When building a house, I had a question - gas (economical and convenient) or solid fuel (no options if there are no communications). But to my happiness, even before the interior finishing began, a gas pipe was laid along our street.

Questions about heating disappeared by themselves. However, in order to have an ace up my sleeve, I still left the shaft for a solid fuel boiler.

When choosing, installing and configuring the boiler, I had to study a bunch of nuances that in the future will save me money on heating my house. I would like to talk about them.

This is a story from our regular subscriber from Belarus, Yuri Sergeevich.

Factors affecting boiler operation

In order to understand what temperature to set the water in the boiler, you need to take into account the main factors:

- the rated thermal power of the boiler declared by the manufacturer;

- outside air temperature;

- room wall material;

- quality of installation of windows and doors, as places of maximum heat loss.

It is easy to find out the thermal power of the boiler by reading the boiler passport - it is indicated for each device. Knowing the power of the boiler, you can apply the formula: 1 kW of thermal energy heats 10 m² of area. It is understood that this calculation (approximate) is suitable for creating a room temperature of +18 C with a wooden wall height of up to 2.5 m and an outdoor temperature of 0 C.

At the same time, it is believed that the house is maximally insulated - there is an unheated vestibule in front of the front door, two frames or a modern double-glazed window are installed in each window, the ceiling on the roof side is insulated with a layer of bulk insulation or stone wool slabs.

For example, the rated thermal power of the boiler is 10 kW, then, substituting this value into the formula, we get 100 m².

Let’s imagine that to heat an area of 100 m² a unit with a rating of 5 kW was chosen - insufficient power will lead to almost continuous operation of the boiler, a sharp decrease in its service life and premature failure.

Hot water priority

In the hot water priority mode, we observe a clear sequence of actions and cyclic switching on for heating. If you want to turn on one of the hot water taps, the boiler will forget about heating and begin to heat the water. This is called hot water priority.

The heating works around the clock, the boiler knows when to turn on and off, maintaining the required temperature in the house. The need for hot water is much less frequent than the need to heat a house. When you turn on the water, the house is “already warm,” but the water is “still hot.” Therefore, priority for heating hot water is higher than for heating.

In most modern gas boilers, the water temperature can be adjusted separately in the range from 35 ºC to 55 ºC. The procedure is similar to the heating procedure. Set the appropriate temperature and use hot water.

Boiler temperature selection options

The basic rule that a novice heating engineer should follow is not to make “sudden movements.” The most comfortable mode of operation of the equipment will be the one in which the temperature regulator on the boiler is turned as little as possible. There is an opinion that during the day you need to set one temperature, and at night you can lower it. But the air temperature outside also does not stay at the same level: during the day it rises and at night it decreases. Therefore, it is worth considering some options for the temperature of the water in the boiler.

40 C.

Ideal boundary mode - the boiler will operate normally at this minimum heating mode in early autumn and late spring. During the day, when the outside air is actively heated by the sun (from 0 C to + 10 C), the boiler will turn on less often, since the room will take longer to cool down. At night, when the outside air temperature drops sharply (from 0 C to – 10 C), the boiler will operate 2-3 times more often, maintaining a comfortable temperature.

The 40 C mode will be undesirable if the daytime outside air temperature drops below –10 C. A poorly heated coolant will not be able to ensure normal heat exchange with the heating radiators, and they, remaining slightly warm, will not warm the air in the room.

50 C.

The lower limit of the optimal heating mode at an outside temperature from –15 C to –20 C. When setting such a threshold value, you need to take into account not the average daily values, but the minimum, cold ones. For better, more comfortable regulation of the air temperature in the room, you need to take into account that the boiler regulator only sets the heating level of the coolant.

Hot water needs several heat exchange cycles to warm the air in the house. In this case, there is a risk that the boiler will operate almost without interruption, at maximum load. This will lead to excessive gas consumption and rapid exhaustion of the unit’s life.

60 C.

The most optimal coolant temperature for a gas boiler in winter. It should be taken into account that the automation turns the burner on and off, based on the level of heating of the water in the inlet pipe, which is called the “return”. The higher the temperature of the coolant in it, the less often the heating will turn on.

Setting the boiler regulator to a value lower than required will result in the burner turning on more frequently, which means excess gas and electricity consumption if the burner is ignited electrically. Therefore, when the outside air temperature is below - 25 C, setting the boiler to 60 C is simply necessary.

70 C.

Upper limit temperature of water in the boiler. Setting such a level of heating of the coolant is justified only when street temperatures drop below –35 C. When setting such high values, the boiler burner almost does not turn off, gas is consumed to the maximum.

