Have you thought about installing water heating in your home? It is not surprising, because a single-pipe heating system for a private house can be traditional and completely energy-independent or, on the contrary, very modern and fully automatic.

But you still have doubts about the reliability of this option - you don’t know which scheme to choose and what pitfalls await you? We will help clarify these issues - the article discusses schemes for arranging a single-pipe system, the pros and cons that await the owner of a house with such a heating system.

The article is provided with detailed diagrams and visual photographs depicting individual elements used in heating assembly. In addition, a video has been selected with an analysis of the nuances of installing a single-pipe system with heated floors.

What is single-pipe heating?

Any heating system consists of the following components:

- Heating device (boiler). Can be solid fuel, electric, gas, etc.

- Heat-dissipating devices. Batteries or underfloor heating system.

- A device for creating circulation inertia of the coolant. This could be an accelerating section of the main line or a water pump.

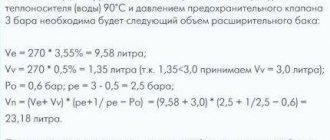

- Compensator for excess coolant pressure in the system. Expansion tank (open or closed).

- Pipes, fittings and necessary fittings.

The choice of heat supply scheme is directly dependent on the type of devices used.

Strengths and weaknesses of single pipe systems

The popularity of single-pipe heating in private construction is explained by the fairly low cost of the structure and the ability to independently carry out installation work. This makes it possible to save on hiring specialists.

Among other advantages of single-pipe systems, the following should be highlighted:

- High level of hydraulic stability. If you turn off some of the circuits, this will not affect the heat transfer of the remaining elements of the system. The same applies to replacing batteries or increasing the number of their sections.

- Low pipe consumption for organizing a main line.

- Slight inertia. To heat up the system, an order of magnitude less coolant is required than in schemes with two pipes.

- External aesthetics. Installation of a single-pipe system usually does not affect the beauty of the interior of the room, especially when using hidden laying of the main pipe.

- Thanks to the use of innovative shut-off valves (automatic and manual thermostats), it is possible to fine-tune the operating modes of the heating circuit and its constituent devices.

- Simplicity and reliability of the design, which makes it possible to install a single-pipe heating system on your own. The same applies to heating maintenance during operation.

By organizing the connection of control and monitoring devices for the heating system, it is possible to achieve its functioning in automatic mode. Integration into the Smart Home system is also allowed: as a result, it becomes possible to program optimal heating modes, taking into account the time of day, season, etc.

The main disadvantage of a single-pipe heating scheme is the presence of an imbalance between the heating of the radiators, depending on their distance from the boiler. This is explained by the gradual cooling of the coolant as it circulates through the pipes. As a result, the batteries closest along the coolant path turn out to be hotter than those located further away. In such cases, it is better to use cast iron devices, which are characterized by slow cooling.

Installation recommendations

In addition to the general rules for installing heating equipment and heating networks, when assembling single-pipe systems with your own hands, you need to take into account its features. Here are some recommendations on the topic:

- first make a correct calculation of pipe diameters, especially for a gravity flow scheme;

- think carefully about the laying of branches or risers so that the former do not cross doorways, and the latter do not fall on the windows;

- Connect radiators for artificial circulation using a DN15 pipe, and for natural circulation – DN20;

- Observe slopes. For a gravity system - at least 5 mm per 1 m, pressure - 3 mm;

- the height of the accelerating manifold should be 2.2 m;

- the expansion tank in an unheated attic must be insulated, and the overflow pipe must be taken outside;

- if the boiler heat exchanger is made of cast iron, do not add cold water directly to the return line near the heat generator;

Do not load one ring of the heating circuit with a large number of batteries, otherwise the last ones will be cold.

Applications of the Tichelman loop

Increased consumption of materials is not always better, so the Tichelman system is rarely used in a two-story house. The exception is a highway with radiators placed around the perimeter of the building. The ring system will require significant costs for materials, but the arrangement of a closed ring is carried out only if there are no obstacles in the form of doorways or floor-to-ceiling windows. We will have to lay another line to return the coolant to the heating device.

If the loop is lengthened, moved away from the heater, the cross-section of the pipes is increased, or a powerful circulation pump is selected, otherwise the system will not be able to operate at full capacity.

To reduce coolant costs in the area where the first batteries are connected, the diameter of the pipeline should be reduced, this will help maintain water pressure in subsequent sections. The diameter is reduced only according to preliminary calculations, otherwise radiators located at a considerable distance from the heating device will not receive a sufficient amount of coolant.

It turns out that using two-pipe wiring with a passing water flow is only possible if the total length of the main line is 70 meters or more, on which 10 radiators are installed. Otherwise, the associated wiring will not justify the investment.

Disadvantages of the system and possible ways to eliminate them

Like any heating system, the Leningradka is not without its drawbacks. However, today there are ways to eliminate them.

