A high-quality circulation pump is an integral part of independent heating systems. It is the circulation pump for heating that is designed to increase the efficiency of the heating system and the efficiency of heating residential premises several times. How to choose from the great variety of offers on the market exactly the model that will be designed to work in a specific heating system? To choose the ideal option, you need to take into account the exact parameters of the network in which the circulation pump is supposed to be installed, and it is important to remember a number of practical subtleties.

Circulation pump for heating: how to choose and what you need to know about it?

Radiators that are not warm enough is an effect well known to those who live in an apartment building on the top floor. Most often, this inconvenience is the result of low pressure in the central heating system. Due to the lack of required pressure, hot water does not pass through the pipes quickly enough and has time to cool down on the lower floors. Residents of the private sector also encounter a similar problem - for the same reason, the pipes and radiators in the section of the heating pipeline furthest from the boiler are cold. To successfully resolve this issue, experts advise choosing a circulation pump. Even for a house with a small living space, where the natural circulation of the heat pipe works effectively, it is worth choosing a circulation pump. This step will significantly reduce overall heating costs and increase the productivity of the entire system if configured correctly.

Circulation pump

- a compact, small device that operates from an electrical network with a voltage of 220 V. It is installed in the section of the heating system pipe to the boiler.

The circulation pump performs a fairly simple task when heating a private property: its operation creates excess pressure, thereby ensuring active circulation of coolant in the system and delivery of heat to any point in the residential building. The installation of a circulation pump should be chosen, if only because it will reduce the diameter of the pipes and install them in the most convenient way, taking into account the features of the interior.

The function of the circulation pump for heating is as follows:

- Pumping the volume of heated water necessary to maintain the desired indoor temperature. Accordingly, in order to select a specific circulation pump, you need to calculate the volume of heat transferred per unit volume of coolant and know how much heat is needed for a particular room.

- Overcoming the resistance of shut-off valves and pipelines. In other words, it is necessary to take into account the friction of water against the walls of the pipeline; this is really important.

Advantages of a circulation pump:

- Significantly saves money;

- Significantly increases the efficiency of the entire heating system;

- Eliminates the risk of boiling of the coolant when using a solid fuel boiler for heating premises;

- Increases the rate of fluid circulation within the system, and accordingly reduces the time required to heat the room;

- Reduces the level of siltation and the formation of a corrosive layer in batteries;

- Allows you to select pipes of a smaller diameter, which makes it possible to save money when purchasing materials necessary for installing the heating system;

- All rooms and even the most distant points are heated evenly.

Disadvantages of a circulation pump:

- Additional costs for its acquisition;

- Complication of the heating system installation process;

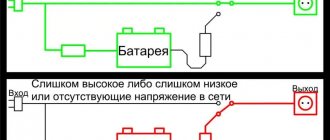

- Dependence of the heat supply system on the electrical system. If there is a power outage, the system will simply stop.

Manufacturers and prices

When choosing manufacturers of a circulation pump, the approach is the same as when selecting any type of equipment. If possible, it is better to take equipment from European manufacturers who have been on the market for a long time. The most reliable circulation pumps in this sector are Willo, Grundfos, and DAB. There are other good brands, but you need to read reviews for them.

| Name | Performance | Pressure | Number of speeds | Connection dimensions | Maximum working pressure | Power | Housing material | Price |

| Grundfos UPS 25-80 | 130 l/min | 8 m | 3 | G 1 1/2″ | 10 bar | 170 W | Cast iron | 15476 RUR |

| Caliber NTs-15/6 | 40 l/min | 6 m | 3 | external thread G1 | 6 atm | 90 W | Cast iron | 2350 rub. |

| BELAMOS BRS25/4G | 48 l/min | 4.5 m | 3 | external thread G1 | 10 atm | 72 W | Cast iron | 2809 RUR |

| Gilex Compass 25/80 280 | 133.3 l/min | 8.5 m | 3 | external thread G1 | 6 atm | 220 W | Cast iron | 6300 rub. |

| Elitech NP 1216/9E | 23 l/min | 9 m | 1 | external thread G 3/4 | 10 atm | 105 W | Cast iron | 4800 rub. |

| Marina-Speroni SCR 25/40-180 S | 50 l/min | 4 m | 1 | external thread G1 | 10 atm | 60 W | Cast iron | 5223 RUR |

| Grundfos UPA 15-90 | 25 l/min | 8 m | 1 | external thread G 3/4 | 6 atm | 120 W | Cast iron | 6950 rub. |

| Wilo Star-RS 15/2-130 | 41.6 l/min | 2.6 m | 3 | internal thread G1 | 45 W | Cast iron | 5386 RUR |

Please note that all specifications are based on water movement. If the coolant in the system is a non-freezing liquid, adjustments must be made. You will have to contact the manufacturer for relevant data for this type of coolant. It was not possible to find similar characteristics in other sources.

