Among consumers, Vector geysers have gained wide popularity due to their affordable cost, attractive design, and reliability. But any technology does not last forever, and individual elements and components of the speakers are subject to wear. The simple design of the equipment allows, in most cases, to repair Vector Lux geysers on your own, without waiting for a specialist to arrive. This option not only saves time, but also money, don’t you agree?

But where to start and how to proceed? We will talk about all this in our article - first, we will understand the features of the brand’s gas water heater and the reasons for its malfunction. We will also discuss repair methods and equipment maintenance procedures.

Why is there a spark, but the water heater does not turn on?

The gas shut-off valve is closed.

To solve the problem, you need to open the shut-off valve. This is the first thing to do when the device does not ignite.

Weak water pressure, as well as in the absence of a spark.

The reason may be the low pressure of the water main; to increase it, you can install a pump to increase pressure.

Weak pressure at the boiler outlet

If it is normal at the inlet, it is due to a clogged filter at the inlet of the device or in the faucet mixer. It is necessary to clean the filters using a brush and strong water pressure. If the scale layer is not completely removed, it is better to change the filter. Preventive inspection and cleaning of the filter must be carried out regularly to extend the life of the device.

Scale builds up inside the heat exchanger when using hard water.

It is necessary to treat the internal and external surfaces of the heat exchanger. To remove scale, the heat exchanger should be removed and placed in a container larger than the heat exchanger itself. When removing, it may turn out that the nuts are clogged with scale and unscrewing them is problematic.

Using an oil can, drip a special liquid, VD-40, or Silit, onto the joints, hold for about half an hour, then unscrew the nuts. When the heat exchanger is removed, prepare a solution of citric acid, 100 grams of powder per liter of water, pour this liquid into the tube using a funnel, immerse the heat exchanger there, keep it dissolved in it for 15 minutes. Then drain the solution and rinse the part very thoroughly with water until all remaining scale is removed.

If some of the scale remains, it may clog the heat exchanger tubes. If necessary, repeat the procedure. It is prohibited to remove scale with a solution of hydrochloric acid, which enters into a chemical reaction with the metal from which the heat exchanger is made; such cleaning can end disastrously for it.

Weak batteries

They may shrink or be of poor quality.

The solution to the problem is to replace the batteries. Due to weak batteries, the speaker may not turn on the first time; you have to turn it on and off several times until it lights up.

Burner contamination

It may also be the reason why the unit does not ignite the first time. It is not safe to clean gas equipment yourself; this should be done by a specialist. The only thing you can do yourself is to remove the soot that is inside the burner jets. How to do this - the jets are freed from soot with a thin copper wire, the soot is removed with a metal brush. After carrying out these manipulations, it is necessary to check the unit for gas leaks (to avoid the possibility of an explosion), prepare a solution of soap, and apply it to the joints and connections. If the soap does not foam or bubble, then there is no leak. The burner needs to be cleaned regularly.

The main causes of problems and how to fix them

For those who want to purchase a Vector geyser, there is a useful bonus. It consists in the availability of such a service as after-sales service. If the water heater breaks down, it will be repaired by a qualified technician as quickly as possible. This will be facilitated by the absence of difficulties in purchasing spare parts, the price of which is quite reasonable.

Problems with the Vector geyser can be as follows:

- Change in flame color and presence of soot traces. This phenomenon indicates that the device urgently needs cleaning. Of course, this problem cannot be unexpected, because cleaning the water heater from dust must occur regularly. Otherwise, disruptions in its work are inevitable.

- Lack of temperature data. They are usually shown on the display. If this does not happen, then damage to the screen itself or the circuit through which the necessary information reaches it is implied.

- No response to switching on. This can happen due to weak water pressure (if there is a spark). To solve the problem, you should clean the filter located at the inlet of the water heater or the heat exchanger. In the first case, the cause of contamination will be dust, and in the second, scale. If there is no spark, you just need to replace the batteries.

- Reducing the flame until it completely disappears. This fact indicates the need to change the membrane of the water unit.

- Spontaneous turning on and off of the device. In this case, you will need to clean the chimney, check the sealing of the pipe and air duct, and eliminate the causes of overheating of the Vector column.

