Selecting a burner correctly is an important step in the construction or repair of a boiler room. The further operation of the heating equipment depends on how responsibly the managers and organizers approached this issue.

Modernization of the heating sector is the most important task facing managers of housing and communal services. Choosing a partner for the design, supply, installation and commissioning of equipment is not a problem, but the question of the efficiency of operation of boiler houses after their conversion remains open. A limited budget forces you to find the simplest solutions - purchase cheap, short-lived equipment that requires constant attention. But now there are fully automated systems, for the selection and maintenance of which it is best to contact highly qualified specialists who have a complete understanding of how a modern boiler room should function.

When choosing burners, consumers are faced with a difficult task: what to give preference to - domestic or foreign equipment. And here sellers of imported burners often use a cunning trick: they compare smooth two-stage burners of foreign production with modulated burners of domestic production. Even with a significant difference in prices for “similar” products, they insist on German, Finnish, Italian quality, trying to persuade buyers to purchase these particular burners. However, any specialist working with boiler equipment understands that comparing different types of burners only based on the price component is at least incorrect. Therefore, it is necessary to know the difference between their technical characteristics and capabilities.

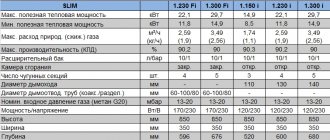

Table for calculating fuel savings when installing modulating burners compared to staged burners

The most widespread in boiler houses are two-stage, smoothly two-stage and modulating burners. Two-stage burners, as the name suggests, have two power levels. The first stage provides 40% of the power, and the second - 100%. The transition from the first stage to the second occurs depending on the controlled boiler parameter (direct water temperature or steam pressure), the on/off modes depend on the boiler automation.

Smooth two-stage burners allow a smooth transition from one stage to the second. This is a cross between a two-stage and modulating burner. Modulating burners heat the boiler continuously, increasing or decreasing power as needed. The range of combustion mode changes is from 10 to 100% of the rated power.

Of course, modulating burners are more expensive than stepped models, but they have a number of advantages over them. The mechanism for smooth power control allows you to reduce the cycle of turning on and off boilers to a minimum, which significantly reduces mechanical stress on the walls and components of the boiler, and therefore prolongs its “life”. Fuel savings are at least 5%, and with proper tuning you can achieve 15% or more

. And finally, installing modulating burners does not require replacing expensive boilers if they are functioning properly. When staged burners operate, the boiler experiences significant loads, which eventually destroy the unit.

Against the background of the disadvantages of stepped burners, the advantages of modulating burners are obvious. The only factor forcing managers to choose step models is their lower price. But savings of this kind are deceptive: wouldn’t it be better to spend a large sum at a time on more advanced, economical and environmentally friendly burners, especially since these costs will pay off in the next few years?

Smart managers understand the benefits of using modulating burners, and now all they have to do is select the necessary models. Which manufacturers are best to contact? Even with a superficial study of prices for imported and domestic burners, it is clear that the difference is quite significant. Some models from foreign manufacturers are more than twice as expensive as Russian-made products. And yet, stereotypes that quality goods come only from abroad force people to pay more. However, a more detailed analysis of the market for burner manufacturers shows that we also have high-quality competitive products. For more than 15 years, the Starorussian Instrument-Making Plant has been producing various models of burners that are successfully installed on all types of domestic and imported boilers. Modulating block burners from this manufacturer comply with all environmental standards for fuel combustion, have a wide range of power control (from 10 to 100%), while ensuring maximum efficiency. When looking for reliable, economical burners for boiler rooms, it’s simply impossible not to pay attention to them. Simple installation of equipment already produces tangible results, and if experienced burner adjustment specialists are involved in the process, fuel savings can amount to more than 15%. With the use of modulating burners from Staroruspribor, managers will be able to temporarily forget about another cost item - replacing the boiler. Switching to a “gentle” operating mode allows you to double its service life

. Those who know how expensive such equipment is (prices are calculated in millions of rubles) will appreciate the possibility of replacing these units more rarely.

Selecting a burner correctly is an important step in the construction or renovation of a modernized boiler room. The further operation of the heating equipment depends on how responsibly the customers approach this issue. If, for example, you use modulating burners produced by JSC “, then after two or three heating seasons the costs will be more than recouped. Stable operation, compliance with environmental standards, longer service life of boilers and the ability to fully automate the operation of a thermal power plant indicate significant advantages of using modulating burners in boiler houses. And if the benefit from their operation is obvious, not taking advantage of it is simply unreasonable.

Important flame modulation function

What is the modulation level of a gas boiler burner? In simple words, this is a mode for automatically changing the flame intensity. This flexible setting allows you to save on fuel consumption, because the strength of combustion will depend on how hot the water flows from the tap.

The temperature inside the heating system is constantly changing, and the boiler’s task remains to maintain it at the same level. Modulation allows the owner to set the optimal temperature indicator, which the device’s automation will focus on. She will be able to control the functionality of the water heating device in accordance with the task.

Modern double-circuit boilers are equipped with modulating burner equipment out of the box.