Which circulation pump to choose for heating?

Most circulation pumps consist of the following elements:

- Directly the housing in which the snail is installed;

- An electric motor (also placed in the pump housing, equipped with a control chip and connectors for connecting wires to them);

- Heating pipes connected to the volute;

- The rotor with impeller is the part of the motor that “pushes” the coolant during operation. Water is drawn from one end of the pipeline and enters the heating system again.

In operating mode, the pump creates the required outlet pressure (compression) and a vacuum area at the inlet.

Depending on the design features, all circulation pumps are divided into two types:

- Dry rotor pump

In these circulation pumps, the impeller is immersed in the liquid, which is isolated from the rotor by rubber seals and gaskets. Accordingly, if you decide to choose such a pump, then exclude direct contact of the engine itself with the liquid.

Such a design solution in the circulation pump allows one to achieve a high level of efficiency (depending on the specific model, it can be more than 80-85%). You can choose this type, but keep in mind that as the efficiency increases, the noise level also increases. It is for this reason that such motors are rarely used in private homes. For large objects, you need to choose the option of installing a pump with a “dry” rotor. There it is usually possible to install heating equipment and a boiler at a sufficient distance from the main living quarters.

In units of this type, motor cooling is achieved by releasing excess heat into the environment through the ribbed surface of the housing and by installing a cooling fan on the back of the device.

Most often, specialists suggest choosing this type of circulation pump for installation at large facilities, for example, for public purposes.

Such pumps require constant and careful maintenance. To avoid abrasion of the working elements of the engine, you need to periodically renew the lubricant.

- Wet rotor pump

Unlike the type already described, for installation of a heating system in private houses and cottages with an independent heat supply, it is recommended to choose a “wet” pump. In these circulation pumps, not only the impeller, but also the motor itself is immersed in the coolant. The liquid performs two important functions:

- Provides engine cooling;

- Performs a lubricating function.

Low noise level during operation is an undeniable plus, for which it is also worth choosing this type of circulation pump. It should not be forgotten that its efficiency level is much lower than that of a pump with a dry rotor and rarely rises above 60%.

When you are at the stage of deciding how to choose a circulation pump for heating your home, keep in mind that the service life of a pump with a “wet” rotor is higher; it does not require systematic maintenance. Taking this into account, for houses with a small volume of coolant in the system, it is optimal to choose the option of installing this type of circulation pumps.

The design of “wet” circulation pumps consists of:

- Pump housings;

- Impellers with motor shaft and rotor;

- Engine;

- Terminal box;

- Air propeller.

Read material on the topic: How to choose a bath faucet: 12 tips

This unit is preferable because a failed part of the device can be replaced at any time, and the air accumulated in the system is released using a special propeller.

A circulation pump with a “wet” rotor can be selected based on the parameters of the motor. Such pumps can be equipped with both single-phase and three-phase motors. The price of the pump depends on which motor you decide to choose. To attach it to the heating system, a threaded or flange fastening can be provided. Information about the power and performance of the device will help you choose the right type for a particular system.

Although the impeller and the rotor itself in such a pump are in constant contact with water, the possibility of corrosion damage to these elements is low. When deciding which pump to choose, you can’t go after the cheapest. This is due to the fact that the parts of a high-quality pump are made from corrosion-resistant materials and are practically not exposed to aggressive environments. And the effect of constant cooling of internal elements with coolant has a positive effect on the service life and service life of the circulation pump.

Pumps also differ in the way they remove air from the system:

- Auto;

- Forced (manual).

For users who are unable to maintain the heating pipe, it is better to choose a pump with an automatic air release system or invite a specialist to service the system each time. A circulation pump with an automatic air release system is more convenient to use. It is for this reason that it is worth choosing this option for installation in a private, and especially country house. It is the most acceptable, although due to its high price.

The temperature in the house is regulated using bypasses. To control the energy consumption (its increase or decrease) of the heating system, the following options are available:

- Using a switch located on the pump body (manual mode);

- Autonomous mode (automatic), when the role of the regulator is taken over by the automatic circulation pump. It allows you to select the speed of fluid circulation by increasing the motor speed depending on the outside temperature.

