Localizing the problem of boiler malfunction

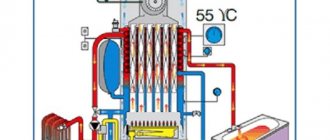

With the development of modern low-rise construction and gas networks, the boiler has become a common household appliance in every house or apartment. Basically, after installation, the boiler does not cause users any trouble. Modern boilers operate completely autonomously and require only regular maintenance or inspection. In our opinion, the average operating time of units before the first breakdown is from 4 to 6 years. Some users encounter problems even after 9 years, and some, on the contrary, earlier. In this material I will tell you what can be done if the boiler simply does not turn on, and I will also consider the most common malfunctions of gas boilers. The concept of “does not turn on” can mean completely different problems:

- There is no indication (the display is not lit)

- The boiler does not light up

- The boiler does not operate in any particular mode

Therefore, these different situations should be considered separately in detail. Please note that to eliminate some malfunctions, user intervention is sufficient, but in some cases it is necessary to call a qualified specialist.

Why does a gas boiler go out? Causes and solutions

Today, gas boilers are used everywhere, especially in winter. They act as the main part of an autonomous heating system. It happens that the boiler refuses to work correctly, for example, the flame may go out. When a consumer has a question about why a gas boiler goes out, it is necessary to analyze whether the device is working differently. Therefore, wind noise may be heard. It is important to pay attention to the display, which may show an emergency sign. In this situation, diagnostics should be performed to identify the causes that led to the problem. Otherwise, the temperature in the home may drop significantly, as a result, the system will defrost, which will then become unusable.

The boiler does not turn on - there is no indication

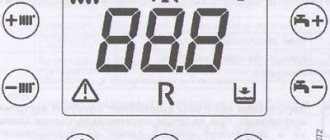

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all you need to make sure that power is supplied to the boiler. Typically, the electrical connection of the boiler is carried out through a separate “automatic machine” - check whether it is turned on or not.

The surest way to make sure that power is supplied to the boiler is to check with a multimeter in voltmeter mode the presence of 220V at the connection point to the boiler board. If there is no voltage, it is necessary to localize and eliminate the problem. In real life, it happens that someone in the household simply pulls the plug from the socket.

Safety fuses

It is also worth paying attention to the location of the fuses. In some boilers, depending on the model (for example, Ariston, Buderus, Vaillant), the fuses are located on the board itself, and in some, before they are connected to the board. If there are no problems with the electrical connection to the boiler, you should check the integrity of the fuses (with the same multitester in the “continuity” mode).

If the fuses are intact and there is 220 volts at the control points, it is likely that the boiler does not turn on due to a malfunction of the control electronics.

If during the inspection it turns out that the fuses have blown, then there was at least a problem with the power supply. In this case, it would be correct to first conduct research on the actuators (fan, pump, priority valve) and boiler wiring for a short circuit. However, in practice, even representatives of specialized organizations simply replace the fuses with good ones and check the boiler in operation. If the fuses blow again, then sequentially turn off the high-voltage parts of the boiler to identify the problem area (this is not a recommendation for action! This approach is not entirely correct).

Several spare fuses are usually supplied with the boiler.

If the fuses blow due to damage to one of the actuators, it must be replaced (or the cause of the short circuit must be eliminated). In the case where it is proven that the mechanisms (and wiring) are in good working order, the control board itself remains. Blown fuses indicate that there was an unacceptable load on the electronics (thunderstorm, pulsed power surge in the network), so the cause of the malfunction may also be a short circuit on the board itself.

Water (moisture) getting on the board

Water ingress is one of the most unpleasant situations. Although the board is in a protective case, water may get inside due to leakage or condensation. Often it gets into the box through the wires. Water ingress almost always causes damage to the board, in most cases irreparable. Characteristic stains and oxidation will be visible on the board due to water.

Varistor and power supply

Often, if the boiler board is damaged, burnt or charred elements can be visually detected on it. A varistor is a protective element of the board that is installed at the input of the circuit. In most cases, this is a blue round part (but not necessarily). When the rated load is exceeded, the varistor is destroyed and opens the circuit. In some cases, if the varistor helped prevent damage to the electronics, biting it out is enough to eliminate the gap in the circuit. Important! Although the board circuit will work without a varistor, it should be remembered that the varistor is a protective device and the correct solution would be to replace it. The power supply is a microcircuit that is also damaged primarily by pulsed power surges or during a thunderstorm. If cracks or damage are visible, the boiler board will likely need to be diagnosed and repaired.