In addition, the service life of the heat exchanger is significantly reduced due to maximum heating; condensation will form in some places of the boiler. Another disadvantage will be the significant heating of the surfaces of the radiators, which can lead to the appearance of an unpleasant odor.

Frost protection

The most important mode is frost protection. The mode is active when the boiler is switched off or winter mode is switched off. Why is it needed:

- the burner continues to work;

- the boiler was in working order;

- works when the heating is turned off.

Not every boiler has a protection mode. When the boiler turns on when water is supplied, the outlet water temperature is checked. Each boiler has a separate threshold, most have 5 degrees. If the temperature is 5 degrees, the boiler brings it to 15, then turns off.

Operation of the heating system when setting the temperature on the boiler

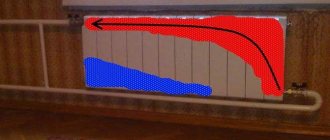

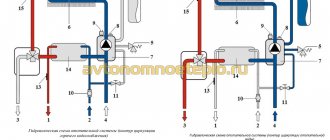

The operation of the heating circuit batteries is directly proportional to the distance of each specific battery from the heat source. Simply put, the further the battery is located from the boiler, the lower the temperature of the coolant that reaches it.

The circulation pump built into the boiler circuit helps to equalize the temperature difference between the first and last batteries, according to their distance from the unit. But even a running pump is not able to completely equalize the heating level, so this factor must be taken into account when installing the boiler and heating system.

Equality of heat transfer between the batteries is achieved by adjusting the heat exchange area of each of them. For example, in order to equalize the amount of heat given off at the beginning of the system with its amount at the end, you need to leave, say, 4 sections at the first battery, and make 6 such sections at the last one.

The location of the rooms in a heated house plays an important role. A room that borders all its walls with other rooms will require up to 30% less heat than a room with walls separating it from the street.

In this case, the most optimal solution would be to install an individual thermostat or thermal head for each battery in the interior room. A device installed on a heating radiator will optimize the level of heat produced by this heating device.

The operation of the thermal head is based on the thermocouple effect - the stronger the heating, the more the element changes its configuration. By selecting the desired level with a knob, the consumer sets the temperature at which the device membrane shuts off the supply of hot coolant to the radiator and opens it again if it has cooled down.

Installing a room thermostat helps in heat distribution. The fact is that when setting the temperature in the boiler, the consumer does not immediately receive the effect of the adjustment - the coolant needs to “go through” several cycles in order for the desired heat mode to be established.

A room thermostat allows you to regulate the level of water heating based on the air temperature in the room, and not on the heating level of the radiators.

It should be noted here that installing a thermostat allows for more precise regulation of the heat in the room, which means that a certain procedure may be required for coordinating the operation of the room regulator and the boiler temperature sensor.

There are modern models of thermostats based on working with special applications for a smartphone - with such a device you can regulate the temperature of a gas boiler while being far from it.

Model examples

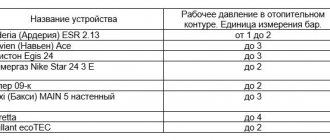

- Baxi.

The optimal operating mode of this wall-mounted gas boiler is achieved as follows: in small apartments the indicators are set to F08 and F10. The modulation spectrum starts at 40% of the highest power. And the minimum possible operating mode is 9 kW.

Many models of this company are very economical and can operate at low gas pressure. Pressure limits: 9 – 17 mbar. Suitable voltage range: 165 – 240 V.

Many devices of this brand work optimally under the following conditions: power - 15 kW. The feed is set at 50-60. The device works for 35 minutes, rests for 20 minutes.

The best conditions: 13 kW for heating, 24 kW for water heating.

Water pressure in the network is maximum 0.1 MPa. The highest temperature indicator at the outlet section is 90 C, the nominal value of the flue gases is at least 110 C. The vacuum behind the apparatus is a maximum of 40 Pa.

Basically, these are two-circuit units. Automation works here. The mode is customizable. The room heating parameter is set. There is a pump that can reduce parameters by 4-5 degrees.

Automatic setting of modes also works. Often people choose models with the Comfort Plus mode.

The following values are usually set on the feed: 40 - 82 C. The current parameter is usually reflected on the monitor. The most convenient summer mode is at 75 C.

Removing air from the heating system

It happens that all attempts to adjust the boiler temperature do not give the desired result. This happens mainly in the fall, after a long summer period of inactivity of the heating system.

When cold weather sets in, the consumer starts the boiler, it starts to work, and the heating radiators heat up unevenly - the sections closest to the boiler at least somehow heat up, and the subsequent ones become slightly warm, or even completely cold.

