Previously, draft and blower fans were used only in industrial boiler installations. The first ones are placed inside the chimney channel and create a vacuum, the second ones pump air into the firebox. Gradually, the units migrated to the domestic sphere - manufacturers began to equip heaters with a closed combustion chamber with turbines. The idea was picked up by home craftsmen, because a smoke exhauster for a boiler helps solve the problem of poor draft in the chimney pipe. Let's figure out whether forced exhaust of combustion products is always necessary.

Design and principle of operation

An exhaust fan for a factory-made boiler includes the following elements (the device is shown in the diagram, the positions coincide with the points):

- Metal heat-resistant impeller with blades bent at 90° relative to the impeller.

- Mounting plate.

- Low-performance electric motor (20…50 W).

- Power cable connector.

- Remote control with controls and controls.

- The flask and capillary tube of a temperature sensor connected to an emergency thermostat.

- Power cord with plug.

Note. The boiler smoke exhauster DM-01 from Kalvis is taken as an example. The design of other types of fans differs in the shape of the housing - volute, box, hemispherical landing pad. The set of parts is similar.

The unit is attached to a special box located on the rear panel of a domestic TT boiler next to the chimney pipe. The temperature sensor bulb is inserted into the immersion sleeve of the water jacket, the remote control is placed separately.

The principle of operation of the smoke exhauster is the forced removal of high-temperature gases from the fire-tube heat exchanger of the boiler into the chimney. The algorithm looks like this:

- The firebox is filled with wood and ignited.

- The loading door is locked, the blower door is opened. The fan is turned on using a key on the remote control, then the performance is adjusted.

- When the heating installation and chimney have warmed up, the impeller speed is manually reduced to a minimum. If the heat generator has enough natural draft, it is recommended to turn off the smoke exhauster.

- When the coolant heats up to a critical temperature of 100 °C or more, at the command of the sensor, an emergency thermostat is triggered, turning off the fan automatically.

Diagram of operation of a boiler smoke exhauster

Reference. On TT boilers equipped with an automatic draft regulator, there is no need to open the ash pan door. The thermostat, through a chain, will open the air supply damper to the required angle.

High or low performance of the draft fan is set individually depending on the quality of solid fuel, combustion mode and degree of heating of the chimney. The main thing is to avoid the accumulation and leakage of smoke into the room.

You also can’t go overboard with the speed - the lion’s share of the heat will go down the drain. Before opening the door and reloading, it is better to increase the rotation speed to maximum.

A ready-made fan unit from the famous Russian brand Zota is mounted on wood-burning heaters with rear gas outlet

Features of use

In solid fuel boilers, such types of fuel are often used that it is impossible to do without a forced increase in air supply - sawdust or peat burn poorly without blowing. A complete heating process here is only possible with the help of a smoke exhauster.

The hood, unlike pressure units, allows fuel to be supplied to the boiler continuously, which increases its performance and prevents gaseous combustion products from penetrating into the room.

Use of hoods:

- improves the efficiency of boilers, leads to complete combustion of firewood;

- prevents the accumulation of smoke in residential premises, eliminates unpleasant odors;

- prevents the return of exhaust gases into the room when the door is open;

- reduces the amount of deposits on the walls of chimneys;

- With proper installation and regular maintenance, the service life of the smoke exhauster can be equal to the duration of use of the boiler.

Types of traction fans

Several types of smoke exhausters are sold for solid fuel boilers and wood-burning fireplaces:

- boiler (the design is discussed above);

- centrifugal channel;

- overhead;

- fireplace/stove (aka roof).

Various attachments that improve natural draft, such as deflectors, round rotating elements and rotating weather vanes, should not be classified as smoke exhausters. The effectiveness of these hoods depends on the wind speed, which changes with the weather.

Varieties of duct smoke exhausters, some models are equipped with temperature sensors.

The duct fan is distinguished by its own housing with two connecting flanges or pipes. The unit is installed vertically or horizontally into the gap in the chimney duct. The device and principle of operation are similar to the operation of a boiler smoke exhauster.

The overhead smoke exhauster for a domestic boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (uninsulated):

- An opening is cut out in the pipe using a paper template.

- The impeller of the traction machine is inserted into the hole, and the platform with the electric motor is pressed to the surface with clamps.

- The connection is sealed with an asbestos cord glued to the inside of the installation site of the smoke exhauster.

