The difference between an autonomous heating system and a central one

In 2022, GOST 31311-2005 Heating appliances was adopted. From this document it follows that radiators cannot be sold without their laboratory confirmed compliance with the declared characteristics. Therefore, the first thing you need to do when choosing a device is to find out whether there is mandatory certification.

The document defines a radiator as a heating device that releases heat by convection and radiation. This definition is suitable for devices in both city apartments and private houses: they perform the same functions. But the requirements for them are different, because in individual houses radiators are part of an autonomous heating system, and it differs from central heating in almost every way.

Compared to a central heating system, an autonomous one:

- The operating pressure on the entire system is much lower, the load on the radiators will be gentle, their very thick walls will not be a big advantage here;

- There can be no water hammer in an autonomous heating system;

- In an autonomous heating system, heat loss is much lower than in a central heating system, they are somewhere around zero, so the coolant always heats up much more;

- But the owner of the house can set the temperature of the coolant himself, and not exceed the required maximum that is set for this type of heater;

- The coolant in an autonomous heating system can be antifreeze - non-freezing liquids. They are especially often used in those houses that may not be heated for a long time in winter. When freezing, antifreeze, unlike water, will not rupture radiators.

- The autonomous heating system is calculated taking into account the area of the house. A small building is one thing, but a huge cottage is quite another.

Option one - classic boilers

The first option is traditional, classic, which has been used for thousands of years in conventional stoves, put in firewood or coal, and adjusted the air supply with a damper. The main disadvantages are the need for constant supervision and low efficiency, the inability to accurately regulate the combustion process. Advantages - the simplest boiler in technical terms and maintenance, operating on almost any type of solid fuel.

Examples of classic boilers:

- ZOTA Carbon

with a steel heat exchanger, operating on coal with a fraction of

10.00 - 50.00 mm

, power

from 15.00 to 60.00 kW

, with top fuel loading, a movable grate and a design that ensures maximum afterburning of fuel and precise oxygen supply to firebox; - Buderus Logano

with a steel heat exchanger, can work either separately or in combination with a gas or liquid fuel boiler with a capacity of

12, 16, 20, 24, 27, 32, 45 kW

, in systems with natural and forced circulation of coolant, is small in size and heat exchanger protection, large volume of ash pan and loading chamber, works on wood (logs up to 33.00 and 53.00 cm long), coal, coke.

The burning time of such boilers is 3-7 hours.

Types of radiators

But the features of an autonomous heating system are not all that needs to be taken into account when choosing radiators. Heating devices for a private home are divided into groups according to design features, material of manufacture, and the principle of heat transfer.

- According to their design features, radiators can be solid or sectional;

- According to the material of manufacture, they are divided into cast iron, aluminum, steel and bimetallic;

- According to the principle of heat transfer - radiating thermal energy, convection and combined.

Batteries for a private home - what are the limitations?

The selection of heaters for a private cottage also has certain limitations. If you do not plan to live in a country house permanently, then you will have to fill the system with antifreeze - a liquid that does not freeze at subzero temperatures.

Since not all metals can withstand such chemicals, the list of suitable thermopiles is limited by the material from which they are made. For example, some sectional aluminum models can only be filled with water as a coolant.

Cast iron batteries, despite their strength, are also vulnerable to the action of chemical compounds: intersection rubber gaskets are quickly destroyed under the influence of aggressive substances. As a result, after 2–3 years of operation, the cast iron battery leaks.

To troubleshoot problems, you will have to completely disassemble the radiator and replace the gaskets - this will require additional expenditure of money, effort and time. For this reason, the best choice for a private home will be durable monolithic models made of steel or bimetal.

Cast iron

Cast iron radiators are a classic, the most popular heating devices over the last hundred years. Long accordions of seven or eight sections can be seen in many retro photographs of Soviet apartments. Even then they were reliable, like a rock, withstanding any external mechanical impact and high pressure from the inside; they served for 50 years, got so hot that you couldn’t touch them, were resistant to corrosion and did not stop working even when they were “poorly heated” and the coolant temperature was low.

They are made from cast iron grade SCH 12-28, which is quite resistant to corrosion, using gaskets made of heat-resistant rubber - thanks to them, the products maintain tightness even when heated to 130 degrees.

But “cast iron” somehow looks antediluvian, they have a high heat capacity, many people talk about the sharp corners of the sections and the rough, unaesthetic casting surface. The best models of cast iron heating radiators are devoid of these shortcomings and will decorate any private home, some of them are even quite elegant, with smooth front surfaces and factory primer, with two- and three-column sections, which allows you to optimally reduce the width of the radiator for a given heat transfer.

