Cast iron radiators have been squeezed out of the market by the influx of modern developments in the field of heating devices, but continue to pose serious competition to new products. When choosing, it is important to consider the weight of a cast iron battery, since this parameter affects the complexity of installation and installation principles.

For a classic sectional radiator, the weight of 1 element is 7.5 kg, that is, a standard design of 7 elements will weigh more than 50 kg.

Classic cast iron radiator

This raises two problems

:

- it is difficult to install a reliable wall mount if the walls are made of porous light blocks or are a frame structure - you will need to install the heating device on the floor;

- It is necessary to carry the battery together and very carefully, since the impact causes microcracks to appear in the fragile cast iron, which expand under the influence of the heated coolant - over time, this provokes depressurization of the heating device.

Heat dissipation of a cast iron radiator

The power of a cast iron radiator directly depends on the area of its outer surface and lies in the ability to release heat energy at the highest possible coolant temperature. Basically, this value ranges from 80 to 200 watts per section . To calculate the required power, the following formula is used: for 25-30 cubic meters. m. battery power should be 1 kW . If there are several external walls, the power indicator increases.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Dimensions of a cast iron radiator.

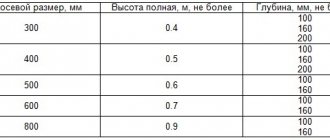

In the Soviet Union, the overall dimensions of cast iron radiators had a certain standard. In one section, the distance between the centers of the coolant supply and discharge pipes ranged from 30 to 50 cm. The width of the section was not standardized and varied among different manufacturers. Almost all modern batteries also have these standards. The most popular model among cast iron products is MS-140. (installed in many “Khrushchev” and 9-story buildings of the 60-80s). The distance between the centers of the pipes is 50 cm; battery height 58.8 cm; width 9.3 cm; depth - 14 cm. The variety of overall dimensions of batteries is explained by the needs of customers.

Classic batteries: basic parameters

The Soviet MC140 battery with the following parameters is considered classic

:

- height 388/588 mm;

- depth 140 mm;

- width 93 mm;

- the volume of one link with a height of 588 mm is 1.5 l;

- the weight of one link with a height of 588 mm is 7.12 kg.

Knowing how much one radiator section weighs and its volume, you can calculate the mass of the MC140 heating device filled with coolant. The total mass of the filled section will be 8.62 kg, a battery of 10 links will weigh about 86 kg.

Wide selection of different battery styles

Manufacturers of cast iron radiators

Most of the Russian market is represented by domestic models. This can be explained by the fact that the cost of transporting cast iron batteries makes up a large part of its final cost. The main manufacturers include:

- CHAZ – Cheboksary Aggregate Plant (Russia)

- Minsk Heating Equipment Plant (Belarus)

- Kiran (Ukraine)

- Viadrus (Czech Republic)

Therefore

To choose the correct fastening principle, you need to find out how much a section of a cast iron battery filled with coolant weighs. For heating appliances made of cast iron, it is important to select the appropriate number of brackets for wall mounting. If the walls are made of porous blocks or the house is built from SIP panels, the number of fastening points is increased in order to more evenly distribute the load.

Correct calculation of radiators and reliable installation guarantee the uninterrupted functioning of the heating system.

Video on the topic:

Installation of cast iron radiators.

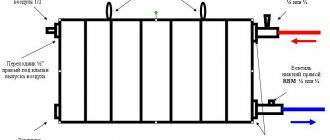

Almost all cast iron products are composite, consisting of separate sections connected by nipple bushings.

Gray cast iron is used in their manufacture. Paronite gaskets are installed between the individual sections. Horizontally, the flow of water always goes in one direction. Vertically, the current flows through channels, of which there are one or more. Depending on the number of vertical channels, the area and power of the battery increases. Due to the need to maintain strength and surface area, manufacturers cannot change the weight-to-power ratio much. The large weight of the battery means reinforced fastenings.

