Closed heating system in the house

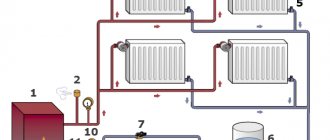

Home heating using a hot liquid heat carrier provides two types of solutions for operating the liquid for operation - in a closed or open heating circuit. The coolant can move through the pipes in a real way - under the influence of gravity and differences in pressure and temperature at a wide variety of points in the system (natural, or natural circulation of water), and forcibly - using a circulation pump. Both open and closed heating systems will usually work in any piping scheme, but a closed system is better and safer, since vapors from antifreeze or other operating fluids, which often contain toxic impurities, do not penetrate into the air.

And, although the formation of heat supply using hot coolants began with the operation of open systems with an expansion barrel, the continuation and discovery of new schemes was achieved by a closed heating system due to its economy, reliability and safety of operation.

Myth 2: according to the type of connection of the building to heating networks

Closed systems (meant in this context) are building heating systems that are connected to external heating networks through a heat exchanger. That is, the consumer’s heating system is not connected in any way to external networks, hence the name “Closed”.

In fact, this type of connection is correctly called Independent (Fig. 3).

Fig.3. Scheme of independent connection of the heating system to heating networks

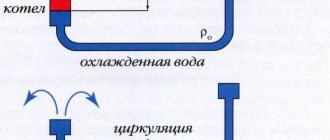

With this connection, the coolant from the source (CHP) circulates through the heat exchanger, giving off heat.

When designing the entire heating system of an object, for example, a residential apartment building, it becomes clear what type of heat exchangers is suitable: shell-and-tube, shell-plate, or it is necessary to buy a plate heat exchanger.

The heat exchanger is installed in the building’s individual heating unit (IHP).

Currently, this type of connection is replacing the outdated one - Dependent .

Open systems are heating systems connected directly to heating networks or through an elevator. In this case, the coolant comes from external heating networks to the end consumer, having previously passed through an elevator to lower the temperature.

The supply temperature in heating networks is 110-150 °C; such a hot coolant cannot be used in heating systems, as burns from radiators and pipelines will be possible.

The elevator, in addition to lowering the temperature of the coolant, performs one more function - it creates the pressure that is necessary for the movement of the coolant in the intra-house system (Fig. 4).

Fig.4 Diagram of dependent connection of the heating system

It would be correct to call such a connection – Dependent .

Closed or open heating circuit - what to choose

There are two solutions for the implementation of heat supply to the house - an open or closed heating system. The circuit is called “open” in view of the fact that the air comes into contact with the coolant in the expansion tank. Differences between an open type system:

During overheating of the coolant

(automation switching off, pump malfunction, dirty pipes and other dangerous situations) the water can boil, and the excess volume of liquid is squeezed into the tank, and the safety valve that drains the water into the sewer is not always installed, due to this there is a danger of overflowing

the coolant

from the tank to floor.

Due to this, this scheme is considered obsolete, and it is implemented only in small-sized dwellings - in dachas or garden houses. The main confusion of such a solution is the need to install an expansion tank at the highest point of the heating circuit, and this is not always a warm room - it is often necessary to install the tank in a cold attic, insulate it and monitor the liquid level each time for work. But closed and open heating systems have one common parameter - the use of a circulation pump for better movement of hot water or antifreeze through the pipes.

District heating

Water for central heating is heated in a central boiler room or thermal power plant. This is where the expansion of water with temperature changes is compensated. Next, hot water is pumped into the heating network by a circulation pump. Houses are connected to the heating network by two pipelines - direct and return. Having entered the house through a direct pipeline, the water is divided in two directions - for heating and for hot water supply.

- Open system . The water goes directly to the hot water taps and is discharged down the drain after use. An “open system” is simpler than a closed one, but in central boiler houses and thermal power plants it is necessary to perform additional water treatment - purification and air removal. For residents, this water is more expensive than tap water, and its quality is lower.

- Closed system. The water passes through the boiler, giving off heat to heat the tap water, connects with the heating return water and returns to the heating network. The heated tap water flows into the hot water taps. A closed system, due to the use of heat exchangers, is more complex than an open one, but tap water is not subject to additional processing, but is only heated.

