Today, many are wondering how and what is the best way to heat their home if there is no gas. Firewood and coal are among the most affordable types of fuel. Therefore, the right solution here would be to build a heating stove, or even better, add a cooking stove function to it. There are a lot of design options both in form and in operating principles.

In this article I will introduce you to the features of the Kuznetsov furnace, its advantages and a step-by-step scheme for constructing such a unit yourself.

Features of the Kuznetsov furnace

Since the main goal of Kuznetsov’s developments was efficiency and productivity (he worked to increase the efficiency value), this required a fundamentally new and improved approach.

If you look at the drawings of Kuznetsov’s furnaces, every professional sees that he has thought out the system of internal gas movement most competently. As a result, thanks to the design solution, hot air lingers in the unit for a longer time and retains heat, and cooled air masses quickly fly away into the chimney through a special recess.

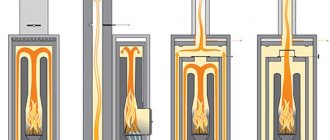

Such furnaces are called “bell-shaped” furnaces. Inside, they combine the hearth and the lower part, creating a kind of cap. Its functional purpose is to separate gases into cold and hot. The last of them rise into the bell and, lingering in it, concentrate the heat. The combustion temperature in such units is higher, and their efficiency is 95%. How much more efficient the functioning of the structures developed by Kuznetsov is is evidenced by the fact that for a traditional Russian stove this figure is 25-40%.

What is the difference

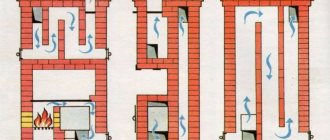

The main feature of the group of stoves invented by Kuznetsov is the absence of extended smoke channels with many turns and bends. To make the most of the heat from burning fuel, duct stoves have a system of passages through which hot smoke heats the bricks. In this case, the oven heats up unevenly at different levels, which can lead to cracking of the masonry. In addition, there is a need for regular cleaning of narrow places and corners.

Kuznetsov's stoves for home and bathhouses do not have this drawback. In them, hot gases from the firebox enter the so-called hood - an internal space limited at the top by the ceiling and having an outlet at the bottom. The heated smoke rises to the very top of the hood, where it lingers until it begins to cool. As they cool, they gradually fall down along the walls of the bell, and a new portion of smoke takes their place.

The cooled smoke exits through the channel into the chimney or into another hood, depending on the design and purpose of the stove. Gradually, as it passes through cascades of hoods, the flue gases cool to a temperature of 120-150 degrees. The temperature of the gases at one level of each cap is the same, which avoids uneven expansion of the brick.

Basic rules for creating a heating stove

- To make Kuznetsov stoves, the ordering (masonry diagrams) should be printed in advance.

- The refractory shell located inside the furnace must be free on all sides, since the brick expands during the heating process.

- Internal refractory masonry when using fireclay bricks is always done on edge. If the bricks are made of clay, on the inner walls and on the posts, they are laid at the discretion of the stove-maker.

- To strengthen the bond, a wire is laid every two brick rows.

- When a Kuznetsov stove is created, the ordering of brick stoves for a home provides that various elements (for example, doors) are installed in such a way that there is room for expansion. A special gasket is placed between the brick and the metal element.

- After completing the construction of a brick structure, it should be treated with a fire-resistant compound.

- The first kindling begins at a minimum temperature and is then gradually increased.

Advantages and disadvantages of the oven

Advantages:

- high efficiency factor of 75-85% (efficiency);

- fuel burns at high temperatures;

- the stove operates on all types of solid fuel - wood, hard and brown coal, briquettes, etc.;

- ease of maintenance, no need to clean long channels (low soot formation);

- durability of the furnace;

- aesthetic, original appearance;

- high efficiency, multifunctionality;

- efficiency;

- long-term heat retention;

- the shape and design of stoves may vary depending on the purpose;

- with the frequency of adding fuel to the Kuznetsovka only twice a day, you can have a thermal regime in the house that compares favorably even with the regime of apartments with central heating.

An apartment in a high-rise building has more frequent temperature fluctuations than a private house heated by a Kuznetsov stove, which gives uniform heat output between the fireboxes;

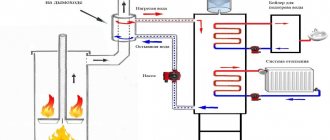

- combining a Kuznetsov stove and water heating of a house is not difficult and is often used in practice.