Weight of standard heating devices

Both traditional and designer pieces are united by the material of manufacture, which is cast iron.

And now, well-functioning classic accordion-shaped radiators are found everywhere, installed:

- in schools and preschool educational institutions;

- in outpatient departments and hospitals;

- in housing stock premises - apartments, private households, dormitories;

- in public and government institutions.

Usually these are models MS-140 or MS-90, since in past years there were no other mass-produced heating devices. Cast iron products NM-150, RKSh, Minsk-1110 and others are presented in small series, but today they are no longer produced. So what is the weight of one section of an old-style cast iron battery? And in this case, there is no exact figure. This is explained by the fact that this value depends on the section parameters.

For example, the MS-140 series battery comes in two modifications depending on the center gap, which is 300 or 500 millimeters. If we are talking about the MS-140-300 model, then the average section weight is about 5.7 kilograms, and when talking about the MS-140-500 device, then 7.1 kilograms.

You can often find a product of the MS-90 series, in which the weight of the cast iron radiator section is 6.5 kilograms with a distance between the axes of 500 millimeters. The difference between the MS-90 and 140 models is the different depth of the sections.

Can we consider that the weight of radiators of these popular series, equal to 6.5, 5.7 and 7.1 kilograms, is final? The answer is negative and there is an explanation for this. The fact is that the current GOST 8690-94, which is a regulatory document regulating the production of batteries from cast iron alloys, indicates their main dimensions.

Regarding how much a section of an old-style cast iron battery weighs, this standard indicates a specific gravity of 49.5 kg/kW. This standard value applies to radiators that are intended for use in heat supply systems with a coolant temperature not exceeding 150 degrees and an excess operating pressure of a maximum of 0.9 MPa (9 kgf/cm²).

When producing heating devices, manufacturers must ensure that their products comply with these values, but GOST does not regulate how much one section of a cast-iron battery weighs. As a result, the mass of radiators manufactured at different factories differs.

Today, the best known products are from several industrial enterprises that produce modifications of the MS-140 series and devices of their own design. Among them: the Belarusian heating equipment plant, the Russian “Descartes” and “Santekhlit” and others.

Advantages of cast iron heating radiators

Heating appliances made of cast iron are very resistant to aggressive coolant environments. This is explained by the physical parameters of this metal. Cast iron radiators can remain corrosion-free for a very long time, even at elevated temperatures. In addition, virtually no harm is caused to cast iron and various chemicals added to the coolant.

If the device becomes clogged or leaks, they can be easily repaired. Blockages that occur in the radiator can be caused by the properties of the coolant with a high content of Ca and Mg salts. As a result of deposits on the inner wall of the device, it narrows, which leads to a deterioration in the heating rate and normal heat transfer. A leak in a cast iron battery can occur as a result of wear of the gaskets between the sections. It is better to eliminate all the problems described above during the summer preventive shutdown of water supply.

The cost of a cast iron battery is approximately equal to the cost of analogues made of aluminum and steel. But at the same time, it is worth noting that cast iron withstands water shocks much better and can withstand pressure surges of about 16 bar.

Cast iron devices can be used at high temperatures and pressures, due to their low coefficient of thermal expansion.

The heat output of the heater is quite high. To achieve the greatest effect from this property, special reflectors should be placed behind the cast iron radiator.

Installation of a cast iron radiator is easy, due to the fact that the radiator sections are connected using a threaded connection and paronite gaskets. The battery is connected to the ends of the pipes in the same way. A special key is used for threading, which can be used to disconnect any section without removing the side ones.

Very long product life of more than 50 years. The only thing is that during this time it is necessary to regularly remove deposits and replace gaskets.

How much does a custom cast iron battery weigh?

Now it has become clear what the weight of the cast iron battery of the series common among consumers is. But the characteristics of non-standard devices vary in terms of cost and weight.

For example, one section of a French-made three-channel floor radiator Guratec Apollo 795 weighs 13.5 kilograms. The product is presented for sale in 7-section batteries, the total weight of which is 94.5 kilograms. When transporting, unloading and installing it, the help of several workers will be required.