Other criteria

circulation pumps

number of speeds. As mentioned above, the presence of several modes is very convenient, since you can independently regulate the intensity of heating the air in the house. This is useful both in the absence of owners and during weather changes - during cold weather you can always increase the power of the system, and during warming - reduce it. The mode control method can also be different. One of them is manual. Switching is done using a special lever located on the pump body. But there is a more convenient option - automatic adjustment of work using sensors. They monitor changes in temperature in the house and adjust the pressure level in accordance with the specified settings. This approach allows you to do without constant intervention in the operation of the equipment;

rotor type. It can be dry or wet. In the first case, the rotor is only partially immersed in the coolant, in the second - completely. Both options have a right to life, but the “wet” variety is still more popular. Such models cope much better with a given load. In addition, they produce much less noise during operation. If the house is large and the boiler room is located in a room far from the bedrooms, then the last factor can be ignored. But in small dwellings, the use of a dry rotor can cause quite severe discomfort, especially at night, when sounds travel especially successfully;

material of manufacture

In order for the circulation pump to serve for a long time and efficiently, you should pay special attention to what it is made of. The best materials for the production of the case are durable stainless steel, brass and bronze

These metals are not subject to corrosion processes. Accordingly, they are not threatened by the destruction caused by the latter. Pumps made from these materials can last 20 years or even longer. There are also cast iron models. This material is also resistant to corrosion, but does not tolerate temperature changes well, which can cause it to crack. Therefore, installing it in a hot water supply system is not a good idea. In addition to the housing, also pay attention to the shaft and bearings. These elements must be made of ceramics. It is worth immediately noting that products made from stainless steel, bronze or brass are sold at a fairly high price in comparison with their cast iron counterparts. But this will be fully compensated by the reliability and long service life of the device.

To ensure a particularly long service life, you should carefully follow the rules for using the device. For example, many owners are bothered by the noise when the circulation pump is running. Some consider this a sign that the equipment is not working correctly. In fact, this is most often due to the presence of air in the heating system. It must be bleed before starting.

For this purpose, special valves are used, as well as Mayevsky taps, about working with which you can read in the corresponding article on our portal. After you have bled the air, start the heating system, wait a few minutes, and then carry out the bleeding procedure again. Only after this configure the necessary operating parameters of the circulation pump.

If the equipment you purchased is manually regulated, then after starting the heating system you must first set the maximum power. If the adjustment is made automatically using sensors, then all you need is to disable the locking mechanism.

Dear readers, if you take into account all the nuances described above when choosing a circulation pump, then be sure that your home will be consistently filled with heat. Good luck!

How to choose the right circulation pump for a heating system?

The choice of a quality pump depends on specific parameters

given below:

- Noise level, recommended frequency of pump maintenance;

- High productivity. It can be calculated by selecting operating conditions at maximum load;

- Amount of electricity consumed;

- System pressure pumped by the pump;

- Conditions for expected operation of the pump:

Features of the house design. Everything is taken into account - the thickness of the walls, the level of their insulation or lack thereof, the condition of the ceilings and floors, their level of thermal insulation. Ventilation in the house and the scheme for its implementation play an important role when deciding which circulation pump to choose.

- Climatic features of the region in which the house was built. The possible minimum air temperature, frequency and strength of wind loads, etc. are taken into account.

Returning to the noise level, it is worth highlighting the importance of this parameter. Despite the fact that it does not affect performance, if you choose a pump with a high noise level, this can significantly reduce the comfort of staying in the heated room. Therefore, try to choose a pump with a “wet” rotor when installing heating systems in a private house.

The circulation pump can be installed in the heating system in two ways.

Please pay attention to this when choosing a pump for your heating system.

- Pump in the heating boiler - most modern boilers are already equipped with circulation pumps.

- The circulation pump is mounted as a separate element on the heating system.

The second method of installing a pump is worth choosing if the house uses an outdated boiler. The systems of such houses implement natural coolant circulation. The coolant moves in the system due to the difference in mass and density of hot and cold water, larger diameter pipes and their installation at an angle to facilitate the circulation process. It is worth choosing to install a circulation pump in such a system - this will increase the speed of movement of the coolant, therefore reducing the heating time.

How to choose a circulation pump for heating according to technical characteristics?

The main operating parameters of the circulation pump are the generated pressure and productivity.

