The efficiency of a heating system depends on the functionality and performance of the main heating element. However, not the last place in this issue is occupied by components for solid fuel heating boilers. They help not only extend the life of the heating device, but also improve the performance characteristics of the heating circuit, increase its safety and efficiency. That is why, when choosing a boiler, no less attention is paid to thermostats, gas burners, pipes, etc.

Installing a draft regulator on a solid fuel boiler and its further adjustment

Before installing the regulator on the boiler, use pipeline fittings to cut it off from the pipeline and drain the coolant from the boiler. If it is not possible to shut off the boiler (the fittings were not installed during installation), all the coolant is drained from the system.

Having unscrewed the plug from the coupling (sleeve), we manually tighten the regulator to check the thread size. If everything is normal and it is clear which layer of FUM tape to wrap on the thread of the device, apply a sealant to the thread and tightly, but without fanaticism, screw it into the sleeve with a wrench. If the sleeve is on the side of the boiler, then the arrow on the regulator handle points upward when screwed in all the way. When mounted from above, the slot of the device scale must be tightened to the front of the boiler.

A lever is inserted into the regulator seat so that the chain inserted into its hole hangs vertically above the ash pan door and does not interfere with operation when tensioned. After broaching, all connections are secured with a heat-resistant compound. After installation, the coolant level in the heating system is restored and the pipeline fittings are opened, and the firebox is loaded with fuel.

The installed regulator must be configured; for this, the following sequence of actions is carried out:

- The ash door is raised completely and the fuel is ignited.

- The latch on the handle of the device is unscrewed.

- The coolant temperature of the lower level of the range is set to 60° C.

- The chain is attached to the lever.

- After reaching the set temperature, the blower door is lowered, leaving a gap of about 2 mm.

- The second end of the chain is fixed on the handle of the ash pan so that the slack is no more than 1 mm.

- The screw on the thermostat knob is tightened.

Life advice. Before actively operating a boiler with a mechanical thermostat, it is necessary to patiently train the heating system at different temperatures within the control range, and, if necessary, adjust the length of the chain to reduce the error to 5%.

Combustion of solid fuel and heating of the coolant to a given temperature is an inert process, not fast. Therefore, the reaction to changing the setting on the thermostat knob will be delayed and it would be right not to rush things.

It is advisable to calibrate the device more often, especially at the beginning of the heating system operation. A change in the type of solid fuel and supplier should also first lead to a regular check of the compliance of the set temperature on the regulator handle and the actual temperature on the boiler thermometer. If necessary, configure the device by adjusting the size of the chain.

Conclusion. This method of obtaining stable operation of a solid fuel boiler is not as accurate as those associated with fans, smoke exhausters and a computer, but for the money it is reliable, autonomous and, in many cases, a benefit for a long time.

Recommended components for a furnace with a water circuit and an air heating boiler

Complete boiler.

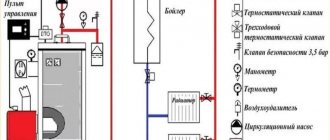

A solid fuel stove with a water heating boiler is today considered as an alternative option for heating a country house. This scheme differs from a traditional stove in the presence of a heat exchanger (register) inside, the heating circuit itself and radiators. To increase the efficiency of the system, many experts recommend installing a circulation pump in this wiring, which will force the coolant to move through the pipes.

However, in this case, you need to remember that if the electricity is turned off, the circulation pump will stop working and the coolant will stagnate in the system, and then it will boil. To solve this problem, it is recommended to make the heating circuit with a maximum slope, which will ensure natural circulation of the coolant.

If we consider solid fuel air heating boilers, then here, as with the analogue of water heating, a thermostat is needed. Many models are already equipped with this device. However, an automatic thermostat will significantly increase the efficiency of the boiler and maintain the microclimate in the house at the desired level.

After all, not every pipe for a solid fuel heating boiler will cope with the task of removing carbon monoxide to the outside.

Many letters and numbers are the markings of pipes in the heating system. Its decoding is detailed here.

What is a draft regulator for solid fuel boilers?