- The first drawback is related to the principle of its operation: as you move away from the heat source, the temperature of the radiators becomes lower and lower, and, accordingly, the rooms will be cool. This problem can be solved by increasing the number of sections or the area of heating devices in each subsequent insert. Another option to ensure balance, i.e. uniform heating to the required temperature is the installation of shut-off and control valves: taps, cone valves, regulators, thermostatic valves, bypasses, etc.

- Another imperfection of such a system (in the classical version) is the impossibility of regulating the temperature and repairing one of the elements without completely stopping its functioning. However, currently such a scheme is found only in old houses. Modern options already include the installation of the above equipment, which allows you to change the degree of heating of each specific radiator, as well as its replacement without affecting the operation of others.

- The use of metal pipes not only increases the cost of the Leningradka, but also complicates its installation and repair. The way out of this situation is to use metal-plastic or polypropylene pipes.

- Like any single-pipe system, for effective operation the Leningradka requires increased coolant pressure in the pipeline. This problem can be eliminated either by increasing the heating temperature of the liquid, which is not always acceptable, or by installing a circulation pump.

Tichelman loop for two floors or more

Most often, such a heating system is installed in one-story buildings with a large area. It is in such houses that it works most effectively. However, sometimes such a system is assembled in two or three-story buildings. When performing wiring in such houses, you should adhere to a certain technology. According to Tichelman’s scheme, in this case it is not each floor individually that is connected, but the entire building as a whole. That is, an equal sum of the lengths of the return and supply pipelines is maintained for each radiator in the house.

The Tichelman loop on two floors is thus assembled according to a special scheme. Experts also believe that using only one circulation pump in this case is inappropriate. If there is such a possibility, the building should install one such device on each floor. Otherwise, if a single pump breaks down, the heating will be turned off in the entire house at once.

Scheme of a single-pipe heating system: types and advantages

Single-pipe heating systems are divided into a single-pipe heating system with a closing loop and a flow-through single-pipe system. The single-pipe method of installing heating systems has two types:

The first type is flow-through

The first scheme is flow-through. There are no supply risers as such. Radiators throughout the entire height of the house are connected to each other in series.

The hot water flow is supplied from top to bottom and flows sequentially through all heating radiators, starting from the top. The lower radiators in such a system will be cooler.

Scheme of a single-pipe system with flow-through heating.

In flow-through types of single-pipe systems, the coolant mixture, flowing through the pipes, passes sequentially through the entire chain of heating radiators, gradually cooling at each of the batteries.

As a result, it will be quite hot on the upper floors, and on the lower floors the heating temperature may not even be sufficient.

To reduce this difference and to balance heat loss, batteries with a large number of sections are installed on the lower floors of buildings.

In flow-through systems, it is not recommended to install control valves, because even if the flow is reduced or such a valve is closed in a particular radiator, the water supply to all batteries lying below in a given riser in the direction of flow is reduced or shut off.

In such systems it is impossible to regulate the air temperature in the rooms. If the house has two floors, then it is impossible to supply water to only one of the floors.

Many years of experience show that such a single-pipe heating system scheme is absolutely ineffective, and therefore is not used today.

The second type - with bypasses

Comparison of a single-pipe heating system with a closing loop and a flow-through single-pipe system. Click to enlarge.

A single-pipe space heating system has a closing circuit and uses special fittings with a bypass inside the housing of these fittings.

From the heating radiator, the coolant flow with a decreased temperature is consistently returned to the riser.

After this, the coolant mixture is supplied to the next radiator. The annular water flow is divided in the valve into flows in the radiator and flow in the bypass.

From the risers, water flows into the upper radiators, the rest of the hot flow is directed down the risers to the underlying radiators.

The water in this connection cools down somewhat less, which makes it possible to reduce the temperature difference on the lower and upper floors.

This connection method is, in essence, a modernized “flow-through” system, in which a jumper is created between the radiator connection pipes - a bypass.

The diameter of the pipe of such a closing section is made one size smaller than that of the riser pipes of the general connection. As a result, the coolant supplied from the upper floors is divided into two flows: the first flows into the battery, and the second, through the bypass, flows to the lower rows of radiators.

If the diameter of the bypass is mounted the same as that of the connection pipes, then the coolant in the radiator will stop circulating, since the hydraulic resistance in the battery will be greater than in the bypass.

Water always flows where there is less hydraulic resistance; with the same diameter, it does not need to flow through the radiator; it will flow calmly through the closing section, which has the same size of pipe from which it flowed.

When installing bypasses with diameters equal to the diameter of the riser pipes connecting the radiators, the incoming amount of water can be regulated by pre-installed valves (to balance the system). Such taps are mounted on the connection pipe and on the bypass.

For example, you can completely shut off the radiator itself and redirect all the water to the bypass, and then to the heating batteries lower down the riser. Or vice versa - shut off the bypass and direct the entire flow of coolant into the battery itself.

