Did the Corestar boiler show errors on the display? This means that the self-diagnosis system “detected” a malfunction. All modern heating equipment is equipped with automation - sensors that monitor the operation of each unit. Sometimes the user does not even need to contact the service center. It is enough to determine the meaning of the code and find the problem.

Power setting

After starting the device, you need to press and hold for 5 seconds. buttons to adjust the temperature to enter the setting mode. Adjust the gas pressure by decreasing and increasing the pressure using the DHW adjustment buttons. While the setup is in progress, a number will appear on the screen. This board designation is the minimum power value in percent: 44–54. When the pressure gauge shows the required pressure value, press the RESET button, the parameters will be saved.

When setting the operating power, set the gas pressure using the buttons that regulate the heating agent temperature. The power percentage will appear on the screen: 0–99. Having set the required value, press RESET, save the parameters, exit the settings mode.

Advantages and disadvantages

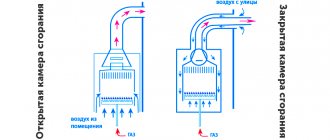

The equipment prevents smoke in the room

When choosing a Corestar boiler, buyers are attracted by the reasonable cost of these devices and the price-quality ratio: few can afford a German-made unit. Coordinated work in the cold winter conditions inherent in a large part of Russia is also of interest to owners of private houses.

Other advantages of these devices are:

- low noise level from a running pump;

- high-quality automatic control unit;

- climate control option;

- optimization of gas supply (initiation - when the burner lights, stops - when it goes out), which saves fuel;

- use of a device that prevents smoke in the room;

- a mechanism that prevents freezing of the coolant.

The downside is that sometimes voltage surges still cause malfunctions of the microprocessor board, despite the manufacturer’s instructions about stable operation with differences within 15% on both sides of the nominal value. Such incidents can be prevented by installing an uninterruptible power supply.

Other faults

In addition to the fact that error codes often appear on the remote control. The Corestar boiler may also fail due to an emergency situation. So, despite the manufacturer’s assurances that its products can withstand voltage surges, in practice this often leads to boiler failure.

The control board can burn out, even due to a small surge in electrical current. Therefore, it is recommended to use these boilers with an uninterruptible power supply.

Source

Installation

Before installing the device, you should make sure that it runs on natural gas. If you plan to use liquefied gas, you need to readjust the heater - this should be done by a specialist. A power supply with parameters of 220 V/50 Hz must be supplied to the installation site of volatile models. Deviation of parameters from the norm leads to decreased performance and reduced service life.

It is prohibited to connect other electrical appliances to the boiler power source. It is also prohibited to use extension cords and adapters when connecting. Violation of safety standards may result in a fire.

The boiler does not turn on - there is no indication

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all you need to make sure that power is supplied to the boiler . Typically, the electrical connection of the boiler is carried out through a separate “automatic machine” - check whether it is turned on or not.

The surest way to make sure that power is supplied to the boiler is to check with a multimeter in voltmeter mode the presence of 220V at the connection point to the boiler board. If there is no voltage, it is necessary to localize and eliminate the problem. In real life, it happens that someone in the household simply pulls the plug from the socket.

Water (moisture) getting on the board

Water ingress is one of the most unpleasant situations. Although the board is in a protective case, water may get inside due to leakage or condensation. Often it gets into the box through the wires. Water ingress almost always causes damage to the board, in most cases irreparable. Characteristic stains and oxidation will be visible on the board due to water.

Features of Koreastar boilers

Boilers are designed for space heating and hot water supply

The company produces double-circuit units designed to implement two tasks - heating a home and supplying hot water. Floor-standing devices and those designed for wall mounting are available. For most devices, liquid for heating the home and for domestic needs is prepared separately. To level out the associated heating slowdown, the products are equipped with a three-way solenoid valve.

When the coolant cools to +5 degrees, the gas boiler is turned on automatically. This prevents water from freezing in the pipes. A decrease in gas pressure (up to a certain limit: minimum - 4 mBar) and changes in mains voltage do not affect the stability of the boiler.

Installation

Before installing the device, you should make sure that it runs on natural gas. If you plan to use liquefied gas, you need to readjust the heater - this should be done by a specialist. A power supply with parameters of 220 V/50 Hz must be supplied to the installation site of volatile models. Deviation of parameters from the norm leads to decreased performance and reduced service life.