The draft regulator is an automatic device designed to control combustion and regulate temperature. The uniqueness of this device is that it is completely energy independent, and therefore, in the absence of electricity, the boiler will be able to continue operating and the functioning of the heating system will be stable. Draft regulators are installed on most simple-type solid fuel boilers. Modern boilers use more complex and multifunctional mechanisms. But these remain popular due to several advantages:

- Simplicity in design and operation;

- Reliability;

- Possibility of making it yourself;

- High accuracy;

- Low cost and easy to repair.

Quite banal, but very important advantages of a draft regulator for solid fuel boilers. They are bought for both old and modern, expensive boilers

Traction controls are important in operation, but how does a simple design take on so much?

Operating principle of a draft regulator for a solid fuel boiler

The regulator itself can be installed in different places on the boiler. As a rule, the manufacturer himself shows where it is necessary to connect the draft regulator for the boiler, or where the water jacket fits. The traction regulator needs to be in contact with the coolant so that the special gas (sometimes liquid) located in the sleeve expands during the heating process. After this, the actuator is assigned the task of lowering the lever, which already reduces the draft in the solid fuel boiler.

The principle of operation is very simple, which is why these levers can be made with your own hands. With the correct design of a homemade draft regulator, it is no different and can also serve usefully.

How to set up a draft regulator for a solid fuel boiler?

- Before setting up, you must disconnect the circuit from the air damper

- Loosen the handle lock as much as possible

- Adjust the scale according to the current situation and set the required temperature level

- Light the boiler and reach the set temperature (see point 4)

- When this temperature is reached, place the chain on the choke handle. When set correctly, the chain should be taut.

After this, you can enjoy the operation of the traction regulator and have peace of mind about heating when you are away from home. These designs are really useful and easy to use; they save the situation when there is a power outage, which often happens in our country. The operating principle, based on mechanics and the laws of physics, is the most reliable way to regulate the boiler.

What kind of thermostat can be used for solid fuel heating boilers?

Temperature regulator of mechanical operating principle (completely non-volatile).

The thermostat for a solid fuel heating boiler can be of the following types:

- mechanical or draft regulator;

- automatic – this is automation, the operation of which is controlled by a microprocessor.

In addition, thermostats are non-volatile. They are not connected to the mains, and their work is based on the expansion of the substance inserted into the device. Volatile thermostats are powered from the mains, but at the same time they have a greater range of functions and capabilities compared to the previous version. Regardless of the type chosen, the listed components are suitable if a solid fuel heating boiler with a water circuit is installed in the house.

Mechanical traction regulators. These components for solid fuel heating boilers are durable and trouble-free in operation, they have a simple design, and therefore their service is inexpensive. The same goes for the starting price. Traction regulators are characterized by their low cost, which attracts an audience of buyers with an average level of income.

Depending on the design of the heating element, a mechanical thermostat can be mounted on the front and side panels, or on top. The main working tool here is a submersible sleeve filled with a substance that expands with increasing temperature and decreases in volume with decreasing temperature. The immersion sleeve must be in contact with the coolant, and therefore its seat is located in the water jacket of the boiler.

So, the temperature of the coolant in the system increases. Along with it, the volume of the working substance in the submersible sleeve increases. At a certain liquid temperature, the thermostat for a solid fuel heating boiler is activated. The working substance acts on the rod, which, in turn, turns on the control mechanism and lever. The latter, depending on the position of the thermostat, lowers or rises, dragging the chain with it.

One end of it is attached to a lever, the other to the boiler damper. The damper closes. The amount of air supplied to the firebox is reduced. As a result, the intensity of fuel combustion decreases. It's just smoldering. At the moment when the temperature of the coolant in the heating system drops to a critically low level, the thermostat mechanism operates in the opposite direction, that is, the boiler damper opens.

An automatic thermostat regulates the air supply.

Automatic thermostat or microprocessor controller. This is a multifunctional thermostat for a solid fuel heating boiler. It can control the following devices and processes:

- control the temperature of the coolant;

- regulate fan operation;

- control the circulation pump;

- ensure uninterrupted fuel supply.