Advantages

A single-pipe heating system for a one-story house has a number of advantages over a two-pipe heating system. In particular, the single-pipe scheme makes it possible to cover the entire perimeter of the inside of the house with one closed ring, because only one pipe comes from the boiler. In addition to being economical, having one pipe has the following positive aspects:

- It is possible to design a heating system with one pipe regardless of the layout of the room and with minimal consumption of materials;

- Pipes are mounted in close proximity to the floor or hidden under the floor, which allows you to hide the entire engineering structure and design the interior without taking into account open communications;

- Any equipment at the owner’s request can be built into single-pipe heating - heated towel rails, radiators, pumps, accessories;

- The temperature of the coolant can be easily controlled, and, therefore, the procedure for creating maximum thermal comfort in the house becomes more flexible;

Existing modifications of the single-pipe heating system Leningradka

The design feature of this heating option allows it to be performed in two versions: horizontally and vertically.

Horizontal scheme

In this case, the contour is laid along the perimeter of the building (floor). In this case, the supply line can be located both above the floor covering and directly in the floor structure. In the second method, it is recommended to insulate the heating pipeline to eliminate heat loss.

Figure 2 – Horizontal diagram of a single-pipe “Leningrad”

Figure 3 – “Leningradka” with the location of the supply line in the floor structure

The horizontal heating circuit can be open or closed.

The open type involves installing an expansion tank at the top of the system, communicating with atmospheric air. The closed-type Leningradka eliminates this possibility, so it uses a membrane tank, which is installed in the same room where the heat source is located.

Vertical scheme

This design is similar in design to the traditional single-pipe system used in multi-storey buildings: radiators must be placed one under the other and connected to a single pipeline. The difference is that the coolant does not move along one riser (i.e. only from top to bottom), but along a circuit (heated water first rises to the upper floor, passing through installed appliances, and then descends to the lower level, passing through the second group of radiators ).

Figure 4 – Vertical diagram of the “Leningradka”

Radiator installation methods

Ideally, the method of turning on radiators should depend specifically on the heating circuit. And the connection to the last battery in the pipeline is selected to be most suitable for a particular case. Connecting heating batteries to the main pipeline occurs in three main ways:

- Lateral.

- Diagonal.

- Lower.

The importance of design does not diminish, but you need to understand that beauty without stable heating will be destroyed, so efficiency is a priority.

Features of the horizontal pipe laying scheme

Horizontal heating scheme in a two-story house

In the vast majority, a horizontal two-pipe heating system with bottom wiring is installed in one or two-story private houses. But, in addition, it can be used to connect to centralized heating. A feature of such a system is the horizontal arrangement of the main and return (for two-pipe) lines.

When choosing this piping system, it is necessary to take into account the nuances of connecting to various types of heating.

Central horizontal heating

To draw up an engineering diagram, you should be guided by SNiP 41–01–2003. It states that the horizontal distribution of the heating system must ensure not only proper circulation of the coolant, but also ensure its metering. For this purpose, two risers are installed in apartment buildings - with hot water and for receiving cooled liquid. A calculation of a horizontal two-pipe heating system, which includes the installation of a heat meter, is required. It is installed on the inlet pipe immediately after connecting the pipe to the riser.

In addition, hydraulic resistance in certain sections of the highway is taken into account

This is important, since the horizontal distribution of the heating system will only work effectively if the appropriate coolant pressure is maintained

Autonomous horizontal heating

Heating with natural circulation

In a private house or apartment without a connection to the central heating supply, a horizontal heating system with bottom wiring is most often chosen. However, it is necessary to take into account the operating mode - with natural circulation or forced under pressure. In the first case, a vertical riser is installed immediately from the boiler to which the horizontal sections are connected.

The advantages of this arrangement for maintaining a comfortable temperature level include the following:

- Minimum costs for purchasing consumables. In particular, a horizontal single-pipe heating system with natural circulation does not include a circulation pump, a membrane expansion tank and protective fittings - air vents;

- Reliability of operation. Since the pressure in the pipes is equal to atmospheric pressure, the excess temperature is compensated using an expansion tank.

But there are also disadvantages to be noted. The main one is the inertia of the system. Even a well-designed horizontal single-pipe heating system for a two-story house with natural circulation will not be able to quickly heat the premises. This is explained by the fact that the heating network begins to move only after reaching a certain temperature. For houses with a large area (from 150 sq. m.) and with two floors or more, a horizontal heating system with bottom wiring and forced circulation of liquid is recommended.

Heating with forced circulation and horizontal pipes

Unlike the scheme described above, there is no need to make a riser for forced circulation. The coolant pressure in a horizontal two-pipe heating system with bottom wiring is created using a circulation pump. This is reflected in improved performance:

- Quick distribution of hot water throughout the entire line;

- Possibility of adjusting the volume of coolant for each radiator (only for a two-pipe system);

- A smaller area is required for installation since there is no distribution riser.

