level No. 1 is required to install the stove.

The height of level No. 2 is calculated depending on the planned type of blower door.

Level No. 3 should be located 20 cm from the top edge of the structure.

Step 2. A circle of the appropriate diameter, cut from sheet steel 5 mm thick, is used as the bottom.

Furnace from the inside

Step 3. All wood-burning stoves include a grate - a metal grate necessary for supplying oxygen to the combustion chamber (installed from below). It will require a circle of metal of the maximum possible thickness, perforated or with slots.

Furnace design Furnace design Furnace design

Step 4. The oven lid will also serve as a support for the stones, so it is cut out of the same 5 mm steel. A hole is made in the center of the lid for the chimney pipe.

Step 5. A hole is made in the lower part of the pipe for the box, and it is closed with a stove door.

Note! The depth of the box depends solely on the thickness of the walls!

Step 6. The box itself is constructed, and a partition is installed inside it to separate the combustion and ash chambers. The level of this partition must coincide with the level of the grate, and the grate itself must be located inside the boiler.

On the right side there is a round door for storing stones

Boiler for a bath

Stage 3. Assembling the structure

This process can be divided into several stages.

Step 1. First, a box is welded into the structure. If the installation takes place indoors (and in our case this is exactly what happens), then the box should go either into the combustion chamber or outside.

Selecting material for the tank

The most common are sheet metal tanks:

- Made of cast iron;

- Stainless steel;

- Enameled.

Each of these materials has certain advantages and disadvantages.

Cast iron tanks are a classic of the Russian bath!

They are durable, not subject to corrosion, have a high heat capacity and do not cool down for a long time, are easy to clean from dirt, and are resistant to shock and mechanical damage.

Can be built into the furnace body. The only drawback is the heavy weight, which creates a load on the stove and requires a frame or hanging on chains.

Cast iron boiler

A stainless steel boiler for a bath with heated water is the most popular at present. Suitable for constructing a water container of any shape and volume. It can be located both inside the oven and outside. Ideal for constructing free-standing containers. The durability of the built-in tank depends only on the thickness of the metal. The only drawback is the rather high cost of material and manufacturing.

Stainless steel tank

Enameled tanks are used only as wall-mounted or free-standing tanks. When in contact with fire, the enamel quickly cracks and crumbles. It is not resistant to mechanical damage, although it has the most aesthetic appearance among other similar products.

Enameled titanium boiler

Cylindrical boilers

The easiest way is to make a boiler for a bath from a pipe with thick walls (6-8 mm). You can take a thin-walled pipe, or even an iron barrel, but such a stove will not last long. So, a pipe with a diameter of 400-500 mm up to 1 m in length will be the combustion chamber. The bottom and cover made of a steel sheet with a thickness of at least 5 mm should be welded to it. Such a boiler for a bath can be made without a grate; all operations are performed through the loading door. The external channel for its installation can be made of rectangular or circular cross-section, its length is equal to the thickness of the bathhouse wall.

Boiler in a bathhouse from a pipe

There is a hole in the center of the lid to which the chimney pipe is welded. You can regulate the intensity of combustion by installing a damper in the chimney, which will reduce draft. But more often they make a hole in the door and cut a pipe with a damper into it, as shown in the figure.

Side on the boiler

A homemade boiler for a bathhouse made from a pipe must have a heater, here a special side made of steel 4 mm thick is welded for it. This is the simplest stove model, and the pipe can be positioned horizontally, especially if it has a large diameter. Then the door will need to be installed at the end, and the chimney will need to be welded at the end of the pipe. For stability, you will need to attach supports to the firebox body.

Homemade boiler for a bath

Let's get started

In order to independently build a reliable and simple metal boiler, you need to acquire the following materials:

- One and a half meter pipe with a diameter of more than 0.5 m

- Meter pipe with a diameter of about 0.35 cm

- Steel hinges, handles and latches

- Sheet metal

- Fittings for making a grate or a ready-made grate

It is very important to pay attention to the thickness of the selected metal - at least 0.8 cm. The smaller this value is, the faster the material will begin to burn out and you will have to think about making a new boiler. All those who value reliability and durability can consider the options of brick stoves

All those who value reliability and durability can consider the options of brick stoves.

It is necessary to cut a one and a half meter pipe into two sections:

- The first, 0.9 m long, will be intended for the manufacture of the combustion part

- The second, 0.6 m long, will be intended for the manufacture of a water tank

If it is possible to find a stainless water container of a suitable diameter, this will be a big plus. Steel, like most other metals, will soon begin to rust.