It is prohibited to connect other electrical appliances to the boiler power source. It is also prohibited to use extension cords and adapters when connecting. Violation of safety standards may result in a fire.

source

The boiler does not turn on - there is no indication

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all you need to make sure that power is supplied to the boiler . Typically, the electrical connection of the boiler is carried out through a separate “automatic machine” - check whether it is turned on or not.

The surest way to make sure that power is supplied to the boiler is to check with a multimeter in voltmeter mode the presence of 220V at the connection point to the boiler board. If there is no voltage, it is necessary to localize and eliminate the problem. In real life, it happens that someone in the household simply pulls the plug from the socket.

A little about the manufacturer

The brand, called Korea Star, dates back to 2010 and is headquartered in Korea, Hanam. This brand is a separate project of Gahbin Corporation, which has eight other world-famous brands at its disposal. In addition to Korea Star, these enterprises produce high-quality original parts for automobile manufacturers Daewoo, KIA, Hyundai, Ssang Yong and others.

The corporation also offers parts and devices to the world market:

Rice. 1 Company emblem Korean boilers Korea Star is the main of the 9 brands due to its quality products and the popularity of its products. As for diesel heating units, Korea Star provides each unit with a special quality certificate ISO 9001 QS 9000-9001.

The room in which gas equipment is to be installed should be equipped with fresh ventilation. Moreover, door and window openings cannot be classified as such if they do not contain devices that ensure constant movement of air flow - fans, holes in the door leaf, etc. When the heater is put into operation, it is prohibited to carry out construction work in the room that could change the ventilation design, thereby affecting the volume of incoming oxygen.

In the boiler room it is prohibited:

Gas boilers Koreastar Buran

There is only one unit in this series. The Korea Star Buran gas boiler is installed on the floor, it is single-circuit, does not depend on electricity and can work with open and closed heating circuits. Such units are called AOGV and are the simplest heaters. At the same time, they are very reliable and have earned a good reputation.

Floor models have a 5 year warranty.

Characteristics of Korea Star Buran:

- open combustion chamber;

- mechanical automation made in Italy (SIT);

- 15 power options from 7.5 to 100 kW.

The Buran model differs from the Koreastar Senator series in the heat exchanger material, which is made of steel. While in the Senator boiler the heat exchanger is made of high-quality cast iron. Buran can only run on natural gas. The gas pressure must be no less than 6 mbar, and the coolant pressure must be no more than 0.4 mbar.

Maximum temperature 90 degrees. When igniting, due to the fact that the coolant temperature is below 30 degrees, condensation may occur. This leads to corrosion, so the temperature of the water in the circuit should not be allowed to drop so low. Before the heating season, the device must be checked for serviceability, and if necessary, clean the heat exchanger and chimney.

- Content:

- Features and technical data of boilers

- Specifics of application and operation

- Tips and tricks for choosing

Despite its name, the Koreastar gas boiler has nothing to do with Korea. It is developed and assembled at the Wilo plant. Moreover, this is practically the only model among all European equipment that was manufactured specifically for Russia, taking into account the peculiarities of operation in domestic conditions. The consumer is offered two basic wall-mounted Koreastar models - classic and bithermic type.

Popular models Korea Star

The company produces many models of boilers, which differ in power, type of coolant, automation production and many other indicators.

All Corestar gas boilers have affordable prices and high quality, but when choosing, you should pay attention to the model’s compliance with the features of your home

For two-room apartments it is worth purchasing more inexpensive and compact boilers of 12–16 kW. If you need to provide a large area with heat, then you should think about 22–24 kW. Also, when purchasing this or that model, it is worth considering its features: the presence of a water heating system for domestic needs, reliable automation, small size.

Premium 16E

Premium class gas boilers are made using advanced technologies, which allows us to speak with confidence about the reliability of this equipment. The Premium 16E model can be purchased in the price range from 15 to 17 thousand rubles. At the same time, its characteristics are not inferior to such foreign brands as Bosh, Ariston and others.

Manufacturers of the Korea Star company confidently declare that if all recommendations are followed, the equipment will serve without failures or breakdowns for about 20 years.