Basic elements of an automatic control system

Devices included in the electrical circuit of the burner for automatic operation:

- The maximum and minimum gas pressure switch has a simple design, which affects its long service life. Its principle of operation is that the gas pressure acts on the membrane, and if it deviates from the set value, it is triggered and the control valve makes the necessary adjustment. The minimum gas pressure switch protects against a drop in gas pressure to a critical value, and the maximum pressure switch carries out regulation, preventing the permissible value from being exceeded.

- The thermostat is an indicator of reaching temperature limits. According to its signal, the combustion modes change.

- The combustion controller is an element that combines the operation of the entire burner into a single process. The burner operation is divided into several points, which correspond to a certain position of the air damper and the fuel control valve. When a low temperature signal is received, the corresponding mechanisms open to increase combustion power. The controller's operation is based on signals from various sensors (pressure, temperature).

- Minimum and maximum coolant pressure relays protect the heating system from excessive drops and increases in coolant pressure. Both cases are dangerous for the continued operation of the boiler, therefore, when a critical value (lower or upper) is reached, the boiler turns off, that is, the gas supply stops.

- The boiler filling sensor is needed to provide protection against turning on the burner without the presence of coolant in the boiler.

Connecting the sensors depends on the brand of the boiler; this information can be found in the unit’s passport, and the specifics of connecting the sensors are described in detail in the attached instructions.

The connection and configuration of the automation system must be supervised by a gas service specialist. Commissioning work is also carried out in his presence with the mandatory drawing up of a certificate of suitability of the equipment for safe operation.

Gas

The work uses the cheapest fuel to maintain flame stability and silent combustion. Such burners ensure complete combustion of gas and the absence of harmful emissions. They can process both liquefied gas and natural gas.

The launch takes place in a matter of seconds. Some models are equipped with a self-diagnosis system. The equipment is installed in gas boilers, heat generators, and is also used for metallurgical furnaces, power plants, welding and construction work.

Having considered what flame modulation is in a gas boiler, you can familiarize yourself with the design of the burner. It consists of:

- extended or regular head;

- gearbox and fuel supply regulator;

- microprocessor for automatic operation;

- nozzles spraying the gas-air mixture;

- ignition systems (piezoelectric element).

The burner mixes gas with air and burns the resulting mixture. This helps maintain an even flame.

In turn, gas burners are divided into several classes according to the method of formation of the fuel mixture:

- Diffusion. Natural air supply. They are used in boilers for heating systems, glass melting and steel furnaces.

- Supercharged. Air injection by fan.

- Injection. Air suction depends on the pressure of the gas jet. They work with natural gas. For propane, you will need to install an additional kit to the cylinder.

Classification of gas burners by type of temperature control

With the development of technology, new, improved methods of automatic temperature control have been developed:

- Single-stage burners are primitive devices; their operating principle is described above. They work in the same mode.

- Two-stage burners are devices capable of operating in two modes (40 and 100% of total power), automatically switching between them.

- Smooth two-stage burners are burners operating in two modes (40 and 100%), but their switching between modes is carried out more smoothly, which significantly increases fuel economy and the quality of temperature maintenance

- Modulating gas burners are the most functional devices, capable of operating in a wide power range (from 10 to 100%). Such burners are capable of maintaining temperature conditions with a deviation of only 20C from the set value. At the same time, the efficiency of fuel combustion increases and the temperature loads on the elements of the heating unit are reduced.

The copper heat exchanger is the most efficient of all, as it has good thermal conductivity and thin walls. But it does not tolerate high temperature stresses well, and therefore has a short service life. In combination with a modulating burner, its service life becomes longer.

Gas burners with the ability to change the degree of combustion are expensive, but their efficiency will quickly pay for the costs:

- saving up to 30% of fuel;

- temperature is maintained within a narrow range;

- the service life of the entire unit increases.

Read about the benefits of installing a magnesium anode for a boiler in the article.

You will find information about TGE universal multi-fuel boilers at the link -

Modulation operating principle

What is a gas water heater with flame modulation? This is a unit with a burner that continuously heats the boiler, smoothly regulating the power of the device. The combustion mode is measured in the range of 10-100% of the rated power.

When the time approaches to shut down the burner equipment, the electronic system sends a signal with a command to reduce the amount of gas supplied to the valve. The combustion power decreases. The boiler or heater does not turn off.

For example: a certain amount of water with a temperature of 40 degrees passes through a gas water heater. If the liquid flow suddenly increases, the burner automatically increases power in order to maintain the water temperature at the same level. Accordingly, if the flow rate decreases, the modulation will switch to a more economical power mode.

It is worth remembering that some speaker models do not support automatic power changes depending on the flow. In such cases, the user adjusts the burner parameters manually.

An example of modulation can be seen here:

To understand flame modulation in a gas boiler, what it is, you need to familiarize yourself with the operating principle of modulated burners. According to this criterion, they are divided into three categories:

- Mechanical.

- Pneumatic.

- Electronic. This is the most accurate type of burner equipment, since it eliminates errors associated with mechanical factors.

How economical is a gas water heater with flame modulation?

Every potential buyer of an instantaneous water heater, when choosing a device, wants to find the most profitable option for himself. If you want to purchase a device that will save not only money, but also your time, you should choose a gas water heater with modulation. Let's take a closer look at the principle of its operation.

