From the author: hello, friends! A geyser is a rather complex structure consisting of many elements. Each of them plays an important role in the operation of the device. If some of these elements break down, the problem is immediately visible and does not require any testing. But how can I check the draft sensor for a gas water heater? And what is this part even needed for? This is exactly what will be discussed in today's article.

In general, a gas water heater is an excellent heating device. No wonder it is the most popular among owners of both apartments and private houses. The boiler is highly efficient, does not require too much maintenance, and the fuel used usually costs literally pennies.

The only drawback of this equipment is the possible danger of its operation in the event of any malfunction. Everyone knows that a gas leak, for example, can have dire consequences, including an explosion, destruction of a house and death. Therefore, each element of the column must work perfectly, any problem must be corrected immediately, and a part that is absolutely faulty must be replaced.

Therefore, it is extremely important to detect a breakdown in a timely manner. To do this, regular checks of the system are carried out, and, as a rule, they are performed by gas service specialists. But you yourself can periodically inspect some elements on which the safety of the people living in the house depends. One such part of the design is the traction sensor.

Types and principles of operation of sensors

To understand how a heating device works, you need to understand its components. In the publication “Design of a geyser” we described in detail what parts the unit consists of. Now let's talk about the purpose of sensors.

Traction sensor

It is located in the connecting part of the chimney and the body. Its main task is to determine the presence of ventilation (draft) in the chimney.

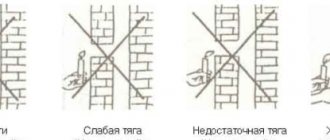

With normal draft, combustion products are discharged to the street through a smoke exhaust shaft. If ventilation is impaired, then reverse draft may occur, which leads to extinguishing the burner and carbon monoxide entering the room.

Violation of ventilation occurs for various reasons: blockage or damage to the chimney, accumulation of soot on the walls, improper installation of the shaft. A sensor is installed to detect violations. When it is triggered, the column stops working.

Depending on the type of gas boiler or water heater, the combustion chamber can be open or closed. The type of sensor and the principle of its operation depend on this.

Devices with an open chamber have an atmospheric type of burner. The flame is maintained by ventilation in the room, and the draft is maintained by the correct diameter of the chimney.

The protective sensor in such units is a metal plate with an outgoing contact. It reacts to rising temperatures. The exhaust gases have a temperature of 120–140 degrees.

When they are output normally, the values do not exceed the norm. But when a problem occurs, gases accumulate and the temperature rises. This causes the metal on the plate to expand, the contact moves away and closes the gas supply valve.

As soon as the work returns to normal, the plate returns to its original position.

Turbocharged engines have a closed combustion chamber. The influx of clean air, as well as the removal of smoke, occurs through a coaxial channel using a fan. In such devices, the protection system is made in the form of a pneumatic relay with a membrane. The device monitors the speed of gas removal by the fan.

During normal flow, the membrane is in a bent state and the contacts are closed. As soon as the flow weakens, the membrane returns to its normal position and the contacts open. Then the gas valve closes.

Therefore, when the protection is triggered, do not ignore the breakdown, but try to fix it immediately.

Overheat sensor

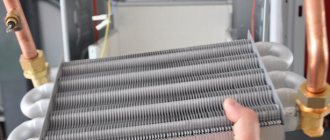

The element is installed on the heat exchanger tubes and monitors the water temperature. When heated above 85 degrees, it triggers and blocks operation. Overheat protection is also called a thermal relay or thermostat. If the thermostat did not operate on time, the liquid would boil in the heat exchanger. This can lead to the radiator burning out and damage to the speaker itself.

The heating thermostat is made on the basis of bimetallic plates or thermistors. When the values increase, its contact opens, causing the equipment to turn off. When it fires:

- when the water is overheated;

- if the sensor itself malfunctions or the wiring is damaged;

- in case of poor contact with the installation site.

If the thermostat breaks down, an error code may appear on the display of the boiler or dispenser.