TeploNetUser FORUMHOUSE

Cast iron radiators will never go out of style. Only the appearance will change.

A modern cast iron battery consists of several hollow sections, usually seven or eight, hermetically assembled together, with horizontal channels through which the coolant passes. Radiators can be one-, two- and three-channel. Their sizes are regulated by special GOST 8690-94 Cast iron heating radiators, according to which

- the distance between nipple holes should be from 300 to 800 mm;

- product height from 400 to 900 mm;

- depth from 100 to 160 mm.

Technical characteristics are given in the product labeling: this is how the MS-140-580-0.9-7 labeling is read: this is a product with a depth of 140 mm, a height of 580 mm, with a working pressure of 0.9 MPa, which consists of seven sections. This radiator fully complies with GOST.

The number of sections is simply calculated based on the area of the room (although there are also precise, complex and labor-intensive calculation methods that take into account many circumstances, from the region - winter is one thing in Moscow, and another in Irkutsk - to the number of windows in the room). A simple calculation is done like this: to heat a square meter of area, you need 100 W, therefore, by multiplying the area of the room by 100, we will find out how much heat is needed. Then we divide this value by the thermal power of one section of the selected model from the selected manufacturer.

The formula for calculating the number of sections of a cast iron battery is: multiply the area of the room by one hundred and divide by the thermal power of the section.

For a room of 21 square meters. meters according to this formula you will need 7.5 sections of a 160W radiator. It's better to round to eight than to seven.

There is nothing particularly difficult about installing cast iron batteries. Like all types of radiators, they must be installed at a certain distance from the wall, floor and window sill. These distances are regulated by SP 73.13330.2012 “SNiP 3.05.01-85. Internal sanitary systems of buildings."

- From the floor 60 mm;

- From the bottom surface of the window sill – 50 mm;

- 25 mm from the wall plaster surface (but the manufacturer may specify other dimensions).

RoaromaFORUMHOUSE user

The radiator will not operate at full capacity if the distance between it and the wall is not maintained. They passed, it’s not even discussed.

A cast-iron radiator is hung from the wall on metal supports, but sometimes, due to the design features of the house and the heavy weight of the device, it is placed on legs. Floor radiators are often stylized as antique ones, decorated with intricate castings; such products, even domestically produced, have a refreshingly high cost, but fit perfectly into a classic interior.

But when deciding on cast iron radiators, you should remember this important feature: they have high thermal inertia; They both heat up and cool down slowly. It will not be possible to quickly change the temperature in a room heated by cast iron radiators.

But in houses that are heated by solid fuel boilers, the disadvantages of cast iron become advantages: the large heat capacity in this case is rather a plus.

Lord LLC User FORUMHOUSE

Aluminum convectors quickly heat the air, but also quickly cool themselves. This is the reason for my choice of cast iron. If there was gas, I would install aluminum.

VashnovoselFORUMHOUSE user

Well, cast iron takes longer to heat up, well, inertia, so this is better with a solid fuel boiler and permanent residence!

And for houses connected to main gas, cast iron batteries, according to reviews from our users, are not the best choice.

TraksFORUMHOUSE User

My neighbor last year threw out cast iron and installed aluminum. Now pay less for gas. His house is well insulated; at a temperature of -25 degrees outside there is no need to heat the coolant to 90 degrees, 50-60 is enough.

Additional installation tips

The efficient, reliable operation of the heating system is influenced not only by the correct choice of the type of heating radiator.

There are a few simple installation rules:

- The distance to the wall is at least 4 cm.

- The distance to the floor and window sill is at least 10 cm.

- The size is no more than 75% of the width of the opening being constructed.

Distances affect the correct distribution of air flows, ensuring uniform and rapid heating of the room. In addition, distances are important for fire safety if the floor consists of flammable materials (parquet, boards, linoleum).

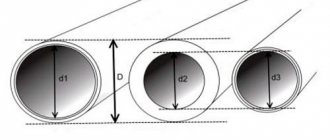

The radiator is placed in window niches, in places accessible for inspection, maintenance, and repair. The standard radiator width is 75% narrower than the opening

The use of a decorative screen will reduce the efficiency to 15-20%. Incorrect connections to the supply and return pipes will reduce productivity by up to 20%. The most effective solution is to connect the supply pipe to the top of the radiator, and the outlet to the bottom of the radiator.