This can happen if the water level in the heating system was not checked before the first start-up of the boiler in the new heating season. On warm summer days, heated by the sun, the water from the system begins to evaporate little by little, the process lasts all summer, and by autumn the coolant level in the system may drop below the minimum level.

After turning on for the first time, the circulation pump, starting to “drive” water through the system, forces some of the air into the heating system. Pushed by water, it accumulates at the highest and most distant points of the system from the boiler.

The system is “aired” - a plug of accumulated air does not allow the coolant to completely fill the heating radiator.

To solve the problem, a Mayevsky tap is screwed into the upper part of the radiator, on the side farthest from the boiler. The device is designed to remove air from a heating radiator.

When you turn the valve head by hand or with a screwdriver, an indirect through passage opens to remove air - a hissing sound of escaping air appears. As soon as the first splashes of water begin to flow through the tap, it is closed.

In the first 2-3 days of heating operation, it is recommended to carry out several such operations with an increasing break between them.

Before opening the Mayevsky tap, you must place an empty bucket or other suitable container under it. It is advisable to place any protective screen made of cardboard, paper, fiberboard or other materials between the tap and the wall to protect the wall covering from splashing water.

As a “disease” of the heating system, airing is typical for large heating circuits due to the possible unauthorized withdrawal of hot water from the heating system. Therefore, in apartment buildings, the procedure for bleeding air from the heating system may be necessary several times throughout the heating season.

Savings and regular equipment maintenance

The basic structure of a traditional gas boiler is almost the same, regardless of the manufacturer. Thermal energy from gas combustion is transferred to the coolant through a heat exchanger. There can be either one or two heat exchangers in the boiler. During operation of any gas boiler, the heat removal surface becomes contaminated with soot deposits from the outside and scale from the inside.

From practice, we can say that it is extremely rare that the system is filled with special prepared water or the water supply system is equipped with a water treatment system. This is especially true for apartment buildings, in which the owners receive a ready-made heating system along with the apartment.

The formation of scale and soot on the walls of the heat exchanger will gradually reduce the heat transfer performance, and more energy will be consumed for heating.

Therefore, annual regular maintenance will definitely affect the efficiency of equipment operation for the better! This especially applies to boilers with bithermic heat exchangers, which, due to their design, are difficult to clean.

Each of us wants to install heating equipment that will work not only efficiently, but also economically. Are there economical gas boilers? Depends on what you mean by that. It would be possible to provide a list of models with minimal fuel consumption, but everything is relative here, and the cost of maintenance is influenced by many factors. Let's look at each of them.

How to save on gas heating

The desire to spend as little as possible on heating is quite natural.

When using gas, there are several ways to save fuel:

- Installation of a gas flow meter. The problem is very relevant, since in the absence of a meter, the resource supplying organization will charge the consumer not for the specific volume of fuel consumed, but according to regional standards. The difference can be up to 2-3 times.

- Reduced heat loss. For example, a private house can lose up to 25% of heat through the roof, up to 25% through windows, up to 35% through walls, and up to 3% through a door.

- Maximum use of automation equipment. Automation will monitor the necessary parameters better than a human.

- Increasing the efficiency of equipment operation. For example, replacing an old-style burner with a more modern version can save up to 5% of gas.

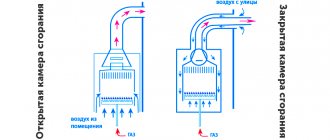

- Application of new means of ventilation. These include recovery systems - this is when the exhaust pipe of a gas boiler through the wall of the house passes inside the supply ventilation pipe. Outside the house, the exhaust pipe raises the exhaust gases much higher, and the cold air from the street enters the house already slightly warmed up. The use of a recuperator allows you to save 5-10% of the volume of gas consumed.

Why is there high gas consumption in the house?

High gas consumption from a home heater can have various reasons. It is known that a floor-standing unit is more wasteful. It is much inferior to wall-mounted options. In addition, the situation can be worsened by an incorrectly designed smoke removal system (for example, made of brick, ferrous metals or uninsulated stainless steel pipes). You can find out more about the places through which heat leaves the house using a special thermal imaging device.

Also read with this article: Checking gas equipment

Gas boiler clocking: causes and ways to eliminate them

The term “clocking” refers to the frequent switching on and instant shutdown of a boiler, which in fact does not fulfill the main task of gas equipment to heat the coolant. Such a “symptom,” if not eliminated, will provoke serious breakdowns, followed by expensive repairs.

Why is this happening

So, you approached the boiler and noticed that it starts working as expected (the torch fires), literally a few seconds pass and it immediately turns off. A few seconds later the situation repeats itself.

The first and most harmless problem from a maintenance point of view is incorrectly installed power when the heating system is short. Let's look at an example: your boiler is set at 55℃, and the pump is set to maximum values.