By purchasing an automatic thermostat, the home owner protects his solid fuel heating boiler with a water circuit from overheating and frequent breakdowns.

Modern solid fuel boilers include an automatic thermostat. However, such models of heating elements are somewhat more expensive compared to under-equipped equipment.

The controller regulates the temperature of the coolant due to the amount of air supplied to the firebox, for which it is connected to the fan at the bottom of the boiler. When the temperature of the liquid circulating through the circuit increases, the microprocessor sends a command to the actuator. As a result, the fan either slows down or stops completely. The amount of air supplied to the fuel decreases. The combustion intensity decreases, the coolant cools down.

The controller is a sensitive device, its operating error is up to 2°C, which is important for modern heating systems. Today, as is known, the efficiency of a heating system is increased by reducing the diameter of the circuit pipes. After all, the faster the coolant, having bypassed the entire heating circuit, returns back to the boiler, the better and faster all the rooms in the building will warm up. However, if the pipes for solid fuel heating boilers are chosen with too small a diameter, then there is a possibility of water hammer as a result of overheating of the coolant. The controller will prevent this and reduce the intensity of the fire in the firebox at the right time.

Principle of operation

The draft is adjusted by changing the degree of rarefaction of the gases in the pipe. For this purpose, a stabilizer is built between the chimney pipe from the firebox and the entrance to the chimney. It can work in manual or automatic mode.

The chimney draft regulator is a damper (valve) built into a separate housing. When the draft increases, the valve opens slightly and releases a portion of air from the room. The gas flow cools, the lifting force from the thermal component decreases, and the ejection speed decreases. And, conversely, with the closing of the valve, the influx of cold air decreases, and the output force increases.

Note! That is, when the valve is closed, the maximum output of combustion products is ensured. Fully open damper – minimal gas flow.

It is advisable to install a draft stabilizer on solid fuel boilers operating:

- on coal;

- firewood;

- pellets;

- peat or coal briquettes, etc.

This is due to the presence of time at which the boiler reaches its planned capacity and, accordingly, a stable operating mode. That is, the oven should melt.

Do-it-yourself installation and calibration of the draft regulator

The simple design allows you to install the device yourself. If we consider the boiler from all sides, in projection, then the front or side surface of the unit is selected to install the regulator. For this purpose, the product has a special hole. The regulator is mounted using a threaded connection. The diagrams show how to install the regulator and how not to install the device.

Note: In this case there can be no middle solution. As indicated in the instructions, this is how the draft regulator is installed on a solid fuel boiler.

Correct installation is determined by aligning the device vertically and horizontally. After the regulator is installed, all rotating elements are tightened, the existing interfaces are subject to sealing with a special heat-resistant compound. The lever is placed in a position so that the hole through which the chain will pass is above the damper, in a vertical position.

If the first stage is quite clear and simple, then subsequent actions require special attention, accuracy and consistency of actions. Calibration of the regulator is the most important step in its functionality.

Stage one

Having installed the regulator on your heating unit, you can start kindling. Having brought the boiler water temperature to 60 C, record this same temperature on the flywheel (thermostat) of the draft regulator. The lever at this time must be connected by a chain to the damper.

Having fixed the damper in a certain position, with the regulator set at 60 degrees, we do the following.

Stage two

We turn the thermostat to 80 0C. If you have installed the draft regulator correctly and completed all previous steps according to the instructions, when the boiler heats up to the set temperature, the damper will automatically close. Air will stop flowing into the firebox, and the intensity of fuel combustion will decrease accordingly. The error in temperature measurement accuracy can reach +/- 5 C, which is not critical for ordinary, simple heating devices of heating systems.

It is necessary to adjust the draft regulator as often as possible. Mechanical damage to the chain or a tightly moving damper can cause a malfunction of the device.

Reviews on the use of mechanical traction regulators: advantages and disadvantages

Owners of solid fuel boilers speak favorably of the device from various manufacturers and recognize its usefulness in creating comfortable conditions in a private country house.