A tubular heat exchanger is installed inside the firebox and connected to the heating circuit pipeline. The main advantage is that the heating technology and heat output of the furnace remain unchanged during modernization, without the slightest decrease in efficiency;

- The design of the blacksmith allows the installation of low chimneys, and there is no reduction in draft. This fact is somewhat surprising to those who are new to the design and operation of these furnaces;

- The internal design features of Kuznetsov stoves allow the unit to be installed in almost any room of any size, regardless of what the room is intended for.

Both in kitchens and in common rooms, the stove looks solid and aesthetically pleasing, and fits organically into many interiors;

- The most interesting and unusual feature of blacksmithing in the context of a house stove: you don’t have to close the view. This is the most important part of the furnace and one of the conditions for safe daily operation - for the Kuznetsov furnace it is needed only if an emergency situation occurs.

The fact is that when the fuel combustion process comes to an end and cooling begins, the draft in the furnace channels is redistributed spontaneously, “automatically”.

It was the bell-type stoves that became the basis for the creation of many new types of household, heating and cooking stoves, which provide a significantly better effect with less fuel consumption.

What can you say about the disadvantages of the stove?

Technically there are none, but there are still some things to consider.

The Kuznetsov furnace cannot have massive walls - this would negate many of its advantages. But at the same time it is subject to fairly high thermal loads.

Therefore, this unit must be carefully calculated and verified at the development stage and built just as carefully, with scrupulous compliance with all technology requirements. At the slightest deviation from the technical regulations, the “blacksmithing” will turn out to be very short-lived.

Ordering the Kuznetsov furnace

Laying out the heating structure yourself is a completely solvable task, but it will require ordering a Kuznetsov sauna stove or another type of heating unit. The operating principle of the heating device is not so complicated that it is impossible to understand.

To create a high-quality heating unit, regardless of the bell-type version or the Kuznetsov stove for a bath, ordering will be required, as will a general drawing. What is order? This is a set of drawings that schematically depict the step-by-step construction of a stove with your own hands, in detail for each row of bricks. No changes should be made to them.

Materials and tools

To work you will need:

- trowel;

- level;

- mallet and other construction tools.

To divide bricks you will need a pick hammer and a grinder with a diamond wheel.

This set of tools will be needed for work

The furnace will be built from two types of bricks: conventional solid ceramic with a grade of M150 (250x120x65 mm) and fireclay grade ShB-8 (250x123x65 mm) or Sh-5 (230x114x40 mm). The firebox walls will be lined with fireclay bricks.

When purchasing fireclay bricks, you should be very careful. Unscrupulous sellers may pass it off as acid-resistant brick, which is similar in appearance but cannot withstand high temperatures. So it won’t hurt to ask to see a certificate.

Brick for laying the furnace

It is often recommended to choose fireclay bricks by color - the darker the better. But this rule does not always apply. If clay taken from different deposits was used, then the characteristics of light brick may well be higher than that of dark brick. It is more correct to evaluate the quality of fireclay bricks according to the following criteria:

- the structure must be uniform and fine-grained - without pores and inclusions visible to the naked eye;

- when tapped with a metal object (light hammer or wrench), the brick should produce a clear, abrupt and ringing sound;

- when dropped, it should break into large pieces (low-quality ones crumble into small fragments down to sand).

For a structure with dimensions of 1015x630x2100 mm, you will need 430 ceramic bricks (excluding the chimney) and 22 fireclay bricks.

How to prepare the solution

The solution used is clay. The clay and sand used for its preparation should not contain organic impurities that can lead to cracking of the seams. In clay, the presence of these impurities can be recognized by a clearly audible smell (it can even be pleasant) - normally clay has almost no smell.

Sand should be used either from mountain sand or made by grinding broken bricks - in these varieties the content of organic impurities is minimal, or they are completely absent. Brick sand usually costs less than mountain sand, but is not inferior in quality. Just pay attention to the following circumstance: for ceramic masonry mortar you need sand from ceramic bricks, and for fireclay - accordingly, from fireclay.

Pay attention to the grade of clay. The mortar for fireclay masonry should be prepared on the basis of white kaolin or fireclay marl. Any clay with fire-resistant properties is suitable for ceramic masonry, for example, gray or blue Cambrian, gray kaolin.

