6610 0 0

Michel July 28, 2016Specialization: plumber with 10 years of experience, computer repair specialist, powerlifting coach. I have extensive experience in construction, interior decoration, and making homemade furniture. Hobbies: sports

This article is devoted to what the layout of heating pipes can be like in a wooden house or a modern apartment building. I am going to talk about diagrams for connecting circuits to an elevator, risers to a heating circuit, and methods for inserting individual heating devices into the circuit. So, let's go.

Heating system installation.

Classification of single-pipe heating systems

In this type of heating there is no division into return and supply pipelines, since the coolant, after leaving the boiler, flows through one ring, after which it returns to the boiler again.

The radiators in this case are arranged in series. The coolant enters each of these radiators in turn, first into the first, then into the second, and so on. However, the temperature of the coolant will decrease, and the last heating device in the system will have a temperature lower than the first. The classification of single-pipe heating systems looks like this, each type has its own schemes:

- closed heating systems that do not communicate with air. They are distinguished by excess pressure; air can only be released manually using special valves or automatic air valves. Such heating systems can work with circular pumps. Such heating can also have lower wiring and a corresponding circuit;

- open heating systems that communicate with the atmosphere using an expansion tank to discharge excess air. In this case, the ring with coolant should be placed above the level of heating devices, otherwise air will collect in them and water circulation will be disrupted;

- horizontal - in such systems, the coolant pipes are placed horizontally. This is great for private one-story houses or apartments where there is an autonomous heating system. A single-pipe type of heating with bottom wiring and a corresponding diagram is the best option;

- vertical - coolant pipes in this case are placed in a vertical plane. This heating system is best suited for private residential buildings consisting of two to four floors.

Bottom and horizontal wiring of the system and its diagrams

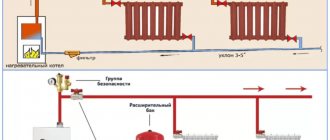

The circulation of the coolant in the horizontal pipe laying scheme is ensured using a pump. And the supply pipes are located above or below the floor. The horizontal line with lower wiring must be laid with a slight slope from the boiler, and the radiators must be installed all at the same level.

In houses with two floors, such a wiring diagram has two risers - supply and return, while a vertical diagram allows for a larger number of them. During forced circulation of the heating agent using a pump, the room temperature rises much faster. Therefore, to install such a heating system, you need to use pipes with a smaller diameter than in cases of natural coolant movement.

should be 60 degrees

On the pipes that enter the floors, you need to install valves that will regulate the supply of hot water to each floor.

Let's look at some wiring diagrams for a single-pipe heating system:

- vertical supply scheme - can have natural or forced circulation. In the absence of a pump, the coolant circulates through a change in density during cooling during heat exchange. From the boiler, the water rises into the mains of the upper floors, then it is distributed along the risers to the radiators and cools down in them, after which it returns to the boiler again;

- diagram of a single-pipe vertical system with bottom wiring. In a scheme with bottom wiring, the return and supply lines go below the heating devices, and the pipeline is laid in the basement. The coolant is supplied through the drain, passes through the radiator and returns down to the basement through the riser. With this wiring method, heat loss will be significantly less than when the pipes are in the attic. And it will be very easy to maintain the heating system with this wiring diagram;

- diagram of a single-pipe system with top wiring. The supply pipeline in this wiring diagram is located above the radiators. The supply line runs under the ceiling or through the attic. The risers go down through this line and radiators are attached to them one by one. The return line goes either along the floor, or under it, or through the basement. This wiring diagram is suitable in case of natural coolant circulation.

Remember that if you do not want to raise the door threshold in order to lay the supply pipe, you can smoothly lower it under the door on a small piece of land while maintaining the overall slope.

Elevator unit

The minimum gentleman's kit for a simple elevator unit consists of:

- Pairs of input valves - on the supply and return threads.

- Mud on the supply and, less often, on the return.

- Essentially an elevator with a nozzle and suction.

- House valves that shut off the house heating system.

- A pair of resets allowing the system to be completely drained.

- Control valves for temperature and pressure measurement.

Optionally there will be:

- Warm water supply taps (one or two for each thread). In the second case, to ensure constant circulation through the DHW circuit, the flange between the taps on each thread is equipped with a retaining washer.

- Insertions of individual consumers (trade kiosks, shops, etc.). Here the insert itself is washerd on the flange in front of the shut-off valve; the washer limits the water flow through a separate circuit.