Table 1. Advantages and disadvantages of mechanical thermostats for solid fuel boilers.

| Advantages | Flaws |

| Low cost for the comfort provided | The declared characteristics are fully complied with in accordance with the instructions, no shortcomings have been identified. |

| Complete independence from power supply, complex electronics and automation | |

| Accessibility for understanding the installation and use of the device for untrained consumers | |

| With proper installation and operation, it lasts a long time | |

| Due to the simplicity of the design, usually high quality workmanship |

If the boiler does not include a draft regulator, then when purchasing separately, you must choose from those recommended for this unit. However, the only negative point is that not all solid fuel boilers are equipped with a threaded socket necessary for using a thermostat.

This is what the seat for the side draft thermostat looks like.

Setting up the draft regulator

In general, using the instructions that come with the device, you can easily understand the design settings. However, in case of its loss, a step-by-step list of moves is provided:

- First you need to light the boiler. Then open the door, but most importantly, do not attach the chain to it. This is necessary in order to create access for air masses.

- Then loosen the screw that secures the position on the adjusting mechanism.

- After which you can set a certain temperature by turning the handle.

- When the value is reached, it is advisable to attach the actuator to the damper. It should be a little open.

- Finally, secure the screw.

The main thing is to periodically monitor the thermometer and not rush to change settings

In addition, the distance of the chain is important - less than 1 millimeter. Some models of the device are characterized by a certain delay, since the coolant is unable to extinguish at lightning speed

Operating principle and functions of draft regulators for solid fuel boilers

Control of the boiler damper or the furnace ash door by the operator (stoker) changed the amount of oxygen in the firebox and changed the temperature of the coolant in one direction or another (due to more or less intense combustion). The operating principle of a mechanical device capable of doing this work is also quite simple.

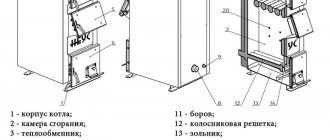

This thermostat consists of the following parts:

- sleeve with a heat-sensitive element;

- mechanical temperature change amplifier;

- calibrated knob that sets the temperature;

- a spring, the compression of which will determine the level of the task;

- lever with a chain that controls the door of the ash pan (blower).

The coolant temperature setting is set by the regulator handle, which compresses the spring with the required force. The difference between it and the force of the cold heat-sensitive element is large, so the lever mechanism opens the damper in a chain to a certain large angle. A lot of air enters the firebox, intense combustion occurs. As it heats up, the linear dimensions of the sensitive element increase, and the difference between the set and operating temperatures becomes zero. The ash pan door, smoothly lowering, takes a position corresponding to the specified one and subsequently reacts to temperature deviations.

The functions of the traction control include the following tasks:

- stable maintenance of the specified temperature of the coolant within the control range, preventing it from boiling;

- control of the power and efficiency of the boiler due to the supply of oxygen, achieving complete combustion of the fuel, which reduces its consumption.

Draft thermostat device

The thermostat is a fairly simple and reliable mechanism. Approximately, the diagram shows the device of the draft regulator, what elements the design of the device consists of.

*

The main task in the mechanism is performed by a temperature-sensitive element, which, when interacting with a spring, plays the role of a boiler temperature control sensor. When the boiler temperature rises or falls beyond the established norm, a spring and a temperature-sensitive element activate the working part of the device. The immersion sleeve interacts with the rod, which is directly connected to the actuator.

Due to a mechanical drive, the working part is connected to the damper of the draft hole. The operating draft regulator, under certain conditions, closes or opens the damper, adjusting the area of the inlet opening. The simplest mechanical action acts as a temperature regulator for a heating unit. The damper is closed more tightly, the boiler switches to a mode of poor air supply. The damper is opened more, more air enters the firebox, the combustion intensity increases accordingly, and the heating temperature of the coolant increases. Everything is simple and clear.

Important! Correct installation of the device ensures normal movement of all elements of a simple structure. Otherwise, the draft regulator will perform work that does not correspond to the specified parameters.

Installation of the regulator is described in detail in the technical documentation for boiler equipment. The instructions tell you how to correctly install the device on an existing boiler and how to configure it.