- No spark when batteries were recently changed. This will require replacement of faulty spare parts, in particular the microswitch, solenoid valve and (or) electronic control unit.

- Reducing the liquid pressure at the outlet of the column. This can happen due to a lack of normal pressure in the entire system, a small pipe diameter and a clogged water filter.

- Insufficient water heating. In such a situation, only cleaning the heat exchanger tubes from scale and dust will help.

Carrying out repairs yourself should only happen if you have such experience. If it is not there, you should definitely call a specialist rather than try to fix everything yourself. Such recklessness is fraught with explosion or spontaneous combustion.

According to experts, the likelihood of the problems described above appears due to the poor quality of the parts that make up the water heater, the lack of automatic maintenance of the required temperature conditions, insufficient thickness of the walls of the heat exchanger and the power of the device.

Here you will learn:

- Geyser Vector JSD 20-W

- Geyser Vector Lux Eco 20-1

- Geyser Vector LUX Eco 20-2

- Geyser JSD 12-W

- Geyser Vector JSD 11-N

- Geyser Vector JSD 20-G

The Vector geyser is a budget option for those who save money in their wallet and do not recognize the need for additional functionality. That is why speakers from this brand have become so widespread. Prices for models with good performance start at 6,000 rubles, which is a good indicator. What are the advantages of Vector geysers?

- Affordable price - these are truly one of the most inexpensive geysers on the water heating equipment market;

- The simplicity of the geyser design ensures maintainability;

- Large model range – buyers have a fairly wide selection of speakers to choose from.

Lovers of good design will also rejoice - especially for the most demanding customers, models with a glass front surface on which various designs are located have been developed. These speakers look just great. As for the quality of the equipment, there are minor complaints about it, as evidenced by the reviews below about Vector geysers.

Next, we will publish reviews of people who have received Vector geysers of various models. Along with the reviews, the advantages and disadvantages of the speakers are described.

Other malfunctions of geysers

The operation of modern speakers is controlled electronically. The devices are literally stuffed with a ton of sensors and electronic modules. Even a minor failure of one of the sensors can lead to unsatisfactory operation of the unit. You won’t be able to solve the problem yourself; you need special equipment.

Most owners of geysers, if the water from the tap is too hot, regulate the temperature by adding cold water using a mixer. In this case, the speakers may go dark. Manufacturers of units do not recommend operating the dispenser in this mode. It is better to set the heating temperature on the column to a lower temperature.

Also, speakers may not work well if the igniter is incorrectly configured. This is why the gas water heater does not light up immediately

It is very important that the gas pressure in the line fully matches the type and design of the igniter. There is a comb on the edge of the burner, and the electrode must be installed so that the spark hits directly on the comb

If the gas pressure is insufficient, the fuel goes down. The electrode must be mounted approximately to the center of the burner. Then the ignition system will work more stably.

Typical malfunctions of individual speakers:

- Astra speakers have frequent problems with the solenoid valve. If the mixer is adjusted incorrectly, the column operates unstable.

- Ariston models have problems with the water unit. Experts also highlight rapid wear of the membrane.

- In Oasis brand speakers there are problems associated with the burner, as well as with the membrane.

- In models from Amina, batteries are discharged very quickly - owners have to change batteries frequently.

- Dispensers of the “Rossiyanka M” brand often have problems with broken valves and clogged filters. But on the Dion columns there are problems with the heat exchanger. What is the reason? The heat exchanger often burns out.

Lights up but goes out

Let's consider several moments when the column fades out some time after ignition and what ways there are to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

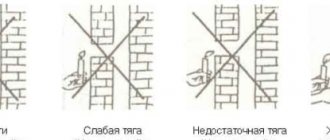

Checking the traction force

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats and the overheating sensor is triggered.

You can eliminate it by opening a window or vent, creating a draft in the room. A gas heater burns a very large amount of oxygen during operation, so it requires a constant supply of fresh air to operate.

The second reason for the column to fade out may be the insufficient time of holding the ignition button. It should be held for at least 20 seconds; if held for less time, the column will go out.

A malfunction of the combustion products exhaust sensor is the next point. To check the sensor, you need to ring it by connecting two terminals. Normally, the resistance should show infinity. If the reading is different, the sensor will have to be replaced.