Single-pipe heating system pros and cons

Advantages

A single-pipe heating system has both advantages and disadvantages. The advantages include the following:

- the ability to cover the entire area of the building using a closed ring, which does not depend on the layout of the building;

- the ability to connect certain additional devices to the heating system, for example, heated floors, heated towel rails or equipping a built-in circulation pump;

- it is possible to direct the coolant in one direction or another. For example, in the course of circulation, colder rooms that are often ventilated can be sent first. In the same two-pipe systems, this function comes down to the location of the boiler;

- ease of installation work. There are not so many materials, and the cost of their purchase and the work itself will be significantly lower than when installing a two-pipe system;

- With thoughtful placement of heating devices and correct piping, the difference in temperatures in different rooms can be minimized, but this phenomenon cannot be completely overcome.

Flaws

The disadvantages of a one-pipe system are:

- the presence of special requirements for the diameter of the key pipeline;

- in the first radiator the temperature will be highest, and in subsequent ones it will be lower due to the constant addition of coolant to the flow of coolant from radiators that have already been passed through;

- the last radiators should have a larger area than the first ones so as not to be too cold;

- It is better not to install more than 10 radiators on one branch, since uniform heating will not work this way.

Temperature equalization occurs by changing the number of radiator sections and installing special jumpers, thermostatic valves, taps, regulators or ball valves. It is advisable to have a circulation pump, and in order for hot water to flow better through the pipes and radiators, you need to install a special acceleration manifold. It is not needed in two-story houses.

If the wiring is of the upper type, then the supply pipe is capable of creating natural pressure, however, with such a scheme, you need to install pipes with a large diameter, and this will negatively affect the appearance of your interior. Therefore, if it is possible to install the wiring unit under the floor covering, it will be much better.

We also recommend that when installing radiators in a two-story building in order to regulate heating, make a parallel connection of batteries with the installation of taps at the entrances. Also, so that the temperature on the second floor is distributed evenly, instead of radiators, you can purchase a heated floor system.

As you can see, a single-pipe system in terms of operation can have a number of difficulties. For example, it requires high pressure levels; also, for it to work properly, it is advisable to use a powerful pump, and this is not only unnecessary trouble, but also high costs. In addition, a one-story building will require a vertical spout and an attic expansion tank.

However, despite this, this solution still has more advantages.

Problems

It couldn't have happened without them either.

Expenses

Obviously, with the same diameter, two pipes will always be more expensive than one. If the area of the heated building is small, the benefits obtained will not compensate for this difference: it is easier to compensate for the temperature spread by increasing the number of radiator sections at the end of the single-pipe ring.

Balancing

The cottage's two-pipe heating system needs balancing.

First, let's outline the essence of the problem.

Imagine that two pipes go from the heating boiler deep into the house. Through the first, water flows to the radiators, and through the second, it returns. Moreover, each radiator is a jumper between these pipes.

What's the problem? Yes, the fact is that each heating device will dampen the difference between the supply and return. If on the first battery it is equal to, say, 0.2 kgf/cm2, then on the second it will be 1.75, on the third it will be 1.5, and so on.

What is heating like?

When it comes to heating an apartment building, one cannot boast of a large selection. All houses are heated according to approximately the same scheme. In each room there is a cast-iron heating radiator (its dimensions depend on the size of the room and its purpose), into which hot water of a certain temperature (coolant) coming from the thermal station is supplied.

example of a cast iron radiator

However, the entire water supply circuit may vary depending on what kind of heating distribution is provided in a particular building - single-pipe or two-pipe. Each of these options has certain advantages and disadvantages. To better understand this issue, you need to know exactly everything about the first and second. So let's briefly describe them.

- Single pipe heating system. Its design is simple, and therefore reliable and cheap. But still she is not in great demand. The fact is that, when entering the heating system of a house, the coolant (hot water) must pass through all the heating radiators before it enters the return channel (also called “return”). Of course, by heating all the radiators one by one, the coolant loses temperature. As a result, when reaching the last user, the water has a relatively low temperature, which is why in the last room it can differ significantly from the temperature in the one it arrives at first. This often causes discontent among residents. Therefore, the described heating system for a multi-storey building is used relatively rarely.

- Two-pipe heating system. It is free from the disadvantages that are inherent in the heating system described above. The design of this system is significantly different. Hot water, having passed through the heating radiator, does not enter the pipe leading to the next radiator, but directly into the return channel. From there it is immediately sent back to the thermal station, where it will be heated to the required temperature. Of course, this option requires significantly higher costs both during installation of the system and during maintenance. But this heating system design makes it possible to ensure the same temperature in all heated buildings. Example of a two-pipe heating system

It also makes it possible to install a heating meter. By installing it on a heating radiator, the owner can independently regulate its heating level and, accordingly, reduce the cost of paying heating bills. This option is not possible in a single-pipe heating system. By reducing the amount of hot water passing through your radiators, you can thus cause a lot of trouble for your neighbors, to whom the coolant reaches after passing through your apartment. That is, the heating rules in this case will be openly violated.