Note. The overhead element is selected according to the diameter of the flue pipe. The installation process is demonstrated in the video.

Electric fireplace hoods are mounted on the head of a brick chimney and secured with spacer bolts. The power cable is laid through a pipe and introduced into the room next to the home stove.

To choose a traction machine, you need to focus on 3 criteria:

- heat generator power, smoke exhauster models are designed for boiler performance up to 20, 30, 50 and 100 kW;

- installation point - on the boiler itself, pipe or head;

- for overhead models – the diameter of the uninsulated flue.

Overhead (left) and roof-mounted smoke exhauster (right)

DIY making

The thermostat, as an automatic device for regulating the operation of the heating system, can be purchased at the electrical goods retail chain. At the back of this device there is a heat removal plate; it will need to be pressed against the exposed part of the unit.

The thermostat has three contacts inside: common, normally open and normally closed. By rotating the adjusting knob, you can change the positions of the contacts.

So you need to set the handle to the minimum mark and connect to the open contacts:

- to the general one .

- We connect one wire from the turbine to the open one

- to the second wire from the turbine .

An automated control system is rightfully considered not only convenient, but also an effective device. With its help, you can significantly simplify the process of operating the heating system.

Solid fuel, such as firewood, has been considered excellent since ancient times.

A wood-burning boiler is perfect for country houses to heat your home. Of course, with the pace at which technology is developing, you can see that firewood has given way to other fuels. But even at the moment, wood-burning boilers continue to fully perform their duties and help out those who do not have the opportunity to connect to gas equipment or use home electricity.

When do you need a smoke exhauster?

Manufacturers of heating equipment equip their products with traction fans due to the increased resistance of the heat exchanger, where gases change direction of movement several times through the flame tubes. The goal is to remove maximum heat from combustion products and increase the efficiency of the boiler installation.

A nuance: the operation of the smoke exhauster in a factory-installed boiler is coordinated with the combustion process and is controlled by an electronic unit. When installing a fan unit on a “brainless” heater, such consistency is excluded; you need to buy an automation unit or adjust the speed manually.

Organize fresh ventilation in the boiler room, and only then think about installing a smoke exhauster

We list the situations when a smoke exhauster will help improve the operation and maintenance of a solid fuel heat generator:

- problems with draft - blowing by the wind, air pockets in the gas duct, many turns, narrowing of the diameter;

- due to the design features, the boiler smokes into the room when the door is opened;

- the height of the chimney is insufficient or the cut of the pipe fell into the wind support zone behind the ridge of the roof or another building;

- Cracks have appeared in the brick pipe, from which smoke is leaking.

Important point. No fan will save the situation if there is no influx from the street in the boiler room. At first, the working impeller will create a slight vacuum, but then the blades will begin to mix the air in place. Supply ventilation is a prerequisite for the normal operation of any heater.

It is better to operate the V. G. Kholmov mine heat generator with a traction fan.

Some designs of wood-burning boilers (for example, shaft type) tend to emit smoke through an open loading hatch. A similar picture is observed in heat generators with a three-pass fire-tube heat exchanger of high resistance. The solution to the problem is to install a traction or blowing machine controlled by a controller.

Strengthening natural draft with the help of a smoke exhauster also has a downside. If, after warming up the pipe, natural exhaust has not been restored, the unit cannot be turned off - you may get burned. Now imagine that in the middle of the night the power supply goes out and the fan stops. While the chain thermostat closes the damper, smoke will fill the boiler room.

Recommendation. The smoke exhauster should not become a panacea. Be sure to take measures to restore draft - repair or alter the flue in accordance with the requirements specified in the boiler instructions.

Automation for solid fuel boiler equipment

The traction control works great, but only when there are conditions for creating traction. The main problem with natural draft is weather dependence: the smaller the difference between the air temperatures outside and in the house, the worse the draft. Modern sealed houses with metal-plastic windows, into which the flow of air mixture is completely absent or limited, also add fuel to the fire. To solve the traction problem, automation was invented. By controlling the operation of the fan and circulation pump, the issue of stabilizing the temperature of the coolant is resolved.

Which is better - a smoke exhauster or a blower?

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct combustion boiler is another matter. You need to understand that in this case, the smoke exhauster solves only 1 problem - creating a vacuum in the firebox and increasing draft. There are a number of negative points here:

- Without an electronic control unit, performance will have to be adjusted manually. Automatic maintenance of coolant temperature is excluded.

