In the vastness of our homeland, there are a huge number of places where there is no electricity or gas supply. This makes living in houses built in such conditions, even for a short time in autumn, winter or early spring, very problematic. Building a stove or fireplace is too expensive.

But what about those who live or work there on a permanent basis? How to create comfortable living conditions around the clock and organize a good and inexpensive heating system?

The answer is clear - a potbelly stove! This metal structure will provide heat to a small cottage, and you can also cook food on it. Thus, it performs two functions simultaneously.

How much area can be heated with a potbelly stove?

Potbelly stove power. Conventionally, 1 kW of furnace power is assumed per 10-12 m2 of room area with a height of 2.5 m in a well-insulated house. But when choosing the power of the furnace, it is still better to consult a specialist. Furnaces available on the market have a power from 3 to 17 kW, that is, they can heat a room with a volume of up to 420 m3.

Interesting materials:

How to reset a locked iPad to factory settings? How is communal heating calculated? How is the percentage of road slope calculated? How is the Lamod redemption percentage calculated? How are CT points calculated for admission? How are octaves counted on a harp? How are steps counted on a fitness bracelet? How to read gas meter readings? How to sit on the courts in GTA 5? How are points burned at Fix Price?

Pros and cons of bourgeois stoves

A potbelly stove is a fairly safe stove with a simple design.

At home, you can assemble a bourgeois stove yourself. It is enough to have basic welding skills. A homemade stove will not be inferior in functionality to a purchased potbelly stove.

Some fuel is needed to heat the room. One fire of wood is enough for several hours.

- The potbelly stove is quite compact and does not take up much space. If you improve the structure by covering it with bricks, it will also not take up much space.

- Design. Modern potbelly stoves not only improve functionality, but also their appearance. A variety of stove design options are available for sale.

- The disadvantages include the fact that the stove is not suitable for houses with a large area and permanent residence. For such premises, more powerful stoves are needed.

- High consumption of solid fuel.

Correct kindling

The process is actually simple

...but only if you have experience working with a potbelly stove. A beginner should do the following:

- Crumple the paper and place it on the grate.

- Place birch bark and brushwood on top of the paper.

- Then place two small logs. Firewood is an important element for a potbelly stove. They should be used at least for warming up.

- You should set the paper on fire with the blower half open. He is responsible for controlling draft in the furnace. There is no need to put a lot of firewood into the stove at once. The main thing is to control the traction force.

Why do you need a brick?

When a potbelly stove gets red hot, it poses a great danger. Even if you take into account all the fire safety tips, you can simply get burned on this structure. In addition, the oven cools down quickly, which is its disadvantage. Many people came up with the idea of covering the structure with bricks because:

brick retains heat for a long time, which accumulates and gently releases it to the room;- It is very problematic to burn yourself with a brick;

- the appearance of the potbelly stove becomes much more presentable with good cladding.

How to do it?

First of all, you should take into account the advice of professionals:

- — the brick must be laid on a clay or special adhesive solution;

- — it is necessary to make several air channels so that air penetrates into the room;

- - the first time after cladding, the potbelly stove should not be heated at full strength in order to strengthen the fastening seams between the bricks;

- - any brick can be used - fireclay, ceramic, but not facing.

The masonry technology is classic with a sling. First, the two side walls are covered, then the back. The front remains open. If you have design ideas, then you can realize your fantasies, everything is in your hands.

Security measures

To safely use the stove, you must follow the following rules:

- the stove must be installed only on a fireproof base;

- any flammable objects must be removed from the stove by 70-80 cm;

- simultaneous loading of fuel should not exceed three kilograms; The firebox door must always be kept closed. It can only be opened to load fuel;

- if the exhaust pipe has any damage, its operation is strictly prohibited;

- The operating oven must always be supervised. It especially cannot be ignored if there are small children in the room;

- Do not touch the oven body while it is running or after the flame has gone out. The heating temperature is very high and can cause severe burns.

If you follow all the above rules, you can operate the “potbelly stove” for many years.

Installation work

For water heating in the garage you will need a set of instruments and parts, including:

- heating boiler;

- metal radiators with good thermal conductivity;

- connecting pipes made of metal or plastic;

- accessories for fastening;

- locksmith tools.

Project development

Before installing the heating system, you need to determine the diameter of the pipes that will connect the radiators. Risers with a large cross-section will increase the flow of hot water to the batteries, increasing the efficiency of the design.

It is worth considering that heating large volumes of liquid will lead to increased electricity costs. The optimal scheme is a balance between the room temperature and the cost of heating. These parameters are also affected by the number of radiators in the insulated garage.

