Heating a private house with gas cylinders is a necessary measure in the absence of a main gas pipeline. This heating method is often chosen for country houses and dachas with an area of up to 70-100 sq.m. In order to save gas, the building is insulated as much as possible, and a gas boiler is used in conjunction with electrical appliances, if electricity is connected.

The fuel used is liquefied propane gas or mixtures (propane + butane), depending on the season. After processing natural gas under high pressure, it changes from a gaseous state to a liquid state and is pumped into cylinders. Liquefied hydrocarbon gases in the abbreviated version are called LPG.

For heating with LPG, cylinders with a capacity of 50 liters are used (gas weight in liquid state is up to 22 kg). The cylinders are filled to 80% of the volume, because... gas is capable of expanding with increasing temperature and can rupture the cylinder. Also, when the contents of the cylinder are exhausted, complete emptying is not allowed, but only 90%.

What you need to connect

To install a heating system on gas cylinders you will need:

- Gas boiler equipped with a burner for liquefied gas;

- Gas cylinders with a capacity of 50 l;

- Gearboxes;

- Ramp, if several cylinders are connected;

- Shut-off valves;

- Gas pipeline in the form of pipes and hoses for connecting equipment to the system.

Equipment for heating a private house with gas cylinders

When choosing a gas boiler, you should pay attention to models with the lowest operating pressure and high efficiency. Many boiler models are already equipped to work with natural and liquefied gas. If a connection to the main gas pipeline is not expected, then it is better to choose just such a boiler to operate on LPG.

Otherwise, additional equipment is purchased: nozzles for the burner or an entire burner for liquefied gas, and in some models, a gas valve. The natural gas boiler burner is designed for lower pressure in the system and has a valve with a large hole, which can lead to an emergency.

Gas heating in a private house: general principles of the device and many useful tips

Natural gas is transported through pipelines, using gas carriers, also called tankers, and in railway tanks. A gas tanker is a vehicle that allows the transportation of the extracted product in a liquefied state.

The advantages of natural gas include:

- high calorific value;

- ease of transportation;

- small amount of harmful emissions;

- automation of the combustion process.

It is used for space heating, water heating, cooking in private properties, apartment buildings, public institutions, for heating offices and commercial premises, as fuel for cars, in technological processes for manufacturing products for various purposes.

Connection diagram to the boiler

The cylinders are connected to the system through a special reducer, which converts the gas from liquid to gaseous for further supply to the boiler.

Gas cylinders with separate reducers Please note! The gas flow rate through the reducer should be 1.8-2.0 cubic meters per hour; a conventional gas reducer with a flow rate of 0.8 cubic meters per hour is not suitable for this system.

When connecting cylinders to the boiler, two options are used: one common reducer for all cylinders or a separate reducer for each. The latter option is safer, but also more expensive.

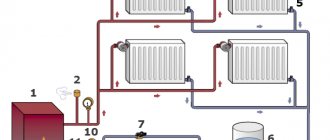

Several cylinders can be connected to a gas boiler at once, which allows you to increase the time between their refills. For this, a ramp is used - a two-arm manifold that distributes the cylinder capacities into two groups, the main and reserve.

First, gas is selected from the cylinders of the main group, and when it runs out, the ramp automatically switches the boiler to the reserve group. The moment of switching is accompanied by a signal. After connecting already filled cylinders to the ramp, the boiler automatically switches to operation from the main group.

Connection diagram of cylinders to the ramp

Note! Gas cylinders are installed at a distance of at least 2 m from the boiler, but the optimal option for their placement is in a separate non-residential premises or an insulated gas cabinet on the north side of the house.

Do not expose gas cylinders to direct sunlight.

The wall thickness of metal gas pipeline pipes must be at least 2 mm. Where it passes through the walls, the pipe is placed in a special case and foamed. The boiler is connected to the gas pipeline using a flexible connection, and a rubber-fabric hose (durite hose) is used for the reducer.

Safe Operation

It is prohibited to use heaters, electric heaters, heating cables, etc. as a means of heating heating cylinders.