In turn, horizontal wiring of the heating system can be combined with a collector one. This is relevant for long-distance pipelines. This way you can achieve even distribution of hot water throughout all rooms of the house.

When calculating a horizontal two-pipe heating system, it is necessary to take into account the rotary units; it is in these places that the hydraulic pressure losses are greatest.

Opinion of country house owners about the system

According to most owners of country real estate, this scheme is indeed very effective - the Tichelman loop.

This system has received simply excellent reviews. If it is properly designed and assembled, a very comfortable microclimate is established in the house. At the same time, the system equipment itself rarely breaks down and lasts a long time. Not only the owners of residential buildings, but also the owners of dachas speak well of the Tichelman loop. The heating system in such buildings is often used irregularly during the cold season. If the wiring is done according to a dead-end circuit, when the boiler is turned on, the rooms are heated extremely unevenly. With a passing system, such problems, of course, do not arise. But assembling heating according to such a scheme is really more expensive than using a dead-end one.

Elimination of deficiencies using bypass

In addition, natural circulation achieves a reduction in the heating effect, and this will be felt on devices located at the farthest point; problems may also arise with heating the lower riser. It will warm up less. Everything depends on the correct installation of the system, and in this case, even devices with forced circulation will not be able to correct the defect. In this case, a bypass is used to close the coolant circulation. In simple words, this is a piece of pipe connecting the supply and return.

There is another option to correct the situation, but it is more complicated. The method consists of parallel insertion of all radiators into the main line, and additionally supplying them with control valves. And most importantly, it becomes possible to repair individual devices without draining the coolant.

Advice. Such installation is necessary if the heating boiler exceeds the system parameter in strength. The valves allow you to balance the temperature and not overheat individual rooms.

A two-pipe system, unlike a single-pipe supply, does not have such inconveniences. But everything is stopped with auxiliary devices. The bypass is equipped with valves that shut off the flow. If desired and possible, it can be made from the remains of pipes. The bypass circumference should be slightly smaller than the diameter of the risers. Otherwise, the liquid will not be evenly distributed, but will be discharged directly into the return line.

Experts recommend an approximate difference in diameter, from 5 to 10 mm. To achieve greater effect, the bypass should be located closer to the radiator. At the outermost device, just before the hole at the inlet, a thermostat is mounted. By taking into account these little things, the operation of heating devices will be more efficient. During acceleration, the same return will be natural and also forced circulation. The difference in thermal performance will be insignificant, even if you have to install the appropriate equipment in the process.

Design and principle of coolant distribution

The system is called single-pipe because heated water is supplied and leaves the heating radiators through a single collector. The pipeline is common to all batteries connected to the main branch. That is, the input and output connections of each heating device are connected to one pipe, as shown in the example of the heat supply diagram of a one-story building.

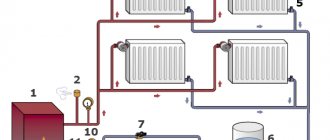

The classic version of a closed circuit with forced movement of coolant connected to a gas boiler

How does a single-pipe radiator heating system work:

- The heated coolant coming from the boiler reaches the first battery and is divided by a tee into two unequal flows. The bulk of the water continues to move straight along the main line, a smaller part flows into the radiator (about 1/3).

- Having transferred heat to the walls of the battery and cooled by 10-15 ° C (depending on the power and actual output of the radiator), a small flow through the outlet pipe returns to the common manifold.

- Mixing with the main flow, the cooled coolant reduces its temperature by 0.5-1.5 degrees. The mixed water is delivered to the next heating device, where the cycle of heat exchange and cooling of the main flow is repeated.

- As a result, each subsequent battery receives coolant with a lower temperature. At the end, the cooled water is sent back to the boiler along the same line.

Important point. In order for the heating circuit to operate stably, the diameter of the distribution pipe must significantly exceed the dimensions of the radiator connections. The rule does not apply to vertical risers with top filling, where the coolant is helped to flow downwards by gravity (read below about the types of systems).

The color and size of the arrows in the figure characterize the temperature and amount of water, respectively.

First, the flows are separated, then mixed, cooling by a couple of degrees . The lower the temperature of the circulating water, the less heat gets to the last heaters. The problem can be solved in three ways:

- at the end of the highway, batteries of increased power are installed - the number of sections is increased or the area of panel steel radiators is increased;

- by increasing the pipe diameter and pump performance, the coolant flow through the main collector increases;

- a combination of the two previous options.

Connecting radiators to a single distribution line is the main difference between single-pipe wiring and other two-pipe systems, where the supply and return of coolant is organized in two separate branches.

Two-pipe scheme

Two-pipe heating system. Click on photo to enlarge.

A two-pipe heating system with bottom wiring differs from the top supply of risers in that both pipes (both supply and return) are located at the bottom. The hot coolant moves along the direct riser from bottom to top, passes through all the batteries and returns through the return riser to the boiler. A two-pipe circuit may contain one or more circuits and provide a passing or dead-end movement of water through the supply and return pipes.

