It seems to many that corrugated pipes are a relatively recent product on the plumbing market. In fact, corrugated pipes have long been firmly established in every home as a shower hose. Corrugated stainless steel pipes for heating came into use a decade ago, successfully replacing smooth-walled counterparts in modern engineering systems. Let's figure out what benefits the use of corrugation brings, what it comes in, and why its installation is considered simple.

Connecting a radiator through a corrugated pipe Source metallobaza-sm.ru

How to troubleshoot possible problems

Even if the assembly of the pipe network was carried out by a master with many years of experience in such work, upon completion of installation or during operation, leaks may occur in the connection nodes.

If a leak is detected in the connection area of the corrugated hose, do the following:

- Shut off the supply of the working medium and bleed its remains from the pipeline (if water flows through the pipes, drain it, if natural gas, light one of the burners of the stove).

- Dry and clean the outer surface of the unit.

- If the pipe is connected by welding, solder the detected hole. If it is crimping, cut off and replace the fitting. If the pipe is connected using a compression fitting, tighten the nut.

- Turn on the supply of working medium.

- If the leak resumes, then repeat all previous operations for the welded joint; for the crimp joint, turn off the supply of the working medium, bleed off its remains, disassemble the assembly and proceed to the next step.

- Check the condition of the assembly elements under the nut. If the edge of the corrugated pipe has burrs or other damage, it is necessary to cut off the damaged section. If the retaining ring or sealing ring is damaged or missing, install the whole part.

- Reassemble the unit, turn on the supply of working medium.

- If it was not possible to get rid of the leak, the fitting's thread may have been stripped, in which case it will have to be completely replaced.

Now let's look at the installation of an internal water supply system made of corrugated stainless pipe. A water pipeline made from corrugated stainless steel is made quite simply, like from metal-plastic pipes. All the advantages of this pipe were discussed in a separate article in the section on choosing pipes, so there is no point in repeating here, I will only give a comparison of the installation of a corrugated stainless pipe and a regular one.

What product shortcomings should we not forget?

- The downside is the high price - this is a controversial issue, since the material itself is not cheap, plus a unique manufacturing technology. The low price of such a thing should alert you, most likely it is a fake. When making a purchase, check the integrity of the packaging - there are markings on it, there are no inscriptions on the pipe.

- Another feature manifests itself during operation and saddens housewives: dust accumulates in the depressions of the pipe, which is difficult to wash out.

- The products are afraid of external mechanical damage; special screens will provide protection.

- The disadvantages of the connections include the fact that the fittings require regular maintenance.

- If part of the heating system is located in an open room, additional insulation is required to avoid heat loss.

- Twisting is not allowed.

- There is a possibility of corrosion caused by electrochemical processes (grounding saves).

Areas of application of corrugated stainless steel for heating

Corrugated gas stainless liner

Using this type of stainless steel pipes and fittings, you can perform the following types of work:

- Connecting heating batteries;

- Replacing indoor heating risers;

- Installation of a pipeline from local (heating boilers) or main sources of heat carrier to residential and non-residential heated premises;

- Installation of an additional element of the heating system (for example, an analogue of a heating battery);

- Connection of “warm floors”;

- Pipeline laying;

- Gas pipeline installation;

- Fire extinguishing and air conditioning systems.

Due to their flexibility and strength, they are also used in the chemical, food and pharmacological fields. This is explained by the fact that, unlike plastic pipes, corrugated stainless steel does not lose its properties and diameter even after being squeezed.

Application and labeling

Stainless steel corrugation is used in the following cases:

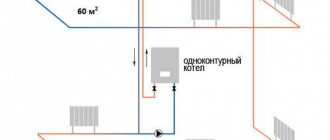

- When installing heating systems of private houses, bathhouses, greenhouses (usually a product with a diameter of 20 mm is used). They help connect heating appliances to the heating riser.

- When installing standard water supply pipelines and connecting plumbing fixtures.

- When installing heated floors and varieties (warm walls, baseboards); in heating radiators.

- As cable ducts for protecting electrical cables.

- In fire extinguishing systems as a fire-fighting pipeline.

- When laying communication networks.

- In gas supply systems.

- In internal combustion engines: transports fuel and removes exhaust gases.

Product markings indicate how they can be used:

- With the letter "A". The corrugation is made of unannealed steel.

- With the letter "M". Annealing technology was used.