Display board

For some boiler models (Vaillant, Ariston, Navien), the control unit consists of a main board and an information board (display board). The boiler may also not turn on if the display board is broken. The display board, unlike the main one, is cheaper, but most often cannot be repaired. In this case, the fault can only be identified by replacing a known good part.

If the gas boiler is working, there is an indication on the display, but it does not start or produces errors, further diagnostics are required.

Hot water supply faults (error 2**)

These types of faults occur in Ariston double-circuit gas boilers. For hot water supply, the safety system is autonomous, which allows you to quickly identify the problem.

Many Ariston boiler models support the ability to connect a solar system as an alternative energy source for hot water supply. Therefore, some errors and warnings of the “2**” series are related to the operation of solar panels.

Error No. 201. Problem with the power supply to the temperature sensor - open or short circuit. It is necessary to eliminate the breakdown of the electrical wiring.

Errors No. 202-205 are related to the operation of the sensors. When the signal stops coming from them or it behaves unpredictably (sudden jumps in data), then these errors are triggered:

- № 202. Problem with the boiler or solar system sensor.

- № 203. Problem with NTC temperature sensor.

- № 204-205. There is a problem with the temperature sensor that records the operating values of the solar collector.

To solve problems No. 202-205, you need to check the contact density. If this is not the case, then you will have to replace the faulty sensor.

Error No. 206. Problem with the cold water temperature sensor in the solar system. The solution is the same as for errors No. 204-205.

The temperature sensor is easier to replace than to clean. They are inexpensive, and they are easy to find, since parts with standard parameters are installed in the boilers

Error No. 207. Overheating of the solar thermostat. This may be caused by solar energy not being used to heat the water. Then the collector must be turned off. This malfunction can also occur when the thermostat breaks down. In this case, it will need to be replaced.

Error (warning) No. 208. Insufficient heating in the solar circuit. There is a risk of the coolant freezing. Turns on when the anti-freeze function is activated. Part of the energy from the gas will be used to heat the collector.

Error (warning) No. 209. Overheating of water in the boiler connected to the boiler. There may be a problem with the thermostat or its contacts.

The boiler does not light up

If a gas boiler does not ignite, then in most cases there will be an error signal on the information panel indicating its number or code, by which you can approximately find out in which boiler system the malfunction occurred and how critical it is. All double-circuit boilers provide switching between summer and winter operating modes. In summer mode, the boiler will not turn on to heat the room (the same is true when using weather-compensated automation or thermostats).

If the boiler does not ignite and does not make any attempts to turn on (stands idle) when necessary, this may be an electronic malfunction, but such cases are rare and concern specific boiler models.

Usually, if there is a malfunction that prevents the boiler from operating normally, the user will receive an error. That is, if the boiler does not ignite, you need to determine the error code and find its meaning in the equipment operating manual. Error codes with descriptions are always indicated there.

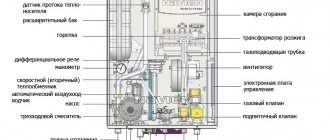

Next, we will consider the most common boiler malfunctions that users encounter. It is worth mentioning here that mostly all modern boilers have the same basic structure and operating procedure. However, to solve a specific problem on a specific boiler, you need to at least read the instructions for that boiler.

Several unsuccessful ignition attempts

This is the very first error code for most equipment manufacturers. For BAXI E01 boilers, for Arison 501 boilers, for Vaillant F28. Ignition of the gas-air mixture in the combustion chamber will occur under two conditions: the presence of gas at the burner nozzles and the presence of a spark. Gas enters the burner through the gas valve, the spark is generated by a transformer on the control board (or remote). A separate case should be noted when ignition occurs, but the boiler cannot detect the presence of a flame and goes out (closes the gas supply valve).

The most common reasons:

Phasing error

. Often, gas boiler boards require connection polarity. For the average user, this means that the position of the plug in the outlet matters. If the connection polarity is reversed, the boiler does not see the presence of a flame, continues ignition (electrode crackling) even when there is already a flame on the burner, then turns off due to an emergency. Even if you did not touch the plug, the polarity could change at the substation!

Ignition or flame ionization electrode

. It can be separate or combined. The main problems may be related to contamination (oxidation) of the electrode or its gap relative to the burner. A dirty ionization electrode prevents the board from detecting the presence of a flame and operation stops.

High voltage wire. High voltage is generated by a transformer and transmitted through a wire to the electrode, where it pierces the air gap between the burner and the electrode with a spark. If a characteristic crackling sound is heard, but a spark on the burner is not visually visible, it is possible that the breakdown is occurring somewhere else. For example, there is a microcrack in the insulation of a high-voltage wire, and a breakdown occurs at the point where the insulation on the housing is broken.