A two-pipe heating scheme with natural circulation and lower risers is used infrequently, since a large number of final radiators requires the installation of an equally large number of air valves, and manually bleeding air from the radiators is a labor-intensive and tedious process. Looping the supply risers with special air pipelines helps solve the problem of air entering the main line through the expansion tank, but then the whole point of using the lower line is lost, because the number of risers on the walls does not decrease, but only increases.

Requirements for organizing a two-pipe system with bottom wiring

The required components of such a highway are:

- boiler;

- batteries;

- connecting pipes;

- expansion tank;

- pump;

- adjustment devices (pressure gauge, balancing device, air vent);

- other fittings (valves, thermostatic and safety valves, pipeline filters).

The expansion tank should be located at the peak - the highest point of the heating system. If the house has a central water supply, then the expansion tank can be combined with a water supply tank to the main line. The main condition for effective use of the tank is easy access to it, so it is not at all necessary to place it in the attic, as is the case in many private homes. In addition, the tank must be installed in a cool place.

For natural circulation, it is necessary to create a pipe slope at the rate of 10 cm per 20 linear meters.

If the front door becomes an obstacle to installing risers, you can arrange two elbows. In this case, the wiring is equipped from the peak of the main line.

Another important requirement for the effective operation of a two-pipe heating main is the use of pipes of different diameters, designed to ensure the movement of the coolant not only in a small circle (boiler - nearby radiator - boiler), but also in longer ones. In long lines it is advisable to include a high-performance electric pump

It will accelerate the circulation of water, which means the heat transfer of the batteries will be higher

In long lines it is advisable to include a high-performance electric pump. It will accelerate the circulation of water, which means the heat transfer of the batteries will be higher.

When designing a two-pipe heating system, competent hydraulic calculation is of decisive importance, the main function of which is to determine the required number of radiators for effective heating of the house, the diameter of the risers and possible heat loss.

Tips for choosing pipe diameters and connections

A single-pipe heating option can be designed and installed independently, without resorting to complex hydraulic calculations. Let’s simplify the task and give useful recommendations on the design of single-circuit systems:

- The maximum number of heating devices on one loop of a closed Leningradka is 5 pcs. To deliver the required volume of coolant to the batteries, a pipe Ø25 mm (DN20) is sufficient. We make the connections from pipes Ø16 mm.

- If, due to objective reasons, the number of radiators on 1 ring of a closed system needs to be increased, the cross-section of the main line is increased to a diameter of 32 mm (DN25), the liner - to 20 mm. It is not economically feasible to install more than 7 batteries on one pipeline; it is cheaper to lay 2 smaller lines.

Examples of Leningradka installation in a wooden house and office space - The minimum diameter of a horizontal collector with natural circulation is DN40, outer diameter is Ø48 mm. In a two-story house, the accelerating riser and the beginning of the distribution branches are made from a DN50 pipe (Ø57 mm), remote areas are reduced to a size of DN32. Vertical lines to radiators - DN20-25 depending on the thermal power of the heaters.

- To automatically regulate heat transfer, select full-bore valves with thermal heads. The hole in standard radiator valves is too small.

- Connection to a wall-mounted or floor-standing gas boiler is made according to the standard diagram shown in the picture below. The wiring of an electric water heating apparatus is done in a similar way.

- It is better to connect the Leningradka solid fuel boiler through a three-way mixing valve and a buffer tank. Since there is too little coolant in the system, there is a risk of overheating and boiling. Gravity distribution, holding more than 200 liters of water, can be connected directly to the TT boiler.

Typical connection diagram for a double-circuit wall-mounted boiler with a Leningradka

Important clarification. When assembling a home heating network, polypropylene pipes PN 22-28, reinforced with fiberglass, aluminum foil or basalt fiber, are often used. There is no standard size of 16 mm in the range of STABI PPR pipes; the minimum outer diameter is 20 mm. Accordingly, radiator connections are made with a cross-section of 20 x 2.8 mm.

Operating principle of a single-pipe system

As the name implies, in this scheme the role of supply and return lines is played by the same pipe. Both supply lines from each heating device, installed one after the other, are connected to it.

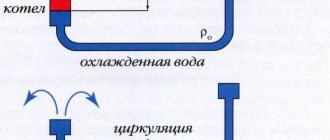

The pipe is laid from the heat source and returns to it, forming a ring circuit. The system functions as follows: the water heated in the boiler immediately goes up a vertical pipe, thereby creating pressure in the network.

When using a single-pipe water heating system in a two-story house, the coolant from the vertical pipe diverges along the contours. In one-story houses, this riser drops again to floor level, forming the so-called accelerating manifold. Only after this the pipe runs horizontally around the perimeter of the building, where the batteries are connected to it, and then returns back to the boiler. The features of such a system are:

- the flow area of the main pipe is unchanged throughout its entire length;

- Each subsequent heating device receives water at a lower temperature than the previous one. The reason is clear - the cooled coolant from the first battery is mixed into the common collector, reducing the temperature of the water passing through it;

- this feature stems from the previous one. To increase heat transfer, each subsequent device must have greater power, that is, the number of sections must be increased from battery to battery.