Boiler for a bath: reasons for construction

Today, a wide variety of solid fuel boilers are on sale. You can, of course, put a brick oven in the bathhouse. But remember, this is a rather complicated process, especially without the experience of a mason.

And the price of such construction will be much higher than the cost of a boiler for a steam room, since it entails the cost of purchasing clay and brick, as well as a thorough study of production technology. The result is considerable additional costs.

Note! What to choose is up to you as the owner. The main thing to remember is that for a small-sized steam room somewhere in the country, a boiler is quite suitable; it can be made from simple improvised means. In addition, such installation of a boiler in a bathhouse will be cheap.

Plus, it’s fun to make it yourself. Construction is, of course, a responsible and important process, so you shouldn’t be afraid of difficulties, you need to get to work with readiness.

How to install correctly

Before proceeding with the installation of the boiler, it is necessary to build a strong foundation. It is made of refractory bricks, in several layers. Then the already prepared concrete solution is poured there, after which the structure is installed.

The walls to which the structure adjoins, and some part of the ceiling through which the chimney exits to the outside, should be laid with a layer of fire-resistant material, for example, Izover material. It should also be borne in mind that the chimney pipe must be straight, and without any bends or turns should come out strictly vertically upward.

Usually the pipe has to be bent if the structure was first made, and only after that they began to think about its location. Therefore, you first need to decide on the location of the structure, and only then begin manufacturing the structure.

The boiler is the main attribute of the bathhouse. For it to truly perform its functions, it must be installed correctly, in accordance with all the rules. Only then will the operating process be a pleasure

Rectangular boilers

Before making a boiler for a rectangular bath, you need to select sheet metal in the required quantity. Its thickness should be at least 4 mm, but it is better to find alloyed heat-resistant steel. If you don’t have it, you can take a regular one, 5-6 mm thick. To heat a steam room with a volume of 20 m3, the dimensions of the combustion chamber should be approximately 450 x 450 with a height of 600 mm. In this case, we consider a firebox standing vertically. Orientation in space does not play a special role; it all depends on the availability of free space.

Rectangular sauna boiler

Further instructions on how to weld a sauna boiler with your own hands:

- Mark the steel sheet and cut it using a grinder. Cut strip metal into stiffeners, pipes for the air damper and chimney.

- Weld the firebox body. Cut a hole at the bottom of the front for the door, and in the lid for the chimney pipe. Weld the pipe as shown in the figure, as well as the remote channel for loading firewood.

- Weld stiffening ribs from a strip 4 mm thick to all walls of the combustion chamber. In addition to strengthening the structure, the ribs improve heat exchange between the firebox and the room air.

- Fabricate and install a loading door with adjustable hinges and a locking mechanism. A pipe with an air damper can be cut into the body of the door, which will regulate the supply of combustion air.

- Attach the sides for the installation of the upper heater. This design is not mandatory; often the entire boiler is fenced with a net and the space between it and the body is filled to the top with stones.

The principle of assembling a horizontal stove is not much different; it can be implemented by studying the drawing for a boiler in a bathhouse:

Drawing for a boiler in a bathhouse

In this design, the heater is immersed inside the firebox due to a recess on top of the body. The stones will warm up perfectly, but the volume of the combustion chamber is reduced. The installation of a grate and an ash pan door is provided here; in this case, there is no need to embed an air damper into the loading door.

Recommendations for effective operation

During operation of a boiler that consumes solid fuels, slag deposits remain in its firebox. As they accumulate, they must be removed periodically. In addition, to maintain the energy efficiency of such a boiler, certain actions should be taken periodically.

Firstly, from time to time the walls of the boiler must be cleaned of accumulated ash and soot. Due to the millimeter layer of carbon deposits on the walls, the energy efficiency of a solid fuel boiler decreases by 3%. It must be cleaned at least once every seven days. In this case, the boiler must be turned off and its walls cooled down.

Secondly, as the grate becomes clogged with ash, the boiler will also gradually lose its energy capacity. If such a phenomenon has been noticed, it can be eliminated quite simply - by slightly moving the contents of the firebox.

Modern models of solid fuel boilers are equipped with a special lever for turning the coals, and, if necessary, it will help dump the coals.

