The use of polypropylene pipes is beneficial, as they have significant advantages. Such a pipeline is reliable, environmentally friendly, and has a long service life. However, if its operation occurs at high temperatures, then the coefficient of linear expansion of polypropylene pipes must be taken into account. To prevent the damage it can cause, it is necessary to understand its nature, be able to calculate the increase in length in such cases, and know how to install the pipeline to eliminate the destructive effects of thermal expansion.

Polypropylene pipes Source trubaspec.com

The history of the appearance of polypropylene pipes

The use of plastic began in the thirties of the 20th century. At first, polyvinyl chloride was used to produce pipes. Its main disadvantages are the release of carcinogens during operation and a high fire hazard. It must be remembered that during the combustion process substances hazardous to health will also be produced.

Polyethylene replaced polyvinyl chloride. It has demonstrated good performance, but can only be used for cold water supply.

Reinforced polypropylene pipes Source trubaspec.com

Polypropylene does not have the mentioned disadvantages and limitations. They do not change their performance when heated or cooled, which makes them suitable for wide use in the manufacture of pipes. Their important advantages are invulnerability to corrosion, lack of reaction to the use of solvents and environmental friendliness of use. Installation of polypropylene pipes is beneficial due to the following reasons:

- Retains its performance properties for decades.

- Easy to install. Light weight makes transportation more convenient.

- Water flowing through such pipes does not degrade its quality.

- There is no need to paint the pipes.

- No rust appears.

- Use in heating systems eliminates the formation of condensation.

- The operating temperature range is 0-95 degrees.

- Due to low thermal conductivity, there is no need for additional thermal insulation.

- Lime deposits do not form inside the pipes.

- When in contact with an open flame, no fire occurs and no substances harmful to health are released.

Preliminary preparation

There are several options for sealing seams:

- using concrete mortar;

- dry mixture of sand and cement;

- special putty mass.

Each method involves surface preparation. Before starting work, the paving stones are treated with water from a hose under pressure.

If a concrete base is used, the sealing is carried out after 3 days, after the solution has completely dried. Laying tiles on a cement-sand base involves grouting the cracks immediately.

Debris is swept away from the working surface, the distance between the paving stones is cleaned with a thin rod, a compressor or a vacuum cleaner. A jet of compressed air will more effectively and quickly remove excess dirt and speed up the drying of cracks. If there is no compressor, an old vacuum cleaner is used. By installing a tube on the exhaust pipe, a kind of compressor is created. After preparing and cleaning the required area, the grouting method is determined.

Porous materials (ceramic tiles, concrete) are sealed with a dry mixture of cement and sand; materials with a smooth and dense texture (marble, granite) are preferably sealed with concrete mortar. For colored tiles, a ready-made mixture is used.

Why is exposure to high temperature harmful?

Due to the increase in temperature, the pipe expands. This stretch depends on the length of the section and the heating force. This may cause the pipe to sag or change its shape. During installation, this situation must be taken into account and measures must be taken to compensate for the effect of increasing temperature.

If there are short sections with rigid fastenings, then expansion can lead to damage to the communication. When designing, movable supports can be used - then during expansion, displacement cannot lead to deformation. The following problems may also occur:

- Due to a violation of the tightness of the connections, air penetrates inside, impairing the throughput of the system.

- Due to the shift, the fastening elements may be torn off.

- The integrity of the pipe may be compromised.

- Due to deformation, the quality of heating operation may be reduced.

If reinforcement is used, the risk of problems occurring is significantly reduced.

Polypropylene pipes with reinforcement Source gorgaznn.ru

Calculation for a two-pipe system

There is a two-story house with a two-pipe heating system, two wings on each floor. Polypropylene products will be used, operating mode 80/60 with a temperature delta of 20°C.

The heat loss of the house is 38 kW of thermal energy. The first floor has 20 kW, the second 18 kW. The diagram is shown below.

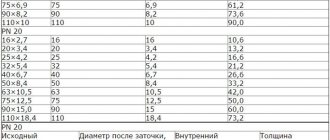

On the right is a table from which we will determine the diameter. The pinkish area is the zone of optimal coolant movement speed.

Let's start the calculation.

We determine which pipe needs to be used in the area from the boiler to the first branch. The entire coolant passes through this section, therefore the entire heat volume of 38 kW passes through.