Flame and ionization sensors

The flame or combustion sensor is a thermocouple that is heated by the flame. With constant heating, the pressure inside the element increases, so the fuel supply valve remains open. As soon as the burner goes out and the element cools down, the valve closes. It can also be called a gas sensor, since it protects the equipment from leaking fuel when the burner is turned off.

The ionization element is in contact with the burner flame. Combustion produces ions that are attracted to the sensor and produce a current. If a sufficient number of ions is detected, the equipment continues to work. If the quantity decreases, the device stops functioning.

When it might work:

- if there is a disruption in the air-fuel supply;

- if the valve or electrode is clogged;

- when the ignition elements are dirty.

Water flow sensor

Controls the power of water flow through the column. Needed to turn off the device when the mixer is turned off.

There is also a sensor that records the water pressure. It will not allow the column to turn on until the pressure reaches the norm.

Is it possible to disable

When installing the sensor and using gas equipment, you can often observe periodic shutdowns in operation. In this case, you may want to turn off the traction device completely. However, there is no need to rush.

Draft sensor for gas boiler AOGV and AKGV

There are several reasons for this:

- Firstly, a sensor disconnection may indicate poor traction performance. Weak intensity of movement of smoke gases leads to overturning of the draft in boiler equipment. Harmful fumes will enter the house in large quantities.

- Secondly, the problem may be backdraft. An air lock forms. The exhaust gases of the smoke move to a certain point in the chimney and then fall back. This occurs due to poor heating of the pipe and poor thermal insulation.

Of course, theoretically it is possible to disable the sensor, but this entails great danger. If an emergency suddenly arises, there will be no protection. Therefore, it is not recommended to operate a gas unit without such a controller.

How to check and disable sensors

If you want the equipment to function normally, then you cannot disable the protection. When the device turns off some time after heating, this already indicates that the sensors are working properly. It’s another matter when the display displays an error code with instructions to check the part. Then the contacts are disconnected, and the protective device is tested with a multimeter.

To ensure that equipment and its security systems work properly, clean the components and parts from blockages and scale. Thus, scale fouling of the heat exchanger leads to untimely operation of the thermal relay. Therefore, use reagents to clean it.

The safety system for gas equipment is very important. Therefore, before purchasing, study the components of the speakers; they are usually indicated in the equipment documentation.

The gas water heater operates on the basis of potentially hazardous fuel. Therefore, manufacturers provide it with a security system. In the event of a malfunction and the threat of an emergency, the protection is activated and blocks the operation of the equipment. Gas water heater sensors are located in different parts of the unit and monitor the operation of the system. Every user should know what they are and what they are intended for.

Review of models and prices

Water flow sensor for Grundfos UPA 120 pump

The main application is automatic control of a water supply system pump. The sensor is designed to provide water supply to an individual house or apartment equipped with an individual water supply system. The automatic sensor switches on when there is a steady flow of liquid in the range of 90-120 liters per hour.

The main purpose is to protect the pump from idling. The sensor is used with GRUNDFOS UPA series pressure booster pumps. These units have small linear dimensions, which allows installation directly into the water supply line.

Using a sensor allows the pump to operate in several operating modes, allowing both automatic switching on and switching on when necessary. The automatic sensor turns off the pump if the pressure in the water supply rises to normal.

Characteristics:

- the pump starts at a water flow rate of 1.5 liters per minute;

- sensor operating voltage – 220-240 V;

- frequency of current consumption – 50-60 Hz;

- maximum current consumption – 8A;

- power consumption – up to 2.2 kW;

- operating temperature range – 5-60 degrees Celsius;

- degree of protection – IP 65;

- manufacturer – GRUNDFOS;

- country of origin – Romania, China;

Price: $30.

Water flow sensor GENYO series – LOWARA GENYO 8A

Products of a company specializing in the production of various electronic devices for control systems. The model is designed to control the pump of a domestic water supply system based on actual water consumption. The main feature of the sensor is to control the pressure in the water supply system during operation. The LOWARA GENYO 8A sensor is designed to start the pump when the water flow rate reaches 1.5-1.6 liters per minute.