How much gas does a modulating burner save?

Flame modulation is an automatic change in combustion intensity depending on the heat demand. The required amount of heat is determined by the automation unit and depends on the water heating temperature set by the user.

A gas water heater with flame modulation provides users with a high level of comfort - you just need to set the desired water heating temperature, and the water heater itself will maintain this temperature. Modulation eliminates the unpleasant situation when, turning on the second water intake point, cold water begins to flow from the first tap.

The main advantage of a column with a modulating burner is its cost-effectiveness. The fact is that when the set water temperature is reached, the burner reduces the combustion intensity to a minimum. If the water begins to cool, the flame increases until the required heating is achieved. Thus, the burner uses the optimal amount of fuel and does not allow its overconsumption, which significantly saves financial costs on gas.

The multi-stage burner is capable of changing power from 40 to 100%. Flame modulation also extends the life of the heat exchanger and the device itself.

Gas water heater selection parameters

A gas water heater with flame modulation may differ in the following parameters:

- Type of flame modulation: hydraulic - implies a direct connection between water flow and flame regulation; electronic - the connection between water flow and changes in fire is provided by a temperature sensor.

- Productivity - it is important to correctly calculate how much water is needed to provide a certain number of water intake points. To supply one tap, a model with a capacity of 5-9 l/min is sufficient. To take a shower, you need more water - 12-15 l/min. To provide 3-4 water intake points, a productivity of 17 l/min or more is required.

- Combustion chamber type: devices with an open chamber require enhanced ventilation and the installation of a full-fledged chimney; columns with a closed firebox are more versatile and convenient to use.

Some models of geysers are equipped with ionization flame control. It is understood as the principle of recording the current appearing between the ionization electrode and the section of the burner device. The flow of ions appears during the oxidative reaction between gas and oxygen. The flow closes the electrical circuit and a signal is sent to the control unit that ignition has occurred.

The best models of geyser with modulation

Mora Vega 10

The maximum thermal power of the device is 17.3 kW with a capacity of 10 l/min. This column is one of the best in quality, it has electric ignition and is suitable for household systems. The device is reliable and has a long service life. The column has an open combustion chamber and a rich security system.

Hyundai H-GW2-ARW-UI307

A geyser with a universal design that starts automatically when the water is turned on. The ignition unit runs on batteries. The panel has a small liquid crystal display. This model is distinguished by the presence of a 4D-guard protection system. It includes an ionization rod and many sensors that control draft, temperature, and the volume of water passed through.

Ariston Fast Evo 11B

The performance of the model is 14 lmin. On the panel there is one knob for regulating the water temperature and an indicator that indicates the need to replace the batteries of the electric ignition. Next to the water inlet there is a knob with which you can adjust the volume of incoming liquid.

Bosch WR 10-2P

The model has large dimensions and ignition with piezoelectric elements. The heat exchanger is made of copper and can last about 15 years. The device does not overheat during operation.

Find out here what are the advantages of a gas water heater with a closed firebox?

Neva 4510-M

This is a fairly compact model with a flat body. Has an aluminum heat exchanger and automatic ignition. Produces domestic hot water at a rate of 10 l/min. The advantage of the model is its low cost and good maintainability.

The panel has two handles and a digital display.

Bosch WRD 13-2G

It is distinguished by reliability and high quality. The model is equipped with a hydrodynamic generator that ensures stable operation of the column.

The water supply fittings are made of polyamide reinforced with glass fiber. The column is equipped with a security system: temperature sensors, draft, flame and water pressure sensors.

Advantages of boilers with modulation function

After we have figured out what flame modulation in a gas water heater is, we can familiarize ourselves with the advantages of such models. There are several of them:

- Constant water temperature in the tap and shower, without interruptions or surges.

- Saving resources. Throughout its “life”, the boiler operates at maximum power 20% of the time. This figure can be significantly reduced by using a modulated burner.

- Fuel economy. The modulated burner allows you to achieve 5% fuel savings. If you configure the element correctly, this figure can be increased to 15%.

- Reducing the number of turns on/off of the unit, and, accordingly, relieving mechanical stress in the components and on the walls of the boiler. And as a nice bonus, the constant “clack” of the unit is eliminated.

- High level of automation for any heating and heating systems.

- Weather-compensated regulation.

- Application in production with strict technological requirements. Some processes do not allow even the slightest temperature changes, so modulating burners are just what you need.

Gas boiler modulation

A gas heating boiler is a device that uses fuel combustion (natural or liquefied gas) to heat the coolant.

Design (design) of a gas boiler

: burner, heat exchanger, thermally insulated housing, hydraulic unit, as well as safety and control devices. Such gas boilers require a chimney connection to remove combustion products. The chimney can be either ordinary vertical or coaxial (“pipe in pipe”) for boilers with a closed combustion chamber. Many modern boilers are equipped with built-in pumps for forced water circulation.

The principle of operation of a gas boiler

— the coolant, passing through the heat exchanger, heats up and then circulates through the heating system, releasing the resulting thermal energy through radiators, heated floors, heated towel rails, and also providing water heating in an indirect heating boiler (if it is connected to a gas boiler).