To wisely choose a circulation pump, you need to know their digital indicators or set them. Calculations in serious engineering systems require the use of cumbersome, complex formulas. The efficiency of heat transfer to heating radiators depends solely on these parameters, their correct selection taking into account the heat needs of the system and its hydraulic resistance. If you want to choose the right type of pump yourself, you can take their simplified versions and average technical data.

Read material on the topic: Ball valves wholesale: criteria for choosing a product and supplier

- Thermal power of the heating system and calculation of the performance of the circulation pump

To determine the required level of circulation pump performance, you first need to determine, calculate or set the useful thermal power of the finished or planned heating system.

The heating output of a heating system is based on the amount of heat required to comfortably heat the building

, and depends on the size of the building, the level of thermal insulation of external walls, floors, doors, windows, the maximum possible outside air temperature, the required indoor temperature, the massiveness of the building and its other parameters. It is easy to calculate the volume and area of heated premises using the existing building plan, calculator and tape measure. Heat losses through windows, doors and other enclosing structures can also be calculated, but it will be necessary to take into account not only their area, but also the materials of manufacture, thickness, design features and their orientation to the cardinal points. All this will turn the calculation process into complex actions that require special knowledge. To simplify it, you need to use building heat loss standards for certain buildings and structures, taking into account the level of their thermal insulation and the climate of the region. You can proceed from the calculation of the thermal power for a country house - 0.1 kW per 3 m3 of heated space, or 0.1 kW per 1 m2 of heated area. If the level of insulation of the heated room is insufficient, calculations are made taking into account large heat losses. If the house is well insulated and modern high-tech materials were used for its insulation, the value of the thermal power can be significantly lower. In any case, it is better to choose the option of additional insulation of the house than to burn large volumes of fuel to maintain a comfortable temperature in living quarters. It will soon pay for itself.

For example, in Finland, the calculated thermal power according to building standards is 3 kW per 100 m2 of heated space. Such phenomenal results are achieved through energy-saving thermal insulation of houses, and the standards themselves are legislated. The country pays great attention to energy saving policies.

To select a circulation pump for already operating heating systems with natural circulation, the thermal power of the system can be equated to the power of the heating boiler.

Having found out the thermal power of the heating system, we will calculate the performance of the circulation pump

using the following simple formula:

V = Q/(1.163 x Δt),

Where:

V – required pump performance level (coolant flow rate), m3/h;

Q – total thermal power of the heating system, kW. As an example, we can choose the case discussed above, when the thermal power of the heating system was equal to the power of the heating boiler.

1.163 – coefficient of specific heat capacity of water.

Δt – temperature difference at the inlet and outlet of the pipeline. For a standard two-pipe heating system circuit, as a rule, the difference is 20°C; for a heated floor, the difference will be about 5-10°C.

For example, in a house heating system implemented according to a two-pipe scheme and a thermal power of 16 kW and a difference in the temperature of the inlet and outlet pipelines of 20°C, the circulation pump must provide a performance of at least:

V = 16/(1.163 x 20) = 0.7 m3/h.

- Hydraulic resistance to the movement of coolant in the heating system circuit and the pressure created by the circulation pump

The only task of a circulation pump is to “push” water and maintain its continuous circulation in a closed system, and this task has nothing to do with pumping liquid from point A to point B, taking into account the difference in height. That is why the proposed “market” method of choosing a pump, based on the calculation of the pressure parameter and the “number of floors” of the building, is not entirely correct. In this case, it would be more logical to choose a pump based on the area that needs to be heated, and, accordingly, the total length and branching of the heating system. However, this will not be a calculation, but rather a way to choose, based not on the concept of the “operating point” of the device, but based on characteristics such as the color and price of the pump.

In a closed loop heating system, the movement of liquid is determined only by the pressure loss to overcome the frictional force in the parts and pipes of the heating system, in contrast to open systems, where the movement of water is determined by the difference in height. Based on this, it should be understood that circulation pumps do not have high pressure values, since there is no need for this.

The pressure of the circulation pump ensures that the total resistance of the heating system to the movement of coolant flow is overcome

with calculated performance. Calculation of pressure loss can be done using simple methods, the choice of which depends on the stage of installation of the circulation pump. At the planning stage of the heating system, the total pressure loss is calculated based on available techniques using certain computer programs. This calculation is based on the sum of local (diffusers/flow confusers, elbows of different diameters, shut-off valves, etc.) and linear (length, pipe cross-section) resistance values, which can be found in reference books or in accompanying documents provided by the manufacturer.