Draft regulator - its importance for solid fuel boiler equipment

The operation of a heating device with an open and closed combustion chamber depends 90% on the state of draft in the heating system. The more stable the draft parameters, the better the heating unit works. Under the influence of draft, solid fuel burns better in the combustion chamber; combustion products easily evaporate through the chimney. With normal draft, the fuel burns more intensely, heat exchange processes improve, and the efficiency of boiler equipment increases accordingly.

Despite the fact that today most models of solid fuel heating devices are equipped with automation, the most effective and efficient are still mechanical control and adjustment devices. Energy dependence is the main drawback of solid fuel boiler automation. There is no electricity in the house, the battery powering the UPS is dead, the boiler becomes uncontrollable. A mechanically driven device installed on the boiler and adjusted in accordance with the specified temperature parameters of the boiler is capable of completely controlling the combustion intensity.

The main advantages of a mechanical draft thermostat are as follows:

- simplest design and reliable operation, unlike automatic devices equipped with electronics;

- non-volatile (automatic traction control requires uninterrupted power supply);

- convenient and understandable installation of the device;

- low cost.

The simple design and principle of operation allow you to make such a device yourself, install and configure it. The mechanism has a scientific and technical name - a thermostat for the boiler. To get the maximum possible effect from the existing heating unit, it is enough to correctly install the thermostat. Subsequent calibration of the device is carried out in accordance with the main functions of exhaust ventilation and the specified temperature parameters.

Choosing a pipe for a solid fuel boiler

When coal or wood burns, toxic gas is released, so do not underestimate the importance of the chimney.

Pipes for solid fuel heating boilers are an engineering structure on which the efficiency of the heating element and the safety of its use depend.

The chimney for the TT heater can be:

- metal – withstands temperatures up to +800°C;

- ceramic – does not lose technical characteristics at a temperature of +1100°C;

- brick - outdated option.

All boilers for water heating using solid fuel are accompanied by instructions that indicate the optimal type of chimney and its technical characteristics. Namely, the parameters of the cross-section of the pipe, its minimum height, the size of the chimney pipe, the maximum temperature of the gases leaving the boiler, the vacuum in the pipe.

The height of the chimney directly affects the draft force in the boiler and the rate of removal of combustion products, and therefore the safety of equipment operation. The instructions for any heating element must indicate the minimum pipe height. This parameter must be strictly observed. Otherwise, a “reverse draft” effect may occur when combustion products are not discharged outside, but enter the living room. In practice, the height of the chimney can be significantly increased.

Pipe section. The wider the pipe for a solid fuel heating boiler, the more intense the combustion in the firebox. At the same time, at a high rate of removal of combustion products from the furnace, heat will evaporate, which reduces the efficiency of the boiler. That is why the chimney is selected in strict accordance with the instructions that accompany the heating element. Combined models of heating equipment, such as a solid fuel and gas heating boiler, also need a good chimney. In this case, the selection criteria remain the same.

Is it possible to bury heating pipes in a floor screed and how practical is this?

What to do if a hole appears in a heating pipe is described here.

Principle of operation

The main role in the design of the draft regulator is played by a thermostatic element located inside a cylindrical body. It has a mechanical connection with the lever, which, in turn, is attached by a chain to the vent flap.

The thermostatic element is presented in the form of a sealed flask, which is filled with a heat-sensitive liquid that has the ability to expand under the influence of temperature.

The element itself is located in the lower part of the housing, which, when installed, falls inside the jacket and has direct contact with the heated coolant. Control of fuel combustion, in this case, is carried out by adjusting the position of the ash valve.

- During the combustion of fuel, the coolant is heated, which acts on the thermostatic element. This, in turn, overcomes the resistance of the return spring and activates the actuator.

- Lowering, the lever loosens the chain, the detached damper lowers, reducing the cross-section of the air supply opening. When the air flow to the firebox is reduced, the combustion process slows down.

- When the temperature of the coolant decreases, all actions occur in the reverse order. As a result, the damper rises, resuming the flow of air to the firebox.

- The cyclical adjustment of the air flow to the firebox occurs continuously until the fuel is completely burned. In this case, the thermostatic element completely releases the return spring, which opens the air supply valve as much as possible.