Connecting a corrugated pipe to a fitting Source prodomostroy.ru

- With the letter "P". The pipe is protected by an additional plastic sheath.

- With the letter combination “El”. For electricians.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Characteristics and advantages over pipes made from other materials

The widespread use of corrugated stainless steel pipes is due to their technical and operational characteristics, such as:

- resistance to corrosion under the influence of water, gases and caustic liquids;

- long service life;

- strength - corrugated steel can be pulled, bent, to obtain mechanical damage, significant effort must be made;

- wide temperature range of use: stainless steel can withstand heating up to 600°, some over 1000, and cooling down to -100 and below.

With their help, you can create pipelines for various purposes that will be reliable, tight and durable.

Well-known manufacturers claim that their products, after installation, do not require maintenance for decades.

If the connectors are selected correctly, they will not leak under normal operating conditions not associated with constant mechanical load.

Checking and replacement may be necessary only after emergency situations: earthquakes, wall falls and others in which an unforeseen load appears.

Selection Instructions

The reliability of the pipeline system and high-quality installation depend on the implementation of several simple rules for purchasing products:

- Fittings must be complete;

- Before purchasing, the pipe must be inspected for mechanical damage and creases; it must be strong and flexible;

- When installing, you must follow the instructions, and after installation, check the system under pressure.

Classification of fittings according to their functions

In this case, the fittings are divided into several types, let’s get acquainted with them.

Coupling

It is the most common type of fitting and is necessary to connect pipes directly to each other on straight sections.

Adapter

It is designed to splice pipes of different diameters. The simplest and most convenient of all connecting elements.

Rotary angle

Used to change the geometry of the pipeline system. But corrugated pipes bend easily, you will notice. This is true, but they need to be bent to a maximum radius that is equal to two pipe diameters.

Stub

With its help, part of the system or, alternatively, the entire operating circuit is closed in accordance with the project (or during repairs).

With its help, part of the flow is redirected from the central highway.

Buy corrugated pipe in Moscow and regions

Our online store offers corrugated pipes, the price of which is lower than that of many competitors. You can also buy everything necessary for installation (couplings, elbows, tees, fixing rings and silicone gaskets). All products are guaranteed.

Delivery of corrugated pipes is carried out throughout Moscow and the region by courier service. Delivery conditions in other regions can be clarified with managers. In many cities of Russia (St. Petersburg, Kazan, Nizhny Novgorod, Voronezh, Chelyabinsk, Omsk, Ufa, Vladivostok) branches have been opened where you can familiarize yourself with the range of Teplolux products and place an order.

Criterias of choice

When choosing a corrugated pipe, you must remember that it must fit all household plumbing fixtures

First of all, you need to pay attention to the diameter of the products that will fit all home communications

At the same time, the cross-section of the pipes must be correlated with the power of the entire equipment. An important point when choosing stainless steel products is the grade of steel.

You should also pay attention to the manufacturing technology of products, on the basis of which annealed and unannealed types are distinguished. For example, annealed types are excellent for installing a heating system, while unannealed types are used for the manufacture of connecting elements

Another criterion for choosing corrugated products is their design. After all, the ability of the pipeline to withstand high pressure depends on the design features.

High-quality corrugated products must have the following parameters:

- maintaining maximum pressure, which is 50 atm;

- presence of connecting elements;

- maintaining temperature conditions from 50 to 110 °C;

- small degree of elongation (about 2% of the total length of the product).

Manufacturers and what to look for when purchasing

As mentioned above, the first stainless corrugated pipes were produced in Japan. But at the moment, other countries have also entered the ranking of leaders in product manufacturing.

The price largely depends on the manufacturer. Let's look at the most famous brands.

KOFULSO

Products of a South Korean company. It is distinguished by its variety of shapes, versatility, ability to withstand temperature changes and high water pressure. Available in both annealed and non-annealed versions in coils of 10-50 m. Diameters - from 15 to 50mm. The price varies from 140 to 2500 rubles/m.

NEPTUN

manufactures corrugated stainless steel pipes with a diameter of 15 to 32 mm. The products are corrosion-resistant, universal, suitable for gas pipelines, water pipes, heating elements, and heating boiler piping. They have high heat transfer. Price – from 85 to 700 rubles/m;

LAVITA

Another South Korean manufacturer. The pipes can withstand water pressure and water hammer perfectly and are suitable for installing water supply systems and other systems. Easy to install, durable. They are produced in annealed, unannealed form, as well as in a shell. The price ranges from 103 to 1050 rubles/m. Diameter – from 8 to 50mm.

