Our material today contains a review of an automatic gas water heater (AGV 80), the technical characteristics of which are designed for use for local water heating of premises and providing hot water. Let's consider the parameters, features of the device, operating rules and other equally important nuances regarding its operation.

AGV 80 technical specifications Source Avito

Specifications

The heating device is designed to work with water heating systems and is capable of providing optimal heating of rooms up to 60 m2. The combi boiler is also equipped with a storage tank for simultaneous heating of water. Storage volume is 80 liters, heating time is no more than an hour (depending on the temperature of the supply and dispensing liquid).

General technical characteristics of the AGV-80 are presented below.

Technical and operational characteristics of the water heater of the AGV-80 unit Source pandia.ru

In terms of operational indicators, the unit showed average gas consumption and relatively good efficiency. However, it should be emphasized that the water heater was put into mass production in the early 70s. last century and had no analogues among its own.

Over the years, with the advent of other, more modernized devices running on natural gas, the device has retained good technical and operational characteristics. This is confirmed by the fact that the AGV-80 is still in service today.

Below are the passport data of the AGV-80 water heater.

Data sheet of the AGV 80 water heater Source pandia.ru

Healthy! Despite the impressive volume of the water heating tank, the unit is characterized by small dimensions. Just over one and a half meters in height and 41 cm in diameter.

Hello from the past or a new breath

Old-style devices are still found in homes today, so it is not recommended to dispose of them, throw them away or sell them for scrap for the following reasons:

- they will also come in handy as a temporary heating option before purchasing a modern boiler;

- in case of a lack of funds, they will become an inexpensive alternative to a leaking boiler.

If we consider the disadvantages: like an unattractive appearance or excessive massiveness, then they pale in comparison to the durability and reliability of such gas boilers, because there is nothing to break in them:

- there is no fancy imported automation that malfunctions;

- the seams of the metal body are securely welded and do not leak;

- The set of components and repairable parts is minimal.

Retro style speakers

Now it has become fashionable to use old-style gas boilers in rooms designed in modern, industrial, steam-punk or retro-chic styles. Rough details complement the severity of these styles, and the devices still work reliably and without failure. Photos with examples of such extraordinary interiors fill the pages of glossy tabloids.

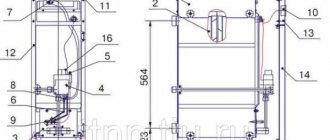

Device

The AGV-80 body is made of galvanized welded metal, resistant to corrosion as a result of constant contact with water. The inside of the tank has additional thermal insulation that protects the liquid from rapid cooling. In fact, the entire structure can be divided into 3 parts:

- Upper, with hot water outlet pipe, safety valve, thermometer coupling and chimney draft breaker.

- The middle one, shown in the schematic image as the main water tank. A chimney pipe with a draft stabilizer is installed inside it.

- Bottom, working part. It contains the main components responsible for the operation of the unit: a burner with a thermocouple and an igniter, the gas supply is regulated, and “fresh” cold water is supplied.

Construction of the first Soviet gas water heater AGV-80 Source pandia.ru

Work node device

The temperature of the liquid in the reservoir is controlled by a thermostat. It refers to devices operating on a two-position principle (in the “open” or “closed” position). Due to this, the water temperature automatically changes. The change in intake valve position is directly related to the response of the brass thermostat tube.

Located inside the container, it is sensitive to temperature changes in the liquid and, depending on its value, is capable of linearly increasing in size. This sends a signal to the invar rod. That, in turn, is installed inside a brass tube and practically does not change depending on the temperature surrounding it. Having received inertial movement from the tubular element, the rod exerts pressure on the spring system of levers, which are connected to the thermoregulatory valve.

Operating principle of the AGV 80 thermostat Source energospravka.ru

The thermostat has a special scale and a pointer knob, by moving which you can adjust to a specific temperature (from 40 to 90°C). The specified parameters are changed by changing the size of the free end of the metal rod by screwing it inside the bushing on the brass tube.

Healthy! When setting the thermostat to the maximum position (90°C), the pointer should be opposite the “Hot” scale. At the minimum value (40°C) – next to “Chill”.

To increase or decrease the set temperature, follow these steps:

- Use a screwdriver to unscrew the screw connecting the rod to the pointer handle.

- Move it to the desired position (up or down).

- Return the removed screw to its original place, connecting the handle and the rod.

- Move the pointer handle to the extreme (upper or lower) position.

Important! Setting the thermostat above 90°C is prohibited.

Gas equipment

The AGV-80 water heater is a gas unit capable of operating in automatic mode. Flame control and gas protection are assigned to a Chromel-Copel thermocouple. At the moment of ignition of the boiler, a change in difference occurs between two connected conductors with zero potential. As a result, a voltage is generated between the opposite contacts, which activates the gas valve. The latter, when triggered, opens and is fixed in the open position. When the temperature around the Chromel-Copel thermocouple decreases, the voltage at its contacts disappears. The valve closes and the gas supply is stopped.