At the end of the thermostat there is a setting handle that can limit the amplitude of movement of the lever, regulating the movement of the damper. This allows you to control the temperature of the coolant. The operating principle of a gas boiler does not allow the use of these devices.

Types of regulators and features of choice

If the solid fuel heater is not equipped with a draft regulator as standard, you will have to install the device yourself.

A prerequisite for this is

:

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are available that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

On the left is a boiler with the ability to install a regulator, on the right is with manual control

When choosing a model, pay attention to the following parameters:

- the force that the drive develops (the value is indicated in the passport, it should be sufficient to lift the ash pan door);

- temperature range for heating the coolant (60-90°C);

- the operating stroke of the drive (it should be sufficient to fully open and close the damper);

- type of threaded connection on the body - it must match the thread in the boiler unit sleeve (usually 3/4″).

The design of the draft regulator may provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the water jacket of the boiler. For such models, the immersion sleeve is removable.

Technical specifications

When choosing a thermostat for a boiler, you need to know several technical parameters that characterize these automation tools:

- The range of water temperatures in which the thermocouple can operate.

- The working stroke of the chain drive lever is in mm; it must be compared with the movement of the ash pan door from full closing to maximum opening. The operating stroke of the regulator drive must be enough to fully open the damper, otherwise the boiler may not gain its thermal power.

- The maximum door weight that the regulator can handle. If the air damper of your heat generator weighs more than the chain drive can pull, then such a product will not suit you; you should look for a model with a greater lifting force. It is also worth checking whether the lifting force includes the weight of the drive itself or whether it must be calculated separately.

- Maximum coolant temperature.

- Diameter (in inches) of the threaded connection of the seat.

The draft regulator for the RT 10 boiler shown as an example is designed in such a way that the actuator can be replaced or repaired without emptying the water jacket of the heating system. This is achieved through a removable immersion sleeve. Products from other manufacturers may not have such an option, then to replace it you will have to drain the water from the entire heating system and boiler tank.

Traction regulator

The combustion process directly depends on the presence of air. If we transfer this statement to the operation of a heating device, then the more air enters the combustion chamber, the faster and at a higher temperature the fuel burns. In other words: by supplying air to the fuel combustion chamber, you can regulate the degree of heating of the coolant. In the design of solid fuel heating systems, an air damper is provided for this function. By changing the position of the damper, conditions are created under which fuel combustion occurs according to the pattern specified by the user.

The only problem: the owner of the boiler unit must adjust the position of the air damper manually, relying on the thermometer readings and his own experience. To automate this process, an automatic draft regulator was invented.

The principle of operation of the regulator: when temperature affects the thermoelement, it changes its shape and, through the rod, acts on a lever, which is connected to the air damper of the boiler unit using a chain. When the coolant temperature changes, the position of the air damper automatically changes. The regulator sets the upper temperature limit.

To set up a draft regulator for solid fuel boilers with your own hands, you need to follow these steps:

- Install the regulator into the heating system. Depending on the boiler model, both horizontal and vertical installation of the device can be provided. Each installation option corresponds to a specific scale color on the regulator. At this stage the chain is not connected to the choke and hangs freely.

- Set (by selecting the color of the scale corresponding to the orientation) the desired temperature indicator of the coolant and start the boiler installation.

- When the coolant temperature reaches the value you set on the thermostat, close the air damper, leaving a gap of 2-3 mm.

- Attach the chain to the damper rod.

Let's digress a little, because we want to inform you that we have compiled a rating of solid fuel boilers by model. You can learn more from the following materials:

- Long-burning solid fuel boilers with a water circuit - domestic manufacturers

- Long-burning solid fuel boilers with a water circuit - foreign manufacturers

Why are regulators needed?

Unlike any wood-burning stove, a hot-water solid fuel boiler is equipped with a water jacket and cannot heat up to too high a temperature, otherwise the water in it will simply boil. In such cases, the resulting steam sharply increases the pressure in the system, causing an explosion. That is, a solid fuel boiler, whose power is manually regulated by the ash pan door, is a source of increased danger.