Expansion tank

The design of the garage heating system involves the use of expansion tanks. These items are made from simple plastic containers or large canisters with fill holes cut in the top.

The water circulating in the system constantly evaporates and requires regular addition of liquid, and the steam formed during boiling needs to be removed. The tank is installed at the lowest point of the heating system and at a half-meter distance from the floor.

Boiler

Before installing the boiler with your own hands, you will need to prepare a metal pipe of a certain diameter with a half-meter or meter length. Its extreme end is tightly welded with a metal sheet.

The next step will be assembling flanges for attaching tubular electric heaters and fixing them to the boiler using bolts. To supply the working fluid to the installation, two sections of pipe with the diameter that will be used in the heating system are welded.

Radiators

Heating batteries are attached to the walls of garages using special reinforced dowels. The distance from the floor to the radiator should be at least fifteen centimeters. For effective heating, you need to leave a few centimeters of free space between the walls and the heating elements for air circulation.

The individual structural elements are connected into a system using metal or plastic pipes with special fittings. The seams of their joints and forks require special attention during installation so that leaks do not occur in the future during operation.

Installation

The connection of metal pipes is carried out using a welding machine. Working with polypropylene will require the use of a special soldering iron. Regardless of the material of the pipes, they should be placed on the walls at a slope - this will improve the circulation of liquid.

The water heating system is considered ready after connecting the radiators to the risers and connecting them to the boiler using a rubber hose. Before starting operation, it is recommended to re-inspect the line, search for defects and seal problem areas.

Places of use

The design is quite appropriate for living spaces, as it quickly provides the necessary heat and allows you to prepare tea or coffee, as well as quite complex dishes.

It is also often used for heating non-residential premises. You can install a potbelly stove in construction or security trailers, sheds, greenhouses, garages and other premises for various purposes.

If the heating area is large enough and maintaining the temperature is vital, then you can opt for an installation with a water circuit.

The stove can operate on wood, waste, peat, briquettes, etc.

Range of applications

Potbelly stoves are universal and are used:

- for heating cottages, country houses, rooms or garages;

- for cooking in the country: in houses, on verandas or even in the yard;

- as a camp kitchen if the model is compact;

- to provide hot water (if the model has a storage tank).

Read More at pechinfo.ru/material/iz-metalla/konstruktsiya-metallicheskoj-pechi-dlya-bani?preview_id=818&preview_nonce=a837fab63d&preview=true © PechInfo[/box]

How to choose: parameters

Before purchasing a potbelly stove, it is important to pay attention to some design parameters.

Device weight

For small country houses and small-sized premises, it is recommended to choose lighter stove designs. If a heavy device is purchased, then it is necessary to strengthen the floor, and when it weighs more than 500 kg, an additional foundation will be required.

A potbelly stove is not only a heating device, but also an interesting decorative element

Potbelly stove power

Everything is simple here. When choosing a potbelly stove, this parameter will depend on the operating conditions, in particular, the size of the room in the apartment or country house where you plan to install the stove. The larger the room, the more powerful the device is recommended to purchase.

Choosing a chimney

There are stoves with a horizontal or vertical type of chimney. The most popular are models with a universal smoke exhaust system.

Duration of use

More complex (and heavy) designs of potbelly stoves are designed for long-term use, while simpler options are recommended for use for a short period of time. The recommended combustion interval is usually specified by the manufacturer.

Functionality

In conditions where there is no gas or electricity (for example, in a country house), they opt for multifunctional potbelly stoves, with which you can heat water and even cook food. In city apartments these functions are optional.

How to choose material

The most reliable option is a cast iron potbelly stove with thick walls. And if the surface of the device is finished with ceramic tiles, it will be even more convenient to use: during operation of the stove, the cast iron (or other metal) from which it is made heats up, which can cause burns. Ceramic finishing prevents this danger.

Review of products from world brands

There are many potbelly stoves on sale today, ranging from purely utilitarian ones to retro-style products. At the same time, the units differ in appearance, design features and price. Due to the fact that the range of stoves is now huge, buyers are interested in the question: what brands of products are in demand? The most popular potbelly stove brands are:

The Guca Prometej stove has excellent thermal characteristics and a unique design

- “Vermont Castings” – the products of the Canadian company can safely be called a standard. Advanced technologies and the latest materials are used in production, so the efficiency of stoves and their aesthetic characteristics are constantly improving. Potbelly stoves from this brand have many advantages: fire safety, ease of assembly, quick kindling, high productivity. Plus, the units are equipped with a perforated double firebox. In a potbelly stove, more than 90% of the chemical compounds found in flue gases are burned. From this we can draw a logical conclusion: there is no negative impact on the environment and people.