The Czech manufacturer Viadrus produces more affordable products. The weight of the Kalor 500×160 cast iron alloy radiator section is 5.6 kilograms.

Before being sold on domestic markets, foreign heating devices must undergo a mandatory certification procedure regarding compliance with GOSTs, but the weight of the section is not taken into account.

Comparison of weight of models from different manufacturers

An analysis of products from domestic and foreign manufacturers showed that imported sanitary ware is 15-30 kg lighter with equal length and width. This is due to the fact that many countries save water, so the depth of imported bowls does not exceed 35 cm. For Russian models, this figure is greater - 45-60 cm.

Chinese and European models are produced with thinner walls; instead of 8-10 mm, they are made of 5 mm. There are thinner options, which affects the characteristics of the entire product and reduces its service life. Chinese manufacturers skimp on the enamel layer, and this negatively affects the quality of the coating and resistance to mechanical damage. Such methods make it possible to reduce the final weight of the product, but other characteristics deteriorate.

The weight of a 170x70 cm Italian bathtub is 78 kg. Among European manufacturers of plumbing fixtures, Castalia stands out; it produces a 170x70 cm model that weighs 120 kg, which is heavier than similar domestic products.

Weight of modern cast iron baths

Modern production has made the products lighter; now they weigh less than their Soviet counterparts. Technologies have made it possible to maintain strength while reducing wall thickness. Modern cast iron bathtubs are not subject to old standards, and GOST standards do not impose strict weight requirements. According to current standards, the minimum thickness of the bowl and the enamel coating layer is not regulated.

Russian 150 cm long

A modern bowl of standard dimensions 150x70 cm weighs about 90 kg. This option is well suited for installation in Soviet-era apartments where bathroom space is limited. The difference in weight with Soviet models is about 10 kg.

Length 170-180 cm

Thinner walls affected the final weight, which became 12-20 kg less than older models. The weight of modern cast iron bathtubs is in the range of 99-108 kg.

Length less than 150 cm, sessile

Cast iron models with a length of less than 150 cm are called “sedentary”; the width of such models is standard - 70 cm. It will be uncomfortable for a person of average height to take a bath, but such products are well suited for small bathrooms. The approximate weight of seated models is about 80 kg, foreign models are 8-12 kg less.

USSR sitz bath.

How do dimensions affect cost?

The price of semi-trailers is influenced not only by the features of the body, but also by its dimensions. As a rule, equipment with a larger usable volume costs slightly more. In the future, the difference in price will be compensated by payments from customers.

We found out how to calculate the volume of semi-trailers and figured out what is included in the concept of “dimensions”. If you are a novice driver, you need to remember these rules:

- The vehicle should only be loaded with oversized cargo. This will save you from problems with equipment and inspectors.

- Do not allow the client to add cargo that is non-standard for your vehicle. You will be responsible for the safety of the goods.

Before purchasing used equipment, undergo a technical inspection. This will save you from unpleasant surprises on the road.

Life time

Well, now a little about the pleasant things: service life and sensitivity to the quality of the coolant are the characteristics in which cast iron radiators are ahead of all competitors. This is understandable - cast iron is absolutely resistant to abrasive wear and does not enter into chemical reactions with the materials of pipes or boiler elements. The dimensions of the channels inside the sections are impressive, so these batteries almost never become clogged, and, therefore, they do not require technical cleaning work.

Many experts claim that the service life of modern cast iron batteries is 30-40 years. Well, it may very well be, because in many houses old Soviet radiators are still alive.

However, there is also a fly in the ointment - hydraulic shocks. We'll talk about this further. Below we invite you to watch a video about the advantages and disadvantages of cast iron batteries:

Results

If you intend to purchase a cast iron bathtub, you should first find out what the weight of the cast iron bathtub is. This parameter must be taken into account when installing equipment in multi-story buildings. If heavy plumbing does not create a special load on concrete floors, then with wooden beams the situation is different.