НYDROSTA

And again South Korea. The company has developed a special steel polish that prevents the formation of deposits and deposits. Suitable for all plumbing systems except sewerage. The diameter of corrugated pipes is from 12 to 50 mm, the price is from 125 to 1500 rubles/m.

INOFLEX

The German company MEIBES produces corrugated metal pipes with a diameter of 12 to 40 mm. The products can withstand temperatures up to 200 degrees and pressures up to 16 Bar. Supplied in coils from 20 to 80 m. The price of one meter is from 650 to 2000 rubles.

When choosing pipes, pay attention to the following nuances:

- There should be no mechanical damage, creases, cracks, or burrs on the pipe;

- The corrugation pitch must be uniform;

- Steel grade – AISI (SUS) 304. I do not recommend purchasing AISI201, AISI409, AISI430 grades; in fact, this is ordinary shiny iron with a minimum amount of alloying additives;

- Connection fittings must be sold assembled;

Important characteristics of pipes for underfloor heating

Now among building materials there are many options for using various technologies and devices for installing a floor heating system that will operate on water. Despite the fact that this heating method is somewhat more difficult to install than using electric heaters, it is still used and is considered quite popular. One of the main elements of this entire system is the pipe through which the coolant will flow. It must have certain characteristics for the heating to work effectively and correctly.

Corrugated Stainless Steel Pipe

Laying corrugated pipes for heated floors

When choosing a water pipe, the following factors are taken into account:

- main operational characteristics - under what conditions this type of pipe can be used;

- features of the installation work;

- thermal conductivity indicators;

- duration of operational life;

- pipe cost;

- flexibility, since during installation of heated floors the pipe will have to be bent many times;

- protection from oxygen penetration, since this element becomes the main cause of rust formation inside the product;

- manufacturer of the material and its reputation.

The use of corrugated stainless steel pipes in the heating system

The inner walls of the corrugated stainless steel pipe are smooth

Pipes for underfloor heating systems can be made of various materials. Each type has its own usage and performance characteristics.

Table. Types of pipes for organizing floor heating.

| Type of material used in manufacturing | a brief description of |

| Copper | This is one of the oldest materials that was used to equip heating systems in homes. Copper is distinguished by: - long service life and high strength; - antibacterial properties; — corrosion resistance; — the ability to withstand critical temperature changes (from -100 to +250 degrees) without harm. However, copper pipes are very expensive and also have certain operational limitations. They cannot be used if the water is highly acidic or hard. Such conditions reduce the operational period of pipes by half. |

| Metal-plastic | Very popular and high-quality pipes that can easily compete with copper pipes. The advantages of such pipes: - lower price; — long service life (minimum 50 years); - they do not rust; — chemically inert; - lightweight but durable; — smooth, which is why deposits do not form on the surface from the inside. The main disadvantage is the difficulty of connecting individual elements. Poor quality connections can cause flooding of the room and failure of the heating system. Metal-plastic pipes can withstand temperature fluctuations from -10 to +95 degrees. |

| Polypropylene | Pipes made from this material have a lot of advantages, but still it is far from the most popular material. Advantages of use: - environmental safety; — durability; - cheap. They are rarely used for installing heated floors, as they are inconvenient to use - they have a large bending radius. Also, the material cannot be used at sub-zero temperatures - use only from +15 degrees is allowed. |

| Cross-linked polyethylene | Quite durable material. Chemically inert. It is not afraid of temperature changes, does not scratch or crack. |

corrugated pipe for underfloor heating

There is also another type of pipe for sale for installation of underfloor heating - a corrugated pipe made of stainless steel.

Production technology

High-precision technology is used to create stainless steel corrugations. The pipes are made of alloy steel; the high content of nickel and chromium provides the coating with anti-corrosion qualities.

The technology includes several stages:

- installation on equipment of the required sizes and configurations;

- cutting elements and connecting them;

- creating a corrugated surface;

- package.

The structure is created from steel sheets, pipes of a given configuration are formed using special devices. The edges of the elements are joined by welding. The quality of connections is checked with a laser device.

The corrugated surface configuration is created by passing through a set of shafts with different diameters.