Modern potbelly stoves that burn wood or coal have excellent performance indicators. They look original and effectively complement the interior. But you need to understand that the installation of units must be carried out by qualified specialists. This is the most important aspect that deserves the close attention of owners of dachas and country cottages.

Homemade products

Homemade potbelly stoves can be divided into three groups:

- Well thought out, embodying useful ideas.

- Efficient, but not sufficiently developed.

- Just curiosities.

Good

Brick stove for a bath

Among the good ones, first of all, I would like to note a potbelly stove made of brick for a bath, the diagram of which is shown in Fig. on right. Generally speaking, brick is contraindicated as a material for a potbelly stove; it was originally designed for metal. But in this case, the author successfully solved all the problems, creating a stove that was much simpler to make and required less material than a regular bathhouse. True, its efficiency, due to the absence of a hog in the chimney, is unlikely to exceed 40%, but for a sauna stove this is not the main thing.

The second design is the already mentioned potbelly stove in development. Its diagram is shown in Fig. lower left. It would seem, what would be simpler - bend the upper end of the gasifier and put it in the vent of the potbelly stove under the grate, which will become the afterburner chamber (afterburner)? The grate will play the role of a hot gas choke, similar to an incomplete partition in the afterburner of conventional furnaces during mining.

Scheme of a potbelly stove during development

But it's not that simple. If the gas exchange holes in a curved gasifier are distributed, as in a straight vertical one, evenly along its generatrix, then the gas column in it will bunch up into a rushing pulsating rope. This is an emergency mode, fraught with fire and even explosion.

The mechanism of this phenomenon is subtle; there are several reasons, including uncompensated Coriolis forces arising as a result of the rotation of the Earth. But the principles of constructing an oil attachment for a potbelly stove are simple:

- The total number and diameter of holes in the gasifier remain unchanged.

- From a quarter to a third of them are located evenly around the circumference on its horizontal part.

- The rest are drilled in two rows on the side surface of the curved and vertical parts symmetrically relative to the longitudinal vertical plane of the gasifier.

It is unknown whether the author of the design shown on the trail came. rice. on the right, to the same conclusions by inference and calculation, or by a series of experiments; I must say, quite risky. But, judging by the nature of combustion visible in the picture, his product is quite functional and provides good efficiency.

Potbelly stove in action

I would like to add only one thing: to save space, especially in the garage, it is advisable to tuck the fuel tank under the stove. To do this, you need, firstly, to lengthen its legs to 400-450 mm, reducing the vertical part of the chimney accordingly. When firing by working out the efficiency, this will not worsen.

Secondly, there is a temptation to place the filling hole (also known as the air throttle) next to the gasifier, so as not to put your hand under the hot stove. This should not be done under any circumstances! Otherwise, the combustion of the oil in the tank will become unstable, it may be released into the gasifier, and this is a 100% fire near the car and fuels and lubricants.

The filling hole should be located in the corner of the tank farthest from the gasifier. Right or left - it doesn’t matter, depending on the location of the stove in place. To add fuel (the furnace cannot be extinguished during testing until all the oil has burned out and the stove has cooled down), you need to use a funnel with a long curved spout, strictly observing fire safety rules.

Video: description of a homemade welded potbelly stove

Workers, mediocre

Potbelly stove from a barrel

A common homemade potbelly stove is made from a barrel. At first glance, it’s not bad: a regular 200-liter fuel barrel has a diameter of 600 mm. A hexagon with a side of 314 mm fits into such a circle, which provides the necessary technological allowance when installing standard furnace appliances. However, the efficiency of a barrel stove turns out to be no more than 15%, and if you try to increase it by shielding, the stove burns out in less than a season with regular firing.

The reason is not only the thin metal, but also the too high height of the barrel: 850 mm. The height of the firebox of a potbelly stove should be 1.3-1.5 times less than its depth. If you raise the grate and make the ash high, then the lower part of the stove will take away the heat necessary for the correct gas dynamics of the potbelly stove from the combustion chamber and give it to the air. There are two possible ways out:

- Wall up the barrel a third or half its height in brick, as shown in Fig. on right.

- In the upper third of the stove, install a refractory-lined oven through which the chimney will pass.