Of course, it is impossible to change the type of heating system in an apartment; this requires titanic efforts and a huge amount of work that will affect the entire house. But still, knowing about the pros and cons of different types of heating systems will be useful for every apartment owner.

This video provides a broad overview of various heating systems.

Advantages

What, in fact, is good about a 2-pipe heating system?

Its main advantage is that it allows you to ensure a more or less constant temperature of heating devices throughout the building.

With a single-pipe heating system, the battery connections at the beginning of the single filling rings will have a supply temperature (typically 70-75 C). at the end - return temperature (50 C). Here, each radiator will receive a coolant with a temperature slightly different from that provided by the supply boiler or the elevator unit after the mixing unit (elevator).

In addition, in the case of a large house with a significant number of batteries, a 2-pipe heating system simply has no alternative: not a single single-pipe ring configuration will cover all the rooms of an 80-apartment building.

Anticipating objections: yes, a manifold circuit can more than replace a two-pipe system. However, its selling price will be tens of times higher due to the enormous consumption of pipes; in addition, a large total length of the connections will mean huge non-target heat losses.

Features of gravity flow systems

Due to the fact that turbulent flows are formed, it is not possible to carry out accurate calculations of systems, therefore, when designing them, average values are taken, for this:

• raise the acceleration point as much as possible;

• use wide supply pipes;

Then, from the beginning of the first divergence to each subsequent one, a pipe of a smaller diameter is connected at a step equal to it, which involves inertial flows.

There are also other features of installing gravity systems. Thus, pipes should be laid at an angle of 1-5%, which is affected by the length of the pipeline. If the system has a sufficient difference in heights and temperatures, horizontal wiring can be used

It is important to ensure that there are no areas with a negative angle, since they cannot be reached by moving the coolant due to the formation of air pockets in them

Thus, the operating principle can be based on the open type or be of the membrane (closed) type. If you make a horizontal installation, it is recommended to install Mayevsky taps on each radiator. since with their help it is easier to eliminate air locks in the system.

Watch the video in which a specialist talks about the conditions for using a gravity-fed, pumpless, gravity heating system:

The principle of operation of a gravity heating system

The principle of heating operation looks simple: water moves through a pipeline, driven by hydrostatic pressure, which appears as a result of different masses of heated and cooled water. This design is also called gravity or gravity. Circulation is the movement of cooled and heavier liquid in the batteries under the pressure of its own mass down to the heating element, and the displacement of light heated water into the supply pipe. The system operates when the natural circulation boiler is located below the radiators.

In open-type circuits, it communicates directly with the external environment, and excess air escapes into the atmosphere. The volume of water that increased due to heating is eliminated, and the constant pressure is normalized.

Natural circulation is also possible in a closed heating system if it is equipped with an expansion tank with a membrane. Sometimes open-type structures are converted into closed ones. Closed circuits are more stable in operation, the coolant in them does not evaporate, but they are also independent of electricity. What affects circulation pressure

The circulation of water in the boiler depends on the difference in density of the hot and cold liquid and on the magnitude of the height difference between the boiler and the lowest radiator. These parameters are calculated before the installation of the heating circuit begins. Natural circulation occurs because The return temperature in the heating system is low. The coolant manages to cool down, moving through the radiators, becomes heavier and with its mass pushes the heated liquid out of the boiler, forcing it to move through the pipes.

Water circulation diagram in the boiler

The height of the battery level above the boiler increases the pressure, helping the water more easily overcome the resistance of the pipes. The higher the radiators are located in relation to the boiler, the greater the height of the cooled return column and the greater the pressure with which it pushes the heated water upward when it reaches the boiler.

Density also regulates pressure: the more the water warms up, the less its density becomes in comparison with the return. As a result, it is pushed out with more force and the pressure increases. For this reason, gravity heating structures are considered self-regulating, because if you change the heating temperature of the water, the pressure on the coolant will also change, and therefore its flow will change.

During installation, the boiler should be located at the very bottom, below all other elements, to ensure sufficient coolant pressure.

Pipe selection

The hydraulic resistance of the circuit, its resistance to corrosion, thermal parameters, and installation technology depend on the material of the pipeline. The list of requested materials includes:

- Steel pipes. Affordable, resistant to mechanical stress. Disadvantages: they are installed with welding or a large number of fittings, the pipes are prone to corrosion and overgrowth.