Note. At the very least, the boiler, without any automation, can work together with a buffer tank - a heat accumulator, whose volume is correctly calculated. Excess heat will go there if you did not close the door in time and did not limit the flow of air into the firebox.

An automatic chimney draft regulator, which you can install on any solid fuel boiler yourself, will supply air for you and much better than you. It will react in time to an increase in the temperature of the water in the boiler jacket and shut off the air supply to the chamber if the firewood gets very hot. Although, by inertia, the temperature will rise for some time, but in general the heating process will stop. In addition to ensuring safety, a mechanical boiler draft regulator helps solve the following issues:

- Does not allow the coolant temperature set by the user to be exceeded. It is not always necessary to accelerate the boiler to 80...90 °C; in spring or autumn, 50...60 °C is quite enough for heating.

- By covering the damper and air supply, the draft regulator increases the burning time of the boiler from one tab. But we must admit that the fuel combustion conditions worsen, and the efficiency of the heater sharply decreases.

Almost any solid fuel boiler can be equipped with 2 types of temperature controllers - mechanical (on the left in the photo) or electronic (on the right).

You can argue that any solid fuel heat generators should be connected to the heating system using a safety valve set to emergency pressure. If it overheats, the valve will work, release steam and no explosion will occur. So the draft regulators seem to be of no use. The statement is only partly true, since without automation the heater will often reach a critical temperature, and the valve will simply leak after 2-3 operations. Yes, and controlling the water temperature manually is quite difficult.

How to configure the regulator after installation

In order to properly configure the device after installation, you must strictly follow the step-by-step instructions:

- Open the boiler door and do not close it with a chain. This is done in order to let air in.

- The locking screw on the adjustment handle is loosened.

- The handle is inserted at the required temperature, for example, 65C.

- The thermometer on the solid fuel boiler is monitored; after the mark reaches 65C, it is necessary to connect the chain wire to the damper. The main thing is not to close the damper completely. It should always be slightly open a couple of millimeters.

- The fixing screw is tightened.

Important! The chain has free play, but it should not exceed 1 mm. After this, the device is checked in all modes, even at the maximum

The main thing to remember is that time must pass between checks, since the solid fuel boiler heats up and does not always have time to cool down. To get the most effective result, you need to wait a while so that the temperature conditions do not go astray

After this, the device is checked in all modes, even at the maximum. The main thing to remember is that time must pass between checks, since the solid fuel boiler heats up and does not always have time to cool down. To obtain the most effective result, you need to wait for some time so that the temperature conditions do not go astray.

Coal or firewood fades gradually, so solid fuel thermogenerators need a little more time to cool down than other similar equipment.

Possible installation problems and ways to eliminate them

Compliance with technical rules, taking into account basic norms and standards cannot always guarantee achievement of the desired result. Even the slightest mistake that was made at any stage of the installation work can lead to improper functioning of the entire system. The most common problems that builders face are:

- Non-vertical arrangement of the tube lumen. The permissible deviation is no more than 10 cm per meter of product. A deviation of only 1 cm is considered ideal, however, it is almost impossible to achieve such results without special practical skills and outside help.

- The presence of gaps that create obstacles for the free passage of the pipe into the chimney channel. The existing gaps must be sealed with a clay-sand mortar or a sealed substance that is resistant to high temperatures. The chimney draft control can be sealed using sealant, soaked asbestos or asbestos cord.

Ferrum devices meet all the presented requirements. Assembling the chimney will not take much time, a tight connection guarantees tightness, and the rigidity of the structure ensures no deviations.

Traction force

The traction force depends on various factors:

- Flue gas temperatures.

- Chimney sections.

- Weather conditions (humidity, outside temperature, etc.).