Closed heating system

The terms “open system” or “closed system” do not apply to the entire central heating system of a city or town, but to each house individually. In one central heating system it is possible to connect houses with both an “open system” and a “closed system”. Gradually, open systems should be supplemented with heat exchangers and turn into closed systems.

Repair and construction Comment

Advantages and disadvantages of an open system

- normal installation, repair and maintenance;

- Silent movement of the coolant - a closed circuit lacks this specificity, since the pump makes noise regularly;

- Energy-independent operation with convective circulation of fluid for operation;

- Another difference between open heating systems is the possibility of installing boilers of different types;

- Low price of materials and equipment.

- Vaporization of the coolant

is the impossibility of pouring antifreeze or other antifreeze into the system, due to the fact that such a solution increases the risk of causing damage to residents; - The need for strict control over the level of coolant in the tank, which is uncomfortable at night or if there is a need to leave home;

- The still open heat supply solutions are distinguished by their high inertia in operation, which is corrected by inserting a circulation pump and a circulation pump;

- For the “underfloor heating” system, the open circuit option without a pump will not be suitable due to the complex branching of pipes and the very high resistance in terms of hydraulics.

Closed heating system - pros and cons

The closed heating circuit differs from the previous one in its own tightness and lack of air in the system. The system itself can be varied - one- or two-pipe, with vertical and/or horizontal risers, since the movement of liquid through the pipes is ensured by the operation of the pump, and the expansion of water when heated is compensated by the shift of membrane tissue in a sealed expansion tank. Forced circulation of antifreeze or water makes the installation of the circuit simple and quick, since there is no need to slope or turn the pipes, and the pipes can be of various diameters and even smaller than the calculated one.

Moreover, the differences in these two solutions are that an open heating system is useless in high-rise buildings due to a significant difference in pressure at the bottom and top of the wiring - the difference in values reaches 1-2 Atm. In the same high-rise buildings, a closed circuit with one or more pumps, collectors and an automatic control and monitoring system will operate without fail.

But, having made a closed circuit, you must always remember about some of its negative aspects:

- Energy dependence of the pump and automation;

- Difficult installation for 2 or more floors of the house;

- In a closed-open heat supply scheme, the coolant , thanks to this the system will work without freezing;

- All wiring or most of it can be hidden in the walls or in the floor;

- There is no need to tilt the pipes or rotate the angle, since the pump will push the coolant through any pattern;

- Low inertia of heat transfer and high heat transfer coefficient of all units and components;

- The absence of air in the pipes inhibits the formation of rust on the walls inside the products.

The main disadvantages of water as a coolant[edit]

The main disadvantages of water as a coolant:

- greater energy consumption for pumping network water compared to its consumption for pumping condensate in steam systems;

- greater “sensitivity” to accidents, since coolant leaks from steam networks due to significant specific volumes of steam are many (about 20-40) times less than in water systems (with minor damage, steam networks can remain in operation for a long time, while water systems require shutdown);

- high coolant density and rigid hydraulic connection between all points of the system.

According to the conditions for satisfying the thermal conditions of subscriber installations, determined by the average temperature of the coolant in the subscriber heat exchangers, water and steam can be considered equivalent coolants. Only in special cases, when steam is used directly for the technological process (blowing, steaming, etc.), can it not be replaced with water.

When supplying heat from boiler steam, it is also used for heat loads of low potential. The correct choice of coolant parameters is of great importance. When supplying heat from boiler houses, it is, as a rule, rational to choose high coolant parameters that are permissible under the conditions of the technology for transporting heat through the network and using it in subscriber installations. Increasing the parameters of the coolant leads to a decrease in the diameters of the heating network and a reduction in pumping costs (with water). When heating, it is necessary to take into account the influence of coolant parameters on the economics of the thermal power plant. The choice of a closed or open water heating system depends mainly on the water supply conditions of the thermal power plant, the quality of tap water (hardness, corrosiveness, oxidation) and the available sources of low-grade heat for hot water supply.

A prerequisite for both open and closed heat supply systems is to ensure stable quality of hot water for subscribers in accordance with GOST 2974-82* “Drinking water”. In most cases, the quality of the source tap water determines the choice of heating system. The primary use of each of the heat supply systems under consideration is determined by the following indicators of the source tap water. With a closed system: saturation index J > - 0.5; carbonate hardness FA≤7 mg-eq/l; (Cl + 3O4) ≤ 200 mg/l; permanganate oxidation is not regulated. With an open system: permanganate oxidation O < 4 mg/l; saturation index, carbonate hardness, chloride and sulfate concentrations are not regulated.