Features of Premium 16E:

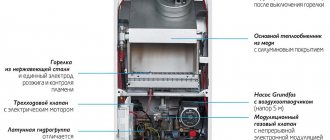

the presence of two heat exchangers: copper and steel - allows you to achieve maximum heat transfer from the coolant to the system; the German-made circulation pump is designed to operate at three speeds, which allows you to regulate the pressure in the system and ensure the speed of warming up the house; the presence of electronic modulation of the panel and an LCD display displaying the main indicators and equipment settings; the ability to provide hot water for a shower with a flow rate of 13 liters per minute; the boiler is protected from water hammer when there is a pressure drop in the system using a bypass valve; the boiler is capable of operating on natural and liquefied gas; the wall-mounted boiler has frost protection, which is important at low temperatures; the equipment can withstand sudden voltage changes, which ensures continuous operation of the device; The boiler weight is 32 kg, the power of 16 kW allows you to heat rooms with a square area of no more than 160 meters; The closed combustion chamber is automatically regulated, which ensures safety when the flame extinguishes.

Korea Star Ace

Advantages of this model:

- proper operation even during voltage surges;

- excellent heating to a given temperature at low gas pressure;

- the ability to heat water for domestic use;

- the presence of two heat exchangers that provide maximum heating of the system in a short time;

- a special fan creates good draft, which ensures effective smoke removal;

- a system that prevents dust from entering the boiler ensures its long-term operation;

- a low-noise pump not only allows you to pump water efficiently, but also creates convenience, since the equipment can be installed in the kitchen;

The normal price is in the range from 17 to 19 thousand rubles.

Premium 24E

Premium 24E

- increased heat transfer due to the use of a copper heat exchanger;

- providing a large amount of hot water (about 15 liters per minute);

- reasonable foreign automation that ensures the maintenance of specified parameters and prevents breakdowns and emergency situations;

- price range of 20 - 22 thousand rubles.

Installation and operation

It is better to entrust the installation of the boiler to a professional

The boiler connection diagram is given in the instructions. It is determined by the device features of this model. Some units are energy-dependent, others do not require power. In the first case, a voltage of 220 V with a frequency of 50 Hz must be supplied to the connection point. You cannot use tees, extension cords, or connect other devices to the source. If a particular model needs to be supplied with liquefied gas, re-adjustment is carried out by inviting a specialist.

The boiler room must be provided with fresh air ventilation using equipment that creates continuous movement of air flows. The use of gas fuel prohibits the storage of chemically active and flammable compounds and materials in the room where the boiler is installed. Do not place the unit near a window, a flight of stairs or in a wall opening, or place heaters or air conditioning units near it. If there is a malfunction, an error code is displayed on the display (the explanation of the numbers is given in the instructions).

Solutions to Question 1

The boiler is equipped with a self-diagnosis system and fault signals are displayed on the display; errors marked with the symbol A cause the boiler to shut down. In this case, the user will have to manually restart the boiler by pressing the RESET button. Errors marked with the F symbol cause the boiler to temporarily switch off with automatic re-ignition after the value that caused the error returns to normal values.

Accordingly, errors A01.

Corestar boiler error codes - troubleshooting instructions

Did the Corestar boiler show any errors on the display? This means that the self-diagnosis system has “detected” a malfunction. All modern heating equipment is equipped with automation – sensors that monitor the operation of each unit. Sometimes the user does not even need to contact the service center. Simply determine the meaning of the code and find the problem.

Basic error codes

a01

Error a01 – there is no signal about the presence of a flame. Gas does not flow or the gas valve or ionization electrode ignition is faulty. The control board may not be working correctly.

It is necessary to check all shut-off valves and, if necessary, bleed air from the water supply. Check the gas pressure on the valve - it should be 20 mbar (2 kPa), as well as the gas valve itself (replace if necessary).

Check the electrode for contamination, as well as the gap between it and the burner. It should be 3 mm ± 0.5 mm.

a02

Error a02 - the signal about the presence of a flame is false. The control board or ignition electrode is faulty. Check for mechanical damage on the electrode itself; it is possible that it is touching the burner. Also set the required gap between the burner and ignition/ionization - 3.5 ± 0.5 mm. Replace the control board if it fails.

Corestar boiler ignition electrode

a03

Error a03 - the boiler is overheating. The bimetallic overheat sensor (or it is also called an emergency thermostat) blocks the operation - the threshold temperature is about 90 degrees. Air has entered the heating system and/or there is insufficient water circulation in the heating system.

