The classic heating scheme with one heat generator is well known to every home owner. However, by combining a gas and electric boiler in one system, a much greater practical effect can be achieved. They say that such a connection is much more economical than usual. Sounds tempting, doesn't it?

Logical reasoning raises doubts: how will electricity help save the budget, since its cost is much higher than gas? And why do this at all from the point of view of the feasibility of increasing the power of the units? Isn't it easier to just buy one productive boiler?

In fact, the project of such a combination is quite justified. We will tell you in detail how to assemble heating with electric and gas appliances. You will learn about the structure of this system and its feasibility. We will help you draw up a diagram and not miss the important nuances of arranging a combined heating line.

Implemented standard solutions (main heating system + backup):

• with a gas boiler;

• with a gas boiler and a backup electric boiler;

• with wood/coal boiler;

• with a wood/coal boiler and a backup electric boiler;

• with a gas boiler and a backup solid fuel boiler.

Building a system solely on an electric boiler is not economically feasible. Especially if the private house is large enough (from 100 sq.m. or more). Utility bills may be too high. If gas is unavailable, we recommend installing a solid fuel boiler and an electric one as a backup.

Heating system with gas boiler:

The most common solution for heating a home is the use of a gas boiler.

. Because this equipment is the most profitable to use.

Danko parapet gas boilers are single-circuit boilers and boilers with the function of heating water for domestic needs. Due to the fact that these are chimneyless boilers, they can be used in houses and apartments where it is not possible to connect to a chimney. gas boilers (https://danko.pp.ua/) of this series are designed for heating rooms up to 140 sq.m. The boilers are equipped with modern gas automatics “Honeywell” and “SIT” with piezoelectric ignition and micro-flare burners.

System calculation.

The boiler is selected at the rate of 100 W per 1 m² of a residential building plus 2 KW for hot water supply, excluding the costs of ventilation and the pool. This technique for determining boiler power is approximate with an accuracy of 5%. But it allows you to determine approximate prices for equipment.

To more accurately determine the boiler power, a thermal calculation performed by a heating specialist is required based on the design, location and required internal temperature of the building.

The heated water enters the distribution manifold and then into radiators located in close proximity to windows and external walls. Knowing the area of the room, it is easy to determine the thermal power of the radiators.

In rooms where heated floors are installed, radiators are not required, only in cases of redundancy and the exclusion of condensation on the windows. Depending on the boiler, hot water can be produced by the boiler or heated in the boiler. Usually for 1 family a boiler with a volume of 200 liters or hot water heated by a boiler is enough. For an accurate calculation, you need to know how many people will live in the house and how much plumbing equipment is installed.

Manual/automatic control options

Control of the boiler backup system or shutdown of failed ones can be carried out manually or automatically. It is not advisable to leave the system running with one boiler turned off, since the water will continue to circulate.

Imagine what will happen when the cooled return flows in the opposite direction and begins to mix with the supply, cooling the coolant and causing the pump to work in vain.

If for some reason you do not want to equip the boilers with complex devices, you will start the unit yourself. That is, everything is standard: you need to turn on the device - turn all the necessary valves and turn it on. When disconnecting, perform the steps in reverse order.

If you want the backup equipment to start automatically, the system is equipped with automation, thermostats, indoor and outdoor air temperature sensors, coolant temperature sensors, and servos.

In the circuit diagram of the automatic backup start of the heating unit, all shut-off valves must be in the open position. According to the counter scheme, the system is equipped with check valves to avoid parasitic circulation of coolant through a boiler that is not operating at a certain time.

However, despite the convenience, the system can cause certain problems, for example, hydraulic resistance of check valves, causing stress on the pumps, contamination and wear of the devices themselves.

To automatically turn on the heating boiler, the system is equipped with a thermostat, which sends commands to the control unit, depending on the temperature in the house. The switch-on time for night standby use is set on a timer. The circulation pump is turned off using a magnetic starter.

Automation for electric boilers can be built-in, homemade, or purchased separately. However, you should not install it yourself using advice from the Internet, without having the proper skills. Invite a specialist for installation and correct system settings

When choosing a control that will be equipped with an electric boiler installed in parallel with a gas boiler, you should opt for automation if:

- The backup boiler is turned on at night, when it is inconvenient to start it manually.