- Metal-plastic pipes. The inner surface is perfectly smooth, which prevents the growth of deposits, corrosion resistance, low weight, resistance to thermal expansion. Disadvantages: high cost, limited service life (about 15 years), the need to use welded fittings or regularly tighten threaded connecting elements.

- Polypropylene pipes. Smooth inside, durable (service life from 25 years), resistant to high temperatures. Disadvantages: high cost, installation using special tools.

- Copper pipes. Maximum heat transfer and durability (over 100 years), stylish appearance. Disadvantages: high cost, need for soldering during installation.

Power calculation

The effective thermal output of the boiler is calculated using the same methods as in all other cases.

By area

The simplest method is the calculation based on the area of the room recommended by SNiP. 1 kW of thermal power should be per 10 m2 of room area. For the southern regions, a coefficient of 0.7 - 0.9 is taken, for the central zone of the country - 1.2 - 1.3, for the Far North - 1.5-2.0.

Like any rough calculation, this method neglects many factors:

- Ceiling height. It is not always the standard 2.5 meters.

- Heat leaks through openings.

- The location of the room is inside the house or near external walls.

All calculation methods give large errors, so thermal power is usually included in the project with some margin.

By volume, taking into account additional factors

Another method of calculation will give a more accurate picture.

- The basis is a thermal power of 40 watts per cubic meter of air volume in the room.

- Regional coefficients apply in this case as well.

- Each standard size window adds 100 watts to our calculations. Each door is 200.

- The location of the room near the external wall will give, depending on its thickness and material, a coefficient of 1.1 - 1.3.

- A private house, which has not warm neighboring apartments below and above, but a street, is calculated with a coefficient of 1.5.

However: this calculation will also be VERY approximate. Suffice it to say that in private houses built using energy-saving technologies, the design includes a heating power of 50-60 watts per SQUARE meter. Too much is determined by heat leakage through walls and ceilings.

Development of a heating system project

The heating device, starting from the inlet system and ending with heating radiators, is created immediately after the skeleton of an apartment building is built. Of course, by this time the heating project for an apartment building must be developed, tested and approved.

And it is at the first stage that a number of difficulties often arise, as with any other very complex and important work. In general, the heating system of an apartment building is complex

The power of your heating system can depend on the strength of the wind in your area, the material from which the building is constructed, the thickness of the walls, the size of the rooms and many other factors. Even two identical apartments, one of which is located on the corner of the building, and the other in its center, require a different approach.

After all, a strong wind in the winter season cools the outer walls quite quickly, which means that the heat loss of a corner apartment will be much higher.

Therefore, they need to be compensated by installing larger heating radiators. Only experienced specialists who know exactly how all the equipment is designed and how it works can take into account all the nuances and select the optimal solutions.

A beginner who decides to calculate the heating system in an apartment building will be doomed to failure from the very beginning. And this will not only lead to a significant overexpenditure of resources, but will also put the lives of the inhabitants of the house in danger.

Central heating system

No one will argue that the centralized system of supplying heat to apartment buildings, in the form in which it now exists, is, to put it mildly, morally outdated.

It's no secret that losses during transportation can reach up to 30% and we have to pay for all this. Refusal of central heating in an apartment building is a complex and troublesome procedure, but first, let's figure out how it works.

Heating a multi-storey building is a complex engineering structure. There is a whole set of drains, distributors, flanges that are connected to a central unit, the so-called elevator unit, through which the heating in an apartment building is controlled.

Two-pipe heating circuit.

There is no point in talking in detail about the intricacies of the operation of this system now, since this is done by professionals and the common man simply does not need it, because nothing depends on him. For clarity, it’s better to consider the heat supply diagram to the apartment.

Bottom filling

As the name implies, the distribution scheme with bottom filling provides for the supply of coolant from bottom to top. Classic heating of a 5-storey building is installed exactly according to this principle.

As a rule, the supply and return lines are installed around the perimeter of the building and run in the basement. The supply and return risers, in this case, are a jumper between the mains. This is a closed system that rises to the top floor and descends again to the basement.

Two types of bottling in comparison.

Despite the fact that this scheme is considered the simplest, putting it into operation is a troublesome task for mechanics. The fact is that at the top point of each riser, a device for bleeding air, the so-called Mayevsky valve, is installed. Before each start, you need to bleed the air, otherwise the air lock will block the system and the riser will not be heated.