With increased oxidation (O > 4 mg/l) in stagnant zones of open heating systems (radiators of heating installations, etc.), microbiological processes develop, the consequence of which is sulfide pollution of water. Thus, water taken from heating installations for hot water supply has an unpleasant hydrogen sulfide odor.

In terms of energy indicators and initial costs, modern two-pipe closed and open heat supply systems are on average equivalent. In terms of initial costs, open systems have some economic advantages if the thermal power plant has sources of soft water that does not require water treatment and meets sanitary requirements for drinking water. When using open systems, water for hot water supply is taken from the heating network, which, on the one hand, relieves the cold water supply network and creates in some cases additional economic benefits, and on the other hand, it often forces main water pipelines to be connected to the thermal power plant, which increases capital costs.

In terms of operating costs, open systems are somewhat inferior to closed ones due to additional costs for water treatment. In operation, open systems are more difficult than closed ones due to the instability of the hydraulic regime of the heating network and the complexity of sanitary control of the system density.

For long-distance transportation of heat in areas with a relatively large load of hot water supply, if there are water sources near a thermal power plant or boiler house that meet sanitary requirements, it is economically justified to use an open heat supply system with a single-pipe (unidirectional) transit and a two-pipe distribution network.

How to run a closed system

Before turning on the heat supply after assembling the pipeline and equipment, you need to fill the pipes with operating fluid and carry out operational checks. The first time filling a closed heating system is carried out in compliance with the following rules:

- It is necessary to close all drain valves and air vents;

- Open the valves on the heat carrier supply pipe and on the return pipe of the cooled water of the heating circuit (on the return);

- To fill the coolant, the water hose must be connected to the liquid supply valve to the circuit, and the pressure in the pipes should not be more than 1.5-2 bar. When the readings of the device for determining the pressure increase, the supply is shut off;

- After which the air is released by opening the air vents, after which the pressure will drop slightly;

- The water supply valve must be opened again and added to the heating circuit so that the device for determining the pressure shows 1.5 bar, after which the valve can be closed;

- After the system is completely filled and all the air has been released, you can begin checking the functionality of the equipment.

The main thing: When leaks are detected in pipes or fittings, filling of the heating distribution pipes ends, leaks are removed by replacing parts or repairs, after which the system must be filled according to the rules.

If, upon completion of filling the water and after starting the heating supply, it is discovered that the heating devices do not heat well, some parts stand out in temperature from the general indicators, the movement of water along a closed circuit is slow or absent in some areas, then this means one thing - there is air and pipes left in the system you need to blow it out, in other words, remove the air pockets. This is done with the help of air vents, and after releasing the air, you need to drain a certain amount of liquid in order to be sure of the complete absence of oxygen in the water mass.

Purge is best carried out at a very high pressure of the coolant in the system. This can be achieved by opening the make-up valve from the cold water supply. Repeating the operation once or twice ensures complete removal of air plugs from the heating circuit. In most cases, this applies only to a closed circuit - an open system is filled much better, since the air also exits through the expansion tank, but such a solution is only permissible for small or townhouses.

Automatic and manual recharge

But the question of which heating system is better, closed or open, remains open unless you find out the need to use manual or automatic replenishment of the coolant

.

In a closed pipeline, high pressure must remain constant. Even very small losses and leaks (for example, when opening an air vent), adding up, reduce the pressure and reduce the efficiency of the entire circuit, which none of those living in the house will be happy about in the winter. To compensate for this deficiency, the closed

circuit must be recharged with a new volume of coolant.

For conventional and small heating systems, in most cases a mechanically controlled faucet is used. It is mounted at the point of lowest pressure, which is located in front of the circulation pump. At this point, a device is installed to determine the pressure value to control the replenishment process. To prevent the penetration of the heat carrier into the water main, a shut-off valve is used.

, heating systems are automatically recharged; the price of the recharge valve depends on the brand of the manufacturer. Sometimes automated make-up valves are part of the boiler equipment. If the replenishment is carried out from a water metering unit, in which the pressure in most cases is 3 - 4 bar, then everything happens very simply. Factory valve setting is 1.5 bar.