Characteristics:

- the pump starts at a water flow rate of 1.5 liters per minute;

- sensor operating voltage – 220-240 V;

- frequency of current consumption – 50-60 Hz;

- maximum current consumption – 8A;

- power consumption – up to 2.4 kW;

- operating temperature range – 5-60 degrees Celsius;

- degree of protection – IP 65;

- manufacturer – LOWARA;

- country of origin – Poland;

Price – 32 dollars.

Types and principles of operation of sensors

To understand how a heating device works, you need to understand its components. In the publication “Design of a geyser” we described in detail what parts the unit consists of. Now let's talk about the purpose of sensors.

Traction sensor

It is located in the connecting part of the chimney and the body. Its main task is to determine the presence of ventilation (draft) in the chimney.

With normal draft, combustion products are discharged to the street through a smoke exhaust shaft. If ventilation is impaired, then reverse draft may occur, which leads to extinguishing the burner and carbon monoxide entering the room.

Violation of ventilation occurs for various reasons: blockage or damage to the chimney, accumulation of soot on the walls, improper installation of the shaft. A sensor is installed to detect violations. When it is triggered, the column stops working.

Depending on the type of gas boiler or water heater, the combustion chamber can be open or closed. The type of sensor and the principle of its operation depend on this.

Devices with an open chamber have an atmospheric type of burner. The flame is maintained by ventilation in the room, and the draft is maintained by the correct diameter of the chimney.

The protective sensor in such units is a metal plate with an outgoing contact. It reacts to rising temperatures. The exhaust gases have a temperature of 120–140 degrees.

When they are output normally, the values do not exceed the norm. But when a problem occurs, gases accumulate and the temperature rises. This causes the metal on the plate to expand, the contact moves away and closes the gas supply valve.

As soon as the work returns to normal, the plate returns to its original position.

Turbocharged engines have a closed combustion chamber. The influx of clean air, as well as the removal of smoke, occurs through a coaxial channel using a fan. In such devices, the protection system is made in the form of a pneumatic relay with a membrane. The device monitors the speed of gas removal by the fan.

During normal flow, the membrane is in a bent state and the contacts are closed. As soon as the flow weakens, the membrane returns to its normal position and the contacts open. Then the gas valve closes.

Therefore, when the protection is triggered, do not ignore the breakdown, but try to fix it immediately.

Overheat sensor

The element is installed on the heat exchanger tubes and monitors the water temperature. When heated above 85 degrees, it triggers and blocks operation. Overheat protection is also called a thermal relay or thermostat. If the thermostat did not operate on time, the liquid would boil in the heat exchanger. This can lead to the radiator burning out and damage to the speaker itself.

The heating thermostat is made on the basis of bimetallic plates or thermistors. When the values increase, its contact opens, causing the equipment to turn off. When it fires:

- when the water is overheated;

- if the sensor itself malfunctions or the wiring is damaged;

- in case of poor contact with the installation site.

If the thermostat breaks down, an error code may appear on the display of the boiler or dispenser.

Flame and ionization sensors

The flame or combustion sensor is a thermocouple that is heated by the flame. With constant heating, the pressure inside the element increases, so the fuel supply valve remains open. As soon as the burner goes out and the element cools down, the valve closes. It can also be called a gas sensor, since it protects the equipment from leaking fuel when the burner is turned off.

The ionization element is in contact with the burner flame. Combustion produces ions that are attracted to the sensor and produce a current. If a sufficient number of ions is detected, the equipment continues to work. If the quantity decreases, the device stops functioning.

When it might work:

- if there is a disruption in the air-fuel supply;

- if the valve or electrode is clogged;

- when the ignition elements are dirty.

Water flow sensor

Controls the power of water flow through the column. Needed to turn off the device when the mixer is turned off.

There is also a sensor that records the water pressure. It will not allow the column to turn on until the pressure reaches the norm.