A heat exchanger is a metal container in which the coolant (water or antifreeze) is heated - can be made of steel, cast iron, copper, etc. The reliability and durability of a gas boiler depend primarily on the quality of the heat exchanger. Cast iron heat exchangers are resistant to corrosion and have a long service life, but are sensitive to sudden temperature changes and are heavy. Steel containers can suffer from rust, so their internal surfaces are protected with various anti-corrosion coatings to extend the “life” of the device. Steel heat exchangers are the most common in boiler production. Copper heat exchangers are not susceptible to corrosion, and due to their high heat transfer coefficient, low weight and dimensions, such heat exchangers are often used in wall-mounted boilers, but the downside is that they are more expensive than steel ones. In addition to the heat exchanger, an important part of gas boilers is the burner, which can be of various types: atmospheric or fan, single-stage or two-stage, with smooth modulation, double.

To control a gas boiler, automation is used with various settings and functions (for example, a weather-dependent control system), as well as devices for programming operation and remote control of the boiler.

The main technical characteristics of gas heating boilers are: power, number of heating circuits, fuel type, type of combustion chamber, type of burner, installation method, presence of a pump and expansion tank, automatic boiler control.

What is the best gas boiler to choose and how to choose by area? You can find out more in the article: How to choose a gas boiler.

To determine the required power

For a gas heating boiler for a private country house or apartment, a simple formula is used - 1 kW of boiler power to heat 10 m 2 of a well-insulated room with a ceiling height of up to 3 m. If heating is required for a basement, glassed-in winter garden, rooms with non-standard ceilings, etc. The power of the gas boiler must be increased. It is also necessary to increase the power (about 20-50%) when providing a gas boiler and hot water supply (especially if it is necessary to heat the water in the pool).

Feature of power calculation for gas boilers: the nominal gas pressure at which the boiler operates at 100% of the power declared by the manufacturer, for most boilers is from 13 to 20 mbar, and the actual pressure in gas networks in Russia can be 10 mbar, and sometimes lower . Accordingly, a gas boiler often operates at only 2/3 of its capacity and this must be taken into account when calculating. More details on the table for calculating the power of a heating boiler can be found here

Most gas boilers can be converted from natural gas to liquefied gas

(cylindered propane). Many models switch to liquefied gas at the factory (when purchasing, check these characteristics of the model), or the gas boiler is additionally supplied with nozzles (nozzles) for switching to bottled gas.

Pros and cons of gas boilers:

Gas boilers are the best choice if you have mains gas or liquefied gas.

(+) low cost of use (+) economical (+) ease of operation (+) high power (+) compact size (+) popularity (+) many options for manufacturers and costs

(-) the need for constant availability of gas and its sufficient pressure (-) strict requirements for installation (-) the need to obtain permission for installation (-) constant monitoring of gas leaks (-) the need for professional connection and maintenance (-) certain requirements for the premises, where is the boiler installed

The heating boiler can have one (for heating only) or two circuits (heating and hot water supply (DHW)). An external boiler can be connected to a single-circuit boiler to provide hot water (from 100 to 3000 liters at the buyer’s choice, the best option for large hot water consumption or with several water collection points). You can also pay attention to boilers with a built-in boiler. Of course, they are larger in size and weight than regular ones, and in some cases their maintainability is lower, like any other device that combines two devices, but sometimes this is the best option to provide both heat and water at once.

The most economical boilers are condensing boilers. Thanks to the use of modern technologies, the efficiency of such boilers is 10-11% than that of conventional ones. Operating principle of a condensing boiler

: When gas is burned, combustion products are formed, which contain a large amount of steam. When steam condenses, it releases a certain amount of heat, which can also be used to heat the coolant. Steam condensation occurs in a special heat exchanger of increased area, which supplies additional heat to the heating system. The advantages of condensing boilers are exceptional efficiency and cost-effectiveness compared to conventional ones, the disadvantages are the high price and the need for constant removal of condensate that forms in the heat exchanger.

Gas boilers by installation method

can be floor-mounted or wall-mounted (mounted). Wall-mounted boilers most often have small power and dimensions, while high-power industrial boilers are floor-standing, have large dimensions and are installed in large-area boiler rooms.

Boiler connection

is carried out in accordance with the installation and operating instructions supplied with it. Each gas boiler option has its own installation features in a specific location. To correctly install and connect a gas heating boiler, you must contact professional installers who are certified to work with gas equipment.

Requirements for the premises, norms and rules for installing a gas boiler

: For gas equipment, strict requirements are imposed both on the room where it will be installed, and on the equipment itself and the installation method. You can read more about this topic here: Rules and requirements for installing gas boilers

Boiler piping

- These are devices for the full operation of the heating and water supply system. It includes: pumps, expansion tanks, filters (if necessary), manifolds, check and safety valves, air valves, valves, etc. You will also need to purchase radiators, connecting pipes and valves, thermostats, a boiler, etc. The issue of choosing a boiler is quite serious, so it is better to entrust the selection of equipment and its complete set to professionals.