If the pressure in the heating system drops below 1.5 bar, the valve will open and remain open until the set pressure is reached. If automatic replenishment will use coolant from other sources, then a pump is needed that will be turned on by a signal from the valve and supply coolant

under a specific pressure into the heating system.

Automatic temperature adjustment

How to automate and select the appropriate mode in your home, especially when you are often away from an apartment or in a private house outside the city. Quite easy, necessary for heating systems

purchase a controller - a device that allows you to program and control the temperature in the house. Before purchasing a heating controller, make sure that the boiler has a suitable control unit. The best option is consultation with professionals.

One of the most suitable automation options comes out when using beam (collector) wiring. Special valves are mounted on the comb, which are controlled by the control unit of the multi-channel controller. This control unit gives a signal to turn on the boiler.

All rooms have a separate thermostat, which is set to a specific temperature. The multi-channel controller of the heating processes data from thermostats and, when the temperature in any room decreases, turns on the boiler and opens the valve of this room on the comb. In any case, the boiler will work until the temperature in each room reaches the programmed value.

Protecting the system from air

Theoretically, air should not enter a closed heating system, but in fact it is still present there. Its accumulation is observed when pipes and batteries are filled with water. The second reason may be depressurization of joints.

As a result of the appearance of air pockets, the heat transfer of the system decreases. To combat this phenomenon, the system includes special valves and air bleed valves.

If air does not accumulate in the system, the air vent float blocks the exhaust valve. When an air lock accumulates in the float chamber, the float stops holding the outlet valve, causing air to escape outside the device

- Supply water from the bottom to the top. To do this, lay the pipes so that the water and the released air move in the same direction.

- Leave the air vent valves open and the water drain valves closed. Thus, with a gradual rise in coolant, air will escape through open air vents.

- Close the vent valve as soon as water starts flowing through it. Continue the process smoothly until the circuit is completely filled with coolant.

- Start the pump.

If the heating circuit has aluminum radiators, then air vents are required on each one. Aluminum, in contact with the coolant, provokes a chemical reaction accompanied by the release of oxygen. In partially bimetallic radiators the problem is the same, but much less air is produced.

An automatic air vent is installed at the top point. This requirement is explained by the fact that air bubbles in liquid substances always rush upward through the pipe, where they are collected by a device for removing air

In 100% bimetallic radiators, the coolant does not come into contact with aluminum, but professionals insist on the presence of an air vent in this case too. The specific design of steel panel radiators is already equipped with air bleed valves during the production process.

On old cast iron radiators, air is removed using a ball valve; other devices are ineffective here.

The body of this device contains a polypropylene float connected through a rocker arm to a spool. As the float chamber fills with air, the float lowers and, upon reaching the bottom position, opens the valve through which the air escapes.

Water enters the volume freed from gas, the float rushes up and closes the spool. To prevent debris from getting inside the latter, it is covered with a protective cap.

The body of both manual and automatic air vents is made of high-quality material that is not susceptible to corrosion. To remove the air lock, turn the cone counterclockwise and release the air until the hissing stops.

There are modifications where this process takes place differently, but the principle is the same: the float is in the lower position - gas is released; the float is raised - the valve is closed, air accumulates. The cycle repeats automatically and does not require human presence.

How to make this tough choice: open vs. closed heating system?

The heating system is considered one of the main technical communications in the house.

The working principle of heating structures is very simple: first of all, the coolant (in most cases it is water) is heated in the boiler to the required temperature.

Then it goes through pipes to heating devices that are installed throughout the house.

Likewise, the heated coolant releases heat to the room, after which the cooled water returns back to the boiler, after which the cycle repeats. Depending on the method of supplying the coolant, closed and open heating systems .

Open heating system

Open system? heating structure in which the coolant

moves in the present way in accordance with

the laws of thermodynamics. For its operation, there is no need for a specialized pump that would create forced circulation of heated water; therefore, a connection to the electrical network is not required. Working principle:

- The water is heated in the boiler .

In other words, an expansion tank is installed in an open installation. The thing is that the liquid becomes wider when heated, and in case of severe overheating it can damage heating devices. In a closed type installation, this kind of problem is solved by reducing the pressure using a pump.