Functionality check

All of the above can be combined into one whole: the sensor is necessary in order to shut off the fuel supply in the event of a danger - such as a gas leak or poor removal of combustion products. If this is not done, then very sad consequences are possible.

Carbon monoxide poisoning has already been discussed more than once above. It very often leads to death, and it’s definitely not worth joking with. And if the burner suddenly goes out, but the gas continues to flow, sooner or later an explosion will occur. In general, it is clear that the sensor is vital.

But it can fully perform its functions only in good condition. It is common for any equipment to fail periodically. Failure of this part will not affect the external condition of the boiler in any way, so it is very important to regularly check the functionality of the element. Otherwise, you risk noticing the problem only when it is too late.

There are several methods for checking:

- attach a mirror to the area where the sensor is installed. During operation of the gas water heater, it should not fog up. If it stays clean, then everything is fine,

- partially block the exhaust pipe with the damper. In case of normal operation, the sensor should react instantly and turn off the boiler. For safety reasons, do not test for too long to avoid carbon monoxide poisoning.

If in both cases the testing showed that everything is in order, it means that the element being tested is ready at any time to react to an unforeseen situation and turn off the gas supply. But there is another type of problem - when the sensor is triggered just like that.

If you have carefully checked the draft level and other aspects, but the boiler still turns off, this means that the control element is not working correctly. You can further test this as follows.

Disconnect the element and test it with an ohmmeter. The resistance of a working sensor should be equal to infinity. If this is not the case, then the part has failed. There is only one option to correct the situation - you need to replace the broken element.

Some homeowners, in situations where the sensor suddenly begins to constantly interrupt the fuel supply in the absence of visible problems with the chimney draft, decide to simply turn off this element. Of course, after this the column starts working smoothly.

But such actions are a direct violation of safety regulations when operating gas equipment. By turning off the sensor, you cannot be sure that everything is in order with the draft and that carbon monoxide does not begin to fill the room. It's definitely not worth the risk. It is better to check the performance of the part using the methods described above. You can also get information on this issue from the video posted above. Good luck to you and a safe and warm home!

Source

How to check and disable sensors

If you want the equipment to function normally, then you cannot disable the protection. When the device turns off some time after heating, this already indicates that the sensors are working properly. It’s another matter when the display displays an error code with instructions to check the part. Then the contacts are disconnected, and the protective device is tested with a multimeter.

To ensure that equipment and its security systems work properly, clean the components and parts from blockages and scale. Thus, scale fouling of the heat exchanger leads to untimely operation of the thermal relay. Therefore, use reagents to clean it.

The safety system for gas equipment is very important. Therefore, before purchasing, study the components of the speakers; they are usually indicated in the equipment documentation.

The geyser is very popular among owners of apartments and private houses. Of course, the device does an excellent job of providing residents with hot water, does not require complex maintenance, and the cost of fuel used is minimal. But the water heater also has one serious drawback - a gas leak can lead to an explosion, destruction of the house and death. Therefore, it is extremely important to identify a breakdown in a timely manner and know how to check the draft in a gas water heater at home.

Each element of the device must work flawlessly, any problems must be corrected immediately, and failed parts must be immediately replaced. Regular checks of the system are carried out by gas service specialists, but you can periodically inspect some elements on which the safety of people living in the house depends on yourself.

We will try to figure out how to test the design, in particular, check the draft of the water heater, at home. In the article we will also consider effective ways to combat the lack of draft in the smoke duct.

Principles of the protection system in geysers

Gas is often not safe. Therefore, many speakers have special protection sensors. With the help of which the supply of gas to the wick is prevented if any danger or emergency situation is observed. In more detail, such sensors prevent overheating of water, leakage of carbon dioxide or carbon monoxide.

Most protection sensors in geysers are designed according to the following principle of operation: some element heats up, which means the torch is burning and gas is supplied, as soon as the sensor begins to cool down, it gives a signal to stop the gas supply.