Tanks with fuel reserves can only be stored inside separate cabinets, the top of which is drilled to form ventilation. It is recommended to insulate the structure from the inside on the sides and below with polystyrene foam, without covering the ventilation holes. It is not allowed to insulate the cylinders themselves by heating them from the outside, even if they are partially covered with frost.

Frozen cylinders

It is important to follow the rules for filling tanks so that equipment does not explode at home. Immediately after assembling the heating unit, it is necessary to check for leaks

Immediately after assembling the heating unit, it is necessary to check for leaks.

Gas pipes must have walls 2 mm or more thick, and in places where they pass through the wall, before pulling the pipeline, a special case with soft filling or a piece of pipe of a slightly larger diameter is placed. In the latter case, the voids are filled with construction foam.

Liquefied gas consumption

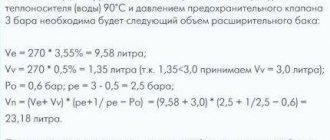

To understand how efficient and expedient it is to heat a house using LPG, let’s calculate the consumption of bottled gas for a house with an area of 100 sq.m. In such a house, according to thermal calculations, it is recommended to install a 10 kW boiler. To produce 1 kW of heat, the boiler consumes an average of 0.12 kg/hour of gas. Gas consumption for heating the entire area will be 1.2 kg/hour, and per day - 28.8 kg. If we consider that a standard 50 liter cylinder contains about 22 kg of gas, then the weekly consumption will be about 9 cylinders, and this is absolutely impractical.

Gas cylinders with a volume of 50 liters

But in this mode, the boiler only works to heat up the heating system. The rest of the time, a properly adjusted boiler consumes 3-4 times less gas, i.e. about 8-9 kg of gas per day or approximately half a cylinder. per week to heat a well-insulated house of 100 square meters. m will need about 3 gas cylinders. In this case, the temperature inside the room will be maintained at +22 degrees (at -18-20 degrees outside).

Heating efficiency can be increased through the use of automation.

Note! A decrease in temperature at night by 6-7 degrees leads to a reduction in gas consumption by 25-30%.

This means that per week, to provide such a system with liquefied gas, you will need about 2 cylinders.

In the case of heating a country house, during the absence of the owners, you can set the temperature to +5+7 degrees (only to maintain the heating system in working condition). Then the gas consumption per week will decrease to 1 cylinder.

When increasing the heating area, the required number of cylinders is calculated in proportion.

Gas cylinders in winter

If gas cylinders are located outside the house, then in winter at subzero temperatures the pressure of liquefied gas decreases and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-flammable materials. Also suitable for this purpose are detached non-residential buildings with minimal heating. When using cylinders, safety precautions should be observed:

Special cabinet for installing cylinders

- It is prohibited to heat containers with gas using open fire;

- There should not be a basement or cellar near the cylinders, since liquefied gas sinks down when leaking, has no odor and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the living space;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Recommendations for buyers

Unlike complex household appliances such as a washing machine with many operating modes, to successfully select a household gas heater with a cylinder for a garage or cottage, several important criteria must be taken into account. They relate to appearance, characteristics, main functions, degree of safety and convenience.

For a home or other enclosed space, try to choose a heater with a body that does not heat up and a maximum degree of safety - protection against leaks and fireFor open areas, powerful units in housings are suitable that reliably protect the burner from extinguishing, and other internal elements from debris and dust.

The criteria listed below should also be considered depending on the installation location and the specific needs of the user.

If a gas household air heater from bottled gas is used frequently, every little detail is important - for example, the location of the power handle, piezo ignition button or power regulator. It is much more convenient to use the switch if it is located on the top or front panel, and not hidden on the back wall.

There are rollers for regular movement - make sure they are made of durable plastic and rotate well

Also pay attention to whether the protective grille is firmly installed, whether there is a carrying case (for compact models), whether the cylinders are securely fastened

Disadvantages of heating with liquefied gas

The main disadvantages of a heating system using gas cylinders:

- The inconvenience of periodically refilling cylinders, especially in the case of self-refueling (there is no delivery of cylinders to your home);

- The imperfection of the method of determining the fullness of the cylinder - by weighing;

- High gas consumption with an incorrectly adjusted system and, accordingly, a decrease in its efficiency;

- It is not always possible to create the necessary conditions for installing cylinders - stopping the boiler at low temperatures;

Gas cylinder refilling device

Advantages and disadvantages

The gas cylinder heating system has many positive characteristics:

- are economical;

- do not require additional devices for normal operation;

- easy to install and replace;

- no need for electricity consumption;

- With this type of heating, oxygen is not burned.