Attention! The tank is used to store superheated water, to stabilize pressure , and also to remove excess liquid when there is a lot of water in the heating installation.

Advantages and disadvantages

- Normal operation and maintenance.

- No need to connect a quiet pump.

- All rooms are heated equally .

- The installation starts and stops quite quickly .

- No connection to the electrical network is required (except when an electric boiler is used for heating).

- Installation does not require complex engineering skills from a specialist.

Photo 1. Expansion tank for heating, volume - 100 l, power - 950 W, manufacturer - “Stout”.

- At the beginning of operation, it is necessary to install an expansion tank.

- The pipes must be placed in a special way in the house (otherwise the water will not circulate).

- If air enters, damage to the installation may occur due to mechanical damage and/or corrosion.

- In winter, due to severe frosts, freezing will occur.

- After turning on, you will need to wait for the liquid to heat up to the required temperature.

- should be regularly monitored .

- as a coolant .

Two types of heating

One of the differences between an open heating system and a closed one is the presence of a leaky expansion tank.

It is into this that excess water enters during expansion. The liquid from this reservoir constantly evaporates and needs to be periodically replenished. The design of an open-type heating system is not complicated. It includes elements such as:

- large diameter pipes;

- boiler for solid, liquid or gaseous fuel;

- radiators;

- expansion tank.

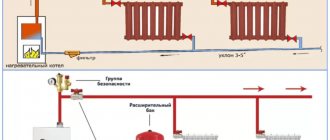

The boiler is located at the lowest point of the system and heats the water. The heated liquid expands, then enters the pipeline under pressure and then moves to the radiators, where it is partially cooled. Rising to the highest point, where the expansion tank is located, the coolant begins to move downwards towards the heater. Natural circulation occurs rather slowly. Sometimes the open type of heating is upgraded with an electric pump.

Today, the closed type of heating is more popular. This system is completely sealed. In addition to the main elements, it uses one or more electric pumps.

The expansion tank must be installed in a place convenient for maintenance

This system is characterized by a special membrane expansion tank. It is a high-strength steel container, divided in half from the inside by a rubber partition. One part is filled with inert gas, and excess water enters the other. As the liquid expands, it fills the tank. It presses on the membrane and compresses the gas. When the pressure decreases, the coolant is pushed back into the pipe.

More details about open and closed expansion tank:

Which heating system is better - open or closed - depends on the room in which it will be used. Each type has its own pros and cons. When choosing the appropriate type, you need to take into account the location and installation conditions, desires and possibilities, as well as many other nuances. For example, if there is no electrification in the house, only an open type is possible, and when using an electric boiler, a closed type is possible.

Closed system and its differences

This is a heating structure in which the circulation of the coolant through the pipes is forced using a specialized pump , and its operation requires a connection to the electrical network. The working principle of a closed installation is almost the same as an open one:

- The coolant is heated in the boiler .

- Then the pump pushes out the heated coolant

. - The heated water flows through all heating devices , which leads to heating of the air in the room. Pipes in the house can be installed as you wish, circulation through them is carried out using a pump.

- After a certain period of time, the cooled coolant returns back to the boiler.

For good functioning it is also necessary to install an expansion tank , thanks to which the pressure can be controlled. Qualified engineers advise giving your own preference to membrane tanks. It makes it possible to reduce or increase pressure in a short time, which is critical for a closed installation.

Reference! In the case of installing a closed heating system , the pipes can be positioned in different ways, because circulation will occur due to the operation of the pump.

- normal installation.

- It is not necessary to monitor the fluid level .

- Antifreeze can be used .

- Requires connection to a stable electrical network.

- It is recommended to connect an emergency power supply.

- Expansion membrane tanks are quite voluminous .

- In order for the pump to operate quietly, the technical room should be soundproofed.

Closed and open heating system using example diagrams

Closed and open heating systems are considered the main schemes used for heating residential buildings. The open heating system is the most popular among convective circulation systems. The operation of this system is based on thermodynamic laws. An area of very high pressure is formed at the outlet channel of the boiler, under the influence of which the heated liquid moves through the pipeline, gradually releasing heat energy.

Having cooled, the coolant

flows back into the boiler, where it is heated again. Similarly, a system with convective circulation does not stop operating. In such a design, only water can be used, because antifreeze used for heating evaporates very quickly.