In a closed system there are only 2 radiators, and outside the window the temperature is above zero. What we have: the return flow pumped from the system returns to the heat exchanger, where, due to the temperature difference, the torch must automatically fire and the boiler ignite in order to eliminate this difference by heating.

Also, the problem of frequent turning on and instantaneous shutdown can be caused by the following reasons:

- Insufficient gas pressure in the system - the boiler automatically goes out because the required volume of gas is not released at the set power.

- Pump malfunction - the unit either does not pump water at all, or pumps it so quickly that it does not have time to go through all the stages from heating to transferring heat to the batteries.

- Overheating of the boiler itself - the manufacturer has established recommended limits for the safe operation of the boiler. If the temperature is higher than normal, an emergency shutdown may occur. This will happen exactly until the boiler cools down.

- Malfunctions of the thermostat - this device can fail due to sudden changes in the voltage in the network, which leads to distortion of the received data and the sending of a false signal to the central board about the need for a quick shutdown.

A pulse shutdown, which alternates with the switching on of gas equipment, significantly depletes the combustion chamber and the working elements in it. Sooner or later, problems will begin with the burner, which tends to fail suddenly when there are no signs of trouble.

What to do

The first thing to do is to correctly set the power of the boiler and pump. If these are the minimum values, then it is enough to set the pump to medium speed. When the water heating is more than 45℃, you can increase the speed.

It is important to set the power correctly

The sequence of actions is as follows:

- Turn off the boiler completely and give it 10-20 minutes to cool down.

- Light it using the lowest temperatures.

- Adjust the pump operation.

- Evaluate the result.

If the problem recurs, but not as often, the thermostat will save you. This device monitors the return temperature and forcibly starts the boiler only if its temperature is lower than the manually set one. The thermostat is good in all respects: it saves gas, protects the boiler, and the pump does not overheat.

Each season has its own regime

Modern boilers are very easy to adjust a variety of parameters, including the intensity of fuel combustion. This function was introduced for a reason, but to prevent excessive fuel consumption due to clocking. It is recommended to choose your own regime for each season:

- Winter - maximum or average power.

- Spring, autumn - minimum power, in March and November - average.

- Summer - the boiler is not used, or - minimum flame.

However, these settings are relevant if the boiler matches the size of the heated room. Many people take equipment “with a reserve” of power, implying severe frosts, deterioration of the heat-saving properties of housing, or an increase in the area of the premises. In this case, it is recommended to immediately set the flame to minimum, especially if the boiler is wall-mounted.

Burner adjustments may stop working or operate incorrectly over time. If boiler repair is not possible, you can change the flame power using a valve on the gas pipe. This method is rarely used in practice, since valve wear can lead to leaks.

Which thermostat is better to choose?

To make the right choice of a room regulator, we suggest considering the pros and cons of two types of household appliances. Disadvantages of mechanical models:

- low accuracy of maintained temperature;

- wired connection - the cable will have to be pulled from the boiler room to the desired room;

- lack of various convenient functions available in programmers.

Note. Judging by the reviews of real owners on the forums, the accuracy of temperature maintenance is not a critical problem and does not worry users too much. Another thing is the wires that need to be hidden under the baseboards, in the grooves of the walls, and so on.

There are also three obvious advantages of bimetallic thermostats:

- low price and availability;

- reliability in operation - in the simplest models there is nothing to break;

- ease of control of the boiler using one handle, which is important for older homeowners.

The negative aspects of electronic regulators are a higher price, a not always clear interface and the need to timely replace batteries. Cheap Chinese models encounter an additional problem - a breakdown in communication with the relay unit when installing the control panel behind 1-2 partitions.

An absolute plus of digital thermostats is comfortable operation. It is enough to set the weekly and daily operating program for the heat generator once; no further actions are required.

Wireless programmers need to change batteries on time.

We list a typical set of functions using the Baxi Magic Plus thermostat as an example:

- temperature control range – 5…35 °C;

- protection against freezing of the heating system, by default starts the boiler when the home cools down to +3 degrees;

- LCD display with backlight, control – push-button;

- shift of temperature sensor readings ±5 °C (read the explanation in the next section of the publication);

- 2 operating modes – economical and comfortable;

- hourly/daily/weekly programmer.

Reference. Manufacturers often call such devices digital chronothermostats. The weak point of the devices is their low maintainability in the event of a breakdown, especially Chinese products for which it is not easy to find spare parts.

Knowing the features of electronic and mechanical regulators, it is not difficult to choose the appropriate model. Focusing on your budget, first of all consider reliable products from European, Japanese and Korean brands, there are also decent brands, but on average the quality of the products leaves much to be desired.