In most cases, a forced impulse is used to move the coolant through the pipeline network in a private house, that is, a circulation pump is installed. Then the system operates stably and more efficiently, although the organization of natural circulation is also possible. This is where the vertical accelerating manifold, whose height is maintained at least 2 m from the floor, will play its role. We should not forget that for normal gravity flow operation, you need to install an atmospheric expansion tank above the highest point of the system, ideally in the attic of the house.

The picture above shows what a single-pipe natural circulation heating system looks like in a one-story house. An expansion tank communicating with the atmosphere is installed under the ceiling (if height allows) or in the attic space and connected to the accelerating manifold. But such schemes do not work very well, since the temperature difference in the supply and return pipelines is small. To create good circulation, a pump is installed in the circuit, as in the figure below:

Now the expansion tank can be taken of the membrane type, since the system no longer requires communication with the atmosphere; excess pressure in it is created by a circulation pump. However, the presence of an accelerating manifold is necessary; here it has an additional function. It consists of maintaining the coolant level in radiators using the principle of communicating vessels. And, of course, it promotes better water circulation.

Conclusions and useful video on the topic

Not only radiators, but also underfloor heating circuits are connected to the single-pipe heating main. The video shows how to carry out such installation.

Single-pipe heating is a simple and reliable system. However, for effective heating it is necessary to carefully select its individual elements. To do this, it is advisable to seek advice from a specialist, who will help you perform an assessment calculation.

Do you disagree with the diagrams presented in our article? Or do you have practical experience in installing single-pipe heating in a private home? Your experience will be useful to our readers. Feel free to share your knowledge in the comments below.

Options for single-pipe heating systems

There are natural and forced types of circulation; the scheme can also be divided by type:

- Heat source. These can be solid fuel, gas, or electric boilers.

- For heat-emitting devices, such as radiators or a heated floor circuit.

- According to the transportation device. If the coolant flows by gravity, an accelerating section of movement is required; if forced circulation is installed, a pump is installed.

- Depending on the equipment for compensating excess pressure. Expansion tanks of open or closed type are used.

Also taken into account are the types of pipes based on the material of manufacture and the types of water fittings.

Schemes with natural and forced circulation

Natural circulation means that the coolant is transported through the pipe by gravity, forced circulation - using a pump. The first option requires the installation of pipelines with a certain slope to ensure water flow. An acceleration section is also needed to obtain the required pressure, which moves the liquid. The acceleration section is a vertical pipe extending from the boiler. The coolant rises through the pipe, then flows down through a pipeline connected to the pipe, filling the entire heating line and radiators.

If a single-pipe gravity heating scheme is carried out with an upper distribution for 2-storey buildings, the supply pipe serves as the acceleration section, only it rises to the required level. When installing a single-circuit system in a one-story building with horizontal wiring, you need an accelerating manifold with a height of at least 150 cm from the level of the first installed radiator.

Gravity flow schemes depend on the number of turns - the more there are, the more difficult it is to transport the carrier, so it is recommended to make no more than 2 turns along the entire highway. Also, the gravitational type of transportation creates problems with warming up the last heating device - cooling water does not warm up the battery well, so the number of sections has to be increased.

It will help to install a pump that can be placed at any turn in the highway. The operation of the pump eliminates all the disadvantages of a single-circuit circuit, accelerates the movement of the coolant, and guarantees the passage of liquid through any turns. Before installing the pump, you need to decide on the zone - despite the ability to install it at any point, the interaction of rubber parts with hot water is taken into account, which reduces the service life of the device. Therefore, it is recommended to install pumps on the carrier return flow pipeline, where low-temperature water circulates.

When choosing a scheme, you should take into account the advantages of forced ventilation:

- simplified implementation of complex heating schemes with turns, raising the coolant to the 2nd floor, attic;

- no need to buy pipes of different diameters;

- there is no need to calculate the angle of inclination of each section of the pipeline.

There are also disadvantages - dependence on power supply, the possibility of clogging of the device and the presence of maintenance costs (payment of electricity bills).

Open and closed systems

Schemes differ according to the type of expansion tank, which is mounted with the system. If it is a closed container, the system is closed; if there is no lid, it is open. The tank is installed at the highest point of the system. In sealed tanks there is an outlet for draining excess water or the internal space is divided by an expansion-type membrane - when there is excess liquid, the gas in one half is compressed, the membrane is extended, as soon as the volume of liquid is normalized, the membrane returns to its original position and provides the required pressure. The closed system is very easy to install and use.