Types of pipe routing

When installing heating, piping plays an important role. It depends on where the risers are installed and how they are connected to the radiators, as well as on the location of the falling pipe.

Installation should be left to professionals

Several types of wiring are used:

- The single-pipe heating scheme is simple and cheap. Its installation is easy and does not require large expenses. All radiators are connected in series to one pipe running at floor level. Passing the entire circle, the liquid gradually gives off heat and then returns to the boiler. The disadvantages of such wiring are the impossibility of adjusting the temperature on each battery separately and uneven heating.

- Two-pipe is used most often. Its essence is that the radiators are connected in parallel. One pipe located at the top carries coolant from the boiler, and the return pipe at the bottom takes it back. This wiring allows you to change the temperature of the battery, but the consumption of materials doubles.

- Leningradka is a modernized single-pipe distribution system. All radiators are connected in parallel to one main pipe. This scheme allows you to regulate the heating of individual batteries or completely disconnect them from the system. The material consumption is only slightly higher than that of a classic single-pipe.

In this video you will learn about the safest and most economical heating system:

Open heating system

An open heating system, the design of which requires the presence of an expansion tank, is used in most homes. During expansion, excess fluid penetrates into the expansion tank itself. Also, if there is excess water in the system, it also enters the tank.

The expansion tank is not sealed, which causes constant water vaporization, so it must be topped up occasionally. The design of an open heating system is incredibly simple, but at the same time it is distinguished by its reliability. An open heating system does not take into account the presence of a pump. The number of components included in the system is quite small: pipe wire, expansion tank, devices for heating the room and a boiler. In such a design, you can install any boilers, not counting electric ones.

The liquid in an open heating system moves very slowly, so the pipes must be gradually heated during use to prevent wear and boiling of water (for more details: “How an open-type heating system works - diagram of a heating system ”).

If the heating supply does not function when it is cold outside, the water from the system must be drained to avoid freezing or bursting of pipes. To ensure good circulation, the heating boiler must be installed at the lowest level, and an expansion tank is placed at the highest point of the system. To use open heating systems in winter conditions, the tank must be insulated. When laying a pipeline for such a system, it is best to use a minimum of connecting parts.

System connection options

The laying of communications is carried out in a dependent and independent way. The first option is characterized by simplicity and minimal costs for components. The second method is used in new buildings.

Dependent method

The specificity of the scheme is an in-house heating unit with an elevator. The heat station mixer mixes hot water from the external main with the return one. The coolant receives a temperature of up to 100 degrees. The advantages of dependent systems include:

- supply of water for heating and supply directly from the heating main;

- simplicity and inexpensive price of input equipment for one subscriber;

- withstand large temperature fluctuations;

- small pipe diameter;

- reduction of coolant consumption.

Disadvantages of central heating include high water consumption, difficulties with temperature control and excessive energy consumption.

Independent way

The scheme provides for the presence of a main and additional circulation circuits, which are separated by a heat exchanger. In the main circuit, water is supplied from the boiler house or thermal power plant to the central heating station, and is directed from it to the heat exchanger. An additional circuit will be home heating, receiving heat from the network.

The system operates on the principle of heating water in two isolated circuits. The mechanism of the external heating main works on a closed internal network without further mixing of the liquid. The advantages of an independent scheme include:

- the ability to connect any number of heat exchangers;

- use of water for heating and household purposes;

- no pressure fluctuations in the home circuit;

- adjusting the temperature in the rooms using a thermostat;

- availability of drinking water in the domestic hot water supply system;

- filtration of coolant from salts in a small circuit.

Disadvantages of communications are the need for periodic flushing of the heat exchanger, the cost of purchasing equipment and control elements.

Closed heating system

If during operation the liquid becomes wider above a certain level, then the valve of the expansion tank opens and eliminates excess coolant. When the system temperature drops, the pump will pump fluid back into the system.

