Stoves in the house have not lost their relevance to this day; they successfully solve the problem of heating a home. If the house is too large, then using only one furnace device it is difficult to achieve a comfortable temperature in all rooms. In such cases, it is impossible to do without installing an effective heat exchanger and multiple radiators. The coolant is usually water or steam. As a result, the air, walls and floor are heated evenly throughout the building, creating a microclimate quite comfortable for people.

High efficiency of steam heating is possible only if high-quality equipment that meets all standards and requirements is used for its installation. Source plasportal.com

Principle of operation

When installing steam heating in a dacha, a stove or boiler is used as a heat source. With their help, water is heated to boiling point, then the evaporation process begins. The steam penetrates the batteries through the pipeline, gives off heat, and gradually condenses. The resulting water flows into the heat exchanger through the return pipe.

Steam boiler

When choosing a water heater, it is extremely important to pay attention to the performance of the unit. The larger the area of the heated premises, the more powerful the heating device should be.

In houses with steam heating, a solid fuel boiler is often used. A modern gas heat generator is comparatively more efficient. Using an electric device to heat a home is not economically profitable, which is associated with high costs for electricity.

Household steam boilers are used as a heat source for heating a house: they heat a container of water and drive the resulting steam into heating pipes Source eurosantehnik.ru

Bake

If the house has a stove, it can serve as a heat source when installing steam heating. This will save you from additional waste on dismantling the device and repairing the premises. It’s also worth remembering: coal and firewood are inexpensive fuels. When using it, there is no dependence on centralized electricity and gas supplies.

The steam generator is a heat exchanger; you can make it yourself or order it. The design itself is quite simple, consisting of interconnected metal pipes.

If you plan to use a wood stove as a heat source, you should immediately calculate and design a special heat exchanger Source 1-teplodom.ru

How the system works

Do not confuse water and steam heating at home. They have many functional differences, despite their external similarities.

Both of these types have components:

- boiler;

- radiators;

- pipes.

Steam heating is considered effective; you can get by with a small number of batteries.

Steam is a coolant for steam heating of a private house. You can make such a system with your own hands, following the instructions for assembling and installing the components. For a water system, water plays the role of carrier. The boiler evaporates water rather than heating it. The coolant vapor moves through the pipes and becomes a source of comfortable temperature in the house. The steam cools inside, after which it condenses. In this case, 1 kg of steam is converted into 2000 kilojoules of heat. For comparison, water cooling at 50°C provides only 120 kJ.

In this video you will learn about the circulation of the system:

The heat transfer of steam is several times higher, which explains the high efficiency of this type of heating. The condensate formed inside the radiator passes to the lower part and independently moves to the boiler. There are several types of heating systems. In this case, the specification is carried out according to the method of returning the coolant, which has been transformed into condensate.

These are the systems:

- Closed. There are no contours in this case. Accordingly, condensate moves through pipes that lie at a certain angle. It goes straight into the boiler for further heating.

- Open. There is a storage tank here. Condensate enters it from the radiators, and the pump is involved in pumping it back into the boiler.

Advantages and disadvantages

Equipped steam heating at the dacha has the following advantages:

- provides intensive heating of rooms;

- steam instantly reaches all areas of the heating system, regardless of its complexity or the size of the building;

- pipes never freeze;

- does not require large expenses for the device;

- can be used in buildings for seasonal residence, for heating several floors;

- maximum heat transfer coefficient;

- Can be used together with heated floors.

Flaws:

- circulating along the circuit, steam creates a lot of noise;

- pipes and batteries can heat up above 100°C, which creates a risk of burns upon contact;

- it is difficult to regulate the indoor air temperature;

- the system is susceptible to corrosion, so it does not last very long;

- in the event of a pipeline breakthrough, a dangerous emergency situation is created (the coolant temperature reaches high values).

Important! Steam heating can be used to heat a house with several floors. The steam rises independently to any height, cools, and returns as condensate. Moreover, the installation of expensive pumps is not required at all.

Scheme

The heating system operates thanks to natural circulation. Therefore, the heat exchanger must be installed below the level of the radiators. The circulation pump ensures constant operation of the thermal circuit.

There are open and closed steam heating circuits: in the first case, the system is connected to the atmosphere (open), in the second, it is completely isolated from the effects of atmospheric pressure Source s-proms.ru

Steam heating in a house involves the installation of a one- or two-pipe heating system. The optimal choice of the latter depends on the area of the building that is planned to be heated.

Single-pipe

With single-line wiring, radiators are connected in series. The resulting steam passes through a pipeline from one battery to the next. As a result, the first radiator is always the hottest, the last one is almost cold. The single-pipe system is suitable only for small-sized rooms (no more than 80 m²).

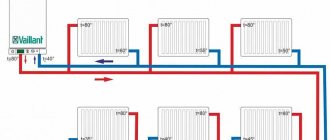

Two-pipe

If the house has a huge area, a two-line heating option should be used. A constant supply of hot steam is carried out through the upper pipe. The cooled condensate returns to the heating unit through the lower pipeline. Regardless of the distance from the boiler, all heating batteries heat up evenly.

A single-pipe heating system is more suitable for heating a summer house or a small house; for a spacious cottage or two-story building, it is recommended to use a two-pipe system Source gubernia.media

Arguments for"

The steam method quickly heats the air in the house.

A wood burning system is a more economical option than gas or electricity.

It is not necessary to demolish the stove, since in addition to the expenditure of effort and time, major repairs may be required.

Due to the absence of mechanisms, any adjustment is carried out manually, which means that the equipment will not break down or malfunction.

This is an option for a dacha or country house, since the presence there is seasonal, and fuel can be stocked up in advance. The heating will not turn off due to bad weather, non-payment of electricity or gas.