Strong cold water pressure and low hot water pressure - this situation also often causes the water heater to fade. This happens when you use hot water and open a cold tap. To eliminate this problem, you need to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is incorrect operation of the device and can lead to damage to the heater.

High water pressure can lead to attenuation. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. In this case, the strong pressure of the flow bends the membrane of the water unit, the membrane moves the rod in the gas supply. It is necessary to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has activated, protecting the device from overheating.

Column temperature sensor Vector

The heater works for some time after ignition, then goes out again. If you try to turn on the device right away, there will be no result. After some time, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only replacing it will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is working, you need to clean the contacts and the automation unit.

The design of the igniter itself (device for generating an electric spark). The electrode is mounted in such a way that the spark hits the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Taking into account the fact that a small reverse draft is almost always formed inside the system, a weak level of gas goes down under the pressure of this draft, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark does not fall on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always lights up, ignition is fast, stable and soft.

The formation of holes between the gas exhaust pipe, the connecting pipes of the gas exhaust device and the chimney, between individual sections of the gas exhaust pipe. Determined visually, to eliminate it, it is necessary to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

Elimination of traction disorders

To test traction, try using an ordinary match. Bring it to the chimney and determine if there is a draft, then the flame will deviate towards the chimney.

If there is no draft, the gas water heater will not light and users will not receive hot water. Many dispensers are equipped with draft sensors, and if they show insufficient draft, ignition will be impossible. Situations are possible when the flame lights up and immediately goes out - this is due to the fact that the combustion products simply have nowhere to go, they remain in the combustion chamber, and the flame goes out due to lack of oxygen. Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages here, they can interfere with the normal passage of combustion products. The column perceives this as a lack of traction and does not allow the gas to ignite (or the gas goes out immediately after turning on). Unfortunately, you will be able to independently check only the part of the chimney that is visible before entering the wall - further work must be carried out by specialists. If the house is private, you can try to figure out the chimney yourself.

Disadvantages of Vector water heaters

Don’t think that for modest money you will buy newfangled equipment that will last for decades - this is not so. You need to understand that budget options are not designed for long-term use and cannot offer innovative technologies that are present in expensive analogues. It happens that after a season of use, equipment requires repairs and replacement of parts.

Another drawback is heat exchanger burnout. Although it is made of copper, its layer is quite thin. Therefore, over time, the heat exchanger can no longer withstand high temperatures and the equipment breaks down.

Even these shortcomings do not stop buyers and the heaters are actively selling out. Some people think that they are much better and of higher quality than models from the more expensive segment. In any case, you cannot say for sure about the quality without testing the water heater yourself.

Turning on the device

The first step is to install the batteries. To do this, open the battery compartment and install them, observing the polarity. Then you need to open the cold water and gas valves. Open the hot liquid tap on the nearest faucet.

At the moment when the liquid flows through the water unit, a spark ignition occurs and, thanks to this, the burner ignites. If it is turned on for the first time or after a long period of inactivity, air may accumulate in the gas line; in order to remove it, you will need to open the mixer several times, hold it for a minute, and then close it.

If the burner ignites, you need to turn the water pressure adjustment lever (located on the right) to the right, this will make it possible to turn on the Vektor JSD 20 device when the liquid pressure in the system has decreased.

Where does the water in the column come from?

To understand the causes of the problem, you need to understand the device. The basis of the design is a metal body, to which two pipes are connected. A flow of water passes through one for heating, and gas is supplied through the other.

Water pressure acts on the membrane, the igniter and burner are activated. It heats the heat exchanger through which cold water moves. You open the faucet and get a hot stream.

Most dispensers operate automatically as soon as the tap opens. Manual and piezoelectric ignition is also found.

Why did the column leak?

There can be several reasons for a leak.

- Gaskets between connections are worn out. Rubber gaskets are installed between the pipes and pipes for tightness. Over time, they tear, become deformed, become damaged and require replacement. If a leak is noticed in the area of the connecting elements, you need to remove the old ones and install new gaskets.