Which boiler is the best? The Russian market of gas boiler equipment has its own leaders in quality and reliability. The best manufacturers and brands of gas boilers are presented in the assortment:

“Premium class” or “Lux” are the most reliable and durable, easy to use, the kit is assembled like a “construction set”, more expensive than others. Such manufacturers include the German companies Buderus and Viessmann.

“Middle class” - good performance, average price, not so prestigious, but quite reliable, standard standard solutions are presented. These are Italian boilers Ariston, Hermann and Baxi, Swedish Electrolux, German Unitherm and boilers from Slovakia Protherm.

"Economy class" - budget simple gas boilers, service life is shorter than that of boilers of a higher category. Some manufacturers have budget models of gas boilers, for example, Ferroli or Neva Lux. Domestic gas boilers and boilers of imported brands, but Russian production (assembly) are distinguished by affordable prices and high maintainability.

See also:

Need help choosing or haven't found the model you're looking for?

Call!

Briefly about the main thing

Modulating burners are a good way to save on fuel and also extend the life of gas equipment. The operating principle of such installations is to automatically adjust the boiler power to maintain the set temperature and reduce the on/off cycle of the unit. This is not just another marketing ploy, but a truly reliable and practical solution for both home heating and water heating systems, and for industrial equipment.

In your opinion, is it worth spending money on modulating burners? Or maybe it’s better to opt for cheaper step options?

Automatic temperature control system

The most primitive system for automatic control of a set temperature with the participation of a gas burner works as follows: gas is supplied to the burner, ignited by the ignition system, and stable combustion occurs. In this case, the burner operates at full capacity.

When a certain temperature value of the coolant or air in the room is reached, the burner goes out. To maintain the set temperature, it is constantly turned on and off.

Modulating gas burner operating principle

Single-stage, two-stage and modulating burners for heating boilers. Review.

When choosing burners, consumers are faced with a difficult task - which burner to choose. This choice allows them to make a small comparison of burners from different manufacturers by type of regulation and level of automation of the burner device.

We invite you to familiarize yourself with the opinion of our company’s specialists, based on the experience of using combined, liquid fuel and gas burners from Weishaupt, Elco, Cib Unigas and Baltur.

Let's determine the basic requirements for burners, depending on the application. Depending on the area of application, burners can be divided into groups.

Group 1. Burners for individual heating systems (in this group we include burners with a power of up to 500 - 600 kW, which are installed in boiler rooms of private houses, small industrial and commercial and administrative buildings).

When choosing burners for this group of consumers, it is necessary to take into account the buyer’s wishes in the level of automation of an individual boiler room:

· if you do not have high technical requirements for the installed equipment and want to have a reliable boiler room that does not require large initial financial investments, then you can opt for burners with single-stage or two-stage operating modes;

· if as a result you want to build a heating system with a high level of automation, weather-dependent regulation, as well as low fuel and energy consumption, then you are better off using modulating burners or burners with smooth two-stage regulation, which will provide the ability to program power and a wide operating range of burner regulation .

Group 2. Burners for heating systems of large residential complexes (in this group we include burners with a capacity of more than 600 kW for the needs of housing and communal services, central heating, as well as for heat supply of large industrial and commercial and administrative buildings).

Comments

| ALEXEY Guest | Added: 02/15/2019 — 9:42 Over the period of more than 20 years of cooperation with Staroruspribor in the field of boiler equipment, not a single criticism. Very strong design department. Always qualified assistance. Burner devices with thoughtful design differences from imported burners. Excellent quality, and the price speaks for itself. |

| to come back to the beginning | Quote |

| Cloud Guest | Added: 11/25/2019 — 21:13 The unique and colorful graphic design will suit the tastes of the fastidious adrenaline fan. The slot machine is ready to introduce the player to extreme sports, which generously gives winnings. https://777gaminatorsslot.com |

| to come back to the beginning | Quote |

| dirdir Guest | Added: 12/23/2019 — 20:04 You will find a great collection of gambling apps. No one will be disappointed, since slot machines https://azino777pro.com/igrovi... are presented in different categories. |

| to come back to the beginning | Quote |

| Alan1221 Guest | Added: 03/02/2020 — 20:36 I made a lot of mistakes, I only recommend https://casinofrank-klub.com/a... |

| to come back to the beginning | Quote |

| Vasichka Guest | Added: 03/23/2020 - 1:11 It’s better to go here https://onlineprestige-vulkan.... so as not to spoil the nerves of yourself and those around you |

| to come back to the beginning | Quote |

Smooth flame modulation - what is it?

There are quite a lot of criteria for choosing heating installations or instantaneous water heaters in which the heat source is a burner. All of them, as a rule, are known to most potential buyers. But to the question of what flame modulation is, only a few will answer correctly; tested, and more than once. But this is far from an insignificant factor, and it should definitely be taken into account when assessing the feasibility of purchasing equipment. That is, ask whether the device you like has such a function or not. So why is it needed and is this engineering solution just another marketing ploy, the purpose of which is simply to increase the price of the product without improving its functionality?

What is flame modulation?

In relation to the burner, the “decoding” of this term is quite simple - the possibility of flexible (and therefore smooth) control of its operating modes. Depending on external factors, the temperature in the heating circuit is constantly changing, while the boiler must maintain it at the required level. The optimal value is set by the user, and the device’s automation is already “oriented” towards a specific value, controlling the operation of the installation (by adjusting its power at the moment).