The modern market offers a huge selection of cast iron plumbing fixtures, so you can purchase a model of the appropriate size, shape and color. Despite the fact that significant weight is a disadvantage of the devices, they are practically indestructible. Therefore, a cast iron hot tub will serve you for many years.

Advantages and disadvantages of a cast iron bathtub

Plumbing manufacturers use new materials - acrylic, earthenware, marble, but cast iron continues to be in great demand; it is the leader in the plumbing market. Such baths, despite their conservative design, have many advantages.

Among them:

- Long service life. Cast iron products are 3-5 times superior to competitors in this parameter. Many apartments still have old bowls from Soviet times in good condition. Manufacturers claim a service life of 30 years, but according to statistics, such things last longer. There are restoration systems for cast iron bowls that extend their service life.

- Temperature preservation. Having heated up once, the bowl gives off heat for a long time, the water slowly cools down. In addition, this allows you to save resources.

- Strength. Cast iron is a hard metal, products made from it will not bend or change shape. Under the weight of water and the human body, the bathtub will not sag or deform when a heavy object falls into it.

- Stability and reliability. The bathtub is heavy, so it is difficult to tip it over when sitting on the side, or to move it from its place. The set includes supports that can withstand the entire weight. This provides additional safety - the bathtub stands firmly on the supports, and due to its large mass it is securely fixed to them.

- Noise insulation. The cast iron walls are thick - 5-7 mm, due to this the sound of water falling from the tap is absorbed.

- Anti-corrosion coating. The original appearance is preserved for a long time, and the enamel that covers the surface lies evenly and smoothly, which gives shine and gloss. It is applied in several layers, so you can wash your pets in the bath - claws will not harm the coating.

- Easy to care for. The smooth enamel surface does not retain dirt, so it is easy to care for. You can clean it with household chemicals that do not contain acid or large abrasive particles.

- There are models on the market with additional useful options - hydromassage, comfortable handles, anti-slip coating.

Disadvantages of cast iron models:

- Difficulty in transportation and installation. The bowls weigh at least 90 kilograms, so the help of loaders will be required.

- Warm-up required. You should pour water hotter than required for swimming, because part of the heat will be used to warm up the thick walls.

- High price. A product made of cast iron has a higher price than analogues made of acrylic, earthenware and other materials, but has a longer service life.

- Limited forms. The complexity of cast iron does not allow us to produce bowls of complex shapes, so the range is limited.

Installing a corner bath

- If the old structure is dismantled, the site should be prepared. First, we remove the nearby plumbing fixtures—the corner sink. If the riser is functional, that’s one less problem.

- We unscrew the siphon from the sewer and put it away to avoid the smell. Naturally, we also plug the sewer pipe.

- Now you should take out the old bowl. If it was mounted on legs fixed with cement, you will have to swing a sledgehammer.

- We focus on the walls. The slope of the bathtub implies a flat surface, and if smoothness is required from the walls, leveling should not be neglected.

- The bathtub can be placed on legs or a low concrete foundation. The second option will require mixing mortar and brickwork.

- After the cement has dried, we attach the outlet to the siphon.

- We place the structure on the podium and finally fix the parts to the sewer.

- At the last stage, we apply sealant along the seams and gaps.

- We collect water and check the connections.

Cast iron is stronger and more reliable than other materials. Of course, there will be difficulties with delivery and installation due to the weight of the structure. But with one effort, you will solve the plumbing issue for a long time. This is the choice of conservatives who value traditions and guarantees. If you want to make the design unique, select an acrylic product to match the color of the walls, and further use will show how lucky you are.

The situation in the modern market

Although not on the same scale as since the times of the USSR, cast iron radiators are still produced today. For example, cast iron radiators MS-140, which are in high demand, are manufactured in Minsk and Lugansk. The radiators have almost the same characteristics, with the exception of one thing - color. Minsk residents produce red radiators, the Lugansk plant produces gray ones.