In both cases, the work becomes more complicated, and the stove will last about 5 years, no more, due to the same thin metal. And the efficiency will be no higher than 20%, another size ratio plays a role here: the depth of the firebox should be approximately twice its width, otherwise the internal gas vortex will not be able to form properly.

The second popular option is a potbelly stove made from a cylinder. Industrial, narrow and tall, will definitely not work. Unless you cut out most of its middle and make a mini potbelly stove. But at the same time, other factors will manifest themselves, see below.

A household gas cylinder is more suitable in size. For a potbelly stove you have to put it on its side: if you use a standard neck under the chimney, then the efficiency of more than the notorious 5-7% will not work. The stove's chimney should be located in the far part of the firebox. And in a potbelly stove made from a cylinder on its side, it is very difficult to install/remove the grate and adapt an air throttle to it, so it is of little use for slow burning.

In both cases, the roof and roof of the furnace are curved, cylindrical or spherical. Both are contraindicated for a potbelly stove. All its gas dynamics were initially calculated for a flat roof and vault. Rounded in one or two planes, they will knock a wide gas vortex into a bundle, which, without having time to burn out properly, will carry heat with it into the pipe. A hog on the chimney will not help, so that the bundle in it has time to unwind, burn out and cool down; it needs a length of about 12 m.

Video: homemade potbelly stove from gas cylinders

Curiosities

Of the curious structures embodied in metal, the most noticeable is the gas stove. Insert a propane torch into the firebox and you’re done. It burns, but this “improvement” consumes a gas cylinder faster than a heat gun. The reason is that the potbelly stove is in no way designed for gas. All gaseous fuel furnaces must have, regardless of the burner design, a developed internal heat exchange surface: fins, hot water register, etc. Gas is an extremely energetic fuel; combustion products are very light and quickly pass into the chimney. There is nothing in the potbelly stove that could hold them back until the heat is released. In terms of design, a good gas stove and a potbelly stove are antagonists.

As they say, for the sake of humor, it is worth mentioning the potbelly stove... from an aluminum 40-liter milk flask! The sources only contain diagrams, which is quite understandable: how would the “authors” heat a furnace made of a material with a melting point of 660 degrees Celsius?

Video: an unusual, not quite potbelly stove made from car rims

Historical excursion

The history of the term “potbelly stove” takes us back to the beginning of the 19th century, when their first designs appeared. Initially, the stove was used as a heating device in the apartments of especially wealthy citizens. This is where the name “potbelly stove” comes from.

During the NEP it was also popular. Then each family received a plot of land for use - a “suburban garden” (the same dachas). There, small-sized, unpretentious stoves were used.

Potbelly stoves were produced in large quantities at factories and for the needs of the Red Army. And more advanced designs, artistically designed and decorated, were even exported outside the USSR.

Advantages of a heating device

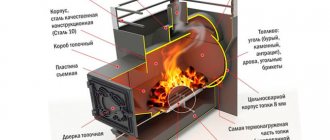

The potbelly stove today has many capabilities. It allows you to instantly warm up your home, without requiring significant financial outlays from the home owners. The product is necessary in cases where it is necessary to heat a room where it is not technically possible to create a full-fledged heating system. This device is used for effective heating of country houses, private garages, greenhouses, and other non-residential buildings. The stove usually has a rectangular shape, a door, a chimney, and a drawer in which ash accumulates. The fuel for this device is firewood, peat and other materials.

Advantages:

- Product availability. To manufacture it and purchase fuel, you do not need to spend a lot of money.

- Simplicity of design, which allows you to make the device yourself.

- The compactness of the device allows it to be used in rooms with a small area.

- For efficient operation of the device, you do not need a foundation or a major chimney.

Modern multifunctional models are equipped with a hob and oven for cooking. The disadvantages of the device include its rapid cooling after the wood burns out. Today, manufacturers have managed to solve this issue by equipping the device with a special function that ensures slow burning. When fuel burns, air circulation inside the stove slows down, which facilitates the transfer of heat to its surface. Models with legs ensure safe use of the heating device. Legs made of metal prevent the device from coming into contact with the flooring, which eliminates the possibility of fire.

Modern models have hermetically sealed doors made of heat-resistant glass framed in metal. They do not allow smoke to enter the room. Special valves are installed on the air intake openings of the ash drawer and the door, thanks to which the air supply can be easily adjusted, which affects the combustion intensity. The internal surfaces of the device are finished with heat-resistant materials, which protects the metal from overheating and helps retain heat. The device is re-burned to increase efficiency and reduce the temperature of the smoke entering the chimney.