It is necessary to cool the boiler and restart it. Replace the sensor if necessary. Remove air from the circuit. Check the pump - open all shut-off valves, check the pump blades for contamination and the supply of voltage to its contacts. Replace the pump if necessary. If a03 appears again, the control board should be replaced.

a08

Error a08 - the exhaust air overheating sensor is faulty. The temperature limiter gives an erroneous value. Check it for open or short circuit and replace if necessary.

f05

Error f05 - a failure has occurred in the smoke removal system. The fan or air relay is not working correctly or is faulty. The chimney is clogged.

Boiler fan Corestar

Check the correct connection of the connectors to the air relay contacts and make sure that the air diaphragm does not stick. Replace the relay if necessary.

f11

Error f11 – the NTC extract air temperature sensor is faulty. Open circuit or short circuit of the device. Check the resistance of the semiconductor - it should be 10 kOhm. There may be no signal between the control board and the temperature sensor. Disconnect the sensor and then reconnect it. Replace if it is faulty.

f37

Error f37 – NTC DHW temperature sensor. Open circuit or short circuit of the corresponding device. With such an error, the burner will not be able to light up only in DHW mode. The boiler itself will be able to continue its work. Check the resistance of the sensor and the quality of the connectors. Replace parts if necessary.

The same code indicates low pressure in the heating system. The exhaust pressure sensor is faulty or the circuit pressure has dropped below 0.8 bar. Check the sensor, replace if necessary, and also find leaks. Fix the problem and replenish with water.

f41

Error f41 - heat exchanger is overheated. Poor circulation of the heat exchanger or air has entered. Remove air and check the pump according to the procedure described in the instructions, with the shut-off valves open. If necessary, replace the circulation pump.

Heat exchanger for Corestar boiler

f50

Error f50 - the control board has failed. Control board faulty. Check that there is no “breakdown” on the case, grounding, and if it fails, replace the board.

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Korea Star boilers. All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article.

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

The equipment of some models includes 2-circuit copper heat exchangers, which are made using the pipe-in-pipe method. They have an anti-corrosion coating and are therefore resistant to heat. The units are equipped with special functions that protect them from freezing, as well as a pressurized gas burner with modulation. The anti-blocking modes of the gas valve and circulation pump protect the combustion chamber from hydraulic shock. Their maximum power is 35 kW.

Korea Star gas boilers are characterized by increased noise due to the use of a modulating supercharged burner. DHW supply is carried out independently of the heating system. An electromagnetic 3-way valve is installed in the hydraulic part of the unit, due to which the heating rate is maximized. Hot water is prepared regardless of the pressure of the heating system. If the temperature of the heating system drops by 5 degrees, the device turns on automatically, preventing the system from defrosting.

The unit is equipped with a self-diagnosis system, which notifies about malfunctions with symbols on the display. Errors marked with code A cause the unit to lock. In this case, you must manually reboot the device by pressing the Reset button. Errors marked with code F cause a temporary shutdown of the device with automatic restart after the parameter that caused the malfunction reaches the required values.

Error code A01 - No flame signal

Probable reasons: Gas is not supplied to the burner. The ionization ignition electrode is malfunctioning or not working properly. Gas valve malfunction. The electronic control board has malfunctioned.

Error code A02 - False flame signal

Probable causes: Problem with the ionization ignition electrode. Faulty electronic control board.

Error code A03 - Korea Star boiler overheats

Probable causes: The bimetallic overheat sensor (emergency thermostat) turns on at a temperature of 90 degrees, and the operation of the unit is blocked. There is air in the heating system. Poor water circulation in the heating system.

Error code A08 - Malfunction of the heating water overheating sensor

Probable causes: Defective temperature limiter.

Error code F05 - The smoke removal system is not working correctly

Probable causes: The air pressure switch is not working correctly. There is a problem with the fan. Smoke exhaust pipes are clogged.

Error code F10 - Malfunction of NTC heating temperature sensor

Probable causes: Short circuit or open circuit of the temperature sensor.

Error code F11 - Damaged NTC DHW temperature sensor

Probable causes: Short circuit or open circuit of the hot water temperature sensor.

Key error codes

Let's try to take a much more detailed look at the error codes of Oasis boilers, and the potential reasons why they appear.

Error

e1. Indicates ignition failure, potential causes:

- There is no gas supply to the device. It is necessary to check whether the gas valve is open, if not, open it. There may also be insufficient or, on the contrary, excessive gas pressure; to eliminate this, you need to contact the gas service.

- The contact connection is broken or missing. It is necessary to check for open circuit and short circuit using a multimeter. They may have oxidized; in this case, clean and separate the wires.