Information on methods of connecting heating devices, taking into account the requirements of building regulations, is given here.

Steel

There are steel radiators

- Panel

- Sectional

- Tubular

Panel

In individual housing construction, panel radiators are most often used, as they are the most inexpensive and common among all steel ones. They consist of panels (usually two) in which coolant circulates. Convection elements may or may not be installed between the panels. Panel radiators with convection elements work like convectors, or rather, they have the functions of both a convector and a radiator, 50/50. The difference is that a radiator transfers heat to the objects surrounding it, while a convector heats the air. And such universal devices heat the room evenly, both above and below, and do it quickly.

Panel radiators without convectors work like regular cast iron radiators, but unlike cast iron ones, they are very easy to clean. Therefore, they are installed in clinics, kindergartens, etc.

High-quality panel panels work on any coolant, and they have a very high efficiency, they effectively transfer heat even at a coolant temperature of +40- +45 degrees (steel radiators will last a long time if the coolant temperature does not exceed +70 degrees, and exceed the indicators by + 100 is not recommended).

But - only high-quality ones, when it comes to steel panel radiators; experts do not even advise messing with cheap options.

vergun_lg User FORUMHOUSE

On the question of the durability of steel radiators: I had to cut off pre-war heating in a private house, the pipes were installed as yesterday, there was no corrosion. When choosing a steel panel, I would advise you to pay attention to the thickness of the panel and the anti-corrosion coating - God saves the best.

The thickness of the walls determines whether the device can withstand high pressure in the heating system. A cheap device with a 0.5 mm wall will not withstand it, but a radiator with a 1.25 mm wall will only withstand it.

Also, a steel panel heater is selected according to its dimensions: its width must be equal to at least 50% of the window opening. And we must take into account the peculiarities of heating wiring: buy radiators with lower outlets for connection if the wiring is hidden in the floor, and with outlets on the sides if the house has a classic wiring. The radiator passport always indicates all the requirements for the heating system: pressure, pH level of the coolant, etc.

VseobinUser FORUMHOUSE

The advantages of steel panels: they cool longer than aluminum and bimetallic radiators, and they have a wide selection of sizes and modifications. Cons: if a panel radiator leaks, you will have to replace it entirely.

Another disadvantage: high requirements for the quality of the coolant due to the tendency of steel to corrosion, and instability to mechanical damage; such radiators must be loaded, unloaded and transported with extreme caution.

The power of a steel radiator depends on its type. You need to read the numbers on the radiator nameplates: the first two are the type of radiator, the second is the width, the third is the height. With width and height everything is clear, the first two numbers are of interest: it is either 10, or 11, or 20, or 21, or 33.

11 – single-section, with one convector, power is 1.1 kW. 22 – two-section, with two convectors, power 1.9 kW. 33 – three-section, with three convectors, power 2.7 kW.

Steel tubular

These are expensive radiators, and they are used quite rarely, in designer interiors, etc.

Hortek SPbForumHouse Member

The tubes are more elegant, but this is a matter of overall design.

These radiators are made of steel tubes with thick walls, connected into beautiful rectangular grilles. From the inside, the metal is protected from corrosion by polymer materials. Therefore, their use is widespread even in houses with central heating, where water hammer is possible, because the operating pressure for this type is 15 atmospheres, and the maximum permissible operating temperature of the coolant is 130 degrees.

They heat up evenly and retain heat for a long time. Their only obvious drawback is their high price.

Sectional

Sectional steel radiators are rarely used for heating individual houses - they are quite expensive. This is a structure of several sections with vertical and horizontal channels. Outwardly, they resemble a cast iron radiator; in fact, they are a symbiosis of panel and tubular radiators, and their main advantage is that they can withstand higher pressure in the system (10-16 atmospheres).

The number of radiator sections can be changed, it can be increased if the power of the device is clearly not enough to cope with the heating of the room; or reduce it if it becomes hot in the house after insulation work.

The disadvantage of such devices is the increased number of joints in the structure, which can even lead to sealing.

Video description

Additionally, see how to connect radiators to a one-pipe system:

Using old metrics

When carrying out repair work and replacing previous heating equipment, you can use the previous data. If the temperature level during the heating season is satisfactory, then the thermal power remains the same. Old batteries will lose 10-15% of their thermal conductivity over time due to internal corrosion. Therefore, the new ones will require a smaller number of sections with a similar battery material.

When installing devices in designer versions, you should approach the installation with special care. Unconventional solutions significantly change the air heating system.