The best ways to test traction

For correct operation of geysers with an open combustion chamber, you will need good draft and proper arrangement of the chimney. Most modern models are equipped with an automatic safety system that prevents the device from starting if there is no traction.

Next, we’ll look at how you can check the draft in the chimney of a domestic gas boiler and water heater.

Method #1 - using an anemometer

A professional check of the draft in the chimney of a gas boiler and water heater is carried out using a special measuring device - an anemometer.

With its help, you can verify the presence of air traffic and determine its strength. The indicator should be 1.96-29.40 Pa.

Method #2 - using a match

If it is not possible to use an anemometer, you can check as follows:

- Prepare paper strips and secure them at the entrance to the mine channel. You must first remove the horizontal part of the chimney pipe. The movement of part of the leaf will signal the presence of traction.

- Sufficient draft can also be determined using a flame. A lit match should be directed vertically towards the viewing window on the front panel of the water heater.

The chimney should be checked before igniting the water heater. A flame brought to the inspection hole at the top of the column during operation should be drawn inward.

Method #3 - checking the traction sensor

The water heater has several control modules installed. Sensors for overheating, draft, ionization, and water pressure prevent emergency situations.

The draft sensor monitors the temperature of the exhaust gases, and when it increases, it reacts accordingly:

- Inside the sensor there is a bimetallic plate connected to the gas valve.

- Metal expanding as a result of overheating transmits a signal to turn off the gas supply.

- The cooled plate returns to its original dimensions, opening the valve.

It is recommended to check the serviceability of the sensor when systematically turning off the column.

You can do this in several ways:

- place a mirror next to the sensor, its surface should not sweat when the water heater is turned on;

- The serviceability of the sensor will be indicated by turning off the gas water heater when the chimney is closed 2/3 with the damper.

In some water heater models, the regulator is mounted on a plastic mount that can be easily moved out of place. This will also lead to frequent speaker shutdowns.

You can also test the serviceability of the sensor using an ohmmeter; its resistance should be equal to infinity. Otherwise, the part should be replaced.

When there is a constant interruption in the fuel supply, home owners often simply turn off the sensor, after which the water heater actually starts working without interruption. But such a decision violates the safety precautions for operating gas equipment. The water heater will remain unprotected; if there is a leak, carbon monoxide will enter the room.

It is strictly prohibited to use a gas water heater if there is no vacuum in the chimney channel. Let's consider the possible reasons for the lack of traction.

Conclusions and useful video on the topic

Checking the draft in the water heater is a prerequisite for the safe use of gas equipment. With the reverse movement of the ventilation stream, the flow of gases rushes into the room, which can lead to smoke and fire of surrounding objects. You can verify the presence of overturning traction yourself, without the involvement of specialists. It is enough to follow the recommendations given above.

Have you also encountered the problem of worsening or lack of cravings? We are waiting for your questions, participation in the discussion of controversial issues or stories from personal experience - the feedback block is located below.

During operation, it happens that the gas water heater does not work. The reasons for this vary. There are two ways to solve the problem - call a specialist or inspect the main components and try to fix the problem yourself. The second option, moreover, will save the family budget.

Reasons for lack of traction

The source of the malfunction can be identified by visually inspecting the column for errors made during its installation.

There are several typical violations:

- The diameter of the air duct is less than the cross-section of the water heater outlet pipe.

- Using more than three repeat angles and adapters when installing a pipe.

- The chimney length is less than 2.5 meters.

- The chimney connections are loose and there are leaks.

- The distance from the water heater to the chimney is less than 30-50 cm.

- The length of the corrugation exceeds 2 meters.

It is also important to assess the compliance of the premises with technical operating conditions. It is prohibited to install a gas water heater and a forced exhaust hood in one room. When installing metal-plastic windows, supply valves must be used.

What to do if the speaker often goes out?

If

the

geyser turns on and immediately goes out; the breakdown is eliminated by replacing the servo drive, solenoid valve or flame ionization sensor. Repair work requires the involvement of a specialist.