In the table we find the corresponding line, follow it to the pink-tinted area and go up. We see that two diameters are suitable: 40 mm, 50 mm. For obvious reasons, we choose the smaller one - 40 mm.

Let's look at the diagram again. Where the flow is divided, 20 kW goes to the 1st floor, 18 kW goes to the 2nd floor. In the table we find the corresponding lines and determine the cross-section of the pipes. It turns out that we are dividing both branches with a diameter of 32 mm.

Each of the circuits is divided into two branches with equal load. On the first floor there is 10 kW each to the right and left (20 kW/2=10 kW), on the second floor 9 kW each (18 kW/2)=9 kW). Using the table, we find the corresponding values for these areas: 25 mm.

This size is continued to be used until the heat load drops to 5 kW (as seen in the table). Next comes a section of 20 mm.

On the first floor we go 20 mm after the second radiator (look at the load), on the second - after the third. At this point there is one amendment made by accumulated experience - it is better to switch to 20 mm at a load of 3 kW.

All. The diameters of polypropylene pipes for a two-pipe system are calculated. For the return, the cross-section is not calculated, and the wiring is made with the same pipes as the supply. We hope the methodology is clear.

It will not be difficult to carry out a similar calculation if all the initial data is available. If you decide to use other pipes, you will need other tables calculated for the material you need. You can practice on this system, but for an average temperature mode of 75/60 and a delta of 15°C (the table is located below).

Types of polypropylene pipes

If the product consists only of this plastic, then the expansion coefficient for polypropylene pipes will be maximum. In order to reduce this effect, pipes are reinforced. For this, aluminum foil or fiberglass is used. In this case, the expansion coefficient decreases several times.

Reinforcement using perforated aluminum foil can occur in three ways:

- The foil is laid on the inside of the pipe.

- It is placed on the outside.

- The metal is located between layers of polypropylene.

The metal is attached using a special glue. Its thickness is usually 0.1-0.5 mm. The disadvantage of using it is its possible loss of adhesive properties under difficult operating conditions. The consequence may be damage to the shell and leakage.

If it is necessary to weld two sections of a plastic pipe, then the aluminum layer at the cut site is cleaned so that it does not reach the area where the welding is performed.

Structure of a reinforced pipe Source gorgaznn.ru

When using fiberglass, the reinforcement is placed between the layers of the pipe shell. The inner layer cannot be made from this material, since fibers will get into the water from it. Fiberglass makes pipes more fragile. To reduce it, the reinforcing layer is installed in still molten polyethylene. In this case, the structure will not contain glue, which will make the pipes solid and prevent delamination.

By watching this video you can learn more about how calculations are made for expansion joints of polypropylene pipes:

Installation taking into account the linear expansion rate

When installing a pipeline for hot water supply and heating (including underfloor heating systems), it is necessary to take into account the elongation of the pipe as a result of exposure to high temperatures.

The optimal choice of products for pipeline installation is reinforced pipes with a fiberglass or aluminum inner layer. Reinforcement - a layer of foil or fiberglass - absorbs part of the thermal energy from the coolant and reduces the coefficient of thermal expansion of the polymer. Thanks to this, the need to compensate for physical changes will also be reduced.

Video description

Calculation of linear expansion compensators for PPR pipes.

The weak point of such pipes is the areas where the cut occurs, due to the fact that in the cases under consideration the reinforcement will protrude outward. In this case, special measures must be taken to seal this material inside the shell layer. The expansion of fiberglass reinforced polypropylene pipes is much less than those using pure plastic.

Thermal expansion deforms pipes Source infotruby.ru

How to make calculations

When designing the installation of polypropylene pipes, it is important to know the expected value of thermal expansion. This data can be obtained as follows.

- It is necessary to take into account whether the pipe is reinforced or not. The expansion of reinforced polypropylene pipes is less than when using pure plastic.

- If it is reinforced, then you need to clarify in what way - using fiberglass or an aluminum layer.

- The expansion coefficient is determined. It represents the amount of elongation of one meter of pipe when the temperature increases by 1 degree (K).

- It is determined how much heat there is in the water passing through the pipe. Calculate the difference between this value and room temperature (Difference).

- Measure the length of the pipe (Length).