Clay of the same grade, but from different deposits, can differ greatly in viscosity, fat content and adhesive properties. Therefore, the solution recipe, namely the optimal ratio of sand and clay in it, should be selected experimentally. In the case of using brick sand, this is done as follows:

- A 1 kg portion of clay should be filled to the top with water and left for a day.

- After this, the soggy clay is kneaded with the addition of water until it looks like plasticine or thick dough and stops sticking to your hands.

Next, the clay is divided into 5 equal portions, to each of which a certain amount of sand is added:

- first - 10% of the volume of clay;

- in the 2nd - 25%;

- in the 3rd - 50%;

- in the 4th - 75%;

- in the 5th - 100%.

Each portion must be thoroughly stirred until smooth and dried for 4 hours. Don't forget to mark how much sand is contained where.

After this, each portion of the solution must be rolled out into the shape of a cylinder 30 cm long and 1–1.5 cm in diameter. All of them are wrapped around a round blank with a diameter of about 5 cm. Now the test samples must be dried for two weeks at room temperature and without drafts .

After this, it remains to evaluate each of the options:

- If there are no cracks on the cylinder at all or they are present in the form of a very fine mesh, such a solution can be used for any part of the furnace.

- If the depth of the cracks reaches 1–2 mm, the solution can withstand temperatures up to 300 degrees. This mixture can be used for laying a country fireplace or barbecue.

- If there are deep cracks or breaks, the solution is considered unsuitable for use - the proportion of sand in it is excessive.

Typically, about 0.2 cubic meters are consumed for a laying of 500 bricks. m mixture of clay and sand.

Note! If you don’t mind the additional costs, you can purchase a ready-made mixture for preparing a stove solution at a specialized store.

Having thus determined the optimal combination of clay and sand, we begin to prepare the solution:

- the required amount of clay (approximately 40 kg per 100 bricks) is again soaked for 24 hours, kneaded until the consistency of dough, but then rubbed through a sieve with a mesh size of 3x3 mm;

- then sand is added according to the experimentally selected recipe;

- gradually adding water, stir the solution until creamy;

- evaluate how the solution wets the trowel and, if necessary, adjust its composition by adding a small amount of clay or sand.

What else do you need?

- A fire door, for example, brand DT-3, with opening dimensions of 250x210 mm.

- Blower door, for example, DPK brand, with an opening of 250x140 mm.

- Grate size 250x252 mm.

- Cast iron hob with two burners, size 586x336 mm.

- Doors measuring 510x340 mm, 2 pcs. – for the cooking chamber.

- Gate valves with a flow area of 130x130 mm, 2 pcs. – for the cooking chamber and for switching between summer and winter operating modes.

- A valve with a clearance of 250x130 mm - for a chimney.

- Equal angle pieces 36x4, 600 mm long (4 pcs.).

- A piece of steel strip 40x4 mm, 600 mm long.

- Steel sheet 3 mm thick, size 600x550 mm.

- 3 mm thick steel sheet measuring 500x700 mm to protect the floor in front of the firebox.

Replace steel with any other fireproof flooring, for example, ceramic tiles.

Have you always dreamed of having a magical fireplace in your home? You can fold it yourself. And the following guide will help with this: .

Materials for building a brick kiln

- Fireclay brick

for interior masonry. You can calculate its quantity according to the order. For a simple design you will need a little of it. - Clay bricks

for external masonry, when created, including Kuznetsov bell furnaces - the order will help you find out its quantity. It is advisable to purchase products of the M150 brand. - Clay

in the amount of 100-150 kilograms. It must be of good quality. Otherwise, during the first firing of the finished structure, the solution will crack. - Cleaned sand

. It will require 2 times more than clay. Ready-made clay-sand mixtures are available for sale. They are needed for 500 bricks, approximately 0.2 m³. - Metal fittings

- grate, combustion and blower doors, 2 steel angles, 5 meters of wire.

Design and principle of operation

The inventor I.V. Kuznetsov used a bell-type furnace, known for its efficiency, as a basis.

This is what a bell furnace looks like - a prototype of Kuznetsov’s model

The high efficiency of such furnaces is due to the nature of the movement of flue gases. If in channel stoves they are drawn into the chimney, often without having time to give off heat to the brick mass, then in bell-type stoves they swirl under the roof of the bell for a long time until they cool down. Only then do they fall down to the outlet, from where they then enter the chimney. The bell filled with gases simultaneously plays the role of a view: cold air from the chimney cannot penetrate into it, just as water cannot fill an inverted diving bell. This effect is called gas view.