Strength and ductility of products are imparted through heat treatment. Finished products are cut to standard lengths and packaged.

The process is completed by quality control, which includes testing the product in water and under pressure. Identified defective products must be reprocessed.

Installation of heated floors using flexible corrugated pipes

To organize heated floors, easily bendable corrugated stainless steel heating pipes are used, which correspond to class AISI 304. In addition to circuits for underfloor heating systems, these products are used in many water heating systems, during piping boiler rooms and connecting pumps.

The coefficient of thermal expansion of such pipes is 0.2 millimeters for every 6 meters of length. Moreover, for pipes made of cross-linked polyethylene, which are also used for heating floors, this value is 4 millimeters for the same length.

Steel pipes have the highest thermal conductivity and efficiency. In this regard, the heat transfer rates of such a system will be the highest. Only copper has higher performance, but pipes made from such a material would be prohibitively expensive to use for such purposes. Steel has a thermal conductivity coefficient of 17 W/m2, which is also considered an excellent result.

When using a stainless corrugated pipe for heating, concrete 10 cm thick is steadily heated. Heating stops if the concrete layer is 20 cm thick. Due to the flexibility of the pipe, a minimum number of fittings will be required, even if the design of the heating main turns out to be very complex. In addition, the installed fittings will not need to be tightened upon completion of the work.

Installation of heated floors is carried out using the following materials:

- corrugated stainless steel heating pipe with a diameter of 15 mm (the steel must be annealed);

- 1.5 inch brass fittings;

- cement mortar in a ratio of 1 to 4 cement to sand, with the addition of a plasticizer;

- steel mesh.

Dimensions and approximate prices

We will summarize all sizes, designations, properties and characteristics into a single table.

| Nominal diameter | 8A | 12A | 15A | 18A | 20A | 25A | 32A | 40A | 50A |

| External diameter | 12.8 | 16.2 | 18.1 | 20.3 | 25.6 | 32 | 37.6 | 48 | 59.8 |

| Inner diameter | 9.7 | 12.7 | 14.1 | 16.5 | 21.1 | 27 | 32.1 | 42 | 53.5 |

| Wall thickness | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.3 (0.25) | 0.4 (0.3) | 0.4 (0.3) |

| Number of pipe folds per 100mm | At least 25 | At least 24 | At least 23 | At least 21 | At least 19 | At least 18 | At least 18 | At least 14 | At least 13 |

| Minimum bend radius, mm | Up to 20 | Up to 30 | Up to 30 | Up to 40 | Up to 40 | Up to 50 | Up to 80 | Up to 120 | Up to 150 |

| Standard length, m | 60 | 60 | 50 | 40 | 30 | 30 | 20 | 10 | 10 |

| Recommended operating pressure, Bar | 17 | 15 | 13 | 12 | 12 | 10 | 8 | 3 | 2 |

Copper pipes

Copper pipes are available in two versions: annealed and unannealed. The latter variety is produced by processing ore into ingots of almost 100% frequency. During the pipe rolling process, the material significantly loses its elasticity, but at the same time gains strength. The internal structure of the metal remains at the same level.

Annealed pipe is produced using a similar technology, but the final stage of processing involves exposure to high temperatures. After complete cooling, the material begins to exhibit the required properties.

The differences between annealed and unannealed copper pipe are only in operational characteristics. Both types are used when creating a heating system, water supply channel and air conditioner. Copper has important properties - thermal conductivity, bactericidal properties, corrosion resistance, which makes the material optimal for the manufacture of household pipes.

In the modern production of annealed and unannealed pipes, polymer coating technology is used, which is aimed at reducing heat loss

This is important for products that will subsequently become part of the hot water supply and heating system. In addition, condensation does not form on the surface

Copper products are characterized by smooth internal walls, so the formation of scale and clogging of the diameter is practically impossible throughout the entire period of use. Copper pipes can withstand high temperatures well, so even thin walls can withstand sufficient loads.

Criteria for selecting communications and components

Corrugated stainless steel pipe for heating systems is selected based primarily on the diameter of the communications, which is included in the plan. With correctly selected values of this parameter, you can obtain an effective system with high throughput. It should be noted that the cross-section of the pipes must be correlated with the power of the equipment.