Interesting materials:

How to check Apple IMEI? How to check Honor IMEI? How to check property according to IIN? How to check pension indexation? How to check Internet traffic? How to check IQOS for originality? How to check IQOS by number? How to check the serviceability of the compressor? How to check the serviceability of the electric motor windings? How to check if the TV cable is working properly?

How to increase draft in a water heater?

One of the main reasons for the lack of draft is a blockage in the smoke channel. This problem often occurs in old-type apartment buildings.

In the so-called Khrushchev buildings, 2 shafts are laid - for the water pump and for ventilation. First of all, you need to call specialists to carry out cleaning.

In a private house, improving draft should begin with an inspection of the chimney and assessing the contamination of the littered pipe. After removing the blockage, a mirror is placed inside the canal. There should be a light at the top of the chimney. It is recommended to carry out this procedure at least once every three years.

Poor draft can also be caused by improper installation of the chimney hood or a large number of unnecessary turns, sharp corners and bends in the pipe. If correcting errors made during installation did not help, you can increase the draft in the chimneys using smoke exhausters and fans.

Installation of the draft sensor

Installation of the device is carried out individually, depending on the equipment used and the choice of a convenient location. First, it is important to purchase a device suitable for this type of boiler. Detailed information about correct installation can be found in the technical documentation of the heating equipment.

Installation of the device must be entrusted to a specialist, since an incorrectly installed sensor will malfunction and, as a result, pose a threat to people’s health in case of gas poisoning. The specialist will also help to configure the device correctly.

Ways to eliminate backdraft

You should pay attention to any, even the most minor, changes in the operation of the gas device. If the water heater makes strange noises or turns on with a bang, you should immediately contact a specialist.

Popping noises are most common in older speaker models. In modern flow columns such defects are extremely rare. Extraneous sounds occur due to accumulated gas in the heat exchanger, which can subsequently occupy the entire chimney.

In most cases, such a violation is provoked by a clogged chimney, a broken valve, or a deviation of the ignition wick.

In new water heater models, a malfunction can be caused by:

- defective spark plug;

- spent battery installed in the control module;

- faulty microswitch located in the water unit.

Having decided to carry out independent repair work, first of all, you need to check the intensity of traction using one of the methods listed above.

Further diagnostics will differ depending on the type of device - with an ignition wick or an automatic ignition system.

Column with automatic ignition system

In this type of water heater, the ignition device is controlled by an electronic module. The system with microswitches located on the fire and liquid regulators is considered one of the most reliable. Repairing a failed part can result in significant costs.

You can determine the severity of the failure as follows:

- Research batteries . Delayed ignition of the gas may be due to a low battery charge. In this case, it is enough to replace the power source with a new one.

- Check the functionality of the liquid pressure microregulator , designed to transmit signals to the control module. Its activity is associated with the supply of water when it is necessary to ignite the gas. Like other regulators, it can fail and issue incorrect commands. The problem can be determined using an ohmmeter and a multimeter. The worn element should be replaced with a new one.

- The appearance of uncharacteristic sounds can also be caused by deformation of the location of the device that ignites the gas . The malfunction is usually caused by a temperature difference. The part is secured using a screw; you should loosen it a little and correct the position of the spark plug. The gap should be 0.4-0.5 cm.

- Gas can also accumulate due to a faulty valve, which causes fluid flow to slow down . The small metal ball should move freely under the lid. If its movement is disturbed, you can try to move the valve from its place with a cable. If there is contamination, the channel should be cleaned. But it is not recommended to carry out such a procedure unless absolutely necessary.

Upon completion of the repair work, it is necessary to check the connections for leaks. You can enhance safety using rubber gaskets and special sealants.

Ignition wick water heaters

Flow-through geysers of the previous generation often emit characteristic pops when turned on. Such structures are considered not very convenient and often even unsafe; at the same time, much less money will be needed to repair them.