- The board is broken. You need to test it and, if it breaks, replace it with a new one; this type of repair requires the necessary qualifications. Boiler control board

- The ignition control electrode is broken. First, clean it using a steel brush and look visually to see if there is any damage to its body. If you find a defect on it or its wire, replace it.

- The plug is not installed correctly in the socket, replace it with the other side

Error

e2. Lights up if the air pressure switch does not close 8 seconds after turning on the fan.

The reasons may be:

Contamination of the pipe or chimney. It is necessary to check the presence of draft and clean the chimney. It will also not be unnecessary to open the firebox, there are 2 pipes connected to the monostat, remove them and blow them out. The relay that controls the air pressure has broken down. Test it to ensure it is working properly and replace it if necessary. The fan stopped working

You need to check its serviceability, look at it with great attention, there are tubes in it, you need to check their integrity, whether they are melted. Next you need to turn on the boiler and after the fan starts working, short-circuit the two wires going to the monostat

Boiler fan Oasis

If the boiler

If it lights up, it means the monostat is broken and needs to be replaced, and if not, then the problem is in the control board.

- The electronic part of the device is faulty, or the cable is coming off somewhere. Perform a visual inspection of all connections of the device and the integrity of the wires. If the board is faulty, then it is better to ask professionals to repair and diagnose it.

Error e6. This means there is no flame. What to do if a similar difficulty arises?

The following needs to be removed:

Presence of stray flame. There may be air accumulation in the system. Try a secondary restart. The connection in the wires is broken. It is necessary to check its impeccability and integrity. Methods for connecting wires One of the board components is broken; it is responsible for starting the device. You need to test the board.

Error e7. Low pressure or small amount of liquid in the hot water supply system.

There is little water in the system, the basis may be a leak in any of the system components, this can be created using a dry cloth

It is necessary to check everything with great attention and if a leak is found, remove it. This can be achieved by using specialized sealants, tightening the joints, and using high-quality sealants. The pressure level in the expansion tank is not adjusted

Just as when heated, the liquid becomes wider, the pressure in it increases and the liquid is discharged using the valve. It is necessary to strictly follow the characteristics of a particular model and adjust the desired level of pressure in the system. Expansion tank in the heating system And, of course, the problem may lie in the electronic board of the device itself. It is worth inspecting the board for separation of contacts and other damage.

Error e9. It indicates that the pump has stopped working, or that the pressure in the system is unacceptable.

The level of favorable fluid pressure in the system varies from 0.1 to 0.15 atm. It is necessary to check the serviceability of the water pump by removing it in advance. If necessary, clean the pump, rinse it, check the integrity of the blades. Broken control board

Needs replacement. You also need to pay attention to whether the temperature sensor is working properly.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Protherm”, “NAVIEN”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Internal structure of Oasis boilers

One of the characteristic features of the modifications is the presence of a closed combustion chamber. Air intake is carried out from the street, using a coaxial chimney. Combustion products are also removed through the pipe. This makes the operation of boilers as safe as possible. In addition, due to the closed firebox, gas consumption is significantly reduced.

Separately, we can note the presence of two heat exchangers. This solution increases the speed of heating water for domestic hot water, and also allows the device to be started in summer mode, which increases its efficiency.

All Oasis wall-mounted double-circuit gas heating boilers have a high degree of autonomy, achieved thanks to an internal structure that includes:

- Burner - a pressurized type device is used. The connected burner is controlled automatically. Electric ignition is provided. Photo sensors are installed on the burner to monitor the presence of gas. After a power outage, the gas supply to the burner is blocked. The boiler uses a coaxial chimney. It simultaneously takes in air and removes combustion products. Not included in the basic package.

- Safety group - 2-circuit mounted gas heating boiler Oasis has multi-level protection that prevents spontaneous combustion and the occurrence of explosive situations. Provided: water flow sensor - monitors the pressure of the water supply and heating system, blocks operation if it drops to critical levels. Relief valves are installed to help in case of overheating of the coolant. When the room temperature drops, the antifreeze system is activated, maintaining minimal heating of the heating system.

Oasis boilers have been certified and received permission to operate by Rostechnadzor. This made it possible to operate equipment from a Chinese manufacturer throughout the Russian Federation.