A clear example of the operation of a gas equipment thermocouple Source telemento.ru

Interesting! This device is successfully used in modern gas equipment. The only difference is the replacement of thermocouple types with ones that are more sensitive to temperature changes.

The next element of gas equipment for an automatic water heater is the igniter. It is intended for heating the thermocouple and igniting the burner. The flame on its injectors does not go out until the gas supply is turned off.

The schematic diagram below shows an example of the location and connection of a magnetic valve with a thermocouple and an igniter. The numbers on the diagram indicate the following details:

- 1 – burner.

- 2 – igniter.

- 3 – thermocouple contact washer.

- 4 – contact washer of the magnetic valve.

- 5 – forced gas start key.

Diagram of a thermocouple, igniter and connecting them to a magnetic valve Source prom.st

Automation

You can choose a budget option aimed at reducing gas in the absence of owners. This mode avoids the danger of the system defrosting in cold weather.

A modern AGV boiler is equipped with many sensors providing a high degree of automation

Sensors on the boiler allow you to notice malfunctions and accurately determine the system that has failed so that you can promptly fix the problem. The AGV automation controls the shutdown of the gas supply if the chimney draft is disrupted, when the gas pressure drops, or when the pilot flame goes out.

Rules to be followed during installation

The requirements for the installation of AGV-80, specified in the instructions for its operation, are not currently considered relevant. Therefore, we provide separate extracts from SNiP 42-01 and MDS 41.2-2000:

- Room area – minimum 4 m2.

- Ceiling height – minimum 250 mm.

- The volume of the room is at least 15 m3.

- The width of the doorway is at least 800 mm, opening outward.

- The gap under the door is at least 20 mm.

- A source of natural light, the area of which is determined by calculating 0.03 m2 per 1 cubic meter of space. Example calculation for a boiler room with an area of 20 m3: 20 * 0.03 = 0.6 m2.

- Availability of a ventilation system.

- The material of the walls separating the room from the neighboring one must be fire-resistant, with a limit of at least 0.75 hours, or be finished with structures assembled from non-combustible elements.

Requirements for the room in which AGV-80 is installed Source gradusplus.com

Criteria for choosing equipment for heating a private home

The main aspect when purchasing a unit is power. It is believed that heating every 10 m² of area requires 1 kW of energy. However, this calculation does not take into account heat loss. They depend on what materials the walls, ceilings and floors are made of in the house, and on the region in which the building is located. Specialists take all this into account when carrying out complex calculations.

The power of the boiler in question is 7 kW. Taking into account the efficiency of 85%, the indicator is only enough to heat 60 m² - if the house is located in the southern region and the walls and ceiling are insulated using modern materials. For the northern regions, the figure is up to 20% of additional capacity.

An important selection criterion is the functionality of the unit (heating only or heating and hot water supply). It is generally accepted that the second option is less profitable because it is more expensive, however, the first type of equipment (single-circuit device), despite the savings, requires the installation of an additional boiler for liquid.

As for automatic security systems, even in advanced modifications they are quite simple. Electronic filling and many levers are not provided, but the security system is reliable and is not inferior to that of imported models.

Features of operation of AGV 80

The manufacturer stipulates that certain phenomena may occur during operation of an automatic gas water heater. Below is a list of them and recommended actions to eliminate them (according to the operating instructions for this unit):

- Starting the device after a long break may be accompanied by a concentration of moisture droplets at the bottom of the container. This occurs as a result of the accumulation of condensate particles formed as a result of temperature differences on different sides of the walls. After the water temperature reaches 25-30°, the accumulation of condensate stops.

- Periodic gurgling sounds heard from the insides of the working volume are explained by the movement of heated water particles up and cold particles down.

- As a result of long service, foreign bodies may accumulate inside the working volume. They are often presented in the form of tow, clay or limestone deposits, rust or other particles of third-party origin. To reduce their concentration on the key elements of the water heater, it is necessary to periodically carry out high-quality cleaning of the internal system. This is done by flushing the heating system and tank two or three times with a strong stream of water, connecting through the inlet fitting.

AGV 80 with a modern heating system Source eco-kotly.ru

Principle of operation

The water in the boiler circulates naturally - according to the thermosiphon principle. Heating occurs from the flame tube, through which hot gases emanating from the lower burner pass.

The main closing element of the gas line is an electromagnetic valve driven by a thermocouple. To light the burner, you need to press the start button on it and bring an open flame to the pilot tube. A current arises in the heated thermocouple, which causes the solenoid valve to operate. After this, the gas supply valve to the burner is manually opened and the boiler is ignited.

Operating principle of the AOGV boiler

To control the heating temperature, there is a coupling in the top cover of the boiler where a thermometer is installed. It is maintained at the same level using an automatic thermostat, the operating principle of which is based on changing the length of a metal rod (brass) when heated. To operate in a given temperature range, its lever rotates only 14°, which is passive protection against unskilled actions.

If you want to raise the upper heating limit, first unscrew the locking screw on the thermostat control lever and turn it counterclockwise, then tighten it again and turn it in the opposite direction. The design does not prevent actions that could cause the water in the boiler to boil. Therefore, it would be better to have them carried out by a specialist. If you don’t have one, read the technical description of AOGV boilers and the rules for their operation by following this link.