An open tank is also placed at the highest point of the diagram, but the tank does not have a lid, so interaction with oxygen entering the pipes is possible - increasing the risk of airing. The advantage of using an open system is that there is no need to monitor the pressure and the possibility of making an expansion tank from scrap material. Users note a number of other disadvantages - water needs to be added to the tank, antifreeze cannot be used (the coolant will evaporate, and its vapors are poisonous), oxygen in the coolant wears out the pipes faster.

Pros and cons of single-pipe wiring

We will try to give an objective assessment and highlight the real advantages of single-pipe water systems:

- A closed circuit with a membrane expansion tank is easier to install. One pipe is laid faster than two.

- It is easier to hide a single main or riser in the walls than double-pipe branches (example in the photo below). The fly in the ointment: the ring manifold crosses doorways, making installation difficult.

- A heating network with risers is indispensable when it is necessary to organize gravity flow in a building of 2-3 floors. There is no point in passing two pipelines through the ceiling; one vertical line is enough.

- Installation is cheap in one case: when a gravity heating system is used in a one-story private house. Savings are achieved by laying one main line instead of two (remember, gravity flow a priori requires pipes of large diameters Ø48-57 mm).

- The closed type system can be automatically controlled using thermostatic radiator valves. Disclaimer: it is necessary to take into account the specifics of the operation of heating devices and choose the right fittings. We will return to this issue below.

Small diameter pipes are walled up in the walls, large diameter pipes are covered with decorative screens

Note. Direct connection of a section of heated floors cannot be considered an advantage of this scheme. The heating circuit is just as easily connected to the two-pipe distribution.

The main problem of the Leningradka is the cooling of the coolant as it moves towards the distant batteries. It is impossible to increase radiator sections and the cross-section of the main line indefinitely; the optimal number of devices is 4-5 pieces. on one circuit.

We list other disadvantages:

- Hydraulic instability is the effect of one battery on the operation of the others. If you close the first radiator valve, subsequent appliances will receive hotter water and begin to overheat the rooms.

- In order for the coolant to flow well into the radiators with a closed Leningrad circuit, it is necessary to use full-bore fittings on the branches. An increase in the hydraulic resistance of the line causes water to flow further in a straight line, and the coolant flow through the battery decreases.

On the left is a standard angle valve with a small hole, on the right is a thermostatic radiator valve with an increased flow area - “Leningradka” and vertical wiring are more expensive than a two-pipe shoulder circuit. If we add the costs for additional radiator sections, then the cost of installation from cross-linked polyethylene will be comparable to a radial system, where fittings are not used, but there is a distribution comb.

- The circuit is complex to calculate and configure (balance). The power and heat transfer surface area of the batteries must be determined as accurately as possible.

An additional disadvantage of gravity distribution is the large diameters of pipes laid with a slope of 3-5 mm per linear meter. Risers coming out of the ceilings stick out in plain sight and spoil the interior of the premises. It is not always possible to wall pipelines into walls; you have to get sophisticated and make decorative boxes.

Sequence of actions when installing water heating with two-pipe bottom wiring

It all starts with the choice of energy resource. If you use a gas boiler as the main one in the same scheme, and an electric or solid fuel boiler as a backup, then you can make the heating system energy-independent.

Next, you should contact the competent authority to develop and approve the project. Only after completing all the necessary documentation and purchasing equipment and consumables does the installation of the heating system begin.

Boiler room equipment

The boiler room should be spacious enough, with a high ceiling and good ventilation. Sections of walls and floors located in the immediate vicinity of the boiler are lined with fireproof materials.

The boiler is installed according to the operating instructions. The chimney is led out into the street through a special opening.

Manifold cabinet

This element is a compartment within which the pump, distribution manifold, regulators and meters will be located.

Pipe installation

The pipes are installed as straight as possible, without bends. If necessary, holes are made in the walls, which are subsequently carefully covered with cement mortar. To connect pipes, welding (metal) or a special iron (polypropylene) is used.

Battery Installation

Heating elements are located under the window sill. The installation requirements for the wall, floor and window sill are the same as for installing a single-pipe system. The length of the radiator (number of sections) should, if possible, correspond to the width of the window opening. Temperature regulator valves are installed at the coolant inlet and outlet areas.

The final stage of installation of water heating with bottom wiring is crimping. The first start-up of the boiler is carried out only in the presence of employees of the relevant service.

Necessary consumables and tools

To install a dead-end single-pipe circuit, you will need the following tools:

- adjustable wrenches;

- welding or soldering machine;

- hammer drill or electric drill;

- file.

You will also need the following consumables:

- radiators complete with fittings, plugs, taps and thermal valves, brackets;

- pipes, fastenings, bends, tees;

- three way valve.

In addition, materials will be required to insulate pipe connections.

Operating principle of a single-pipe heating system

The operation of a single-pipe heating system follows fairly simple principles. There is only one closed pipeline through which the coolant circulates. Passing through the boiler, the medium heats up, and passing through the radiators imparts this heat to them, after which, cooled, it again enters the boiler.