The accumulation of gas in an area not intended for this purpose can be caused by improper placement of the ignition wick. Failure to do so results in a reduced flame and an inability to reach the edge of the burner with the edge. The main reason for insufficient gas supplied to the wick is a clogged nozzle.

You can fix the problem yourself, but to do this you need to completely disassemble the device.

The first step is to turn off the water and gas supply.

The main part of water heaters has the same type of circuit, so the repair instructions will practically not differ:

- First you have to dismantle the protective casing of the water heater.

- Provide free access to the tee.

- Unscrew the fastening screws, and then remove the nuts securing the supply tubes and regulator.

- The tee must be carefully pulled out of the groove.

- Examine the lower pipe. A small screw with a through hole is the jet.

- The nozzle should be cleaned using a needle or wire.

- Upon completion of all work, you need to reassemble the water heater in the reverse order.

If the problem persists, you should contact a gas company specialist for help.

There are other reasons for the appearance of reverse thrust:

- Seasonal changes , in this case it is necessary to make sure that there are no errors when installing the chimney, and insulate the channels.

- An air lock inside the smoke channel can cause reverse draft in the chimney of a household gas water heater. To fix the problem, set fire to the newspaper inside the pipe.

- Forced exhaust in a room with a column causes a compensation process , air comes from the smoke duct. Metal-plastic windows only aggravate the problem; in some houses, air from the chimney begins to actively flow into the room.

We discussed more information about the causes of backdraft in a chimney in the next article.

The situation with air compensation can also be corrected using a check valve for the chimney of a gas water heater. You should also dismantle the fan and buy supply valves for metal-plastic windows.

Mechanical shut-off devices, known as a check valve or water heater damper, ensure that liquid and gas flow in only one direction.

Designed for turbocharged geysers. Their action is based on the opening of the exhaust hole when the column is operating and its closing after shutdown, which guarantees safe use.

Diagnosis of causes and elimination of breakdowns

Most internal violations can be identified through external diagnostics, testing the operation of the column. External symptoms indicating a frog malfunction most often point to the direct culprit. Only some of the external manifestations may be the result of various reasons, which will become clear after dismantling the water unit.

Problem #1 - low hot water pressure

If the pressure in hot water is less than cold, the cause may be a clogged filter mesh . It can be eliminated by cleaning, which does not require disassembling the frog, however, more often than not this reason is not the only one, so the device should be disassembled, at least for the purpose of prevention.

Another reason is a clogged Venturi fitting channel . In this case, disassemble the gearbox, unscrew and clean the fitting.

We discussed other reasons for low water pressure in the column in this article.

Problem #2 - the column does not turn on

If the column does not turn on with sufficient water pressure, then the diaphragm may break . It can be eliminated by disassembling the frog and replacing the membrane. The best replacement option is silicone. Normal - like the original one (sold separately or in a repair kit). Not the best - replacing it with a suitable one or making it yourself.

Another reason is souring of the rod . Remedy: the gearbox is disassembled, the rod is cleaned of scale, ground and lubricated with mineral oil, and the seals are replaced.

Breakage of the water reducer plate is less common than a diaphragm breakthrough. It is necessary to use the original part to replace it; for this purpose it is more rational to purchase a repair kit

Also among the possible causes is a broken plate . Without it, the membrane is not able to move the rod. Eliminated by replacement.

Problem #3 - turning on the speaker with a delay

If, when you open a hot water tap, the column turns on with a significant delay, this may be due to incorrect adjustment of the ball valve (the adjusting screw is turned out too much). To correct, screw in the screw after making several turns.

Other reasons: clogged bypass channel or jammed retarder ball . We need to analyze the frog. The blockage is removed by cleaning the channel with a thin wooden stick and rinsing. The ball can be removed by unscrewing the plug and the adjusting screw.

Problem #4 - the column works after closing the tap

If the column, after closing the tap, continues to work for some time and then turns off, most likely the reason lies in incorrect adjustment of the smoothness of activation . The adjusting screw must be turned out after making several turns. To adjust the smoothness of turning on the gas, unscrew the plug, then use a screwdriver to screw in the adjusting screw a few turns to speed up the turn on of the gas supply, or unscrew it a few turns to slow it down.