First launch and adjustment

At the preparatory stage, you should ensure the tightness of the threaded connections of the gas pipeline, the tightness of the shut-off devices, and the proper operation of the automatic systems. It should be borne in mind that it is not recommended to carry out most of the listed work yourself. Therefore, to receive qualified assistance, it is recommended to contact a specialized company providing these services.

Before starting the AGV-80 water heater for the first time, you must make sure that the heating system connected to it is filled with water. The storage tank of the tank must also be filled with liquid. This can be easily done by looking at the signal tube. The appearance of water in it indicates a sufficient level. After this, turn off the water supply and carry out the first start.

Preliminary work before the first launch Source 1-teplodom.ru

The next steps are to ensure that there is adequate draft in the chimney. This can be done in any convenient way. The simplest one involves manipulations like this:

- Light a match and bring it to the cap located on the traction breaker.

- With a well-functioning draft, the flame will tend (to be drawn) into the hood.

Important! If this does not happen, and when ignited the flame tries to “break out” through the firebox door, it is prohibited to use gas equipment. Subsequent operation is permitted only after the causes have been eliminated and appropriate traction has been created.

Gas burner AGV-80 Source chipmaker.ru

Types of heat exchangers

The main heat exchanger of the boiler can be made of different materials:

- A stainless steel heat exchanger is used in wall-mounted boilers.

- The steel heat exchanger is designed for economy class boilers.

- A cast iron heat exchanger is used in floor-standing boilers.

- The steel heat exchanger belongs to the low price segment, but its performance characteristics are appropriate. Heat exchanger made of stainless steel or cast iron occupy equal positions. Moreover, the latter option has good heat capacity, and the first has a more advanced design and manufacturability, which determines their floor or wall location.

The most common malfunctions

The AGV-80 unit is a device with a long history of existence. Over more than half a century of history, the device has proven itself from a positive point of view. However, technical problems may occasionally arise. According to information taken from the operating instructions provided by the manufacturer, the most popular are a number of the following.

The igniter goes out

Due to the resulting oxidation on the contacts of the magnetic valve and thermocouple, the core does not hold the armature. The problem is solved by the following steps:

- Unscrew the nut on the magnetic valve.

- Clean the contacts with fine sandpaper and, if necessary, treat with a special liquid.

- Screw the nut into place.

- Check the operation of the igniter.

A similar opening can be created by poor contact between the poles of the core and the plane of the armature. In this case, you should perform the following steps:

- Use a screwdriver to unscrew the 4 screws and remove the starting column cap along with the armature.

- Using gentle movements, wipe the glossy surface of the armature plane and the electromagnetic core.

- Reassemble in the reverse order of removal.

- Check the operation of the igniter.

Electromagnetic valve of the water heater AGV-80 Source ooowest.ru

The thermocouple does not work (the required voltage is not generated). This happens in most cases due to a burnt-out limit switch. The problem can only be solved by installing a new element. It is strictly prohibited to press or tie the start button.

The fire on the igniter goes out or smokes. In this case, you should pay attention to the gas holes on the pilot burner. Most likely they are clogged; the problem is solved after cleaning the slots.

Beautiful chimney deflector Source gradusplus.com

Poor chimney draft. The existing smoke exhaust duct does not provide a nominal removal of natural gas combustion products. In this case, the core does not attract the armature of the magnetic valve, which is reflected in the fact that the burner receives a feed composition that does not correspond to the one intended for it. The abundance of air discharges the gas mixture, making it slightly flammable.

Problems of a different nature

Problems associated with a poorly burning or extinguishing burner are the most common type of malfunction of any gas equipment. In addition to these, other malfunctions may occur during operation of the AGV 80.

Gas path of the boiler

The boiler design includes a fan that forces combustion air into the boiler furnace forcibly. The pressure created is sufficient for the combustion products to be forced through the heat exchanger, leaving through the chimney. This is a closed type of firebox. Here the volume of air is as close as possible to the ideal volume, due to this the amount of heat going into the flue is minimal.

Some boilers involve creating the draft necessary for combustion using a chimney. This is a type of boiler with open fireboxes; it makes the design somewhat cheaper. But when there is no fan in the boiler, the efficiency indicator decreases, and the requirements for the pipe increase. For example, for boilers with a fan, the chimney can be routed vertically through the wall, but for a boiler with an open firebox this is not possible.

What are the requirements for installing a gas boiler, see here.

Floor-standing boiler OAGV (Lux non-volatile)

By using the energy of the gases escaping through the coaxial chimney, it is possible to supply already heated air into the boiler. If the air temperature in the combustion furnace is increased, this is beneficial for the process itself: ignition improves, the torch burns evenly, without prolonging the combustion, this ensures better heat removal.

In reality, the increase in temperature for this reason is not too noticeable if cold air comes from the street. But overall efficiency indicators increase, since savings are achieved by heating the air that enters the house ─ the boiler sucks air from the room and exhausts it through the chimney.