Important: some residents of the upper floors try to move the air release valve to the attic so as not to have to deal with housing and communal services workers every season. This kind of modification can be expensive.

The attic is a cold room, and if you stop heating for an hour in winter, the pipes in the attic will freeze and burst.

A serious disadvantage here is that on one side of the five-story building, where the input passes, the batteries are hot, and on the opposite side they are cool. This is especially felt on the lower floors.

Option for connecting radiators.

Top filling

The heating device in the nine-story building is made according to a completely different principle. The supply line, bypassing the apartments, is immediately carried out to the upper technical floor. An expansion tank, an air release valve and a valve system are also located here, allowing the entire riser to be cut off if necessary.

In this case, the heat is distributed more evenly across all radiators in the apartment, regardless of their location. But here another problem emerges: the heating of the first floor in a nine-story building leaves much to be desired. After all, having passed through all the floors, the coolant reaches downstairs already barely warm; this can only be combated by increasing the number of sections in the radiator.

Important: the problem with freezing water on the technical floor, in this case, is not so acute. After all, the cross-section of the supply line is about 50 mm, plus in the event of an accident, you can completely drain the water from the entire riser in a few seconds, you just need to open the vent in the attic and the valve in the basement

Temperature balance

Of course, everyone knows that central heating in an apartment building has its own clearly regulated standards. So during the heating season, the temperature in the rooms should not fall below +20 ºС, in the bathroom or in the combined toilet +25 ºС.

Modern heating of new buildings.

Due to the fact that the kitchen in old houses is not very large, plus it is naturally heated by periodic operation of the stove, the permissible minimum temperature in it is +18 ºС.

Important: all the above data is valid for apartments located in the central part of the building. For side apartments, where most of the walls are external, the instructions prescribe an increase in temperature above the standard by 2 - 5 ºС

Heating standards by region.

Methods of obtaining and types of hot water supply

According to the method of production, DHW systems are divided into two types:

- open,

- closed.

Hot water supply for an apartment building comes in two versions:

- with single-pipe risers,

- with two-pipe risers.

The two-pipe system consists of two risers:

- server,

- circulation.

The heated water flows through the supply riser to the apartments, and through the circulation riser into the central main. Both pipelines are nearby. Heated towel rails are placed on the circulation riser in bathrooms - curved pipes that not only heat the rooms, but also compensate for temperature changes in the length of the pipe. The water in them will no longer be disassembled by consumers, but will be returned through the central pipeline back to the boiler room.

In a single-pipe scheme, each consumer has one riser - supply, and all circulation pipes are combined into one “idler”. It has no consumers, and the water through it returns to the main line.

Heated towel rails with this design:

- placed on the supply pipe,

- electric ones are installed,

- connect to the heating bed.

In the latter case, heated towel rails only operate during the heating season.

With any wiring scheme, the hot water supply system of an apartment building must be able to drain periodically occurring air pockets. With the top wiring, automatic relief valves are installed for such purposes; with the bottom, air can be removed through the top water intake valve.

Two-pipe heating system with overhead wiring

Installing a two-pipe heating system with overhead wiring minimizes or completely eliminates many of the disadvantages described above. In this case, the radiators are connected in parallel.

Its installation requires significantly more materials, since two parallel lines are installed. Hot coolant flows through one of them, and cooled coolant flows through the other. Why is this top vent heating system preferred for private homes? One of the significant advantages is the relatively large area of the room. The two-pipe system can effectively maintain a comfortable temperature level in homes with a total area of up to 400 m².

In addition to this factor, the following important operational characteristics are noted for a heating scheme with top filling:

- Uniform distribution of hot coolant over all installed radiators;

- Possibility of installing control valves not only on the battery piping, but also on individual heating circuits;

- Installation of a water heated floor system. A collector hot water distribution system is only possible with two-pipe heating.

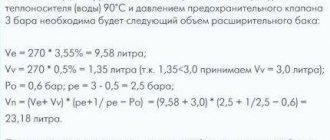

To organize forced top filling in the heating system, it is necessary to install additional components - a circulation pump and a membrane expansion tank. The latter will replace the open expansion tank. But the location of its installation will be different. Membrane sealed models are mounted on the return line and always on the direct section.

The advantage of such a scheme is that it is not necessary to observe the slope of the pipelines, which is typical for the upper and lower heating distribution with natural circulation. The required pressure will be created by a circulation pump.

But does a two-pipe forced heating system with overhead wiring have any disadvantages? Yes, and one of them is dependence on electricity. During a power outage, the circulation pump stops working. If the hydrodynamic resistance is high, the natural circulation of the coolant will be difficult. Therefore, when designing a single-pipe heating system with overhead wiring, you need to perform all the required calculations.

