Gas heating of residential and industrial buildings is carried out under the control of automatic control systems.

Modern technologies allow fine adjustment of a given temperature regime, while saving fuel. This result was achieved through the use of burners with power control function.

A gas burner is a device that mixes gas and air and burns this mixture in a combustion chamber.

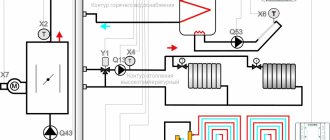

Automatic temperature control system

The most primitive system for automatic control of a set temperature with the participation of a gas burner works as follows: gas is supplied to the burner, ignited by the ignition system, and stable combustion occurs. In this case, the burner operates at full capacity.

When a certain temperature value of the coolant or air in the room is reached, the burner goes out. To maintain the set temperature, it is constantly turned on and off.

What type of burner do you prefer?

Some types of devices were developed specifically to solve such a complex problem as quickly boiling water in difficult weather conditions. These burners are ideal for cooking freeze-dried food. The special design of these systems minimizes fuel consumption, which makes them very profitable. The special manufacturing technique of these devices determines their focus on maximizing the acceleration of the process of boiling water.

Integrated cooking systems are ideal for quickly boiling water. However, their main disadvantage is that it is extremely difficult to prepare any dish with their help.

To prepare complex foods, you should choose burners with precise flame control. This is due to the fact that for high-quality cooking of different types of products, different flame strengths are needed. Such devices also boil water very well, however, the boiling time is significantly influenced by the dishes. The quality of flame control is largely determined by the product model.

Classification of gas burners by type of temperature control

With the development of technology, new, improved methods of automatic temperature control have been developed:

- Single-stage burners are primitive devices; their operating principle is described above. They work in the same mode.

- Two-stage burners are devices capable of operating in two modes (40 and 100% of total power), automatically switching between them.

- Smooth two-stage burners are burners operating in two modes (40 and 100%), but their switching between modes is carried out more smoothly, which significantly increases fuel economy and the quality of temperature maintenance

- Modulating gas burners are the most functional devices, capable of operating in a wide power range (from 10 to 100%). Such burners are capable of maintaining temperature conditions with a deviation of only 20C from the set value. At the same time, the efficiency of fuel combustion increases and the temperature loads on the elements of the heating unit are reduced.

The copper heat exchanger is the most efficient of all, as it has good thermal conductivity and thin walls. But it does not tolerate high temperature stresses well, and therefore has a short service life. In combination with a modulating burner, its service life becomes longer.

Gas burners with the ability to change the degree of combustion are expensive, but their efficiency will quickly pay for the costs:

- saving up to 30% of fuel;

- temperature is maintained within a narrow range;

- the service life of the entire unit increases.

Read about the benefits of installing a magnesium anode for a boiler in the article.

You will find information about TGE universal multi-fuel boilers at the link -

Criterias of choice

A diesel burner for a boiler is widely used due to the 100% automation of liquid fuel combustion processes, the availability of energy in all regions of the country, and the absence of the need to obtain special permits and approvals for the start of work on a diesel boiler house. Therefore, the market is oversaturated with such devices and choosing one is not an easy task.

Basic parameters for choosing a diesel burner for a boiler:

- Availability and type of fuel pump for the burner; it may not be suitable for a certain type of fuel, for example, viscous fuel oil. Before choosing a device, check the technical parameters of the pump according to the manufacturer’s passport for compliance with the required data with the fuel quality certificate from the manufacturer.

- The operating principle of the burner device depends on the existing fuel supply circuit with or without a cleaning and heating system. The first option is better and can fit a large list of liquid fuels.

- Design of a diesel burner, regarding the possibility of its installation in a boiler unit. Compliance with the requirements of the burner manufacturer and the boiler designs.

- Thermal power and degree of automation.

Basic elements of an automatic control system

Devices included in the electrical circuit of the burner for automatic operation:

- The maximum and minimum gas pressure switch has a simple design, which affects its long service life. Its principle of operation is that the gas pressure acts on the membrane, and if it deviates from the set value, it is triggered and the control valve makes the necessary adjustment. The minimum gas pressure switch protects against a drop in gas pressure to a critical value, and the maximum pressure switch carries out regulation, preventing the permissible value from being exceeded.

- The thermostat is an indicator of reaching temperature limits. According to its signal, the combustion modes change.

- The combustion controller is an element that combines the operation of the entire burner into a single process. The burner operation is divided into several points, which correspond to a certain position of the air damper and the fuel control valve. When a low temperature signal is received, the corresponding mechanisms open to increase combustion power. The controller's operation is based on signals from various sensors (pressure, temperature).