- When air is supplied through the open ash chamber door, the fan will force the boiler to operate at maximum. Setting up a long burn mode will not be easy.

- In the event of an emergency stop of the impeller, fuel combustion will not stop, since gases pass freely through the volute or the body of the smoke exhauster. Air enters the firebox, increasing the likelihood of overheating.

- The impeller and internal surfaces of the unit become covered with soot, which must be removed. The rate of sticking depends on the moisture content and resin content of the wood.

Comment. We don't mention the fan's power consumption. The consumption is relatively small and will not have a significant impact on the overall cost of heating.

A blower fan with an automation unit performs the same functions as a smoke exhauster.

The disadvantages described in paragraphs 1 and 2 are eliminated by connecting the smoke exhauster with a controller that controls the speed of the impeller and the temperature of the water jacket. Electronic units can be purchased at a price of 50-100 USD. e.

Blowing machines always work in conjunction with a controller, so the problems listed above do not exist:

- the blower changes performance and turns off at the command of the control unit, the coolant heats up to the set temperature;

- during the combustion process, the ash pan door is hermetically closed, air is supplied through a separate channel;

- when there is a power outage, the air channel is automatically closed by a gravity damper;

- the impeller blades do not come into contact with hot smoke and soot.

Reference. In pyrolysis boilers, pressurization is always used, since the operation of this type of heater is based on forced air injection.

Now let’s compare the cost of a traction fan and a blower fan, not taking into account the price of the controller. A smoke exhauster for a TT boiler up to 30 kW will cost 90 USD. e., supercharger - 60-65 cu. e. The difference is due to the design features of the exhaust unit - hot gases should not overheat the electric motor, plus the impeller is made of metal (when pressurized, it is made of plastic).

Behind the mounting flange of the unit there is a small impeller designed to cool the electric motor

The installation complexity of the units is approximately the same. Installation of the discharge volute involves cutting out an opening in the ash pan door, and the smoke exhauster involves disassembling or cutting out the pipe. It is easier to install a roof hood, but you will have to pull a long cable.

Brief conclusion: install a smoke exhauster only if necessary, or better yet, correct mistakes made during the construction of the flue. Add electronically controlled turbocharging as desired - the system will automate and secure the combustion process.

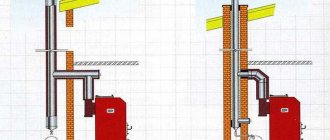

Chimney for solid fuel installation

Speaking about the dependence of the operation of a solid fuel boiler on draft, one cannot help but touch upon the topic of arranging a chimney, thanks to which the combustion products are released into the atmosphere in a timely manner. Modern boiler units with a closed combustion chamber are equipped with a coaxial smoke exhaust, which has many advantages and does not require it to be installed above the roof. Most models of boiler equipment with an open combustion chamber require a stationary chimney, which must be in accordance with fire safety rules and have the necessary design to ensure unhindered removal of combustion products.

https://www.youtube.com/watch?v=ZUXWDzWeXk4 The following materials are used to construct the chimney:

- Brick. Traditional brick pipes do their job quite well, but they are heavy, have a complex masonry pattern and require a solid foundation.

- Stainless steel sandwiches. An excellent design, which consists of sections of double pipes, between which there is insulation. This material allows you to do without a foundation and can be assembled by one person, like a constructor. But this design also has a disadvantage - high cost.

- A ceramic chimney is an excellent alternative to steel sandwiches. It is easy to assemble, has good fire resistance and a perfectly smooth inner surface, and can withstand temperatures up to 900°C.

It’s easy to install a ceramic chimney for a solid fuel boiler with your own hands, because it is assembled from chimney blocks, like a children’s construction set. A ceramic pipe insulated with mineral wool is inserted into the assembled chimney. Advice: when choosing a chimney for a solid fuel boiler, be guided by the installation data sheet, which gives the recommended cross-section of the smoke exhaust channel. In addition, when choosing, focus on the temperature and pressure of the exhaust gases when operating in natural draft and boost modes. Don't forget about condensate drains and collectors!

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.

We offer ordinary homeowners the least thorny path - buy a factory electric motor with an impeller and a cooling impeller, weld the box and assemble a fully functional duct smoke exhauster for a TT boiler. How to do this correctly, watch the video.