You should also take into account the following installation and operation features:

- When the pump stops, reverse movement of the coolant is possible. Therefore, in critical areas it is necessary to install a check valve;

- Excessive heating of the coolant can cause the critical pressure to exceed. In addition to the expansion tank, air vents are installed as an additional protective measure;

- To increase the efficiency of a heating system with top-pipe distribution, it is necessary to provide automatic replenishment of the coolant. Even a slight decrease in pressure below normal can lead to a decrease in heating of radiators.

The video will help you clearly see the difference for different heating schemes:

Most of the heating systems of apartment buildings and private buildings are built precisely according to this scheme. What are its advantages and are there any disadvantages?

Can a two-pipe heating system be installed with your own hands?

Convector in a two-pipe heating system

General requirements for installation of beam distribution

When using collector-beam wiring, a common method is to lay pipes in the floor in a screed, the thickness of which is 50-80 mm. Plywood is laid on top, covered with a finishing floor covering (parquet, linoleum). This thickness of the screed is quite sufficient for free “monolithization” of the intra-apartment (intra-house) radial wiring of the heating system. It is possible to lay pipes externally along the walls under decorative skirting boards, which entails an inevitable increase in the length of the pipelines. There are known options for laying radial distribution pipes in the space of a suspended (suspended) ceiling, in grooves.

Connecting radiators with a collector-beam circuit.

Metal-plastic or cross-linked polyethylene pipes (PEX pipes) are used, laid in a corrugated pipe or in thermal insulation. PEX pipes have an undoubted advantage here. According to SNiP, only unbreakable connections can be “mortared” into concrete. PEX pipes are connected using tension fittings, which are permanent connections. Metal-plastic pipes use compression fittings with union nuts. “Monoliquing” them means violating SNiP. Each detachable pipe connection must be accessible for maintenance (tightening).

Even without fittings, not every metal-plastic pipe is uniquely suitable for laying in a floor screed. Manufacturers' products suffer from a serious defect: layers of aluminum and polyethylene delaminate under the influence of repeatedly changing coolant temperature. After all, metal and plastic have different coefficients of volumetric expansion. Therefore, the glue connecting them should be:

- internally strong (cohesive);

- adhesive to aluminum and polyethylene;

- flexible;

- elastic;

- heat resistant.

These requirements are not met by all adhesive compositions even from well-known European manufacturers of metal-plastic pipes, which delaminate over time; the inner layer of polyethylene in such a pipe “collapses,” reducing its cross-section. The normal operation of the system is disrupted, and the location of the malfunction is almost impossible to find - usually the “sin” is due to malfunctions of thermostats, pumps and other products with moving parts.

In light of the above, we recommend that readers pay attention to metal-plastic pipes from VALTEC, which uses American adhesive from the DSM concern, which ensures the strength of the metal/plastic connection, adhesion and the complete absence of delamination

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is necessary to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the diameter of the pipe, etc. You may need professional help when performing the calculations.

Closed system with gravity circulation

In EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet received widespread use. The operating principles of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands and water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container consists of a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs and the gas squeezes water out of the tank.

Otherwise, closed-type systems work like other heating schemes with natural circulation. The disadvantages include the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a spacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantage of an open system is the ability to independently manufacture a container from scrap materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the entry of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing of the system is also a frequent “guest” in open-type circuits. Therefore, radiators are installed at an angle; Mayevsky valves must be provided to bleed air.

Single-pipe self-circulating system

A single-pipe horizontal system with natural circulation has low thermal efficiency and is therefore used extremely rarely.

The essence of the circuit is that the supply pipe is connected in series to the radiators. The heated coolant enters the upper branch pipe of the battery and is discharged through the lower outlet. After this, the heat flows to the next heating unit and so on until the last point. The return flow returns from the outermost battery to the boiler. This solution has several advantages:

- There is no pair pipeline under the ceiling and above the floor level.

- Saves money on system installation.

The disadvantages of this solution are obvious. The heat transfer of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a single-pipe heating system for a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often redone (by installing pumping equipment).

Two-pipe self-circulating system

A two-pipe heating system in a private house with natural circulation has the following design features:

- Supply and return flow through different pipes.

- The supply pipeline is connected to each radiator through an inlet branch.

- The second line connects the battery to the return line.

As a result, a two-pipe radiator-type system provides the following advantages:

- Even heat distribution.

- No need to add radiator sections for better heating.

- Easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe circuits.