Additionally, attention is paid to the steel grade

It is important to consider the manufacturing technology of products. For example, there are flexible communications made of annealed and unannealed steel. The difference between them lies in the operating conditions

For example, annealed pipes are good for installing heating systems. It is recommended to use brass fittings as connecting elements

The difference between them lies in the operating conditions. For example, annealed pipes are good for installing heating systems. It is recommended to use brass fittings as connecting elements

For example, there are flexible communications made of annealed and unannealed steel. The difference between them lies in the operating conditions. For example, annealed pipes are good for installing heating systems. It is recommended to use brass fittings as connecting elements.

Review of manufacturers and product prices

There are several popular brands, including Neptun. The product range includes annealed and unannealed products, as well as a wide range of fittings. If a corrugated pipe for heating systems is being considered, the price will depend on its cross-section. For example, a product with the smallest diameter of 15 mm costs on average 110 rubles/m.

As an alternative, you can choose products from the Lavita brand. The cost of communications with a diameter of 8 mm will be higher - 150 rubles / m, which is determined by the grade of steel. In the assortment of this manufacturer you can also find fittings for any requirements.

Recommendations from experts

The pricing of flexible products is simultaneously influenced by three factors: steel grade, product cross-section, manufacturing method. If a small-diameter pipe from one manufacturer costs less, it means that a different grade of steel was used in its manufacture

Therefore, these parameters should be paid attention to first.

Accordingly, this type of communication is preferable, especially when it comes to installing a heating system. Since in this case significant loads will be exerted in two directions: temperature and pressure.

Installation

How to assemble a fitting on corrugated stainless steel with your own hands?

The instructions depend on the type of fitting:

| Image | Description |

|

|

| Flare fitting:

5. Tighten the union nut on the thread of the fitting or plumbing fixture being connected. |

Installation of corrugated pipes

The corrugated chimney pipe is made of stainless steel, produced in multilayer foil format. The individual strips are connected using the locking method and fixed using a spring, also made of stainless steel (read: “Which stainless steel chimney pipes are best to use - types and advantages”).

Such a device has a lot of advantages - for example, if necessary, the finished pipe can be bent at an angle of up to 180 degrees or stretched, increasing the length by more than three times relative to the original value. In this case, a very important factor is that such manipulations with the pipe do not affect its integrity at all (if you do not bend it too many times, of course).

To achieve the highest possible durability and increase reliability, the steel corrugated chimney pipe is treated on all sides with a special solution, which increases resistance to most aggressive substances. The service life of a quality pipe is at least 20 years.

The only thing that needs to be done separately is to install the insulation of the corrugated pipe, which is necessary to prevent heating of the outer part of the chimney. Most often, rolled basalt wool is used for these purposes.

How to make a corrugated pipe from stainless steel

High quality steel strip is sent to the forming line. There, on bending machines, it is given the outline of a cylinder. When rolling, special clamps are used, and the cylindrical blank becomes a corrugated pipe.

The product blank is placed in a chamber, filled with a special gas mixture, in the environment of which welding takes place. The entire process is automated, which allows you to achieve a high-quality weld and eliminate the human factor.

To achieve plasticity, the products are additionally annealed: heated to 1000 degrees, then cooled to 200 °C.

The pipe is cut into pieces ranging from 20 to 50 meters in length, which are rolled into a coil, packaged and labeled.

Features of installing corrugated pipes

When installing corrugated pipes, there are some nuances that you should know about so that they do not become an unpleasant surprise. As is the case with most bendable building materials, you should not abuse this quality - repeated bends over time are guaranteed to lead to the fact that the corrugated stainless steel heating pipe will be deformed. It would be much better to bend the pipe to the desired shape and not return to it.

Conclusion

Corrugated stainless steel pipe for heating is an excellent solution for arranging a heating system. To achieve maximum effect, it is necessary to correctly select materials and carry out high-quality installation work. The resulting heating system will perform its functions properly for many years.

Summarize

Corrugated stainless steel pipe is a relatively new, and according to manufacturers, if used correctly, it is an almost eternal invention.

There is not much experience in use yet; time will tell what can be improved in the technical characteristics of the corrugation.

And I say goodbye for today, and as always, I invite you to join us on social networks. It’s very convenient to share skills, track news and ask questions. We are waiting for your videos and reviews!

(

3 ratings, average: 5.00 out of 5)

Advantages and disadvantages

I propose to figure out why corrugated stainless steel pipes are so popular in the domestic market. Let's look at the advantages and disadvantages in detail.