What to focus on in operation

Boiler piping - the internal structure of the boiler contains a circulation pump and an expansion tank. During installation, you will need to additionally install a filtration system. The automation is sensitive to voltage drops, which is one of the main disadvantages of the Oasis boiler. To eliminate possible failure of the control board, you need to connect a UPS. Lots of noise – the forced-air burner is noisy. The noise level requires installation of the boiler in a separate room. The technical characteristics declared by the manufacturer in this regard are somewhat different from what actually happens

It is especially noisy when the DHW is turned on.

Coaxial chimney - it is extremely important to comply with the installation requirements, strictly adhere to the maximum height, angle of inclination and other parameters. Productivity and efficiency ultimately depend on a quality installation

Chinese doesn't mean bad

All components from the closed combustion chamber to the temperature sensor are checked for quality and compliance with standards. The only condition for trouble-free operation is the installation and operation of the boiler in accordance with all the rules and in accordance with the manufacturer’s recommendations.

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

The boiler does not turn on or ignite

Several unsuccessful ignition attempts

This is the very first error code for most equipment manufacturers. For BAXI E01 boilers, for Arison 501 boilers, for Vaillant F28. Ignition of the gas-air mixture in the combustion chamber will occur under two conditions: the presence of gas at the burner nozzles and the presence of a spark. Gas enters the burner through the gas valve, the spark is generated by a transformer on the control board (or remote). A separate case should be noted when ignition occurs, but the boiler cannot detect the presence of a flame and goes out (closes the gas supply valve).

Phasing error. Often, gas boiler boards require connection polarity. For the average user, this means that the position of the plug in the outlet matters. If the connection polarity is reversed, the boiler does not see the presence of a flame, continues ignition (electrode crackling) even when there is already a flame on the burner, then turns off due to an emergency. Even if you did not touch the plug, the polarity could change at the substation!

Flame ignition or ionization electrode. It can be separate or combined. The main problems may be related to contamination (oxidation) of the electrode or its gap relative to the burner. A dirty ionization electrode prevents the board from detecting the presence of a flame and operation stops.

High voltage wire. High voltage is generated by a transformer and transmitted through a wire to the electrode, where it pierces the air gap between the burner and the electrode with a spark. If a characteristic crackling sound is heard, but a spark on the burner is not visually visible, it is possible that the breakdown is occurring somewhere else. For example, there is a microcrack in the insulation of a high-voltage wire, and a breakdown occurs at the point where the insulation on the housing is broken.

Problems with electrical connection. The presence of parasitic potentials on the boiler body, lack of grounding or low voltage of the supply network can cause problems with ignition. I often hear the argument: everything used to work without grounding. No one will understand how the boiler worked without grounding. According to the operating instructions, this must be done! For normal operation of the boiler there must be: a network voltage of at least 180 volts, a potential between the neutral and ground wires of up to 10 volts, and the presence of grounding.

Lack of gas on the burner. The gas valve controls the gas supply to the burner: it opens and modulates (gas dosing). The gas valves are regulated and controlled by a control board. Accordingly, the cause of the problems may be a malfunction of the valve (or the need for adjustment), its electrical part, or the control circuit on the board. This device should be checked by a specialist. The lack of gas can also be due to external factors: a faulty meter, dirty filters.

Control board. In some cases, lack of ignition or flame control is caused by a malfunction of the boiler main board. This can be considered after the other possible causes as described above have been accurately checked.

Types of wood fuel

Wood fuel obtained directly from wood processing plants

- Technological chips.

- Sawdust.

- Lumber scraps.

- Cuttings from lamellas.

- Trimmings from timber trimming.

- Top farmers from whip logging.

- Roundwood debris resulting from processing.

- Sorted low-quality firewood is not suitable for production.

- Gorbyl.

- Tree bark.

- Scraps from the production of plywood, chipboard, mdf and osb.

- If there is a railway section on the territory of the woodworking enterprise. loading and unloading of wood, then the waste from this link can also be used as fuel.

This fuel was obtained during the production process at the enterprise. Its utilization as fuel is simply a vital process for many. The disadvantage of this type of fuel is that it is not always fully prepared for combustion and is heterogeneous.

The advantages of such fuel include its low cost and, of course, the ability to transfer production to a higher level - waste-free production. Taking into account all the pros and cons when choosing a combustion technology, it is necessary to take into account all these factors and only then select a boiler. We'll talk about this below.

Wood fuel made specifically for heat production

Such fuels include:

- Pellets. Today we will look at pellet boilers, but they are not yet very actively used in industry in Russia.