- Lack of strict rules for installing a two-pipe system. Small deviations regarding slopes are allowed.

The main advantage of a two-pipe heating system with bottom and top wiring is the simplicity and at the same time efficiency of the design, which allows you to eliminate errors made in calculations or during installation work.

Connecting batteries

The sectional radiator can be connected in three different ways.

Three possible connection diagrams for a sectional radiator.

- The side connection is optimal when the number of sections is no more than 7. All of them will be heated evenly, but the end sections will require periodic washing;

- A diagonal connection is suitable for long radiators and equalizes the temperatures of the first and last sections. Flushing is required and performed through a tap installed instead of a blind bottom plug;

- The bottom connection differs favorably from the diagonal one in that the radiator does not require flushing at all. The sludge is carried away by the coolant circulating through the lower collector. However, due to the uneven distribution of circulation between the lower and upper collectors, the device loses 10-15% of thermal power.

With a bottom connection, you can forget about flushing.

general information

Basic moments

The absence of a circulation pump and generally moving elements and a closed circuit in which the amount of suspensions and mineral salts is finite makes the service life of this type of heating system very long. When using galvanized or polymer pipes and bimetallic radiators - at least half a century. Natural circulation of heating means a fairly small pressure drop. Pipes and heating devices inevitably provide a certain resistance to the movement of the coolant. That is why the recommended radius of the heating system we are interested in is estimated at approximately 30 meters. Of course, this does not mean that with a radius of 32 meters the water will freeze - the border is quite arbitrary. The inertia of the system will be quite large. Several hours may pass between lighting or starting the boiler and stabilizing the temperature in all heated rooms. The reasons are clear: the boiler has to warm up the heat exchanger, and only then the water will begin to circulate, and quite slowly. All horizontal sections of pipelines are made with a mandatory slope in the direction of water movement. It will ensure the free movement of cooling water by gravity with minimal resistance

What is equally important is that in this case all air pockets will be forced out to the top point of the heating system, where an expansion tank is mounted - sealed, with an air vent, or open.

All the air will collect at the top point.

Self-regulation

Heating a house with natural circulation is a self-regulating system. The colder the house, the faster the coolant circulates. How it works?

The fact is that the circulation pressure depends on:

Differences in height between the boiler and the lower heating device. The lower the boiler is relative to the lower radiator, the faster the water will flow into it by gravity. The principle of communicating vessels, remember? This parameter is stable and unchanged during operation of the heating system.

The diagram clearly demonstrates the principle of heating operation.

Curious: this is why it is recommended to install the heating boiler in the basement or simply as low as possible indoors. However, the author has seen a perfectly functioning heating system in which the heat exchanger in the furnace firebox was noticeably higher than the radiators. The system was fully working.

Differences in the density of water leaving the boiler and in the return pipe. Which, of course, is determined by the temperature of the water. And it is precisely thanks to this feature that natural heating becomes self-regulating: as soon as the temperature in the room drops, the heating devices cool down.

As the coolant temperature drops, its density increases, and it begins to quickly displace heated water from the lower part of the circuit.

Circulation speed

In addition to the pressure, the circulation rate of the coolant will be determined by a number of other factors.

- Diameter of distribution pipes. The smaller the internal cross-section of the pipe, the greater resistance it will provide to the movement of liquid in it. That is why, for distribution in the case of natural circulation, pipes with a deliberately oversized diameter are taken - DN32 - DN40.

- Pipe material. Steel (especially if damaged by corrosion and covered with deposits) has several times more resistance to flow than, for example, a polypropylene pipe with the same cross-section.

- Number and radius of turns. Therefore, if possible, it is better to make the main wiring as straight as possible.

- Availability, quantity and type of shut-off valves. various retaining washers and pipe diameter transitions.

Every valve, every bend causes a drop in pressure.

It is precisely because of the abundance of variables that an accurate calculation of a heating system with natural circulation is performed extremely rarely and gives very approximate results. In practice, it is enough to use the recommendations already given.

Equipment

So, we are going to install water heating with our own hands. What main elements will our scheme include?

Boiler

Domestic gas heating boilers are the cheapest to operate. In the Moscow region, the cost of heating a 200 m2 house with main gas does not exceed 3,000 rubles per month.

Boilers can be volatile (with electronic ignition) and non-volatile (using piezo ignition and a pilot burner). The former are noticeably more economical - the pilot burner consumes up to 20% of the total amount of gas.

In second place in terms of efficiency are solid fuel boilers. Coal and firewood will be an excellent solution where there is no main gas. However, using solid fuel requires frequent loading: you will have to light the boiler at least twice a day.