Pros:

Flexibility. The element can be bent without damage. This allows you to use a minimum number of fittings during installation and install the product in hard-to-reach places. The pipe bends easily by hand; Strength. Unlike plastic, a metal flexible pipe does not lose its cross-sectional geometry when compressed and can withstand water hammer and high pressure; Aesthetics. The design does not need to be painted or hidden - it is elegant and visually attractive; High resistance to temperature changes. It should be noted here that the material can withstand up to 40 freezing cycles, after which damage to the macrostructure is still possible. The product is not sensitive to high temperatures; Length. Sometimes an engineering solution requires laying long-distance communications (warm floors, walls). Stainless steel corrugation will allow you to install long sections of pipeline without additional fittings; Corrosion resistance

This is especially important when working in basements, damp rooms, when installing communications under the plaster layer, in grooves, behind decorative panels. Immunity to vibrations and other mechanical loads; Smoothness of the inner walls; Reliability and durability.

Manufacturers set service life limits only for fittings.

- Small weight of 1 linear meter;

- The pipe is not counterfeited; it is still difficult to find a product made from cheap, low-quality stainless steel. Unfortunately, as you understand, the key word in this phrase is “yet.”

Minuses:

- Brass fittings that fasten pipes together require regular maintenance (checking tightness, tightening, replacing liners);

- The appearance will not fit harmoniously into every room;

- Low level of resistance to some chemical elements;

- Dust constantly accumulates in the folds of the corrugation;

- Electrical conductivity. In some systems (warm floors, walls, etc.) stray currents occur. To prevent emergency situations, grounding and dielectric gaskets are necessary;

- High heat transfer coefficient. Complicates the use of products in unheated rooms. The problem is solved by a layer of insulation;

- Inability to use for sewer networks;

- High price.

pros

Stainless corrugated piping technology is attractive for the following reasons:

- The product is not subject to corrosion due to the metal - ordinary, stainless or galvanized steel. Stainless steel corrugation has the highest corrosion resistance.

- An important property of pipes is durability. The service life of the system is virtually unlimited, and is determined by the service life of the couplings used for crimping. Some parts (O-rings) are designed to last 50 years.

- Economical technology. Construction budgets are saved due to overall low metal consumption and reduced assembly time. According to experts, costs are reduced by 20-25%.

- The products are ideal for organizing heating and plumbing systems. A stainless steel corrugated pipe for water supply has characteristics that allow it to cope with temperature fluctuations (up to freezing of the coolant) and water hammer.

Flexibility is one of the main advantages of corrugation Source amazon.com

- Practicality during use. The pipes are flexible and resist static and dynamic loads well. Bends do not affect the permeability, therefore, when using corrugated products, you can avoid fittings (connecting parts).

- The weight of corrugated pipes is insignificant, comparable to some types of polymer analogues.

- Due to the high heat transfer coefficient of metal, corrugated pipes are effective in heating systems.

- The smooth inner surface prevents the section from overgrowing; hydraulic resistance remains minimal. Pipes do not require additional flushing.

- Installation is as easy as possible; Standard fittings are used for connections. Thanks to its flexibility, utility lines can be laid in hard-to-reach places. The number of connections has also been reduced.

Material with a polymer shell of different colors Source atmosfera.ua

Corrugated pipes and fittings

Stainless steel pipes and connecting elements for its installation can be used for a long time if used correctly.

Video 3.

And the important thing is that the pipe can bend without causing damage to the entire communication. Microscopic cracks do not form in it over time, and there is also no mechanical stress at all.

This communication is indifferent to internal and external temperature differences, since this is all compensated by the possibility of expansion or contraction.

Using corrugated stainless steel pipes in the water supply system, you do not need to install special cleaning devices.

In such a pipeline, the inner side of the constituent elements is polished, so it does not retain any sediment, mold or other deposits.

The universal appearance will allow you to combine all stainless steel elements with any, even the most sophisticated interior design.

As a result, everything can be hidden under the plaster in a concrete screed, which indicates the reliability and durability of the structure.

If you need to reduce or trim the components of the system, this can be done with a metal knife, a pipe cutter, or using a grinder. The choice must be made based on the section diameter.