Corner design Source remkasam.ru

Aluminum

In individual heating systems, aluminum radiators are used even more often than cast iron ones. Modern radiators are made of aluminum alloys; they consist of sections (and you can assemble a radiator of the required power from them).

They are inexpensive, very light, quite durable and reliable, and can withstand high pressure (there are models that can withstand 20 atmospheres). They have a high heat transfer coefficient (much higher than cast iron), they are easy to install, and they are not inertial, which is why temperature regulators are installed in such batteries.

“Lyuminki” could be called the best heating radiators for a private home, but they have one big drawback - poor corrosion resistance, which means high demands on the quality of the coolant. Therefore, such radiators are not recommended for installation in high-rise apartments and private houses with central heating. Central heating systems are filled with an alkaline coolant with a pH level greater than 8, and often of rather dubious quality; this is too much for sensitive aluminum radiators: an incorrectly selected coolant leads to corrosion, and the protective layer that protects the aluminum collector from the inside is destroyed.

In autonomous heating systems, you need to ensure that the coolant does not contain mechanical impurities (filters solve this problem) and corresponds to a normal pH level (approximately 7). In a neutral environment, radiator aluminum is not subject to corrosion! If you control the quality of the coolant, there should be no problems with aluminum radiators.

An aluminum radiator can be protected from chemical corrosion only by monitoring the quality and composition of the coolant.

If you leave this issue to chance, it won’t be long before the heating system depressurizes.

If the coolant is water, then you must monitor its hardness. And it is better not to reduce the hardness with reagents, but to fill the system with distilled water.

To summarize: for autonomous heating systems in which the quality of the coolant can be controlled, aluminum radiators are quite suitable. It is important to buy quality products and ensure that the characteristics of the antifreeze comply with the manufacturer's recommendations.

novor113FORUMHOUSE user

A good aluminum is as good as a good steel radiator, but it is cheaper and has a good design. And for a steel one with a good design you will pay twice as much.

Option two - semi-automatic boilers

A boiler that requires manual loading, but controls combustion using automation, is called semi-automatic, which ensures higher equipment efficiency; it operates on any fuel, like classic boilers. But these boilers are energy dependent.

Let us note the models of the Polish manufacturer Metal-Fach

SDG

line , boilers run on coal and wood, heat exchanger made of

P265GH

6.00 mm

thick , water-type cooling grate, with a vertical chimney system, large loading chamber and

efficiency

up to

81%

, designed for open and closed heating systems with forced and natural circulation of coolant.

Bimetallic

Bimetallic radiators are those that are made of aluminum and steel. But unscrupulous manufacturers even call bimetallic devices in which only the vertical channels of the collector are made of steel. This is incorrect, a real bimetallic radiator has a manifold made entirely of high strength carbon steel, in fact it is a steel manifold inside a section of aluminum. But in a private house, where the owners have the opportunity to monitor the quality of the coolant, this may not be so important, although the service life of bimetallic batteries is longer than that of aluminum ones. This can be considered an additional advantage, but bimetallic ones are also more expensive.

VseinstrumentiUser FORUMHOUSE

Bimetallic ones are stronger. I agree that it is usually more profitable to use aluminum radiators in a private home.

Pros and cons of bimetal

As you can easily guess from the name, heating devices are made of 2 metals - silumin and steel. Externally, the batteries are indistinguishable from aluminum sections, but inside the collectors and vertical channels there are iron tubes welded together. The steel frame is designed to solve 2 problems:

- protection of the silumin part from the chemical effects of the coolant in old centralized systems;

- increasing the reliability of the radiator by increasing the operating pressure threshold to 20...30 Atm.

For reference. There are bimetallic models with double vertical channels made to improve water flow and heat transfer. An example is the Rifar SUPReMO line of non-separable batteries, shown in the photo below.

In terms of other technical characteristics, bimetal differs little from aluminum - the power of 1 section, weight and capacity are almost the same. The operational advantages of radiators also remain, but a couple of disadvantages appear:

- the price of batteries is 30-50% higher, for example, the original bimetallic section from Global Style Plus with an axial spacing of 500 mm costs about 15 USD. e. (970 rub.);

- due to different coefficients of thermal expansion of silumin and steel, the pipe core can burst at the welded joints, making repairs and sealing the leak is unrealistic.

In a monolithic structure, the collectors of adjacent sections are connected by welding. Feature of Rifar products - 2 vertical channels

Important addition. Sometimes on sale there are defective bimetallic radiators with steel tubes embedded only inside the collectors. The vertical channel of the section remains unprotected.