- Minimum and maximum coolant pressure relays protect the heating system from excessive drops and increases in coolant pressure. Both cases are dangerous for the continued operation of the boiler, therefore, when a critical value (lower or upper) is reached, the boiler turns off, that is, the gas supply stops.

- The boiler filling sensor is needed to provide protection against turning on the burner without the presence of coolant in the boiler.

Connecting the sensors depends on the brand of the boiler; this information can be found in the unit’s passport, and the specifics of connecting the sensors are described in detail in the attached instructions.

The connection and configuration of the automation system must be supervised by a gas service specialist. Commissioning work is also carried out in his presence with the mandatory drawing up of a certificate of suitability of the equipment for safe operation.

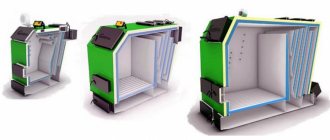

Design and principle of operation

From the storage tank, diesel fuel is pumped to the burner device. To ensure the required fuel pressure, the pump is equipped with a recirculation line to discharge diesel fuel unclaimed by the burner. At the supply level, a fuel purification system is installed in front of the nozzle, consisting of two types of purification: first, it passes through a coarse filter, where mechanical impurities are removed, and just before the burner, the diesel fuel heated to operating temperature passes through a fine filter.

Next, the diesel enters the nozzle, and, mixing with air, lights up from the igniter, the torch burns in the combustion chamber, its shape is regulated by special blades that create an air flow that swirls the atomized fuel particles. Electrodes are installed in front of the injector, igniting the air-fuel mixture. The process is fully controlled by safety devices.

The air supply is forced by a fan; pressure sensors regulate its volume. The combustion chamber is designed in such a way as to ensure complete combustion of the liquid energy carrier at operating temperatures. Flue gases are removed through the gas path by a smoke exhauster, the operation of which is also automated based on pressure drops in the path. It is regulated by air dampers and the guide vane of the smoke exhauster.

Diesel burner device

1

Design features

To make the right choice of device model or components for self-production, the buyer needs to know the key factors that need to be paid attention to. These primarily include equipment, compliance with standards, types of units, what they can be made from independently, and the like.

A diesel burner must include the following key elements:

- fuel pump;

- pressure gauge;

- nozzle;

- divider;

- ignition equipment;

- fuel heating tank with pre-installed electronic heaters.

This set is the main one. But this does not mean that it cannot include additional elements. For example, a vacuum gauge, temperature and flame control sensor, which will give a signal to stop fuel supply when the fire goes out. The vacuum gauge records the level of soot and nitrogen in combustion products.

By using such a device during testing, you can not only significantly save your budget on heating bills, but also get rid of unnecessary used oil. If a gas main is not connected to the house, then it is better to install the burner in the boiler and make a water circuit. Thus, you can completely solve the heating problem.

Making your own Babington oil burner

Types of automatic control systems for gas boilers

There are control systems of various brands and purposes, but they all work on similar principles, the only difference being the functionality of the system and its dependence on the electrical network.

All equipment can be combined into three main groups:

- non-volatile;

- volatile wired;

- volatile wireless systems.

The non-volatile gas boiler control system is the very first automation for heating equipment. Its operating principle is based on the physical law of expansion of a material when it is heated.

The approximate effect of this law can be considered using the example of a thermometer - when heated, mercury expands and rises up the tube attached to the scale. The reverse process occurs upon cooling.

To learn about the operating principle of combi heating boilers, click here.

For information on how to create a kitchen design with a gas heater, read the information at the link -

Also read about the Buleryan furnace-boiler, the principle of its operation and the main types.

Now imagine that a similar design is installed inside the boiler and measures the temperature of the heated coolant, only instead of mercury, another material (metal) is used.

When heated, it expands and acts on a lever mechanism that stops the gas supply. As soon as the coolant cools down, the metal contracts, acts on the lever, and the gas supply is resumed.

The energy-dependent gas boiler control system operates from the electrical network - this creates inconvenience, but in return the functionality of the equipment increases. The main element of such systems is a thermostat.

Depending on the temperature conditions, it supplies an electromagnetic pulse to the gas valve. But with the help of a special program, it becomes possible to program the temperature regime for several days, weeks or months in advance.

The non-volatile wireless gas boiler control system operates on the same principle as its wired counterpart. The difference is that the wireless automation control module is located in any place convenient for the user, and is not connected by wire to the unit.