In traditional boiler models, burners are either unregulated (outdated versions) or two-stage (more modern versions). But even this improved performance is not without its drawbacks. In order to select the optimal mode and better adapt to real conditions, such burners switch to another in jumps. Consequently, there is no need to talk about any smooth control, that is, precise temperature control.

Types of flame modulation

In practical terms, there is no big difference between engineering solutions, since they all pursue the same goal - to optimize the operation of equipment. There are only small but fundamental differences in the circuit design and its individual elements.

• Electronic modulation - in such burners, power is controlled by dosing the fuel supply depending on changes in coolant temperature.

A typical example is the boiler of the famous brand “Proterm” (Bear series) KLOM, which has a built-in boiler to provide domestic hot water.

• Hydraulic modulation - this method is implemented, as a rule, for DHW. Most often in instantaneous water heaters (gas water heaters). The sensor detects changes in water flow (its consumption) and transmits the corresponding command to the control valves, changing the supply of “blue fuel”. • Ionization modulation - with this method, the flame is controlled by a special sensor. He also controls the operation of gas fittings.

What is burner modulation level?

- How can I determine if the ZONT thermostat is suitable for my boiler?

ZONT has a relay whose contacts are connected to the boiler. Most boilers have terminals for connecting a room thermostat. It is to these terminals that the relay contacts are connected.

- How does the ZONT thermostat control the boiler?

ZONT turns on or off the relay connected to the boiler. The boiler turns the heating on/off. This ensures a certain average coolant temperature (TH).

- What is hysteresis and how is it used?

Hysteresis is the temperature value that makes the “dead zone”. For example, we set the temperature to 25 degrees and the hysteresis to 0.5 degrees. Then, when the temperature rises to 25.5 degrees, the boiler will turn off and when it cools to 24.5 degrees, the boiler will turn on.

What will happen to the boiler in the range of 24.5-25.5 depends on the management history. As long as the temperature is in this range, the boiler will maintain its current state. That is why this zone is called the “dead zone” or the hysteresis zone.

In the case of the OpenTherm interface, hysteresis is not used; a different algorithm is used there.

- What is "dry contact"?

The point is to isolate electrical circuits. The relay contact is a special case of a dry contact; it has no connection with the rest of the circuit. Therefore, it can be used, for example, to connect to 220V circuits, a dangerous voltage for both humans and electronic circuits.

- What is the temperature control error of the ZONT thermostat?

If you do not take into account the inertia of the house, then the error will be equal to the hysteresis value. In life, everything is more complicated, because the inertia of water supply to the radiators and the inertia of heat transfer to the room can significantly increase this error.

- In what cases is notification performed not only about an event, but also about its end?

- How to connect a ZONT thermostat to a Baxi Luna 3 Comfort boiler?

ZONT is connected in relay mode to the terminals for the boiler room thermostat.

There is a parameter F10 on the boiler control panel. If you set its value to 02, the boiler will be switched to control mode from an external room thermostat (in this case, by commands from ZONT). If you set its value to 00, the operating mode will be enabled through the boiler’s own control panel.

- What if, after connecting via the OpenTherm interface, the boiler control does not work?

If the ZONT web interface “does not see” the boiler parameters (or all parameters are zero), then the circuit is most likely assembled incorrectly. The connecting circuits between the ZONT thermostat, the OpenTherm interface and the boiler should be rechecked.

You can measure the voltage on the communication line with the boiler. Usually there should be a voltage of 5-7 Volts. If you disconnect the wires from the boiler, then there should be a voltage of 20-24 Volts on the boiler, and 0 Volts on the OpenTherm Interface.

- How can I determine if my boiler will work with the OpenTherm interface?

In most cases, the instructions directly indicate that the boiler can operate using the OpenTherm interface. In cases where this is not expressly stated, you can contact the boiler manufacturer’s service center specialists. An indirect sign of working using the OpenTerm interface is the display of additional boiler parameters through a remote thermostat. Such as pressure, coolant temperature, modulation percentage, etc.

- How to make a fixed TN temperature when using the OpenTherm interface?

You can set the maximum temperature of the heater equal to the desired one. And set the temperature in the room much higher than the real one, let, for example, 60 degrees. Then the boiler will soon enter the fixed heater temperature mode.

- How does the OpenTherm interface control the boiler?

The only heating parameter that is controlling is the heating element temperature. The ZONT thermostat calculates it according to its algorithm and transmits it to the boiler. The task of the thermostat is to maintain the set temperature in the room; for this, it constantly recalculates the temperature of the heater.

- How does the boiler ensure the set heater temperature in the case of the OpenTherm interface?

Typically, boilers with OpenTherm have a modulating burner. Therefore, they can smoothly regulate the temperature of the HP using their own computer. However, it must be understood that the boiler’s smooth control capabilities are limited. Sometimes the minimum modulation level is quite large, for example there may be a modulation range of 30%-100%. Then the boiler computer, which has been set to a low heat pump temperature, will be forced to periodically turn the boiler on and off, that is, work in relay mode, just like a boiler without modulation.