However, there are several negative aspects to using gas equipment:

- there is a possibility that the heating system will turn off if gas cylinders freeze on frosty days;

- choosing a room for installing cylinders is quite difficult, since their installation in rooms with poor ventilation is prohibited;

- gas has a higher density than air and if the system is not tight, it will fall into the lower parts of the building and, accumulating there, can cause unpleasant consequences.

Conclusion

The heating system, which uses cylinders, is quite simple and convenient, and also saves a good amount of money both during installation and during the period of operation. If you carefully approach all installation processes and equipment selection, you can eliminate all the disadvantages of this heating system.

In what case can such a system be used?

This heating method is often chosen if electricity is not supplied to the house, but in the future it is planned to connect to the main gas pipeline. Then there is no need to buy two boilers, and buying a gas boiler will justify itself - it will only be enough to switch it from operating on liquefied gas to normal mode. Sometimes liquefied gas boilers are used simultaneously with electrical equipment or a heated floor system in order to save money.

When choosing a heating system using LPG, the area of the house and the degree of its thermal insulation must be taken into account. The optimal heating area with such a system is up to 100-150 square meters. m, and houses with high-quality thermal insulation and no cracks. Heating of areas over 150-200 sq. m is already becoming inefficient and requires regular refilling of too many gas cylinders.

Types of products by location

Equipment operating on liquefied fuel can be floor-mounted or mounted. Each option has specific characteristics that make it attractive and practical under certain conditions.

Having this information in hand, owners can independently determine which device is most suitable for them, and then purchase it in a specialized store.

Option #1: floor equipment

Floor-standing devices are the most widespread. These are high-power units that can provide comfortable heat and hot water not only to standard residential buildings, but also to large-sized country cottages.

The main operating element of the devices is a pressurized gas burner. It has a good degree of efficiency and has high heat dissipation.

Floor-standing devices exhibit stable operation even with a strong drop in gas pressure in the system and reliably serve in intensive use for 15 to 25 years, depending on the manufacturer

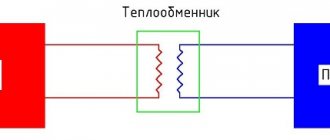

The boilers are equipped with a cast iron or steel heat exchanger. The cast iron element is heavy and has a long service life. A steel object is much lighter, but exhibits fragility, sensitivity to mechanical damage and shock, and lasts for a shorter period of time.

In addition to basic elements, progressive modules contain all kinds of auxiliary equipment that increase operational safety. These are sensors for monitoring the draft level, coolant volume and presence of flame, as well as thermostats that block operation in the event of an abnormally high level of heating of the working fluid

Depending on the manufacturer, the device is equipped with a piezo or electronic ignition system. In the first option, the device is started manually by pressing a button.

In the second case, activation occurs automatically, and the boiler does not consume excess fuel during operation, since the system does not have a pilot light with a flame burning continuously.

Detailed information on the selection and installation of floor-standing gas boilers is presented in the articles:

- Floor-standing gas heating boilers: types, how to choose, review of the best brands

- Do-it-yourself installation of a floor-standing gas boiler according to technical installation standards

Option #2: wall mounted devices

Boilers designed for wall mounting are compact in size and have a modern appearance. They take up a minimum amount of space and are suitable for placement in small rooms with complex layouts.

The installation of a mounted boiler is always carried out by a specialist who has experience in such work. The equipment must be installed in accordance with the safety requirements for domestic gas systems

Functionally, wall-hung gas units are no different from floor-mounted ones, however, they have slightly less power and are not very suitable for use in large, spacious houses. But they use fuel economically, while providing a high level of comfort in the living space.