Electrical connection problems

. The presence of parasitic potentials on the boiler body, lack of grounding or low voltage of the supply network can cause problems with ignition. I often hear the argument: everything used to work without grounding. No one will understand how the boiler worked without grounding. According to the operating instructions, this must be done! For normal operation of the boiler there must be: a network voltage of at least 180 volts, a potential between the neutral and ground wires of up to 10 volts, and the presence of grounding.

No gas on the burner

. The gas valve controls the gas supply to the burner: it opens and modulates (gas dosing). The gas valves are regulated and controlled by a control board. Accordingly, the cause of the problems may be a malfunction of the valve (or the need for adjustment), its electrical part, or the control circuit on the board. This device should be checked by a specialist. The lack of gas can also be due to external factors: a faulty meter, dirty filters.

Control board.

In some cases, lack of ignition or flame control is caused by a malfunction of the boiler main board. This can be considered after the other possible causes as described above have been accurately checked.

Insufficient draft (fan does not turn on)

Also a popular problem. If there is a problem with the removal of combustion products, the boiler will not start and ignite until it is completely eliminated. Such malfunctions and their solutions are described in more detail in a separate article - chimney errors.

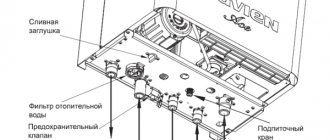

Insufficient water pressure (refill required)

Traditional gas boilers operate in a closed heating system; accordingly, to prevent the boiler from turning into a hydrogen bomb, there must be a minimum water pressure inside the heat exchanger (in fact, the presence of water and circulation there). The pressure is controlled by a special sensor - a pressure sensor. The boilers are provided with an additional mechanical pressure gauge for the user. Although the systems are closed, the pressure in them can drop over time (for example, water escapes through leaks in the connections). As soon as the water pressure in the boiler drops below the minimum level (0.5 - 0.7 bar), the boiler sensor detects a malfunction and blocks operation. In most cases, you just need to study the readings of the mechanical pressure gauge and recharge the system according to the instructions for the boiler.

Electronics failures (error 3**)

Such complex modern equipment as gas boilers are equipped with electronics for automatic operation and response to different situations. Control boards can fail as a result of aging, power surges, excessive humidity, or mechanical damage.

Error No. 301. Problems with the EEPROM board (non-volatile memory) of the display. If such a message appears, you need to check whether the EEPROM key is installed correctly on the motherboard. This must be done as described in the user manual for the corresponding model.

If the key works correctly, then you need to check the contacts of the cable from the motherboard to the display board. There may also be a problem with the LCD screen itself. Then it will have to be replaced.

The display is connected to the board using a cable. If the boiler is working and the screen goes out, then first of all you need to check the quality of the connection. Naturally, with the power completely off

Error #302 is a special case of the previous problem. Both boards pass the test, but the connection between them is unstable. Usually the problem is a broken cable core that will have to be replaced. If it is ok, then the fault is on one of the boards. They can be removed and taken to a service center.

Error No. 303: Main board faulty. Rebooting usually does not help, but sometimes it is enough to turn off the boiler from the network, wait and turn it on again (this is the first sign of aging capacitors). If this problem becomes regular, the board will have to be replaced.

Error #304: More than 5 reboots in the last 15 minutes. Talks about the frequency of problems that arise. You need to turn off the boiler, wait a while and turn it on again. You should monitor it for some time to identify the type of warnings if they occur again.

Error No. 305. Program crash. You need to let the boiler stand off for a while. If the problem persists, you will have to reflash the board. This must be done at a service center.

Error #306 : Problem with the EEPROM key. The boiler needs to be restarted. If the error repeats, you will have to change the board.

Error No. 307. Problem with the Hall sensor. Either the sensor itself is faulty, or there is a problem on the motherboard.

Error No. 308. The combustion chamber type is incorrectly set. You need to check the installed combustion chamber type in the menu. If the problem is not resolved, then the EEPROM key may be installed incorrectly or the motherboard may be faulty.

You can try to repair any electronic boards at a computer repair shop. Especially if the problem is caused by loss of contact or aging capacitors

Error No. 309. Registration of flame after blocking the gas valve. In addition to a malfunction of the motherboard (it will have to be replaced), there may be a problem in the ignition unit - loose closing of the gas valve or a malfunction of the ionization electrode. If the problem is in the electrode, then you can simply try to dry it.