Modern antique radiator

Modern cast iron radiators are made from high quality cast iron. This largely determines their parameters and stability of characteristics, including weight. In particular, regardless of the delivery batch, the weight of 1 section of the MS-140 cast iron radiator is 7.1 kilograms. Thanks to this, during the design calculations it is possible to determine the load that will be experienced by the walls to which the heating radiators will be attached.

Belarusian and Ukrainian factories, of course, are not the only enterprises producing cast iron batteries. Since recently such products are in increasingly high demand, radiators are produced in various colors and sizes. In addition, batteries decorated with casting and imitating antique products have recently appeared on the market. This significantly increases interest in products of this type.

Products of non-standard sizes

Such baths deserve special attention. They will be useful for those who want to create an exclusive design in their bathroom, and for owners of small bathrooms, and even for people with special needs. The most common option for a bathtub with a non-standard configuration is corner models. This configuration allows you to install a spacious bathtub very compactly, leaving plenty of space for other bathroom furnishings.

Corner baths usually have two identical straight sides, the length of which can be 150-180 cm, connected by a side bent along a circle of the corresponding diameter. There are also corner bathtubs of compact sizes with sides of 90 cm, but a tall person will hardly be comfortable in such a bathtub. The depth of such models usually varies quite widely: 48-65 cm. These are spacious bathtubs, with a volume of about 400 liters. Round-shaped models with a diameter of 140-200 cm are considered exclusive. Such bathtubs look very impressive if they are fully or partially built into the floor.

Owners of small bathrooms should pay attention to models with ergonomic shapes. Such bathtubs are made in such a way that they have one end of normal size, and the other is narrowed

This results in a compact version of the corner bathtub model. In a narrow room, this end cut in width frees up space for other plumbing fixtures, such as a washbasin.

The combination of an asymmetrical bathtub and a washbasin similar in configuration and design looks impressive even in a small bathroom

There are sets of bathtubs and washbasins, which also have an irregular, elongated shape. In a small room, such plumbing fixtures are installed nearby to save space. A faucet with an extended spout mounted on the wall may be convenient in such a situation.

The spout can be rotated, using one mixer for both the washbasin and bathtub. Such sets look very stylish, especially if they are made in the same color scheme, and the modest size of the asymmetrical corner bathtub does not interfere with taking water procedures in comfort.

Vertical and sit-down models are another option for bathtubs that take up minimal space. The first ones allow you to stand, the second ones have a seat. These are narrow and deep bowls; they take up much less space than conventional models. There is a special sealed door for entry, which makes it easier to enter the bathtub bowl.

This drawing shows the structure and parameters of a standard size sitz bathtub. These models are intended mainly for people with special needs.

Despite their compactness, seated and vertical models are not in great demand, since they do not always provide the opportunity to be completely immersed in water. Most often they are used as an alternative to a traditional bath as they are more convenient for the disabled, the elderly, the sick, i.e. for those who for some reason find it difficult to use a conventional horizontal model.

The sizes of sitz baths vary widely. Large models with parameters of 120X110 cm are considered the most comfortable. Models with parameters of 120 or 150X70 cm are considered standard. Some prefer to take a small volume model: 100X70 cm.

An interesting and useful addition to both a sitz bath and a regular model can be hydromassage equipment.

These procedures have a pronounced healing effect, useful both as part of the treatment of various diseases and for recuperating after a busy day at work.

But acrylic is not the only option. In addition to the already mentioned cast iron and steel, you can order a bathtub made from non-traditional materials. For example, some prefer to use glass, marble, or a combination of several materials in one product. A bathtub made from a single piece of wood, resistant to moisture, looks completely non-trivial in the interior. If you decide to make a custom-made bath, you should remember that the implementation of such a project will not be cheap at all.

Adviсe

How to calculate power?