The inventor worked with a complicated version of such a furnace, which had two hoods.

Diagram of a two-bell model

Scheme of a two-bell furnace

As you can see, the hoods are connected in series, that is, heat from the flue gases is removed in a two-stage manner. Previously, the construction of stoves with such a design was not very willingly undertaken - not only because of the complexity, but also some undesirable features. So, for example, the draft in the second bell can easily break the gas plug in the first, negating the effect of the “gas view”.

The master dealt with this drawback in the following way. The furnace was equipped with so-called downstream channels, laid to bypass the heat-accumulating parts of the array. While the flame is burning in the firebox, the convective flow it creates ensures that the draft operates as usual. When the fuel is consumed and convection stops, the draft will redistribute itself in such a way that the cold air flow will follow through the downstream channels, and not through the heated body of the furnace.

This solution not only compensated for the instability of the gas coil, but also turned out to be more reliable: a plug formed by gases can be pulled out by a strong gust of wind, while in the Kuznetsov furnace, the draft is redirected away from the hot mass under any conditions. In addition, thanks to the presence of downstream channels, there is no need to arrange room ventilation.

Order samples

This article discusses the Kuznetsov bell-type furnace, and more specifically, one of its variants. Each row should be laid out in a numbered order in full accordance with the images. This oven has a simple design and is a universal solution for household use.

Similarly, when there is an order on the Kuznetsov stove for a bathhouse, you can do the laying yourself (read also: “Ordering a stove for a bathhouse with your own hands”). After the work on creating a heating unit is completed for the first time, it becomes clear to every performer that this is not difficult and quite doable.

Next time we will be able to make a more complex design without any problems. It could even be a two-bell Kuznetsov stove - the order of one of the creation options of which is available as an example on the website. Perhaps in the future there will be a desire to bring into reality one of the many projects of the great master. Video of the phased construction of the Kuznetsov furnace according to the drawings:

Preparatory work before assembling the stove

The most important step before constructing a furnace is laying the foundation. Its construction must be approached with all responsibility, because an incorrectly poured foundation can negate all the work - a sagging stove will eventually crack and fall apart.

An example of a foundation made of sand-lime bricks with the names of the materials used and markings

In order for the foundation to meet the requirements of the standards, its linear dimensions must be 10–15 cm larger than the dimensions of the furnace base.

The procedure for laying the foundation for the furnace is as follows:

- A pit is dug in the ground to a depth of at least 0.9 m (to the depth of soil freezing in the cold season). The edges of the pit should be as smooth and vertical as possible - this will prevent excessive consumption of cement mortar.

- Clean sand is poured into the bottom of the pit to a height of at least 15 cm. Builders call this a cushion. The shrinkage time of the pillow is 2–3 days.

- The formwork is assembled from boards and available materials. The height of the top point of the formwork should coincide with the floor level in the house (minus 2 bricks, i.e. approximately 13 cm).

- The fittings are being installed. This can be a metal mesh with a mesh size of 50 mm and a rod thickness of 5 mm or more. The mesh should not lie at the bottom of the pit, but is located inside the thickness of the foundation. The optimal place is where the concrete emerges from the soil to the outside.

- The concrete solution is poured. The composition may include gravel and heavy mineral additives. A good practical addition would be a water repellent that prevents the absorption of moisture into the foundation during operation. After pouring, the top surface is leveled in a horizontal plane and all large defects are immediately eliminated by smoothing with a trowel or spatula.

Concrete mixed with a water repellent has water-repellent properties, which improves the quality and properties of the foundation

The time for complete drying of the foundation is considered to be from 20 to 30 days, depending on weather conditions. But you can begin installing the furnace within a week, when the solution sets and hardens. The ideal option for foundation shrinkage is one year (a full cycle of freezing and thawing of the soil).

One of the options for constructing a Kuznetsov furnace with your own hands

Before starting masonry, pay attention to the following important points:

- A waterproofing layer is laid between the foundation and the first rows of the furnace. It can be roofing felt or foil isothermal film (foil up to reflect thermal energy);

- It is highly undesirable to make changes to the order. This may cause the oven to malfunction in the future. Kuznetsov’s original designs have been tested in practice, which guarantees the quality and service life of the furnaces. The only exception is the rows of solid flooring, which can be modified for aesthetic purposes;

- For facing masonry, bricks without chips, cracks and other noticeable defects are selected;

- Bricks are cut using a grinder. Edges and planes must remain smooth and even: a torn shape is unacceptable.