- In case of long trips from home during the heating season.

- If the gas boiler is unreliable.

In other cases, it is quite possible to use the simplest manual scheme.

With a gas boiler with a backup electric boiler:

To eliminate problems with heating in case of accidents on the gas distribution system, an electric boiler is installed as a backup heat source.

An electric boiler is selected based on the electricity limits allocated for the building. To accurately determine the power of a backup electric boiler, a calculation is required based on the estimated duration of the emergency and the temperature maintained in the building.

To install an electric boiler in a heating system with a gas boiler, additional equipment will be required to eliminate problems with hydraulics.

More information about electric boilers in the section: Electric heating.

Conclusions and useful video on the topic

Synchronization of operation and shutdown of boilers in a parallel installation:

Installing 2 heating boilers, gas and electric, is a wise solution to increase the power of heating equipment, as well as for backup heating of the building. Parallel installation of units is not as difficult as it might seem at first.

The main thing is to correctly select the arrangement scheme and correctly calculate the total or reserve power of the equipment. If you are not confident in your abilities and cannot cope on your own, it is best to contact plumbers. They will help you quickly and efficiently install a system for reliable and comfortable heating of your home.

Heating system with wood/coal boiler:

The most common solution in the absence of gas is to use a solid fuel boiler.

For a house with an area of 100 square meters, the minimum tank capacity is 250 liters. For a more accurate calculation, you need to know the parameters of the wood-burning boiler and the duration of fuel combustion.

An electric heating element can be installed in the storage tank, which will maintain the temperature when the solid fuel boiler is not in use. If you have an electric boiler, then it can be used instead of a heater.

With a gas boiler with a backup solid fuel boiler:

To eliminate problems with heating in case of accidents on the gas distribution system, a solid fuel boiler is installed as a backup heat source, which is selected in the same way as a gas one.

To accurately determine the power of a solid fuel backup boiler, a calculation is required based on the estimated duration of the accident and the temperature maintained in the building. To install the boiler in a heating system with a gas boiler, additional equipment will be required to eliminate problems with hydraulics, overheating and long-term heat retention.

You can ask questions to our specialists by calling the numbers listed in the Contacts section.

We install heating in private houses and cottages. We carry out design, selection and supply of equipment, installation. We guarantee high quality and reliability of systems.

Why do you need a protection system?

Let's look at possible options for creating backup heating systems. The most reliable and progressive option is a modular protection system that can warn the user about a malfunction of the main heating equipment.

In the event of an emergency with the main boiler, sensors instantly signal a drop in temperature, and the backup boiler starts automatically. Thus, leaving your home for a long time in winter, you will be sure that you are insured against an accident and subsequent troubles associated with overcooling of the heating system.

Reserve boiler

Automation will immediately inform you about malfunctions. If the gas pressure drops below a preset level, the main boiler will not go into error due to the presence of a flame; after eliminating the cause of the failure, a restart will not be necessary and the presence of a service technician will not be required.

Combined use of gas and electric boilers in one heating system.

Let's consider heating systems consisting of a Gas boiler and an Electric boiler. Why are such systems installed? There are several options here, or to duplicate the heating system, if it fails for some reason, the consumer will be able to use another one. But in most cases, the installation of an electric boiler is used for use at night, when the electricity tariff is minimal, subject to a formalized tariff for electric heating and the presence of a 2-tariff electricity meter. The economic benefit when using an electric boiler at night is 2.52 times. If electric heating is used as an auxiliary system.

We compare the performance and cost of electric heating with gas.

If the efficiency of electric boilers is about 98%, then the majority of gas boilers have an efficiency of about 90%, with the exception of condensing boilers, which have an efficiency of more than 100%. However, it is worth taking into account that when calculating the efficiency of most gas boilers (especially imported ones produced in Germany, Italy and others), the calorific value of gas was taken into account of about 8250 kcal per 1 cubic meter of gas. However, in the current situation, gas is supplied via a mixed system. The minimum calorie content of mixed gas should not be lower than 7600 kcal. As practice shows, many gas consumers during the heating season state that the gas supplied to them is significantly lower than 7600 kcal. Consequently, with low-calorie gas, the efficiency of branded gas boilers will be declared by the manufacturer.

| Calorie content of gas kcal | 8250 | 7600 | 7600 |

| Boiler efficiency | 90% | 82% | 82% |

In the calculations, we will use the calorie content of gas as 7600 kcal, since this is the minimum permissible calorie content according to existing legislation. If we compare the calorific value of gas and electricity with an efficiency of 100%, we get

7600 kcal = 8.838 kW = 1 cubic meter of gas.