The OpenTherm interface displays the percentage of modulation, but remember that this may have different meaning for different boilers. Some boilers display the actual level of modulation, others display something of their own. For example, if a boiler has a minimum modulation level of 30%, then some boilers may display 30%, others - 0%.

What does flame modulation do?

Those who take a practical approach to any task and are accustomed to spending money rationally should pay attention to these types of devices. The meaning and benefits of smooth flame control are easy to understand.

• Fuel consumption is optimized. Automatic regulation of flame intensity makes it possible to achieve - in terms of the season - a reduction in the cost of heating the building. • If the boiler is double-circuit, then the volume of consumed hot water does not affect its temperature in any way - it remains unchanged. • A decrease in gas pressure in the main pipeline (and this is not uncommon in winter) does not affect the efficiency of gas equipment. • The risk of failure of some boiler elements is minimized. Statistics on equipment repairs (of any type) show that the main cause of all malfunctions (up to 90%) is various switching. Therefore, step modulation clearly loses to smooth power control.

Practical recommendations

ALFATEP has been working in the field of engineering communications for several years. She will always help owners of buildings located in the Moscow region in solving problems related to heating buildings and structures. Its warehouses have a significant assortment of relevant equipment, and its staff includes qualified craftsmen. You just need to call the ALFATEP contact phone number, and its employees will help you choose the optimal boiler model, taking into account all the features of the house and the heating scheme. If necessary, they will develop another one, deliver the device to the site, install it, carry out proper wiring and test it in action. The company also guarantees technical support for the devices sold, and service specialists (upon concluding a contract) are ready to take on the responsibilities for post-warranty maintenance and repair of equipment.

Comparison of staged and modulating burners

Selecting a burner correctly is an important step in the construction or repair of a boiler room. The further operation of the heating equipment depends on how responsibly the managers and organizers approached this issue.

Modernization of the heating sector is the most important task facing managers of housing and communal services. Choosing a partner for the design, supply, installation and commissioning of equipment is not a problem, but the question of the efficiency of operation of boiler houses after their conversion remains open. A limited budget forces you to find the simplest solutions - purchase cheap, short-lived equipment that requires constant attention. But now there are fully automated systems, for the selection and maintenance of which it is best to contact highly qualified specialists who have a complete understanding of how a modern boiler room should function.

When choosing burners, consumers are faced with a difficult task: what to give preference to - domestic or foreign equipment. And here sellers of imported burners often use a cunning trick: they compare smooth two-stage burners of foreign production with modulated burners of domestic production. Even with a significant difference in prices for “similar” products, they insist on German, Finnish, Italian quality, trying to persuade buyers to purchase these particular burners. However, any specialist working with boiler equipment understands that comparing different types of burners only based on the price component is at least incorrect. Therefore, it is necessary to know the difference between their technical characteristics and capabilities.

The most widespread in boiler houses are two-stage, smoothly two-stage and modulating burners. Two-stage burners, as the name suggests, have two power levels. The first stage provides 40% of the power, and the second - 100%. The transition from the first stage to the second occurs depending on the controlled boiler parameter (direct water temperature or steam pressure), the on/off modes depend on the boiler automation.

Smooth two-stage burners allow a smooth transition from one stage to the second. This is a cross between a two-stage and modulating burner. Modulating burners heat the boiler continuously, increasing or decreasing power as needed. The range of combustion mode changes is from 10 to 100% of the rated power.

Of course, modulating burners are more expensive than stepped models, but they have a number of advantages over them. The mechanism for smooth power control allows you to reduce the cycle of turning on and off boilers to a minimum, which significantly reduces mechanical stress on the walls and components of the boiler, and therefore prolongs its “life”. Fuel savings are at least 5%, and with proper tuning you can achieve 15% or more

. And finally, installing modulating burners does not require replacing expensive boilers if they are functioning properly. When staged burners operate, the boiler experiences significant loads, which eventually destroy the unit.

Against the background of the disadvantages of stepped burners, the advantages of modulating burners are obvious. The only factor forcing managers to choose step models is their lower price. But savings of this kind are deceptive: wouldn’t it be better to spend a large sum at a time on more advanced, economical and environmentally friendly burners, especially since these costs will pay off in the next few years?

Smart managers understand the benefits of using modulating burners, and now all they have to do is select the necessary models. Which manufacturers are best to contact? Even with a superficial study of prices for imported and domestic burners, it is clear that the difference is quite significant. Some models from foreign manufacturers are more than twice as expensive as Russian-made products. And yet, stereotypes that quality goods come only from abroad force people to pay more. However, a more detailed analysis of the market for burner manufacturers shows that we also have high-quality competitive products. For more than 15 years, the Starorussian Instrument-Making Plant has been producing various models of burners that are successfully installed on all types of domestic and imported boilers. Modulating block burners from this manufacturer comply with all environmental standards for fuel combustion, have a wide range of power control (from 10 to 100%), while ensuring maximum efficiency. When looking for reliable, economical burners for boiler rooms, it’s simply impossible not to pay attention to them. Simple installation of equipment already produces tangible results, and if experienced burner adjustment specialists are involved in the process, fuel savings can amount to more than 15%. With the use of modulating burners from Staroruspribor, managers will be able to temporarily forget about another cost item - replacing the boiler. Switching to a “gentle” operating mode allows you to double its service life

. Those who know how expensive such equipment is (prices are calculated in millions of rubles) will appreciate the possibility of replacing these units more rarely.