Below is the order of I. Kuznetsov’s bell furnace with comments and recommendations.

An example of the ordering of a bell-type furnace: a strict order of laying out the rows will ensure the reliability and longevity of the entire structure

- The first and second levels are laid out with fireclay heat-resistant bricks. In this case, an oven bonding solution is used. The refractory layer will prevent thermal energy from escaping into the foundation.

- Four cleaning doors (standard sizes) are installed in the chimneys for ease of servicing the stove.

- The grate is laid at level 5. At the same time, partitions are laid between the blower, firebox and hood.

- Starting from row 5 to row 14, the combustion chamber is laid out from fireclay bricks. It is important to remember that a compensation gap must be left between the fireclay and red bricks of the masonry. This will protect the oven from damage caused by thermal expansion of materials.

- Installation of the firebox and ash doors is done using asbestos sealant.

Asbestos sealant of the combustion chamber cracks allows heat to be retained between the metal and the brickwork

- In rows 17 and 18, the ceilings of the caps have a continuous plane (except for the chimney openings).

- In row 21 there are two aisles remaining, running along the inner wall.

- In rows 28, 29 and 30, deviations in the installation of floors are allowed if you need to create an unusual appearance. If the ceiling is low, fireproof cuts are made in this place.

- As you lay it out, it is necessary to line the inner surface of the brickwork (smoothing the joints is done with a mortar with the addition of a heat-resistant material).

The firebox is covered with two metal support corners. Dimensions are selected according to the load, arm length starts from 45 mm.

The thermal gap between the fireclay brick of the firebox and the furnace body protects the brick from destruction during heating of the furnace

Following the exact order instructions, any man who knows how to handle stone and mortar can assemble the blacksmith stove. The main thing is to observe the vertical and horizontal projections of the structure.

Even a woman can cope with such work: building a stove with your own hands is interesting and exciting

After finishing the masonry, the stove should be checked and a test fire should be carried out. The intensity of the first fire should not be high. Smooth heating of the body evenly dries the cement mortar in all directions, from the ash chamber to the exit of the chimney pipe to the outside.

Video: Kuznetsov furnace project in 3D

Video: Kuznetsov furnace project in 3D (part 2)

Construction of “blacksmiths”: diagrams and procedures

Creating a “product” for the mass user, the author took care of the practical application of his research, creating a huge set of diagrams and drawings. For the precise construction of a great variety of modifications of bell-type furnaces, orders are used - step-by-step diagrams with images of each row of bricks.

Ordering a sauna stove

Unlike Russian stoves, “blacksmiths” are smaller in size and, accordingly, take up minimal space. The amount of brick is also reduced, due to the large amount of free internal space. Thanks to the optimal thickness of the walls, they heat up quickly, and what is especially valuable, they cool down quite slowly. If you carefully analyze the dome arrangements, you will see how much unfilled space there is inside the structure.

Multifunctional design of the Kuznetsov furnace

Part of the free space is occupied by caps, fixed in a horizontal or vertical order, not necessarily symmetrical. The size of the domes can be the same or different. The vertical arrangement is often used to save space in the room, especially if an oven or dryer is planned. Thanks to the variability of the installation of domes, it is possible to erect a structure of any shape, designed for a specific room or special conditions.

Ordering a heating stove

The space under the second hood is often used for mounting heat exchangers, hobs, bread ovens, etc. In projects designed for a bathhouse, a hot water tank or heater is installed in it.

If you correctly “read” the order drawn up by an experienced master, you can achieve amazing results. For example, to maintain room temperature in a house made of rounded logs in winter, you will need 2 fireboxes (morning and evening) with only 5-6 logs each; in the off-season, one firebox is enough.

Procedures for building a fireplace

Various modifications of bell furnaces

The followers of I. Kuznetsov created countless options suitable for independent construction, but each time they started from one of the standard projects. Let's look at some of them that can be used to improve a private home or cottage.

Heating structures for home

There are more than 25 standard schemes for constructing heating structures inside house structures, some of which perform only a heating function, but some options have useful additions in the form of a stove bench or oven.