In a finished heating system, it is more difficult to accurately calculate pressure losses. In this case, average values and coefficients of influence on pressure in main pipelines and fittings are used. Simplifying, you can choose the following values as a basis: 0.015 m pressure drop per 1 linear meter. pipes. In shut-off valves and fittings, it is customary to proceed from the calculation of 30% of the total linear pressure losses. The use of thermoregulation valves in a heating system increases the system flow resistance by 50-70%.

Read material on the topic: Engineering plumbing wholesale: range and prices

To calculate the pressure of the circulation pump

to overcome resistance to water movement in a heating system, use a simple formula:

H = k×R×l

Where:

N – circulation pump pressure, m.v.st.;

l – length of the pipeline to the most remote heating battery, m;

R – average resistivity of the pipeline, Pa/m;

k – takes into account local resistance in connections and shut-off valves, Pa;

For a simplified calculation we take:

- Additional local resistance factor k = 1.3 - in heating systems with a minimum amount of fittings (simple systems), 2.2 - for systems with control equipment and 2.6 - for complex systems;

- Pipeline resistivity R = 100 - 150 Pa/m.

Example: a standard heating system implemented using a two-pipe scheme has a main pipeline length of 45 m. With these initial values, the pressure loss will be:

H = 1.3×0.015×45 = 8.7 kPa = 0.87 m.w.st.

Having thus calculated the values of pressure and productivity, the combination of which is usually called the “operating point” of the pump, you can select the desired circulation pump using manufacturers’ catalogs.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heating device, as well as significant energy consumption.

The required amount of coolant is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

Calculating the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio in which 1 kW of thermal energy is enough to effectively heat 10 m2 of living space. This ratio is fair in the presence of ceilings whose height is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S – cross section;

- π is a constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the cross-sectional area of the pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

You can determine what capacity the expansion tank should have by having data on the coefficient of thermal expansion of the coolant. For water this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K – expansion coefficient;

- D – efficiency of the expansion tank (indicated in the technical documentation).

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first count their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the product technical data sheet. In the absence of such information, you can navigate according to average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 = 12 liters.

As you can see, calculating the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in a system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, fill the system to approximately 90%, after which the functionality is checked. Next, the accumulated air is released and filling continues.

During operation of the heating system, a natural decline in the coolant level occurs as a result of convection processes. In this case, there is a loss of power and productivity of the boiler. This implies the need to have a reserve tank with working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it.

How to choose the right circulation pump for heating, taking into account external aspects?

To select the right circulation pump, it is worth considering both its operating characteristics and the conditions under which the pump will operate.

As we mentioned earlier, the heat-insulating materials used to insulate the house will help retain heat inside the premises, and, accordingly, less thermal energy will be required to maintain a comfortable temperature in the house.

The ambient temperature (the operating environment of the pump) will also contribute to a change in the operating mode of the circulation pump; at low temperatures, the performance of the device will be less.

Choosing a circulation pump is not easy. If you want to save money, you may prefer a cheaper option without paying due attention to such an important parameter as pump power. If it is insufficient, it can lead to overheating and further failure.

As the diameter of the pipeline increases, the required pump power increases, which is necessary for “pushing” large volumes of liquid. It should also be taken into account that in addition to water to fill the heating system, the user can choose a non-freezing liquid, the density of which will differ from the density of water. Accordingly, this parameter will also need to be taken into account when calculating the required pump power and choosing the most suitable option.

To choose the most economical pump, pay attention to such an important criterion as the amount of electricity consumed. Modern circulation pumps consume from 50 to 150 W. If you choose one that is overly powerful, its untapped potential may affect your budget.

Where can I buy a heating circulation pump

Choosing a suitable circulation pump is difficult, but purchasing one is not difficult. Any hardware store will provide you with a wide range to satisfy any needs. If you are still not satisfied with the product offered, you always have the opportunity to choose a pump online in an online store.

Many today prefer to choose a circulation pump using catalogs. This method allows you to easily compare the parameters of different pumps and greatly facilitates the final selection of the product that is right for you. It is worth considering that all characteristics are indicated based on operation at maximum loads.

The catalog offers high-quality circulation pumps from the manufacturer AQUALINK. Products manufactured under the AQUALINK brand have proven themselves well among buyers of plumbing equipment. Today the AQUALINK brand is the optimal ratio of price and quality. AQUALINK circulation pumps are used to circulate water in open and closed individual heating systems. The company's consultants will help you choose the pump that suits its characteristics, and will also advise you on pricing and delivery to your city.