There are, however, a number of ways to solve this problem.

- Gas-generating solid fuel boilers split the fuel combustion process into two stages. Initially, it smolders with limited air access, forming flammable pyrolysis gas; then this gas is burned in its own furnace. A gas generator boiler is capable of operating on one load not for 2-5, but for 8-12 hours.

- Top-burning devices use the smoldering of a thin top layer of coal or wood. A coal boiler can operate for up to 5 days without maintenance or cleaning.

- A simple and universal solution is to use a heat accumulator (a thermally insulated container with a volume of 300-2000 liters). Working at full power, the boiler heats the water in the tank after lighting. Over the next few hours, the accumulated thermal energy is gradually released to the heating devices.

Finally, solar and electric boilers differ little in heating costs. They provide the maximum cost per kilowatt-hour of heat. In addition, it is not possible to provide the power required for heating with electricity everywhere.

Pipes

Their choice is determined by whether we are talking about central or autonomous heating.

The optimal material for central heating is steel pipes of several types.

- Black steel is cheap but susceptible to corrosion. In addition, steel risers and connections require a lot of time and effort for installation. Connections are most often made by welding.

- Galvanized steel is protected from corrosion by a zinc layer; It would be correct to assemble a galvanized liner ONLY on threads. Welding breaks the protective coating, including inside the pipe.

- Finally, a wonderful material is corrugated stainless steel. The pipes are connected using compression fittings with silicone seals and are easy to bend.

Why steel? Because in the central heating system you are not protected from exceeding the design temperature and water hammer. It is better to overpay when installing heating, and not when eliminating the consequences of a dirty boiling water leak.

But autonomous heating means that all parameters are constant and under your control. Hence the choice of materials:

- Metal-plastic with press fittings.

Important: it is better not to use compression fittings with union nuts on heating and hot water. After several heating and cooling cycles, they begin to leak.

- Polypropylene. Preferably reinforced: reinforcement not only increases the tensile strength of the pipe, but also reduces its thermal expansion.

- Cross-linked polyethylene. In addition to strength, these pipes have another advantage: they are flexible and are supplied in coils up to 500 meters long, which is useful for radial distribution with laying pipes in a screed.

Heating devices

And here it is worth separating central and autonomous heating.

In central heating systems, it is better to use steel tubular radiators, steel convectors and bimetallic radiators. Aluminum is not desirable.

And not only from the point of view of strength: the instructions for the use of aluminum radiators specifically stipulate the ability of this metal to accelerate destruction in combination with copper water supply. Metals form a galvanic couple.

Since you can’t know what your neighbors’ eyeliners are made of, it’s better not to take risks.

But for autonomous heating, aluminum radiators are undoubtedly the best choice.

Safety

- Expansion tank. It accommodates excess coolant during its expansion accompanying heating.

- Safety valve - additional insurance against circuit overflow. The valve is activated and releases excess coolant when its pressure reaches a preset threshold value.

- A pressure gauge or thermomanometer is installed for visual monitoring of parameters.

- An automatic air vent or a manual air vent is mounted at the highest points of the circuits and in air pockets.

House heating scheme

It was already mentioned above that most modern houses in cities are heated using a centralized heating system. That is, there is a thermal station in which (in most cases using coal) heating boilers heat the water to a very high temperature. Most often it is more than 100 degrees Celsius!

Water is supplied to all buildings connected to the heating main. When connecting a house to a heating plant, inlet valves are installed to control the process of supplying hot water to it. A heating unit is also connected to them, as well as a number of specialized equipment.

heating unit operation diagram

Water can be supplied both from top to bottom and from bottom to top (when using a single-pipe system, which will be discussed below), depending on how the heating risers are located, or simultaneously to all apartments (with a two-pipe system).

Hot water, entering the heating radiators, heats them to the required temperature, ensuring its required level in each room. The dimensions of radiators depend both on the size of the room and on its purpose. Of course, the larger the radiators, the warmer it will be where they are installed.

Useful little things

- When balancing with chokes, the time interval between changing the throttling mode and stabilizing the temperature of the heating devices reaches 6 - 8 hours.

- For a cottage with an area of up to 100 m2 with forced circulation of coolant in a two-pipe system, a reasonable minimum filling cross-section is DU2, up to 200 m2 - DU25.

- In a gravity system, filling cannot be made thinner than DN32 when using polymer pipes and DN40 when using steel pipes . In addition, gravity systems are used on an area of no more than 100 m2: in a large room, the hydraulic resistance of a long circuit simply will not provide the minimum required circulation rate.