Some systems provide for the installation of a GSM module, which provides access via a mobile device (smartphone, tablet). To get the latest data on the status of the equipment, you need to go to the application on your phone and enter the password.

Through a mobile device, it is possible not only to control, but also to control the boiler. And if an emergency occurs, the system automatically sends a notification in the form of SMS to the specified number.

Modern technologies are capable of providing full automatic control over the operation of an autonomous heating system, without creating unnecessary hassle.

Modern heating and hot water systems use various types of burners to ensure reliable and efficient operation. The choice is most often related to the characteristics of the installation location and the requirements for heating equipment.

Staged burners provide power control in 1-3 modes, which is not enough in many production processes. To increase the reliability and efficiency of boilers and heat generators, burners with automatic power control are installed.

Practical recommendations

• To ensure that your money is not wasted, it is better to consult with a specialist regarding the purchase of a boiler with a modulating burner. There are so many nuances of choice that it is hardly possible to take them all into account without specialized training. And if we are talking about a device with such a (smoothly controlled) burner, even more so. • It is advisable to buy a heating unit from a company that has its own service center. This ensures that in any situation the user will not be left alone with the problem that has arisen regarding the boiler or the system as a whole.

ALFATEP has been working in the field of engineering communications for several years. She will always help owners of buildings located in the Moscow region in solving problems related to heating buildings and structures. Its warehouses have a significant assortment of relevant equipment, and its staff includes qualified craftsmen. You just need to call the ALFATEP contact phone number, and its employees will help you choose the optimal boiler model, taking into account all the features of the house and the heating scheme. If necessary, they will develop another one, deliver the device to the site, install it, carry out proper wiring and test it in action. The company also guarantees technical support for the devices sold, and service specialists (upon concluding a contract) are ready to take on the responsibilities for post-warranty maintenance and repair of equipment.

The principle of modulation in burners

Modulation is a smooth change in boiler power in automatic mode. This principle allows you to most accurately regulate the operation of heating equipment and maintain the set temperature. Considering that only 20% of the time the boiler operates at full power, to reduce costs, more economical equipment is used - modulated liquid fuel or gas burners, which maintain the temperature at a given level.

The burner power automatically adjusts to the conditions required for heating or water heating. With the help of such devices, the boiler consumes as much fuel as is needed at the moment and the flame height is adjusted depending on changes in fuel consumption.

How does a modulating burner work?

Unlike stepped burners, which use mechanical connections of control and actuator mechanisms in the form of levers, pins, rods, modulating burners use an electronic control unit. Servomotors are connected directly to the air and fuel supply devices, which eliminates mechanical errors and ensures the accuracy of setting the set temperature to 0.1 degrees.

With the help of the fuel flow regulator and the ignition system, the fuel mixture is ignited. Then the servo drive smoothly opens the fuel supply valve until maximum power is reached. After which it automatically continues to regulate the combustion intensity and burner performance, reducing or increasing power depending on the required amount of heat.

General operating rules

Before starting the burner, you must carefully read the factory instructions and the requirements of government regulations regarding the safe operation of boilers and burners operating on liquid fuel.

After completion of installation and commissioning work, the owner of the boiler unit must familiarize the operating personnel with the rules of operation of the boiler equipment.

The procedure for putting a liquid fuel burner into operation:

- Check the correctness and functionality of electrical lines, grounding systems and boiler safety.

- They check and test the operation of diesel fuel supply lines: pump, fittings, safety devices.

- Check the tightness of all fuel supply elements, including fine and dirty filters. If there are leaks, they must be repaired.

- Remove air from the fuel supply system through a pressure gauge on the diesel pump. Do not operate an empty pump for more than 5 minutes.

- Remove air from the boiler and heating system.

- Check for leaks in the boiler and heating circuit.

- Check the operation of the boiler's automation and safety circuits.

- Check the operation of the smoke exhauster and fan.

- The smoke exhauster is put into operation in accordance with production instructions and boiler operating charts.

- After ventilating the furnace, under stable conditions of the boiler equipment, the burner device is put into operation, the fuel and air consumption is adjusted for complete combustion.

- Monitor the operation of auxiliary equipment: pumps, smoke exhauster, fan.

- Check the functionality of the automation and security systems.

- In case of violation of the boiler operating mode, it is stopped in an emergency order, and the supply of diesel fuel to the boiler is stopped.

The operating principle of an oil-fuel boiler with a diesel burner

Blitz tips

- Recently, combination burners have been gaining popularity. These are some of the safest structures, but at the same time they are very complex. Their efficiency is quite high, but the price also makes itself felt.