Thirdly, in order to improve the circulation of water along the thermal circuit of the boiler, a circulation pump can be used. This will significantly increase the energy efficiency of the thermal unit, since the movement of the coolant through the system will occur much faster, and it will return to the boiler at a higher temperature.

This means that less thermal energy will be required to reheat it, therefore, the energy efficiency of such a boiler will be noticeably greater.

The circulation pump can be located in front of the boiler entrance in the water return pipe

Fourthly, it is worth monitoring the state of draft in the smoke exhaust duct. To keep it in optimal condition, the chimney must be cleaned at least once a year. Sections of the chimney duct running through rooms without heating must be insulated.

This must be done to prevent the formation of condensation vapors. They, in turn, are harmful because, when they accumulate, they interfere with the normal release of combustion products.

And in order for the fuel to be used most efficiently, it is necessary to set the temperature regulator to the minimum performance position, but only when the room in the house has warmed up well and the temperature outside has become warmer.

The owner of a private house can always choose how to perform the entire range of work: with his own hands or through specialists from companies involved in installing boilers

Boiler models

- Gas.

- Electrical.

- Solid fuel.

- Liquid fuel.

- Pyrolysis.

Installing a boiler in a gas bath is considered the most optimal solution. This will be the most economical option for a steam room if gas is supplied to your site. Another advantage is that during combustion it does not emit an unpleasant burning odor.

Gas boiler

Of all the types, the most compact is gas:

- The weight of such boilers is about 50 kilograms.

- Power reaches up to 40 kW.

- Such a device can heat not only a small steam room, but also an area of 300 square meters.

The electric boiler is rightfully considered the most environmentally friendly.

Useful qualities of such a unit:

- They do not need ventilation.

- They are easy to use, can be easily adjusted to the desired temperature, and do not require a fuel supply.

Required Tools

For bathhouse needs, they usually purchase double-circuit gas boilers with a closed combustion chamber. They are easier to install, and in addition, do not require the use of a carbon monoxide indicator. Such sensors are required for boiler equipment with an open chamber or with air intake from the dressing room or boiler room.

The sensors are very capricious in operation, they are easily triggered by cigarette smoke and even fried potatoes, so it is still better to buy closed models for a bathhouse.

To install the boiler you will need:

- Hammer with ring drill and drill;

- A set of anchor bolts or hooks, this fastener is often included with boiler equipment;

- Template for marking the wall.

Simultaneously with the installation of the boiler, the heating system is being installed, so you will need a soldering iron for polypropylene pipes, registers, taps and shut-off valves.

Oven made of metal sheets

Oven made of metal sheets

Let's consider another option for a sauna stove - an open metal heater lined with brick.

Stage 1. Preparing everything you need

Most of the consumables can be purchased at a hardware store, but the components of the firebox are sold only in specialized retail outlets. So, the work requires:

- sheet steel (5 mm) for the walls of the structure;

- steel (10 mm) for the bottom - it should be thicker, since the lower part of the boiler is usually more exposed to high temperatures;

- factory boiler elements (doors, taps, tank, etc.);

- reinforcement rods ø3 mm - a mesh for stones will be constructed from them;

- channels;

- 1.5 mm thick tin for making a chimney (more precisely, its lower part);

- asbestos for the top of the pipe.

Note! To fasten the chimney elements, a flange connection is used, and a damper is installed at the junction. This is the most fireproof option, since most of the channel will be protected from ultra-high temperatures.

Stage 2. Assembling the structure

stove-heaters with a built-in water tank: a - heater with single walls; b - heater with a side wall in the form of a water tank; c - heater with water tanks and an air gap in the wall

Step 1. First, a drawing of the future boiler is created - this is a very important and mandatory stage of work. The drawing should include: a top, side and sectional view of the structure, the main parameters of all elements separately (in millimeters), sketches of the most important components, etc.

To do this, you need to clearly understand the principle of operation of the boiler, master special terms and the “language” of the circuit.

Marking a metal sheet

Welding a body from steel sheets cut according to markings

Housing welding

Housing welding

Step 2. Buying everything you need (this was described in the previous section).

Step 3. Metal cutting is performed. A thick-walled box is formed from sheet steel, which will serve as the body for the boiler.

Note! When cutting, you should use only high-quality metal scissors, since the evenness of the edges will depend on this.

Step 4. The cut sheets are welded. To do this, you need to be a professional welder or hire one (for an appropriate fee), because the welding seams must be perfect.