Heating dome stoves

The place is chosen not near the wall, but in the center of the room, which entails a number of advantages:

- uniform and efficient heating of the room;

- lack of a cooling element (outer wall of the house);

- the possibility of free access for maintenance (for example, cleaning vaults);

- the ability to add built-in elements (hob, dryer, water heating circuit).

It should be noted the aesthetic perfection of bell-shaped structures: they occupy a minimum of space and look elegant, despite the presence of such details as a foundation. Modifications made “to the ceiling” have a short pipe (a characteristic feature of many “blacksmiths”) and slender outlines. The design possibilities are endless and depend solely on the taste and wishes of the homeowners.

Cooking modifications for the kitchen

Turning a brick heating device into a cooking device is not so difficult - just add a metal stove with a couple of burners and slightly change the design of the base. However, full-fledged cooking structures include several additional horizontal surfaces (trays or drying racks), as well as an oven chamber.

Cooking "blacksmith" in the interior of a village house

In terms of the quality of prepared dishes, the dome device is not inferior to branded gas or electric equipment that city residents are accustomed to using. Among the standard designs there are those specially created for baking bread, which are called bread ones. For farmers, gardeners and inveterate gardeners, this is a real find: you can steam berries, dry fruits and mushrooms, and preserve vegetables according to old recipes.

Obviously, the cooking device is also a source of heat, so its more accurate name is heating and cooking. The best place for installation is a kitchen or a large hall that combines a kitchen area, a dining room, and sometimes a living room - in Russian national traditions.

Sauna stoves

To designate bath devices there is a special marking - BIC. Even externally finished “blacksmiths” compare favorably with other heaters. On the one hand, the material for manufacturing is very carefully selected, on the other hand, the installation of the dome does not interfere with the construction of neat and practical configurations. For example, bathhouse owners appreciated the rounded corners, which minimize injuries and burns.

Sauna stoves

By installing the stove in the right place, you can simultaneously heat and supply several rooms with hot water - a steam room, a shower room, a dressing room (or a rest room). Moreover, the parts of the structure opening into a particular room will perform various functions: create steam for the steam room, heat water for the wash room, and moderately heat the dressing room.

The sauna perfectly implements the principle of long-term heat preservation, characteristic of “blacksmiths”. Maintenance is kept to a minimum, as logs or briquettes only need to be added occasionally - all thanks to the dome design.

Fireplaces for decorating the living room

Kuznetsov's fireplaces, unlike most dome modifications, have an open design and a reduced efficiency index, but their heat transfer parameters are quite high. The cap prevents the rapid release of heat into the chimney, trapping hot gases in the upper part of the building. When using a conventional fireplace, at the end of the combustion process the room begins to cool; with bell-type heating, a comfortable microclimate remains in the room for a long time.

Construction of a fireplace according to Kuznetsov’s order

The possibilities to change the design and decorate the façade of the fireplace are endless. In addition to the usual shelf, you can build a number of functionally useful elements - small dryers for shoes or clothes with niches and hooks, and also line the outside with ceramic tiles or tiles. Interestingly, fireplaces are included in the design of some multifunctional structures.

Outdoor cooking solutions

Entire oven complexes have been developed specifically for outdoor cooking, which are distinguished by their functionality and ease of use. The simplest design is a brick mini-barbecue structure. It holds the heat for a long time and allows you to extend the cooking period.

Barbecue built according to Kuznetsov's drawings

Fans of summer kitchens, barbecues and grilled dishes will be pleased with the design diversity of outdoor stoves with layer-by-layer, pyrolysis, bottom and top combustion types. There are models that allow you to simultaneously fry, bake, and stew several dishes at once. Options for ordering bell-type stoves with an oven or grill can be found in the public domain or on the author’s official website.

Stove with bench

The stove with a stove bench is especially popular among our people. This design is also possible for bell-type furnaces. They heat themselves with wood. Such models are used mainly in dachas or country houses. All stoves with benches consist of the following elements:

- heating oven;

- bed;

- hob;

- oven;

- ash pan;

- woodcutter;

- place for kitchen utensils.

As with any stove structure, such models require a separate foundation. First, the base of the furnace is built. It consists of several brick rows aligned horizontally. They must have right angles. You should also maintain a distance from the rows of the base to the wall of the room of approximately 15 cm (more is possible). Then a vent and air vents are installed, thanks to which the air heated in the firebox rises up, is evenly distributed throughout the entire structure of the stove and optimally heats the stove bench.