- The burner of a gas boiler should be cleaned if the gas consumption in the room begins to noticeably increase, if there is some kind of unpleasant odor, if, despite all the indicators remaining unchanged, the air temperature in the heated room begins to noticeably decrease.

Private gas sector: selecting and installing a boiler

The army of gas boiler buyers accounts for approximately 60% of the total number of boiler buyers. Blue fuel is the most profitable for owners of private houses. To choose, you need to understand what they are. We will build on your needs and capabilities.

Do you have a big house or a small one?

You need to choose from floor and wall. They are designed differently. Wall-mounted ones are good for buyers with limited space. Suitable for an apartment or small house (50-350m²). Power range 10-40 kW. They are compact and easy to install. There is a lot to choose from among the models based on design. All wall-mounted boilers are a small boiler room, where all the necessary equipment for heat supply and hot water supply (DHW) is built in: a heat exchanger, a membrane tank, equipment control and safety elements, a circulation pump. And you don't need to buy anything else. There is a line of boilers with modulation - the burner controls the gas flow and supply. The owner sets the water temperature, and it is maintained unchanged, even with changing water flow. Fuel is consumed in an economical mode.

Operating principle of combination burners

Combination burners are the most advanced devices; they are used only in high-power units and energy boilers, when the technology requires burning several types of energy fuel.

They are installed in cases where there is an unstable supply of one type of fuel:

- there are interruptions in the supply of main gas or it is transported to consumers with low pressure, and it is urgently required to transfer the boiler to backup fuel;

- low consumer quality of gas, unable to provide the required temperature conditions;

- with a night gas supply schedule in a power plant, when there is a night mode for equalizing daily gas consumption in the area where the thermal energy source is located.

There are several types of combined burners: gas-oil and gas-coal. The first ones are most widespread and, as a rule, are produced with forced air supply for both medium and high gas pressure. The installation of such combined devices provides the greatest effect than the parallel operation of gas and fuel oil nozzles or gas and pulverized coal devices separately.

Such modifications of universal burners are installed according to the requirements of reliable and uninterrupted operation of powerful industrial or power boiler houses, in which stopping the production of thermal energy is unacceptable.

What does flame modulation do?

Those who take a practical approach to any task and are accustomed to spending money rationally should pay attention to these types of devices. The meaning and benefits of smooth flame control are easy to understand.

• Fuel consumption is optimized. Automatic regulation of flame intensity makes it possible to achieve - in terms of the season - a reduction in the cost of heating the building. • If the boiler is double-circuit, then the volume of consumed hot water does not affect its temperature in any way - it remains unchanged. • A decrease in gas pressure in the main pipeline (and this is not uncommon in winter) does not affect the efficiency of gas equipment. • The risk of failure of some boiler elements is minimized. Statistics on equipment repairs (of any type) show that the main cause of all malfunctions (up to 90%) is various switching. Therefore, step modulation clearly loses to smooth power control.

An atmospheric gas burner is installed in boilers with an open combustion chamber. The type of operation is very similar to a simple gas stove: gas enters the burner and burns when mixed with air coming from the room.

The positive features of an atmospheric burner are its simplicity of design and silent operation. Disadvantages: low efficiency (up to 90-93%) and rarefaction of air in the room. It is for this reason that such boilers are installed in specially equipped rooms, combustion chambers, which are equipped according to special rules.

There are several nuances in using imported atmospheric gas burners.

According to EU standards, the mains must have a stable gas pressure of at least 150 atmospheres. In Russia, these standards are similar, but may fall in winter and rise in spring. Such pressure drops lead to burner burnout in winter and heat exchanger burnout in summer. This means that in areas with unstable gas pressure it is better to use inflatable burners, the operation of which does not depend on gas pressure.

Gas sauna stove

The appearance on the market of sauna heaters powered by a gas network has made the life of steam room owners easier. The compact unit performs the functions of a traditional oven. The device is economical and easy to use. Suitable for Russian bath, dry sauna, Turkish hammam.

The cost of the device directly depends on the material of manufacture. Metal options belong to the economy class segment. A brick installation with a built-in inflatable burner is more expensive. The model is considered to be of high quality, effective, and safe. The features of a gas heater for a bath should be considered in detail.

Advantages

It is worth deciding on the type of heating bath equipment at the design stage. The market is filled with many models of heaters that use wood, electricity, and gas as fuel. Gas models in a wide range appeared on the market five years ago. They are widely popular for the following reasons:

- affordable price for the masses;

- widespread gasification.