There is also only one riser in a single-pipe system, and its location depends on the type of building. So, for one-story private houses a horizontal scheme is best suited, while for multi-story buildings - a vertical one.

To improve the efficiency of a single-pipe system, several improvements can be made. For example, install bypasses - special elements that are pipe sections connecting the forward and return radiator pipes.

This solution makes it possible to connect thermostats to the radiator that can control the temperature of each heating element, or completely disconnect them from the system. Another advantage of bypasses is that they allow you to replace or repair individual heating elements without shutting down the entire system.

Installation features

In order for the heating system to provide warmth to the owners of the house for many years, during the installation process it is worth adhering to the following sequence of actions:

- According to the developed project, the boiler is installed.

- The pipeline is being installed. In places where the project provides for the installation of radiators and bypasses, tees are installed.

- If the system operates on the principle of natural circulation, it is necessary to ensure a slope of 3-5 cm per meter of length. For a forced circulation circuit, a slope of 1 cm per meter of length will be sufficient.

- For systems with forced circulation, a circulation pump is installed. It is worth considering that the device is not designed for operation at high temperatures, so it would be better to install it near the entrance of the return pipe to the boiler. In addition, the pump must be connected to the electrical network.

- Installation of expansion tank. An open type tank should be located at the highest point of the system, a closed type - in any convenient place (most often it is mounted near the boiler).

- Installation of heating radiators. They weigh a lot (especially when filled with water), so they are secured using special brackets, which are usually included in the kit. Installation is most often carried out under window openings.

- Additional devices are being installed - Mayevsky taps, plugs, shut-off devices.

- The final stage is testing the finished system, for which water or air is supplied to it under pressure. If the tests do not reveal problem areas, the system is ready for operation.

Advantages

For private houses with a small area, a single-pipe heating system looks more preferable due to its following advantages:

- Ease of drafting.

- Ease of installation of the system.

- Reducing costs for the purchase of materials and equipment.

- Steady hydrodynamics.

- Safety of coolant circulation, which occurs naturally.

Flaws

There are also a number of disadvantages that owners of single-pipe heating systems will have to put up with:

- Difficulty in correcting errors made at the design stage in a commissioned circuit.

- Uneven heating of heating elements located at different distances from the boiler.

- Close interdependence of elements.

- High hydrodynamic resistance.

- Impossibility of adjusting coolant flow.

- Relatively large heat losses.

- Limited number of radiators that can be placed on one riser.

(no votes yet)

Tichelman heating feature

The idea of changing the operating principle of the “return” was substantiated in 1901 by the German engineer Albert Tichelman, in whose honor it received its name - the “Tichelman loop”. The second name is “reversible type return system”. Since the movement of the coolant in both circuits, supply and return, is carried out in one, parallel direction, a third name is often used - “scheme with parallel movement of thermal fluids”.

The essence of the idea is to have the same length of forward and return pipe sections connecting all radiator batteries with the boiler and pump, which creates the same hydraulic conditions in all heating devices. Circulation circuits of equal length create conditions for the hot coolant to travel the same path to the first and last radiator and receive the same thermal energy.

Tichelman loop diagram:

Radiator connection options

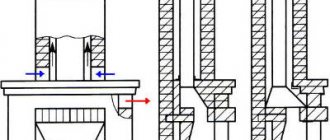

When installing a one-pipe heating system, use the following options for connecting radiator heat exchangers:

Lower. The lower connection is most often used in Leningrad. Although it is considered not the most successful in terms of the efficiency of heat exchange between batteries, due to the lowest consumption of pipe materials and the aesthetic appearance of the open line, this method has become quite widespread.

Also, with a bottom connection, all contaminants at the bottom of the batteries are better washed away, which increases their service life and reduces the likelihood of narrowing of the passage channel due to deposits.

Diagonal. Connecting batteries diagonally is considered one of the best options for heat transfer efficiency. When organizing it, the supply pipeline is connected to the upper branch pipe, and the return line to the lower terminal on the opposite side.

Components and principle of operation

Single-pipe heating systems for a private house consist of the following elements:

- boiler;

- a pipeline through which heated and cold liquid moves;

- shut-off and control valves;

- expansion tank;

- circulation pump (if necessary);

- connecting parts;

- security block;

- radiators or batteries.

The operating principle of the Leningrad tank is simple: the heated coolant entering the system from the boiler reaches the first radiator, where it is divided into several flows by a tee. More fluid flows through the line, and the rest remains in the radiator. After heat is transferred to its walls (the water temperature drops by 10-15 degrees), the coolant returns to the common collector through the outlet pipe.

Mixing, the water cools by 1.5 degrees and flows into the next radiator. At the end of the circuit, the cooled liquid is sent to the boiler, where it is heated again. The last battery no longer receives such a hot coolant, so the room is heated unevenly. To eliminate this drawback, you can install a more powerful battery at the end of the circuit, increase the performance of the circulation pump or increase the diameter of the pipe.