At the level of 8–9 rows, overlaps should be laid on the bench and firebox. After this, you need to continue laying brick rows for the oven and hob according to the order. It is mandatory to lay a row separating the latter from the wall of the room.

The next stage: laying out the jumpers. In the oven area, you need to use regular or figured masonry in the shape of an arch or wedge for this purpose, and it is advisable to install metal corners and a decorative shelf above the stove casing. Subsequent brick rows connect all the chimneys together. Windows are made on the walls, and a summer house is placed near the oven (it can be used in the summer season). Those located higher will warm the room in winter.

The pipes are mounted higher and have a square cross-section. It is recommended to lay 2.5 bricks. Those floors that are laid in the area where the chimney is located should be insulated in several layers with basalt slabs.

It is advisable to cover the outer surface of the chimney with silicate brick, since it is characterized by resistance to temperature fluctuations and climatic precipitation. After its erection, all available fittings are installed on the stove.

For example, you can not limit yourself to simple brickwork (although it looks quite solid), but paint the structure with heat-resistant paint and decorate it with ornaments and designs. This model will look beautiful in any interior. In financial terms, the finishing will be more expensive, the higher the quality of the tiles used for it. And tiles serve not only an aesthetic function - they retain heat well. And these elements are unpretentious in care. If you can’t do the finishing yourself, professional craftsmen can come to the rescue.

Recommendations for self-construction

If you decide to build a stove according to one of Kuznetsov’s plans with your own hands, get ready for careful and scrupulous work. On the diagrams you will find a graphic representation of each row, but before starting laying you need to become familiar with the features of the technique, in particular:

- selection and pre-processing of bricks;

- purchase of metal parts (plates, dampers, doors, valves);

- determining the most suitable location;

- preparation of the base and foundation;

- possibility of installing a chimney, etc.

Fireclay refractory brick (Sh-5, ShB-8) is recognized as the best material for the internal masonry of “smiths”, and ceramics (M-150) for external decoration. To strengthen brick walls, metal elements (rebar, wire) are used. In order for the stove to function with maximum heat output, experienced craftsmen hone not only their skills, but also every brick - literally. They polish every detail, which is why projects completed by professionals look flawless.

Fireclay brick masonry

Having the author's order in hand, we recommend not to experiment, but to follow the designated order. Deviations from the diagram do not guarantee complete heat transfer.

Operation in various modes

In summer mode, Kuznetsov’s stove turns from a heating and cooking stove into a cooking stove. To do this, it is enough to open a special valve (it is called the summer valve), after which the flue gases will enter the chimney directly, bypassing the caps. Accordingly, only the hob will be subject to heating.

The temperature inside the cooking chamber can be regulated by a valve installed on the exhaust duct extending from it. By closing the valve and the chamber door, it can easily be turned into an oven. For ease of use, shelves for baking sheets can be fixed in the walls.

If you need to quickly warm up the room or dry out, open the door of the cooking chamber. At the same time, the temperature on the burners remains high enough for cooking.

DIY construction

Undertaking construction on your own is appropriate only for a person with the skills of a mason. There are many subtleties in stove construction that become clear only after many years of work. It is worth learning the main points in order to control the work of hired craftsmen and choose materials yourself.

Model selection

For construction, you can choose a model with a warm bed.

Construction begins with choosing a model. Even at the design stage, the following is determined:

- appointment;

- required heat transfer power;

- configuration;

- materials for masonry and their quantity.

The summary table on the website shows the geometric dimensions and heat transfer of each side. After going to the “free drawings” section, the amount of materials is calculated in order, accurate to the brick. For drawings of some stoves you will have to pay a small amount - registration on the site will be required to purchase.

Materials and accessories

All consumables are selected and purchased in advance, since after the start of construction you may not quickly find, for example, doors or valves of the required size.

To lay out the combustion chamber of the furnace you will need a heat-resistant brick

For the Kuznetsov furnace you will need:

- three types of bricks - solid red with a grade of at least M-150, fireclay heat-resistant, preferably ShB-8, and finishing for the outer layer of masonry;

- sand-cement mixture for stoves;

- cast products according to the drawing - doors for the combustion and ash chambers, grate, valves and views, doors for cleaning channels;

- wire for tying rows at the rate of laying along the perimeter of every two rows;

- ceiling corners for the firebox;

- reinforcing mesh for pouring the foundation;

- asbestos cord for thermal insulation of cast iron.