Also, the cause of this problem may be a stuck microswitch . When exposed to flowing water, its internal contacts become deformed and crack. The device is replaced with a new one. After replacing the microswitch, the testing column is turned on for a couple of minutes and turned off. The leak itself is a reason to dismantle the frog and inspect the rod seals.

The microswitch is mounted on a platform attached to the water part of the unit. To protect against leaks, the body of the new part is lubricated with lithol or solid oil.

Another reason is the appearance of interference with the free movement of the rod . There are two possibilities: the reason is the design of the gas part or a malfunction of the water unit. In the latter case, the rod may be delayed by the resulting scale or may not move due to broken springs. The gearbox is disassembled, cleaned and, if necessary, parts are replaced.

The last two malfunctions ( sticking of the rod and microswitch ) can lead to serious consequences. Immediate elimination is required.

Problem #5 - the water heater does not gain power

The full power of the water heater is not achieved, and the blue flame of the burner is sluggish and goes out during operation. The most likely reason is a leaky membrane . Eliminated by replacement.

Problem #6 - no clicking noise is heard when igniting

If (with a wick igniter of the burner) the jet is cleared, but the flame dances too far from the edges of the burner, its tongues are more than 3-5 cm, then the diaphragm has broken. It is necessary to disassemble the assembly and replace the membrane.

Problem #7 - there is a water leak from the gearbox

The main reason is wear of the sealing gaskets or oil seals. They make a replacement.

Problem #8 - when the water is turned on, the rod is inactive

In some models, the movement of the rod can be observed visually. If the rod remains motionless when opening a hot water tap or does not extend to its full length, then the problem is a leaky membrane or a broken plate , which will become clear when disassembling the frog.

In columns with a microswitch, if the rod plate breaks or the membrane breaks, the platform foot does not return to the microswitch, but remains at a distance of more than 1-2 mm from it. After the hot water is closed, the gas continues to burn, and the column is turned off by a thermal relay. If the distance does not exceed 1-2 mm, the foot can be carefully bent until it fits completely

Such damage can be eliminated by replacing the damaged plate or membrane. Before disassembling the unit, it is advisable to stock up on new gaskets and seals.

Possible reasons for the sensor to trigger

Frequent operation of the gas boiler draft sensor is often observed immediately after the installation of new equipment and subsequent commissioning.

Malfunctions of the boiler with this option are usually due to:

- incorrect scheme for constructing a smoke removal channel;

- unusual weather conditions in the region;

- violation of the traction characteristics of the equipment;

- incorrect settings of the control controller.

In regions where strong winds prevail, the reason for the sensor to trigger may be trivial - wind entering the flue gas exhaust channel. For such cases, it is recommended to additionally install a traction stabilizer on the pipe.

The traction characteristics were noted above, and specialists should be involved in setting up the gas water heater controller.

What is the problem with the gas water heater, the water was turned off, but the water heater did not stop working?

We have a gas water heater. The water was turned off, but the column did not stop working. They immediately turned on the water in the shower and black water poured out of the tap. The column was blocked. What could this be and what are the consequences?

Each geyser has a special valve, which, when the water is turned off, is activated automatically and stops the gas supply. Most likely, it is the solenoid valve that has failed, so it should be replaced. As for black water, everything is obvious here - the water boiled in the coil and scale got into it.

Until the solenoid valve is repaired, the column can be used, but monitor its operation and heat the water manually.

To begin with, I’ll tell you from my own experience what such a problem with a speaker means for people.

1) At a minimum, when the water is turned off and the column continues to operate (gas combustion), the pipes are heated by the burning gas, but the water there is no longer flowing, but stands still, and accordingly it boils. Further, if this is not noticed by the one who tries to open the tap, first steam will come out of it, and then the remains of water heated to the limit, as a result of which you can get burns.