The influence of these parameters on the operation of heating devices can be different, so you should always consider the specific operating conditions of communications. It is necessary to note one more parameter, which often escapes the attention of consumers, but has a significant impact on the traction force - the type of boiler equipment. As practice has shown, the dependence of the operation of gas and solid fuel boilers on their type is as follows:

When operating gas equipment, the traction force fluctuates slightly; the indicator can be considered stable. This is explained by the fact that the flue gases generated during boiler operation have almost the same temperature. Unevenness can only occur when the chimney warms up and is short-term. Solid fuel boilers show different data. It is impossible to unambiguously judge the influence of absolutely all models on traction performance. This is explained by the use of different types of fuel (firewood, peat, coal, pellets, sawdust). Also, the heterogeneity of indicators may depend on the type of solid fuel boiler. Despite the type of boiler and type of solid fuel, there are a number of similarities

The following are of greatest importance: the long time required for the fuel to ignite, a significant difference in the temperature of the exhaust flue gases at the beginning of operation of the equipment and after the boiler returns to normal operation. When operating solid fuel boilers, there is a possibility of not only a decrease in draft and a deterioration in the combustion process, but also the appearance of hyperdraft. A sign of this phenomenon is loud noise during equipment operation, and the most “pleasant” consequences are smoke and increased fuel consumption.

What type of gas burners should be used for boilers?

Gas burners are mainly purchased for solid fuel heating boilers of the combined type, that is, the boiler operates on several types of energy carriers simultaneously. In this case we are talking about the “solid fuel + gas” system. The combustion chambers of different types of fuel are located separately from each other, which is why there are no special requirements for gas burners here.

The burner can be:

- diffusion - gas mixes with oxygen during combustion;

- injection - gas is mixed with oxygen before combustion;

- complete and incomplete pre-mixing of components;

- atmospheric – partial enrichment of gas with oxygen;

- turbocharging – forced enrichment of gas with oxygen due to the operation of a fan.

There are burners with which it is easy to convert a solid fuel boiler to a gas heating element.

How to choose the right draft regulator

The modern market offers a large number of models of solid fuel boilers. But not all of them are equipped with automation. In such models, the sleeve is mounted directly into the heat exchanger. Such boilers must be equipped with a draft regulator.

In order to choose the right mechanical traction device, you must adhere to the following instructions:

- To successfully lift the sash, it is necessary that its weight and the power of the thermostat match.

- The temperature range should be between 60-80C.

- The lever must have a rotation angle such that it is enough to completely close and open the sash.

- The threads in the boiler and the draft regulator must match each other in order to be connected.

Attention! The sleeve on the equipment may be located on the top or side, so it is very important to select a regulator with the correct operating mode. Models have been developed in which work can be done in any position

UPS is the key to uninterrupted operation of the thermostat

Uninterruptible power supply with batteries.

A UPS for solid fuel heating boilers is a mandatory attribute of a modern boiler room, which will ensure uninterrupted operation of all equipment during a power outage.

When choosing a UPS, pay attention to the amount of energy consumed by the boiler room. Depending on the obtained value, a battery of appropriate capacity and power is selected. The second mandatory attribute of a high-quality UPS is a sinusoidal output voltage. This parameter is fundamental. Otherwise, neither the circulation pump, nor the thermostats for solid fuel heating boilers, nor other boiler automation will simply function.

Today on sale you can find a UPS belonging to the On-Line group. Although this is an expensive model, it has a reliable operating circuit and will ensure the safe operation of electrical appliances in the complete absence of voltage in the network. The Line-Interactive group is optimal today. It is capable of converting voltage from 12/24V batteries into the 220V required for electrical equipment. At the same time, the UPS has a built-in voltage stabilizer. The Off-Line type is a budget option. It has a simple and durable operating system.

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of increasingly complex systems for automatically controlling the processes of heat production and hot water supply. They are more accurate and do not require user participation in most operations. However, such systems are becoming increasingly dependent on electricity and increasingly expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. Operates reliably in the range of 35˚-95˚С, operating temperatures from –20°C to +150°C. Can be used with various antifreezes, allows replacement of the thermostatic element. When used in low temperature environments, it requires heating. Can be installed in any position and does not require service. Inserts into a sleeve with 3/4" pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuel, due to its extreme unpretentiousness, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device can be mounted in a vertical or horizontal position; the temperature level scale allows this. Coolant temperature control range 30–90°C, maximum operating temperature +120°C. Coupling for connection with internal thread G3/4”. Device weight 0.42 kg, manufacturer – Czech Republic.

Cost: from 1500 rubles.