To work, you will need a trowel or trowel, containers for mixing solutions, a level, jointing, tape measure and a plumb line.

At the first stage of construction, a foundation is built, the length and width of which corresponds to the size of the furnace. To do this, make a hole in the ground, pour and compact 10–15 cm of sand. The prepared formwork is poured with heavy concrete.

The upper edge of the poured foundation is made 13–15 cm below the floor level, then the recess is filled with two layers of refractory brick. They are needed to prevent heat from escaping through the floor into the ground.

The time it takes for the foundation to gain full strength is 28 days, but laying can begin in 17–20 days if the construction is not planned to be completed very quickly.

At the next stages, the “body” of the furnace is erected, strictly following the instructions, observing the order and checking the horizontal and vertical levels.

The passage of the chimney through the ceilings is provided with thermal insulation, which prevents heating of building materials.

Immediately after completion of construction, a low-intensity test fire is made. At this time, all substances that give off an unpleasant odor burn out, and the walls warm up and dry evenly.

Possible difficulties

Most problematic situations with the Kuznetsov system arise due to improper operation. At first, you should not heat the sauna room at full power. The torch inside the Kuznetsov firebox is almost three times higher than that of a conventional furnace, so the walls and especially the vault heat up very quickly. As a result, cracks appear and the masonry adhesive crumbles.

In addition, all metal parts inside the firebox must have a loose fit to prevent thermal expansion of the metal from tearing the seam or pushing out the stone.

Another problem may arise in a situation where the firebox door frame is in close contact with the hot chamotte; over time, the refractory stone will squeeze out the metal base, and Kuznetsov’s apparatus will begin to smoke inside the bathhouse for no apparent reason.

Calculation of basic parameters

In order to correctly build a Kuznetsov furnace, it is necessary to strictly follow the diagram developed by specialists. Craftsmen who have extensive experience in the construction of such furnaces recommend that before starting major masonry, practice laying it “dry” if you are doing this for the first time.

If the stove is being built during the construction of the house itself, then it is necessary to draw up the project in such a way that it can heat several rooms at once.

The foundation for the stove must be of high quality and must have a waterproofing layer. It is also necessary to take into account that the foundation of the house should not go into the base for the stove. This structure must have its own foundation, which shrinks on its own.

The concrete base should be approximately 10 centimeters larger than the size of the stove on all sides. The degree of its depth will depend on the height of the structure and the soil composition where the furnace will be built. Typically the depth of the pit is from 40 to 60 centimeters. A sand cushion is placed at the bottom for waterproofing and a layer of crushed stone to strengthen the building. To form the side walls, formwork from boards is installed.

Layout diagram of the bell-type furnace OVIK-9

- The oven (OVIK-9) has a cooking chamber with 2 burners and steel lockable doors.

- It is equipped with a separate exhaust duct, which allows you to regulate the temperature inside the locked niche.

- It can be used as an oven, so metal runners for baking sheets are built into the walls.

- The two-bell stove can be used in “summer” and “winter” mode. Therefore, in the summer you can only cook with it.

Heating and cooking stove Kuznetsov OVIK-9

The depth of the firebox is 450x470 mm with a dry seam to expand the brick by 2–3 cm. If the firebox needs a large size of 510x530 mm, then the back wall is laid out not in ½ brick, as shown in the order, but in ¼ brick.

How to prepare a place for the stove

To properly install such a stove, you need to carefully study the step-by-step installation instructions, features and recommendations. In general, this process consists of a preparatory stage, laying the first and second stages.

To properly install the stove, you will need some tools, including:

- Scoop and bayonet types of shovels.

- Reinforced metal rods.

- Formwork.

- Polyethylene film.

- Cement mortars.

- Sand material.

After preparing all the material and tools, you need to start preparing the place for the stove.

This process is carried out in several stages:

- Preparing a hole measuring one and a half meters by one meter, the depth should be eighty centimeters.

- Covering the bottom with sand material. The size of the layer of sand material should not exceed fifteen centimeters.

- After covering, the pit is left for two days to allow the sand materials to settle.

- Preparation of formwork, which is made from plywood or waste boards.

- Performing reinforcement using rods made of steel materials.

- Pouring cement mortar. It is necessary to distribute the solution evenly.

After all these activities, you need to leave it all for a certain period of time for the mortar and foundation to harden.