The boiler does not work in DHW or heating mode

And finally, situations when the boiler does not operate in a particular mode. They happen much less frequently compared to others. In this case, it is likely that the boiler will need to be diagnosed by a specialist. The process of ignition and operation of the boiler in different modes is virtually the same, with the exception that different modes may have different power. In hot water preparation mode, the boiler power is usually full, but in heating mode it can be minimal. You can read about problems in the operation of the DHW mode in a separate article.

Communication with peripheral devices (errors 4**)

The screen of Ariston geysers displays error codes for standard peripheral devices. This was done in order to explain the reaction of the boiler automation to an emergency situation. In this case, the consumer will be able to try to fix the equipment breakdown or conflict on his own.

Error No. 401. Communication problem between the bus and the data transfer device. It can be caused either by a malfunction of the device itself or by damage to the bus. Repairs are only possible at a service center.

Error No. 402. GRRS/GSM modem malfunction. You need to check its connection or replace the device.

Error #403: SIM card problem. The contact has come loose or the card itself is damaged.

Error No. 404: Data transmission between modem and motherboard failed. First of all, you need to check the contacts. If they are tightly connected, then the modem is faulty.

The GSM gas boiler control module allows you to remotely control the heating modes of the building. However, in addition to the obvious advantages, there is also a disadvantage - this is another unit that can break

Error No. 405-406. Data bus (interface) problem. Usually the fault lies in loosely connected contacts. Less often the tire itself needs to be replaced.

Error No. 407. Lost signal from the room temperature sensor. You need to check the connection (wire and contacts). If they are in good condition, then you need to replace the sensor itself.

Summary

In this article we looked at the most common cases when the boiler does not turn on or ignite. No one anywhere on the Internet will definitely tell you why your boiler won’t turn on; this requires at least an external inspection. This material will help you get acquainted with possible situations in general and is written on the basis of our statistics over several years.

If there is a malfunction, you need to determine the error and read the boiler operating manual. Also, for many boiler models, error descriptions with recommendations are available on our website. Malfunctions can be simple, which the user can fix independently, or complex, requiring qualified assistance and spare parts. We strongly do not recommend performing any actions with the boiler if you do not fully understand its structure and principles of operation, disabling protective devices or changing the boiler’s operation circuit to restore its operation. If there is a malfunction, it must be eliminated! If the cause of the malfunction is not completely clear to you, it is better to call a specialist.

Problems with multi-zone control (errors 7**)

Ariston brand boilers allow you to divide your house into zones, each of which will have its own heating mode. If a problem occurs with one of the sections, the system accurately determines the malfunction, so repair of a specific circuit can be carried out without interfering with the remaining normally operating parts of the heating network.

Error #70X. There is a problem with the coolant supply temperature sensor in zone X. It is necessary to check the sensor contacts or replace this part.

Error #71X. The same thing, only with a sensor on the return line.

Error #72X. Overheating has been detected in zone X. First of all, you need to check the operation of the thermostat responsible for this area. It may simply be a loose contact or a broken unit. If it works correctly, then you need to change the settings.

Error No. 750. Hydraulic circuit error. The correct type of hydraulic module connected must be set (menu parameter 720). If there is no error here, then the problem is in the settings of the circuit itself.

Conclusion:

Taking into account the cost of the Ariston boiler, it is not advisable to take excessive initiative in identifying and eliminating the flame separation error on your own. Everything that is recommended for the user to check and perform is indicated in the article. There is no result - call a representative of the service organization.

Practical advice

- A one-time visit from a technician due to a problem with the boiler is expensive. On thematic forums you can find the following data: 5000 rubles for eliminating the flame separation error. It is more expedient to conclude an annual maintenance agreement with a service center (cost about 2500). The benefit is double – significant money savings and professional service.

- Experts recommend mitigating the risk of electrical interference on the gas main. For this reason, the control circuit of Ariston boilers often gives failures and errors. In some cases, the program is broken, and the board has to be reflashed. This problem can be avoided by installing dielectric inserts on the pipe (in several places); with professional installation this is done immediately.

- When connecting an Ariston boiler to a gas tank, you need to choose the right supplier of “blue fuel” and conclude an agreement with him. If the flame separation error is caused by low quality LPG, there will be someone to file a formal claim and compensate for possible damage (both moral and material). And one-time calls to fill the reservoir of representatives of little-known organizations, even those offering a low price, should not be practiced. Solving possible problems with the operation of the Ariston boiler will ultimately cost more.