The pressure in such systems is always within specific limits, due to which the coolant is regularly deaerated. The tank for a closed heating system is in most cases made of very durable metal. Structurally, the tank consists of two parts, which are rolled to each other. In the internal void of the tank there is a diaphragm made of heat-resistant rubber. Moreover, a minimal amount of gas (mainly nitrogen or air) is regularly found in the middle. The diaphragm divides the tank into 2 halves, one of which receives the expanded liquid, and the second contains gas. Getting into the tank, water presses on the membrane fabric, filling the empty space of the tank, and when the liquid in the system cools, under the influence of the diaphragm, the water in the tank is forced back.

Differences between open and closed systems

What is better - a closed or open heating system?

There are a number of indicators that significantly distinguish between open and closed heating systems:

- Installation location of the expansion tank. In an open system, the tank must be located at the maximum point, and a closed heating system does not impose any requirements on the placement of the tank.

- In a closed heating system, constant atmospheric pressure is maintained, because outside air does not penetrate into the system of this kind (for more details: “Closed heating system - diagram with examples”). Thanks to this, the service life of the heat supply becomes significantly longer. Additional pressure from above the system makes it possible to reduce the risk of air pockets clogging the heating devices placed on top.

- An open heating system

requires large-diameter pipes, which are quite uncomfortable during installation and during operation. Also, they are very difficult to veil, which is poorly reflected in the design of the premises. For such a system to work, a constant slope is required, the creation of which requires extra effort. - A closed system is structurally much simpler and cheaper, because the installation of thin pipes is less difficult, and their price is much lower than the price of thick pipes.

- With proper installation of the circulation pump, annoying noise can be avoided.

Positive qualities of an open heating system:

- ease of use;

- no need to install a pump;

- equal heat distribution throughout the rooms;

- not difficult to start and stop the system;

- network independence;

- reliability;

- the easiest installation.

Disadvantages of an open heating system:

- deterioration of the wear resistance of the system when air enters it;

- poor resistance to low ambient temperatures during intermittent operation;

- slow warm-up after startup;

- the need for continuous monitoring of the level of coolant in the expansion tank;

- incompatibility of the system with antifreeze;

- big sizes;

- low efficiency.

Positive qualities of closed heating systems:

- easy installation;

- there is no need to monitor the level of coolant in the tank;

- good resistance to freezing due to the use of antifreeze as a coolant;

- the ability to regulate the temperature of the system by increasing or decreasing the amount of energy carrier;

- the possibility of long-term use of one batch of water, which occurs due to the tightness of the system;

- controlled pressure level;

- economy;

- manufacturability, resulting in a long service life;

- possibility of working in conjunction with additional heating devices.

Disadvantages of a closed heating system:

- dependence on electrical energy, which is required to operate the pump (you can get rid of the problem by installing a small generator);

- any leakage may allow air to enter the system;

- expansion tanks with diaphragms have quite large dimensions, which very often complicates their installation.

Conclusion

Choosing a suitable heating system is mainly a personal matter, and any home owner can choose a very good option. Closed and open heating systems have different parameters and functionality, differ in a significant number of parameters and are suitable for different cases.

An open heating system is much better suited for small buildings: very often a system of this kind can be found in dachas or cottages. The open type heating circuit looks very simple, and its reliability is quite high.

A closed system is more difficult to install and use, but it has several positive qualities. Heating systems

closed type in most cases is used in buildings with several floors or cottages.

Single-pipe Leningradka Open Forced type START HEATING

Installation rules

Open expansion tank

The rules for connecting equipment and creating a system depend on its type.

Requirements for installation of an open system

When setting up you should:

- Select the lowest point for the heat source and the highest point for the tank.

- Use pipes with a large diameter for the movement of coolant.

- A narrow pipeline is necessary to normalize pressure.

- Install a high riser that will distribute the water evenly.

- Avoid a large number of turns, forks and connections.

- Install the system in a limited space - up to 159 square meters.

- In private households it is better to install a good circulation system.

The open system is suitable for a small country house or cottage.

Installation procedure for a closed system

Closed expansion tank

If a closed-type heating system with a pump and expansion tank is installed, you must:

- Place the boiler in the basement and the expansion tank in the attic.

- Ensure high-quality thermal insulation of rooms with a container and riser.

- Do not use a large number of shaped elements.

- Avoid overheating the water.

- Drain the coolant if the system does not start in winter.

- Form a pipe slope of 2-3 mm per 1 m of contour.

The principles for calculating the cross-section and slope of a closed heating pipeline are prescribed in SNiP 2.04.01-85.