- Eurodrova.

- Charcoal.

This fuel is much more convenient to use for heat production, since it is already prepared in all respects:

- Its heat transfer is much higher, which means that the amount of fuel required to produce one volume of heat is less than that of firewood.

- When using special wood fuel, less waste is generated on site.

- The presence of various foreign inclusions is practically excluded in the prepared fuel.

- Ability to operate on fuel in semi-automatic and automatic modes.

Design and principle of operation of Corestar boilers

Despite the name, Koreastar gas boilers have nothing in common with Korea. These are European boilers, designed specifically for Russian conditions.

Wall-mounted boilers Koreastar (Korea Star) have a classic design - a circulation pump, two heat exchangers, a closed combustion chamber, an automatic bypass valve, and safety groups. These devices can easily withstand voltage surges of 15% and have a flow capacity of about 13.6 liters per minute (DHW). They are designed to heat rooms up to 240 square meters.

Many models have copper double-circuit heat exchangers, which are made according to the “pipe-in-pipe” principle and, thanks to the anti-corrosion coating, are resistant to heat.

The models are equipped with built-in functions aimed at preventing freezing, as well as a pressurized burner, which is of a modulating type.

Anti-blocking systems for the gas valve and pump protect the combustion chamber from water hammer. Boiler productivity reaches 32 kW. Koreastar gas boilers are quite noisy. This is due to the working forced-air burner, so it is recommended to install it away from housing.

Hot water is heated independently of the heating system. Thanks to the presence of an electromagnetic three-way valve, the heating speed is significantly increased, and a uniform supply of heated water is ensured regardless of the system pressure.

Motorized 3-way valve

When the system temperature drops to +5 degrees, the boiler starts automatically, preventing the system from defrosting.

Why doesn't the boiler start?

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“BAXI”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

Internal factors include breakdowns of electronics - sensors, wiring, as well as individual components - pump, heat exchanger.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vaillant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

Installation and connection

The Oasis boiler is a wall-mounted model. Unlike floor-standing devices, it does not require boiler room equipment; it can be installed even in small rooms.

Fastening is done either with anchors or large screws, since the weight of the boilers is comparable to the weight of a regular gas water heater, and the dimensions are approximately the same.

The described gas boilers are produced with a closed combustion chamber. What does this mean? To ensure the combustion process, an air flow is required. A device with a closed chamber in this regard is isolated from the room in which it is mounted. Air is supplied from outside using a fan equipped with the boiler.

Therefore, before purchasing the Oasis product, you need to think about installing a special coaxial chimney. For private houses this is not a problem, but installation in an apartment will require specialist advice. Although such models are considered safer and more environmentally friendly.

The boiler does not work in DHW or heating mode

And finally, situations when the boiler does not operate in a particular mode. They happen much less frequently compared to others. In this case, it is likely that the boiler will need to be diagnosed by a specialist. The process of ignition and operation of the boiler in different modes is virtually the same, with the exception that different modes may have different power. In hot water preparation mode, the boiler power is usually full, but in heating mode it can be minimal. You can read about problems in the operation of the DHW mode in a separate article.

READ Start-up of the viessmann vitopend 100 boiler

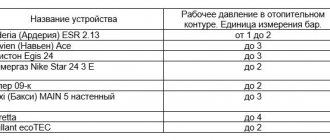

Insufficient water pressure (refill required)

Traditional gas boilers operate in a closed heating system; accordingly, to prevent the boiler from turning into a hydrogen bomb, there must be a minimum water pressure inside the heat exchanger (in fact, the presence of water and circulation there). The pressure is controlled by a special sensor - a pressure sensor. The boilers are provided with an additional mechanical pressure gauge for the user. Although the systems are closed, the pressure in them can drop over time (for example, water escapes through leaks in the connections). As soon as the water pressure in the boiler drops below the minimum level (0.5 - 0.7 bar), the boiler sensor detects a malfunction and blocks operation. In most cases, you just need to study the readings of the mechanical pressure gauge and recharge the system according to the instructions for the boiler.

Display board

For some boiler models (Vaillant, Ariston, Navien), the control unit consists of a main board and an information board (display board). The boiler may also not turn on if the display board is broken. The display board, unlike the main one, is cheaper, but most often cannot be repaired. In this case, the fault can only be identified by replacing a known good part.

If the gas boiler is working, there is an indication on the display, but it does not start or produces errors, further diagnostics are required.