In practice, 100% can only be achieved with condensing boilers; all others will actually operate at 82% or less. That is, when using low-calorie gas to generate 7600 kcal of heat, you will have to spend not 1 cubic meter of gas, but 1.18 cubic meters of gas.

If electric heating is used as an auxiliary system.

| 7600 kcal | Fuel | Efficiency % | Consumption | Price | Bottom line | Benefit |

| Gas | 82 | 1.18 cc | 6,879 | 8,11 | 2.52 times | |

| Electro | 98 | 9.014 kW | 0,357* | 3,217 |

*In the calculation, we used a tariff of 0.357 UAH per 1 kW, provided that a tariff for electric heating was issued, and the main load on the boiler falls from 23.00 to 7.00, so electric heating acts as an additional system.

What you need to pay attention to when installing an electric boiler, when installing it in an existing heating system, where the main source of heating was a gas boiler.

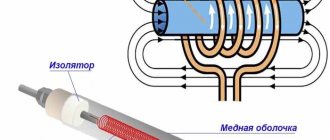

Fig. 1 Diagram of serial connection of an electric boiler T with a gas boiler without a built-in safety group and expansion tank. KE1 - electric boiler, KG1 - gas boiler without a built-in safety group and expansion tank, BR1 - expansion tank, RO - heating radiators, V - shut-off valves, VR - control valves, KZ1 - relief valve, PV - automatic air vent, M1 - pressure gauge, F1 filter.

In most cases, each heating system is unique. Very often, the consumer has a gas boiler installed as a single module, i.e. circulation pump and expansion tank are already installed in the boiler. Many installers very often offer to save your money and offer to install an electric boiler in series, i.e. both boilers operate in a common flow. The point of saving is that you will be offered to purchase a cheap boiler that does not have an expansion tank or a circulation pump. Such an electric boiler will indeed be cheaper than a fully equipped one. Many people agree to such an offer without much thought. However, this is a dubious method of saving, since most of the functions in this scheme are carried out by the gas boiler, and in the event of an emergency stop of the gas boiler, for example, failure of the circulation pump, or expansion tank, etc., etc. The entire system will stop.

On the one hand, you have two sources for heating, and on the other hand, you are highly dependent on the performance of the gas boiler. Conclusion - serial connection of an electric boiler will not always provide you with complete comfort.

The second method of installing an electric boiler in a heating system with a gas boiler is a parallel installation.

An example of installing a gas and electric boiler in parallel.

This installation method is considered the most correct, since you get two heating sources that are independent from each other, and if one fails, you can fully use the other. With a slightly larger initial investment, you will receive the most reliable and comfortable heating system.

Features of parallel connection

Let's take a closer look at what a standard parallel connection diagram for gas and electric boilers looks like:

- Each unit has coolant supply circuits. They join the common line.

- It is imperative that there are safety groups and shut-off valves.

- The return lines, also equipped with shut-off valves, are connected to the other line.

- A circulation pump is installed on the return line (or supply), in front of the unit for combining the piping circuits.

- The lines of both heating units are connected to the collectors.

- An expansion tank is installed on one of the distribution manifolds. A make-up circuit is also connected to its pipe, equipped with a check valve and shut-off valves.

- From the distribution manifolds there are main branches to the heated floor, radiators, boiler, each with circulation pumps and valves for draining the coolant from the system.

This is not a schematic diagram, but only its main features. It gives a general idea of how best to connect an additional electric boiler to the main gas boiler. The assembly option can be complicated and improved, for example, with an automation system and a servo drive.

With a parallel connection, you can also install a hydraulic arrow and an automation unit, but before doing this, carefully consider this decision; installing them is not always advisable