- After this, the degree of increase in length (Ul) is determined using the appropriate formula.

To calculate the expansion of polypropylene pipes, the following expression is used.

UV = Length * Difference * K

The result in this formula is measured in millimeters. In order to imagine what quantities we are talking about, you need to consider the following:

- K = 0.15 for unreinforced pipe.

- K = 0.03 for those reinforced with aluminum.

- K = 0.035 when using fiberglass.

Thus, it can be seen that as a result of reinforcement, the linear elongation of polypropylene pipes decreases by approximately 5 times. To illustrate this, consider the following example. The temperature of hot water flowing through polypropylene pipes is 75, and the room temperature will be 20 degrees. The pipe is not reinforced. Its length is 10 meters. Next you need to apply the appropriate formula. UV = 10 * 55 * 0.15 = 82.5 mm.

Loop-shaped expansion compensator Source infotruby.ru

Why you need to know about the coefficient of thermal expansion

Linear increase must always be taken into account, otherwise the pipe network may collapse when the temperature of the transported medium changes. This is especially important for heating and hot water supply systems.

This applies to a slightly lesser extent to the “warm floor” system. When laying a polypropylene pipe line, you need to keep this detail in mind. Every meter of it will subsequently suffer a linear increase of almost 1.5 mm.

And glass fiber reinforced products reduce this figure by almost six times. This is very important because deformation changes resulting from thermal expansion will lead to increased noise during the passage of the fluid. This also has a negative impact on the stability of the system as a whole.

Based on the above, the first rule for installation actions is formulated: “For a pipe rolling system that is subject to high heating, it is recommended to select a product range with a minimum thermal change rate.

Nuances of pipeline laying

Fiberglass began to be used not very long ago. Glass fiber has a very small linear change coefficient, 0.009 mm/mK.

It should also be noted that this additive has excellent strength under different loads.

Watch video [sociallocker]

If you compare it to steel, it is three times larger. It follows from this that the rolled pipe assortment with fiberglass combines elasticity and strength, and this ensures a lower expansion coefficient.

The conclusion is that this additive to polypropylene is simply ideal. But fiberglass has one significant drawback - fragility.

This disadvantage was leveled by creating three-layer blanks, where the materials are bonded to each other at the molecular level. This number of layers was chosen for a reason. And the logic is as follows:

- Neither the inner nor outer layers can have fiber additions.

- For the inner layer, this is not permissible for hygiene reasons, so that the fibers do not end up in the supplied water.

Measures to protect the integrity of pipes during expansion

In order to prevent the occurrence of critical situations due to the expansion of polypropylene pipes when heated, the following measures can be taken:

- Adequate space must be left between the pipeline and the stop. In this case, it is necessary to calculate the degree of expansion in advance and ensure the availability of sufficient space.

- You need to pay attention to the places where the rotary couplings are located. It is important to arrange them in such a way that no stress or deformation occurs in the pipe.

- If you need to install a long section of pipe, then expansion compensators are placed on it. They are structures that fix the position of the pipeline, but allow it to safely expand at each small section.

When installing pipes, try to avoid the presence of hard joints. The use of loop-shaped sections of pipes is common. In this case, adjacent elements of the highway do not fit tightly to each other.

Application of a loop-shaped compensator Source trubanet.ru

Another compensation method is to install U-shaped connections between straight pipe sections. Moreover, they are made in such a way that the corners of the structure can safely move in this place.

Application of a U-shaped compensator Source santechlike24.com.ua

There are spring structures used to counteract the thermal expansion of polypropylene pipes. An example of such a solution is the Kozlov compensator. In this case, rings connected by a spring are attached to the ends of the pipeline section located opposite each other. Such a node is located inside a section of pipe with a larger diameter. When heated, the ends of the pipes move closer together, held back by a spring.

Kozlov compensator for propylene pipes Source infotruby.ru

What else does the calculation of cross-country ability depend on?

The outer diameters do not play a special role. Passability is determined:

- Because there are so many turns and places where one size goes into another.

- Deposits and age indicators.

- Properties of the product. On a flat surface the speed will be greater.

- Pipeline length. The resistance that slows down the movement of water increases with increasing length.

- Systemic pressure.

- Internal section. A polypropylene pipe, the internal diameter of which is calculated separately, is no exception.

Video: table of diameters in video format