Don’t forget – gas in the post-Soviet space is cheaper than electricity. During operation, the device is more profitable than its analogues.

The advantage of a gas appliance is its versatility:

- maintaining temperature in the steam room;

- heating the water supply in the tank.

The heating process occurs due to combustion products. Waste is removed from the premises through a chimney. The water in the tank is heated during the process. A tin water tank is located under the heater, above the heating device, and placed in the adjacent room.

Gas appliances are more environmentally friendly than their analogues. With the help of such a heater, the steam room warms up in 20-30 minutes. Heating of a bathhouse depends on the size of the building, wall material, and seasonality. On average, in summer the process takes up to 3 hours.

Combined models occupy a separate niche. Gas-fired stoves are popular in Russia. The design allows you to work on two types of fuel: gas and wood.

Device

The design of a gas stove resembles a classic wood-burning or electric model with additional elements: the model is equipped with a fuse. The mechanism will stop supplying gas if the burner goes out.

The structure of gas equipment is described below:

- Gas burner with fuse. The function of the element is to maintain the set temperature. The fuse is responsible for emergency situations in the system. The burner (inflatable model) depends on electricity.

- Firebox with built-in chimney system. Combustion products are discharged by the system to the street. Thermal energy is used without loss.

- The heat exchanger is a removable device. Additionally installed in the firebox. Its function is to heat the water tank. The container is placed in an adjacent room. The tank is installed in the washing room.

- The tunnel is a rigid structure. The element allows you to place the firebox in an adjacent room and makes using the stove convenient.

- Ventilated space of the heater. The design ensures quick heating of the stacked stones.

- Convector that creates an optimal flow of hot air.

- The ash pan is intended for servicing the stove and removing combustion products.

The design principle of most devices is similar.

Main types of devices

It seems that the principle of construction of such heaters is the same, and is also based on a burning flame that warms the air. At the same time, warm air fills the room and provides the required temperature. But it's not that simple. The operation of many modern equipment is based on the use of newer technologies for the generation and movement of heat when creating. So both the instructions and operating features of different types of gas heaters can differ greatly from each other.

All gas heaters can also be divided into several groups:

- warm gas guns (strong heat fans);

- infrared outdoor heaters;

- catalytic gas devices;

- ceramic gas products;

- gas convectors for stationary use;

- Convenient portable gas devices.

Despite the rather distinctive principle of device design and operation, all equipment of this format is characterized by approximately the same set of advantages and disadvantages.

The advantages of the device include:

- Network or liquefied natural gas is considered more affordable in price than all other energy carriers. This type of heating will not require the user to spend money on operational repairs. Some types of designs include a connection to the power supply, for example, to ensure full operation of fans and the functioning of the main control units. Energy consumption in such devices is minimal, so it does not affect the family budget in any way.

- The design of many gas heaters is quite simple and does not have any complex components. This helps to increase the reliability and safety of using such equipment.

- Modern models of heaters have a high efficiency, that is, this indicates their efficiency and economy. Some models of heaters are distinguished by a high level of mobility - they are very small, easily moved from one place to another and transported by transport. Some types of devices can even be taken with you outdoors, on a hike, or fishing.

- The operation of such devices causes almost no harm to the ecological system - the products of complete combustion of gas are considered harmless.

- These devices are usually easy to use.

- Warming up of the room takes place in a short period of time - the devices are not inert in operation. Gas heaters respond very quickly to changes in their settings.

- More modern models in this class include a multi-level protection system that helps protect a person and minimize the possibility of a threat developing.

- Many devices are distinguished by high performance capabilities - they can work efficiently for more than ten years.

Of course, like all devices, such heating devices also have their drawbacks. These include:

In any gas heater for a summer residence, the fire hazard cannot be completely eliminated, since in this case highly flammable fuels are used, and their operation occurs with high-temperature heating

Such devices require special care and compliance with all safety rules. You cannot leave them unattended if there are small children in the family. Unburnt natural gas is considered quite toxic, so even a minimal leak can result in severe poisoning

It is this fact that imposes additional requirements for careful use. Gas combustion must occur with a regular supply of oxygen; in many devices it is taken directly from the room itself where the heater is located. This means that you also need to take into account the supply and exhaust ventilation system so that the room does not have a heavy and uncomfortable atmosphere for humans, which in some cases can even be harmful to health. And also the requirements for creating ventilation refer to additional air circulation if there is also a gas stove in the room. If with water or electric heating such indicators are sometimes not paid any attention, then in the case of using gas heaters, a neglectful approach to the ventilation system is extremely dangerous.