Before installing heating batteries, it is necessary to calculate the power required in the desired room. Taking into account the fact that, in accordance with building codes, 100 W of thermal energy is required per square meter of a room with standard ceilings of 2.7 meters, we obtain the formula:

K = (Sroom x 100 W) / P, where K is the number of sections, S is the area of the room, P is the power of the section.

Installation Tips

The most useful advice for installing cast iron batteries is to seek help from a professional. But if you are still confident in your abilities and intend to install the equipment yourself, then you should adhere to the following tips:

- determine the middle of the window opening, set aside the distances on both sides to the fasteners;

- place the radiator at a distance of 8-14 cm from the floor - this will facilitate the assembly process and avoid the formation of cold zones;

- so that convection is not disturbed and the thermal power is not reduced, 10-12 cm should be left between the window sill and the battery;

- the gap between the wall and the installation is 3-5 cm.

Self-installation steps:

- screw the air vent into the adapter and place it on the upper manifold opposite the supply pipe connection area;

- install plugs on the collectors;

- install shut-off and control valves;

- connect the pipelines;

- When performing pressure testing, open the taps gradually.

Tips for use

The service life of a cast iron heating system is determined by several decades, but with proper operation of cast iron radiators they can last for even longer.

To do this you need:

- install batteries correctly and efficiently;

- flush radiators every season;

- keep elements clean;

- try not to knock on the batteries or hit them with heavy objects.

How to hide?

Above, the not very presentable appearance of cast iron radiators has been noted more than once. Therefore, many owners are concerned about the question of how to harmoniously fit batteries into the interior of the house.

You can use these tips:

- installation of pipes in the walls of the room (possibly implemented during the construction or major renovation stages);

- purchasing in advance aesthetically pleasing modern equipment (the range is varied these days);

- painting in the desired color, decoration;

- installation of hard screens (they can be purchased at plumbing stores);

- use of special dense fabric, which is attached with Velcro to the wall or window sill;

- batteries can be hidden with furniture (this method is suitable for the bathroom and toilet).

Advantages

Among the advantages of cast iron batteries, it is worth noting the following:

- durability: the service life specified by the manufacturer is 50 years, but with proper care it can last much longer;

- resistance to pressure of 9–12 atmospheres, which provides protection against water hammer (this is why cast iron radiators are usually used in high-rise buildings with central heating);

- temperature endurance from 100 to 130 degrees;

- the ability to produce one section of power up to 160 kW;

- resistance to exposure to aggressive environments that provoke corrosion;

- no need for frequent cleaning;

- the ability to distribute heat to other objects due to infrared radiation;

- simple modification;

- the ability to install a battery of the required power;

- affordable price.

What to consider when choosing a bath

When choosing a cast iron hot tub, you need to consider the following recommendations.

- Like any other bathtub, it needs to be selected according to size . In a cramped room, only a rectangular modification with minimal or medium dimensions will fit. In a spacious room there is more choice.

- The wall thickness in modern models is 5–6 cm. Such bathtubs are lighter and easier to install. Products with a wall thickness of 4 cm already do not retain heat well.

- The thickness of the enamel is 1–1.2 cm, without chips or scratches.

Preference is given to options with anti-slip coating and handrails.

Hard past

It is difficult to determine how much a cast-iron bathtub from the times of socialism weighs - the exact figure has changed over time. They gradually became lighter due to technological progress and the periodic struggle to save materials. It is known that in the 80s, a cast iron bathtub 170 cm long weighed 168 kg , but this weight was not a record.

And today you can encounter a situation where, in the course of replacing outdated plumbing fixtures, a team goes out to fight such a monster: only 4-6 adult men manage to remove it from the upper floors and load it for removal. When looking at such a scene, a thought arises: what is the situation with such products today? Isn’t it too difficult to equip a modern bathroom with a cast-iron container for water procedures? After all, it needs to be brought, raised to the floor, and installed. Will its mass outweigh the traditional advantages of such a bath - durability, reliability, thermal comfort during long relaxing procedures?