How to calculate power

The power of any radiator for an individual home is calculated based on the fact that to heat an average room with one window, one door and a shelf height of less than three meters, the coolant temperature should be about 70 degrees, and to heat one square meter you need 95-125 kW. The parameters of this scheme are adjusted if real conditions differ from the average: in a room with second light, the battery power should be greater by as many times as the ceiling height is higher than average; if the ceilings are low, the power is reduced.

If the coolant temperature is less than 70 degrees, then the power of the radiators should increase (15-20% for every 10 degrees). In corner rooms with several windows, the average radiator power is increased by one and a half times. It should also be borne in mind that the most effective radiator connection scheme is when the coolant is supplied to it at the upper side inlet, and the return line is connected diagonally to the lower outlet. All other connection schemes slightly, by 5-10%, but reduce the heat transfer of the batteries.

It is impossible to increase the number of radiator sections indefinitely. There should not be more than ten of them; no coolant will warm up such a battery.

Floor convectors

This is a relatively new solution in arranging a heating system - floor convectors consist of a box, a grille (it performs a purely decorative function) and a heat exchanger. Floor convectors are installed in rooms with large windows (“floor-to-ceiling”); they are actively used in arranging the heating systems of airports, train stations, hospitals and clinics.

Advantages of sexual convectors:

- light weight;

- the design is durable and easy to install and operate;

- the room is heated as evenly as possible;

- easy to clean from dust and dirt;

- do not spoil even the most intricate design of the room - floor convectors are practically invisible.

Disadvantages of sexual convectors:

- the length required for high-quality installation is quite large;

- forced ventilation cannot be installed;

- heat transfer is low.

The third option is automatic boilers

Fuel loading into the chamber and combustion control are carried out automatically. The advantage is autonomy (5-9 days on one load), the disadvantage is the high cost.

Such boilers are equipped with a loading hopper for supplying solid fuel and automation. The operating principle is quite simple. Fuel of a certain fraction is loaded into a bunker, from which it is supplied to the loading chamber as it burns.

Let us note the automatic boilers of the Polish manufacturer Metal-Fach

with a steel heat exchanger (P265GH steel with a thickness of up to 6.00 mm is used),

efficiency

over 90

%

, a modern, innovative type controller

FL 310LGRTC

, which allows servicing one mixer and up to four circulation pumps with continuous logic and PID control functions, an upper combustion chamber, retort burner of the following lines:

- SEG (work on coal of various fractions)/SEG BIO (pellets, oats, grape and olive seeds, other agricultural solid waste and coal are used as fuel). These are devices with automatic fuel supply, the ability to connect room (internal) and weather (external) sensors, a lambda probe and the STRAŻAK (FIREMAN) protective system, which prevents the ignition of granules;

- SD DUO

, coal is used as solid fuel, including sunflower seeds, coal dust, and any hardwood (in manual mode). The boilers are equipped with a fuel dispenser, two loading chambers, an automatic device responsible for supplying fuel; if necessary, a lambda probe can be connected; - SD DUO BIO

, configured for burning pellets, agricultural waste, grain crops (wheat, oats), as well as coal, hardwood and coal. The devices are equipped with an automatic tray loading device with a feed screw, an ignition device, a lambda probe (if necessary), and the STRAŻAK (FIREMAN) protection system, which prevents fuel from igniting outside the firebox. - SMART

and

SMART EKO

, running on pea fraction coal, pellets, with a unique Ekoenergia burner. These boilers can operate in both manual and automatic modes, which guarantees stability in the heat supply to the premises. The MASTER 500 controller allows you to control two pumps and a room thermostat.

Separately, we note the automatic boilers of the Russian company Vulkan

, developed on the basis of proven European manufacturers of heating equipment.

They are unpretentious in operation and fully adapted to Russian operating conditions. They work on coal of various fractions ( up to 40.00 mm

), including pellets, pellets (fraction

from 6.00 to 8.00 mm

), heat exchangers are made of boiler steel 6-8 mm thick, have a screw supply of solid fuel from a bunker.

These automatic coal boilers are capable of operating autonomously from five to ten days, and are equipped with electronics from various European manufacturers, which allows you to control two circuits of the heating system and the hot water supply system (DHW) simultaneously.

Anyone can understand the controls thanks to a simple and intuitive menu (interface). Additionally, a GSM module

for remote monitoring and control using mobile communications, an automatic ash removal system and automatic ignition.

, Vulkan automatic boilers

one of the best offers on the Russian market.