We weld a piece of pipe inside the furnace body

We weld a piece of pipe inside the furnace body

We form a water tank. We cut a hole in the combustion chamber for the chimney

Water tank and chimney with damper

We equip the stove with a combustion door

We weld a pipe to connect the tap to the back of the water heating boiler

Step 5. A brick screen is built. It is necessary to mitigate the effects of high temperatures, the source of which will be a metal structure. A kind of brick box is constructed with ventilation holes around the perimeter (as in the previous version).

An example of lining a stove in a bathhouse with bricks

An example of lining a stove in a bathhouse with bricks

Types of heat exchangers

Heat exchangers

Heat exchanger is a device used to heat water. The more efficiently it works (the greater the efficiency), the better the heating stove heats, the higher the temperature in the rooms can be. The heat transfer coefficient depends on the material of manufacture and the total area.

Example of a copper heat exchanger

It is best to make heat exchangers from copper, but this option has three significant drawbacks:

- high cost of copper. The heat exchanger requires a large number of thick-walled copper pipes; at current prices, the cost of such material can be equal to the cost of the entire boiler;

- complexity of manufacturing. Copper can only be welded in an inert gas environment; it is impossible to do this at home. Another method of making a copper heat exchanger is soldering. Unfortunately, such connections do not have satisfactory strength indicators, especially at high temperatures;

Welding (soldering) of copper

- copper under the influence of an open flame quickly oxidizes, becomes fragile and burns out.

Heat exchanger made of copper pipes

For heat exchangers in solid fuel boilers, it is optimal to use materials made of carbon sheet steel of ordinary quality with a thickness of at least one millimeter.

Thick-walled pipes

An important factor in the efficiency of a boiler is the heat exchanger area. There are two options to solve the problem.

Tubular heat exchanger

Prices for heat exchangers

heat exchanger

First. Increase the internal area of the firebox and, due to this, the dimensions of the heat exchanger. The option is good, but difficult to implement. A large firebox is not always appropriate in a sauna stove; increasing its dimensions causes significant difficulties during manufacturing, excessive consumption of materials, etc.

Second. Increase the heat exchanger area. Heat exchangers can take the form of containers with flat walls or be tubular. The second option significantly increases the effective heat exchange area, the water heats up faster, and the efficiency increases noticeably.

Heat exchanger - photo

Building a boiler yourself

There is nothing special or complicated about building a boiler for a sauna with your own hands. Before starting work, you need to prepare special tools and materials, and if there are instructions, study them carefully.

Material

The correct installation of the boiler in the bathhouse depends on the material that will be used in the process.

- When installing boiler equipment, professionals usually choose metal barrels with a volume of up to 200 liters for its base. To do this, you can use a small piece of thick pipe, up to 1 meter long and 51 centimeters in diameter.

Advice! Do not install the sauna boiler very close to wooden walls to avoid fire.

Homemade boiler diagram

- Such an installation can heat a room with a volume of up to 15 cubic meters, which is an area of 3 x 3 square meters. First you need to prepare > with metal circles and a home welding machine. grinder>

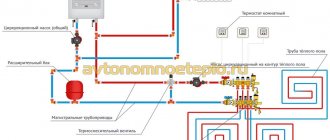

Heating system with heated floors

Modern underfloor heating systems are represented by electric and water heated floors. Water floors are an economical and affordable way to heat rooms, requiring high-quality installation, since repairing such a system is quite difficult.

To heat a rest room, dressing room or washing room, it is enough to install heated floors. All work can be done with your own hands. To do this, it is necessary to select pipes of a suitable diameter, calculate the operating resistance of the heating circuit and the required pump power, taking into account the area of the room.

Warm floors can be combined with radiator, electric and air heating.

Power control mechanisms

One of the main criteria for choosing equipment for a bath is temperature control tools. There are only 2 scenarios on the specialized market: stepped and smooth.

Models operating on the basis of several heating elements usually provide stepwise power adjustment. To change the operating mode of such a boiler, it is necessary to activate or turn off some of the heating elements. Depending on how many of them will be involved in the work, you can set 4 power levels from 25% to 100%.

Step power adjustment

But judging by user reviews, smooth adjustment is more comfortable and economical, since it can be used to set specific temperature parameters. A smooth transition between indicators is ensured using a rheostat.

You can find budget models on sale that are characterized by low power and do not provide adjustment tools at all.