Even if the furnace itself is located in a neighboring building, it is possible to install a steam system. The main thing is to take care of thermal insulation.

How to do this is clearly shown in the following video:

Materials and equipment

To properly equip steam heating, you need to prepare:

- heat exchanger;

- radiators;

- pipes (preferably galvanized steel, copper);

- pressure reducing valve;

- brackets;

- valves;

- clamps, elbows, fasteners;

- welder;

- hydraulic valve;

- reduction-cooling device;

- pump;

- container for collecting condensed steam.

Advice! To minimize the cost of organizing steam heating, expensive equipment can be rented.

Radiators for steam heating are selected in accordance with the characteristics of the material from which they are made, taking into account the operating temperature Source otoplenieblog.ru

Heat exchanger

When building a brick stove, a heat exchange device will have to be ordered or made on your own. To do this you will need a welding machine and metal pipes. The thickness of the walls of the latter should be more than 2.5 mm. By welding they must be connected in the form of a coil. In addition, it is worth taking care of the tightness of the joints. It is important to take into account that 1 m2 of the surface of a curved spiral produces about 9 kW.

After creating the structure, it is important to check for permeability: fill it with kerosene, then outline the seams with chalk. Darkening of the latter will indicate penetration of a flammable liquid into the heat exchanger. Therefore, it is unacceptable to use such a device for heating with steam.

Self-manufacturing of a heat exchanger is only possible for people who have certain skills, tools and knowledge Source heatylab.com

Installation process

Steam heating in a private house from a stove should be installed in this way:

- When building a stove, place the heat exchanger in the combustion chamber. If the stove device is planned to be used for cooking, there should be no pipes left on top.

- Install radiators and connect the pipeline to them. To ensure natural circulation in the future, it is necessary to maintain a slope (3 mm per 1 m).

- All converters must be equipped with valves designed to remove air.

- For safety reasons, install a shut-off valve in front of each battery or one for the entire system.

- At the beginning of the circuit, install a cooling device, a pressure reducing valve.

- Connect a container to collect condensate. From it, water will flow at an angle back into the heat exchanger. It is not advisable to use a membrane expander: it is not designed for temperatures exceeding 85°C.

- When using forced circulation, install a pump directly in front of the stove (in the return circuit).

Important! Heating systems with natural circulation of steam do not require the installation of a tank or pumping equipment. Therefore, their work does not depend on the presence or absence of electricity.

If heating is planned to be done with solid fuel (for example, wood), then metal pipes must be used to install the system Source 1poteply.ru

Useful tips

When selecting equipment for creating a steam heating system, during its installation it is advisable to take into account the following recommendations:

- You cannot use used heating radiators. They are highly likely to have hidden damage, which will subsequently cause the system to depressurize.

- It is not advisable to use cast iron batteries. Under the influence of large temperature changes, they begin to collapse.

- Installation of the circuit must be carried out by workers with certain knowledge and skills. Otherwise, the created design may be ineffective.

- If you install a steam generator in a conventional wood-burning stove, you can significantly save usable space. In addition, home heating costs will be minimal.

- When using natural circulation, it is recommended to install the stove in the basement of the house. This will ensure that condensation quickly drains to the lowest point.

- For safety reasons and to prevent emergency situations, you cannot refuse to install valves.

The installation of steam boilers in a central heating system is prohibited by law. In private homes, this type of autonomous heating can function for decades without requiring replacement of the main structural elements.

The chimney of a stove with a built-in heat exchanger gets dirty faster than a conventional stove, so it needs to be cleaned more often Source roof-tops.ru

Boiler selection

Choosing boilers

In order to choose the right heating device, the first thing you need to do is calculate the area that will be heated. To do this, you need to calculate the area of each individual room by multiplying the width by the length. After this, all the results must be added, the final figure will be the desired value. It is important to remember that this is true for ceiling heights up to 3 m; if it is higher, then it is necessary to make an additional power reserve.

- For a total area of up to 200–300 m2, a capacity of 25–30 kW is sufficient.

- For 400‒600 m2 - 35‒60 kW;

- 600‒1200 m2 - 60‒100 kW.

The next step will be the choice of fuel. Steam boilers can easily operate from the following sources:

- Liquid. This could be, for example, diesel fuel or used oil. When using this option, it will be necessary to place the unit in a separate room. This will help avoid inhaling harmful fumes and their negative effects on health.

- Solids - firewood, coal, peat and anything that can burn and release a large amount of heat.

- Gaseous. This is usually natural or liquefied gas.

- Electrical.

In some cases, solid fuel solutions are significantly cheaper, but it is worth considering not only the cost of fuel, but also the time that will be spent on kindling. In this case, it can reach several hours, and it is necessary to constantly replenish the firebox to maintain the temperature at the proper level.

Some manufacturers combine different types of fuel. For example, they combine a firebox for loading solid fuel and provide the presence of a heating element. At the same time, efficiency does not decrease, but it turns out to save on consumption, and therefore on payment.

How does steam heating differ from water heating?

In a water heating system, the coolant is often water. It moves inside the pipeline and gradually cools there. In the case of steam heating, the liquid being poured evaporates and hot steam moves through the pipes. After cooling, it condenses and then flows through the return pipeline back to the heating unit.

When the coolant is steam, the thermal output of heating devices is significantly higher, rooms heat up three times faster. Such a system starts up quickly even after a long break in use.

Additionally, it is worth noting the lower cost of materials for steam heating devices. This is explained by the use of compact and ergonomic equipment during installation (for example, pipes of relatively small diameter).

Unlike water heating, steam heating gives greater heat transfer and warms up the room three times faster Source pechiexpert.ru