Application of corrugated pipe

Comparison of corrugated and conventional pipes

The main criterion for choosing stainless steel corrugation for heating is its quality and the properties of the original manufacturing material. External signs of deformation, creases or traces of corrosion are not allowed. But more difficult is checking the quality of welding - the durability of operation depends on it. On average, if the installation rules are followed, a corrugated stainless steel pipe for heating can last up to 20 years.

It is also recommended to familiarize yourself with the certificates of conformity that sellers must have. Their presence will confirm the quality and manufacturer. Additional criteria are determined by the type of corrugation:

- With numbered length. Fittings must be complete;

- With arbitrary length. You need to check the quality of the cut. The edges of the pipe cannot be damaged.

Each corrugated stainless steel pipe for heating has a certain diameter. It has a standard size so that no additional hydraulic resistance occurs on a specific section of the highway. To calculate the volume of coolant that a stainless steel heating pipe of 1 m.p. can contain. you can use the data from the table.

| Inner diameter, mm | Volume, l./m.p. | Area (m²) 1 m.p. |

| 15 | 0,219 | 0,0646 |

| 20 | 0,447 | 0,095 |

| 25 | 0,71 | 0,12 |

| 32 | 0,982 | 0,15 |

The scope of application of corrugated stainless steel pipes for heating is varied. In addition to complex sections of the main line, it can also be installed in other heating elements.

Warm stainless steel floors

Warm water floor made of corrugated stainless steel

The main property of stainless steel is its high corrosion resistance. Given the flexibility, high temperature conditions and maximum pressure indicators, most often a corrugated stainless steel pipe for heating is used to organize a heated floor.

The advantage of this scheme is the high thermal conductivity of the pipe. It is capable of uniformly heating the concrete surface of 10 cm of screed. For installation, it is best to use special mats with guide grooves.

Basic installation rules:

- The distance between turns at which maximum efficiency is achieved is 20 cm;

- It is not allowed to twist corrugated stainless steel pipes for heating in certain areas. This creates surface tension, which can lead to damage;

- Installation using additional polymer casings is not recommended. They will not increase strength, but will lead to a decrease in heat transfer.

Cutting a stainless steel pipe for heating can be done using a grinder. To do this, you need to fix the product using clamps or a bench vice.

Supply to heating appliances with corrugated pipes

Connecting a radiator to the heating system using a corrugated pipe

Due to its flexibility, a corrugated stainless steel pipe for heating can also be used to connect radiators. With its help, you can minimize the complexity of installation and reduce the length of the entire highway.

One of the disadvantages of such a connection is the complexity of manufacturing the bypass unit. Installing shut-off valves will be problematic.

Unlike a heated floor system, corrugated stainless steel must be carefully insulated before installation in heating. Large heat losses will reduce operating efficiency and lead to uneven distribution of thermal energy throughout the house.

The installation technology consists of following the following steps:

Using a grinder or a special pipe cutter, a corrugated stainless steel pipe is cut for subsequent installation in heating; Installation of a previously selected fitting. To fix it to the surface, you need to tighten the nut

It is important to control the force - damage or deformation of the pipe is possible; After final installation, the tightness of the assembly is checked.

To select a high-quality stainless steel corrugated pipe for a heating system, it is recommended to purchase products from trusted manufacturers. Currently they are Kofulso, Lavita and EasyFlex. The average cost of their products ranges from 160 to 270 rubles/m.p.

The video shows a comparison of a corrugated metal pipe with its analogues:

How to choose a suitable design

The first selection criterion that you need to pay attention to is whether the stainless corrugation has been heat treated. To do this you need to bend the pipe. If the product is annealed, then deformation will not occur. Minor changes will occur in pipes that have not been annealed.

After identifying the annealed specimens, you can proceed to selecting a model based on the following criteria:

- the kit should include a full set of fittings for connecting the pipe;

- there should be no damage to the seams (chips or cracks);

- the product must be neat, so that the corrugations show up clearly in the pitch (high-quality pipes will have the same pitch);

- when bending, the pipe should not be deformed;

- seals for fittings must be elastic and not damaged.

One of the advantages of stainless corrugated pipes is the absence of counterfeits on the market. The reason is that the manufacture of such products requires special equipment. But this fact does not eliminate the need to familiarize yourself with the packaging and the markings indicated on it.

When turning to unknown brands, you can come across cases where, in order to make money, low-quality products are placed in packaging for expensive models.