Selecting a burner correctly is an important step in the construction or renovation of a modernized boiler room. The further operation of the heating equipment depends on how responsibly the customers approach this issue. If, for example, you use modulating burners produced by JSC “, then after two or three heating seasons the costs will be more than recouped. Stable operation, compliance with environmental standards, longer service life of boilers and the ability to fully automate the operation of a thermal power plant indicate significant advantages of using modulating burners in boiler houses. And if the benefit from their operation is obvious, not taking advantage of it is simply unreasonable.

BAXI Forum

no, the boiler controls the modulation itself and the zont does not show it.

My boiler starts at minimum, then checks to see if the return flow is cold and turns on full, then when it approaches the coolant temperature limit it reduces the modulation, from 100% to 50%. At minimum it whistles, but it doesn’t work at maximum, you can hear the noise of the flame, so there are some intermediate values. affected by heat loss. until the coolant temperature level is exceeded. The brains of the boiler do all this, using openterm you can only set the temperature of the coolant, and look at the current temperature in the boiler, it can be a little higher due to inertia. if you use a zont, then it is convenient to use the PZA of the umbrella, it focuses on the temperature both outside and in the room and adjusts the heating curve, very often it does not try to raise it, even if it is cold outside, it sees that the room is warming up.

Tell me, BAXI-Ural, RADAR, specialists, how dangerous is it for the boiler to operate at low temperatures, 40-50 at the supply, or is it not dangerous? on the Internet they say I need to keep 60 in the supply while I have radiators in the house, but I’m moving soon and I plan to turn on the TP, but there is a cold return from the TP, because the mixer is installed. I plan to also install a mixing valve on the RO, so that in the off-season we can let 40* into the RO and connect a mixing pump, to increase the return temperature, you can always turn it off (in order not to install a HS, then you can’t turn off the pump). if you can safely work with T* 40-50 at the feed, then I won’t fool around

Modulation control via Opentherm

- Quote

Post by RADAR » 05 May 2022, 20:03

Modulation control via Opentherm

- Quote

Post by junkies » 05 May 2022, 20:46

Modulation control via Opentherm

- Quote

Post by Ilgiz » 06 May 2022, 05:47

Modulation control via Opentherm

- Quote

Post by BAXI - Volga » 06 May 2022, 15:29

Modulation control via Opentherm

- Quote

Post by RADAR » 06 May 2022, 17:44

Modulation control via Opentherm

- Quote

Post by junkies » 06 May 2022, 18:02

Modulation control via Opentherm

- Quote

Post by RADAR » 06 May 2022, 19:31

Modulation control via Opentherm

- Quote

Post by asolovey » 11 Jan 2022, 14:02

Colleagues, happy holidays to all!

I’ll raise the topic of modulation and OpenTherm. I have a Baxi Eco 4s 1.24F boiler. It works in tandem with Zont H2000 via a digital bus (OpenTherm)

And after watching how it works for some time, I came to the conclusion that Zont cannot set the modulation level of the boiler. Although he knows how to do it and should. As a result, the boiler control does not work correctly.

Accordingly, question 1) Does Baxi Eco 4s 1.24F really not support external modulation control via a digital bus? 2) Are there any other Baxi boiler models that support this?

Maybe the gurus know RADAR, BAXI-Volga, BAXI-Ural?

Well, I also have a small wish for Baxi - it would be great to make such important information available for each boiler. After all, it turns out that a simple statement in the description of the boilers “supports OpenTherm” is not enough to understand how to choose the right equipment and how to configure it.

For example, I spent a lot of money and, more importantly, time on automation of heating control, fell for this story with OpenTherm, and now (apparently) it turns out that it was in vain, since in fact it is necessary to transfer the boiler to relay mode without any digital buses. If I had known in advance, I would have built the system completely differently. Or does this information actually exist and I just haven’t found it?

Thank you all in advance for your constructive responses.

Modulation control via Opentherm

- Quote

Post by RADAR » 11 Jan 2022, 14:19

Modulation control via Opentherm

- Quote

Modulation control via Opentherm

- Quote

Post by tsv63 » 11 Jan 2022, 15:16

Modulation control via Opentherm

- Quote

Post by asolovey » 11 Jan 2022, 15:28

I would not be so categorical in the statements after carefully reading the Zont documentation. And also after familiarizing yourself with its configuration interface. Where the modulation level settings are explicitly specified. And just in case, a quote from the documentation.

page 17 from the instructions for Zont H2000

Modulation control via Opentherm

- Quote

Post by Starik » 11 Jan 2022, 15:38

Modulation control via Opentherm

- Quote

Post by asolovey » 11 Jan 2022, 15:53

Perhaps you are right, yes. But how fashionable it is now to say “this is not certain.” The fact is that in many places the ability to control the boiler’s power digitally is mentioned. Unfortunately, so far all these “many places” are not trustworthy, as this is either marketing information or unconfirmed information. I already wrote about the Zont doc above.