Specifications

Not only factory-made hoods can be installed in the chimney. If desired, it is not difficult to install a homemade smoke exhauster. In order not to make a mistake when purchasing or manufacturing components of a mechanism, you first need to familiarize yourself with its technical parameters.

The design of the smoke exhauster consists of:

- housing or casing for the impeller made of heat-resistant steel, the thickness of the sheets of which is not less than 1.5-2 mm;

- an AC electric motor installed outside the impeller housing, this arrangement increases its service life;

- a shaft connecting the engine to the impeller and mounted on bearings with hermetically sealed seals;

- inlet and discharge pipes and dampers;

- ash collection bunker;

- impeller (impeller), material of manufacture - alloy steel.

The metal must withstand temperature loads of up to 300° C and the aggressive effects of hot gas exhaust. Before installation, careful balancing is necessary to prevent excessive vibration, leading to premature wear of the mechanism. Impellers can be bladed or centrifugal.

Exhaust parameters for solid fuel boilers consist of:

- electric motor power;

- productivity (calculated in 1 m³/h);

- created pressure.

It will be good if the resources of all indicators of the unit are higher than those required by operating conditions. This increases the reliability of the machine.

Deflectors for hoods

This is a fairly common option for forced ventilation. A deflector is an aerodynamic device that is installed above the chimney. It increases draft in the chimney due to changes in air flow. The essence of its work is the pressure drop when air flows around an obstacle, as well as the principle of changing air flows. It turns out that its shape allows you to increase draft in the chimney. Made of stainless steel, they are not afraid of corrosion, resistant to acids and high temperatures.

It cannot be called a full-fledged fan, since the deflector has a simple shape, without working mechanisms. But, there are types of smoke deflectors designed specifically for chimneys.

- Wolpert deflector.

- Grigorovich deflector.

- Round or spherical deflector.

It is the round deflector that can create rotational movements under the influence of wind and remove smoke from the room. But, again, the disadvantage of the product is that it is ineffective in the absence of wind. The operating principle of this draft amplifier for ventilation pipes and chimneys is demonstrated in the video*

In addition, weather vanes, umbrellas and similar structures are often installed on chimney pipes. But they can't do everything that a high-temperature chimney fan can do. Let's look at how they work and what makes them special.

Traction regulator

The only problem: the owner of the boiler unit must adjust the position of the air damper manually, relying on the thermometer readings and his own experience. To automate this process, an automatic draft regulator was invented.

The device consists of a thermal element, a regulator, a metal lever and a chain. The thermoelement and regulator are assembled into a single housing made of heat-stable and corrosion-resistant steel. The thermostat is installed in the mounting socket until it comes into contact with the coolant circulating in the water jacket of the boiler unit.

The principle of operation of the regulator: when temperature affects the thermoelement, it changes its shape and, through the rod, acts on a lever, which is connected to the air damper of the boiler unit using a chain. When the coolant temperature changes, the position of the air damper automatically changes. The regulator sets the upper temperature limit.

To set up a draft regulator for solid fuel boilers with your own hands, you need to follow these steps:

- Install the regulator into the heating system. Depending on the boiler model, both horizontal and vertical installation of the device can be provided. Each installation option corresponds to a specific scale color on the regulator. At this stage the chain is not connected to the choke and hangs freely.

- Set (by selecting the color of the scale corresponding to the orientation) the desired temperature indicator of the coolant and start the boiler installation.

- When the coolant temperature reaches the value you set on the thermostat, close the air damper, leaving a gap of 2-3 mm.

- Attach the chain to the damper rod.

Let's digress a little, because we want to inform you that we have compiled a rating of solid fuel boilers by model. You can learn more from the following materials:

Blower for the boiler: why install a blower

Installing a blower for the boiler is necessary to create forced draft. Thanks to this installation, the required amount of air will be supplied into the chamber continuously.

Thanks to the boiler vent, you can speed up the combustion process

Why else do you need a blower:

- If there is not enough air, the full operation of the boiler may be disrupted. The fuel will no longer burn completely, and the chimney will become clogged more often. This will lead to additional cleaning costs.

- If the fuel does not burn completely, the insulating materials will begin to burn out, and their regular replacement or repair will lead to an increased cost of operation.

- Due to the decrease in draft, the room will begin to become saturated with smoke. This will result in the owner needing to install additional ventilation.

It is for these reasons that it is better to initially purchase a blower, spending a certain amount on it once, and you can do the installation yourself.