Practice of use

Corrugated pipes are widely used. Due to ease of installation, accessibility and unique properties, they are relevant in a variety of areas. Based on practice, corrugation is useful in the following cases:

- Arrangement of heating units using solar collectors.

- Warm floor.

- Connection to batteries

- Hot or cold water supply.

- Connecting dishwashers and geysers.

- Installation of taps and mixers.

- Laying cable products, etc.

The choice of corrugated pipe is due to its ability to withstand high heat and pressure up to six atmospheres. I am attracted by the ease of installation and flexibility of the material.

Features of corrugated pipes

Corrugated culverts originated in Japan many years ago. Since then, they have become indispensable not only in the markets of this Asian country, but also in Western countries, including the European market.

The main features of these components of any modern water supply system lie in their unsurpassed characteristics. They can be used for a variety of purposes, because they are very reliable, strong and durable.

Another feature of corrugated pipes is a wide selection. Each buyer will be able to find products of various diameters on the market. This will allow for the installation of a wide variety of communication systems. It is difficult to find more suitable technical equipment that would cope with this task.

Information about the joining of such products deserves special attention. This is possible using special fittings made of brass. They have all the necessary characteristics to cope with this task perfectly. In addition, they have a very simple design.

Tips for choosing and installing corrugated stainless steel pipes

When purchasing pipes and components for a pipeline system, you should remember that its high-quality installation and long service life depend on a number of factors, which must be taken into account in the process of purchasing materials. In this regard, the following should be taken into account:. During installation, you must strictly adhere to the algorithm of actions and follow the instructions

During installation, you must strictly adhere to the algorithm of actions and follow the instructions.

- When purchasing a product, it must be carefully inspected for mechanical damage and bends.

- The pipe must be strong and bend easily to take the desired shape.

- It is better to give preference to proven and well-proven brands in the construction market; do not be tempted by the low cost. The average price per meter of high-quality stainless pipe ranges from one to three thousand rubles, depending on the type of product and the type of steel used in production.

- During installation, you must strictly adhere to the algorithm of actions and follow the instructions.

- After installing the system, it must be checked for integrity using the maximum permissible pressure.

- Fittings must be complete.

- When it becomes necessary to connect a stainless corrugated pipe with another material, it is recommended to use brass fittings.

- The use of cheap, low quality fittings at the junctions of corrugated pipes can lead to a significant reduction in the service life of the system.

- You should not make much effort when tightening the plastic elements, as the plastic will simply burst from excessive pressure.

- To organize installation, it is necessary to prepare in advance special open-end wrenches, as well as metal scissors for cutting pipes at right angles.

The use of cheap fittings can lead to a significant reduction in the service life of the system.

Corrugated stainless steel pipes are characterized by practicality and reliability during operation, so the popularity of such products is rapidly growing. They are successfully used in various areas of repair and construction: in the installation of plumbing and heating, as chimneys and connections to gas appliances in the ventilation system. Their installation is quite simple, so if you approach the process responsibly and don’t skimp on materials, you can quickly and independently install a reliable and durable pipeline.

Hose for gas stove: (read more)

Installation recommendations

As mentioned above, assembling stainless corrugated systems is extremely simple. Judge for yourself: the only special tools required are a knife that allows you to quickly cut the pipe strictly at an angle of 90º. In addition, you will need open-end wrenches to tighten the nuts and that’s all. There is no need to do any stripping or chamfering; the cut pipe is simply inserted into the fitting and clamped with a wrench. Only first you need to disassemble the tee, remove all the rings and, following the nut, put it on the pipe in the same order.

The pipe must be carefully bent manually in place to the required angle, observing the smallest bending radii. They are easy to calculate: the bending radius is equal to the diameter of the pipe, multiplied by 3. Despite the fact that the product has good rigidity and low weight, the installation of stainless pipes must be done in such a way as to prevent the slightest sagging. The supports should be placed in areas of high load, for example, where fittings and connections to radiators are located. Linear elongation does not need to be taken into account; it is insignificant.

Advice. In places where it intersects with electrical networks, it is recommended to put a case made of a steel pipe on a corrugated pipe that is laid hidden. It will serve as a screen for eddy currents and protect the material from electrochemical corrosion.

As for heated floors, their installation is carried out using traditional technology. Two additional requirements must be met:

- the pipe must be in a polymer sheath;

- Joints with fittings cannot be embedded in the screed.