- The heat exchanger (radiator) is leaking. Most often, water drips from the connections between the pipes and the radiator. Due to temperature and moisture changes, supply pipes wear out and corrode, so water flows from below. It is necessary to seal or replace faulty parts.

- Prevention has not been carried out for a long time. Gas equipment requires periodic inspection and maintenance to prevent breakdowns.

User manual

Before turning on the gas water heater and starting to use it, you must carefully read the rules for using the device and safety precautions:

- When operating gas equipment, you should use only the type of gas recommended by the manufacturer.

- When turning on the device for the first time, remember that air may accumulate in the pipes, which is why the burner may not ignite immediately. Therefore, ignition should be done twice with a short interval between attempts.

- Setting the heating parameters is carried out by turning the regulator located on the body of the device. When switching on for the first time, set the lever to the minimum value and perform a test heating. Once it becomes clear that the device is working correctly, you can begin testing different temperature conditions in increasing increments.

- In the process of further use, you should not forget to change the electric ignition batteries on time and periodically clean the column from scale, carbon deposits and dust.

- If there is no draft in the chimney, the device cannot be turned on.

- Unlike gas boilers with a closed combustion chamber, the column cannot be left unattended for a long time. This is dictated by fire safety rules and the design features of open-type burners.

- Unauthorized disassembly of the device and installation of third-party spare parts is prohibited. Only a service center technician or a gas service specialist can repair dispensers.

Conclusions and useful video on the topic

In order to repair a geyser yourself, you must have at least minimal repair skills and understand the structure and operating principle of the device.

A detailed overview of the malfunctions of the Vector gas water heater can be seen in the video:

Looking at the information presented above, it is worth concluding that geyser malfunctions can be caused by insufficient pressure when providing water and gas, improper maintenance of the water heater, and the presence of breakdowns in individual equipment components. Some problems are easy to fix yourself.

However, for more complex issues of speaker repair, you should contact qualified technicians. This approach is relevant when the gas water heater is not operating correctly for no apparent reason. In such a case, a thorough diagnosis and a professional approach to repair are necessary.

Do you have a Vector Lux gas water heater and would you like to tell us about your experience in repairing it? Or would you like to add one more to the list of breakdowns discussed in this article? Write comments, add unique photos of your own repair of the Vector column, ask questions, participate in the discussion - the feedback form is located below.

Possible reasons

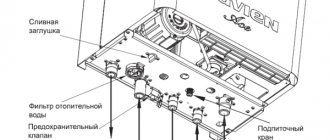

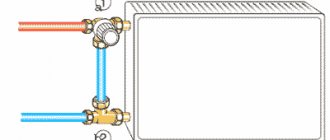

In case of incorrectly connected pipes, the water heater protection system itself blocks the gas supply, which is why it does not turn on. The pipe connection diagram is very simple:

The gas supply pipe is connected on the left, the cold water supply pipe is connected in the center, and the hot water outlet pipe is on the right.

It is also necessary to ensure that all gas supply valves are in the open position. It may well be that after installing new equipment you simply forgot to turn on one of them. All taps with yellow handles must be open.

No or poor draft in the chimney.

Accumulated soot, construction debris or other foreign objects entering the chimney can prevent combustion products from being removed through the chimney, which poses a danger not only to the health, but also to the lives of residents.

hood

You can easily check the presence of draft in the chimney yourself. To do this, you just need to bring a burning match to the inlet. If its flame rushes towards the hole, then the chimney is working properly. Otherwise, you will have to look for the reason why there is no traction. As you can see, an ordinary match can help eliminate a dangerous malfunction and protect your household from carbon monoxide poisoning.

If there is no draft, make sure that there are no obstacles above the ventilation shaft exit, such as a satellite dish. In this case, the problem can be completely solved without seeking help from specialists.

If no external circumstances interfere with the proper operation of the chimney, then you are definitely dealing with contamination. What to do in this situation? Of course, you can try to clean it yourself, but there is a possibility of damaging the branches from neighboring apartments.

Increased relay sensitivity.

The most likely cause of the malfunction is the increased sensitivity of the thermal relay, the protection of which is activated against overheating, stops the gas supply and the column goes out.

How to install and configure?

After purchasing a geyser, you should take care of its correct installation. The procedure for connecting the device to the mains must be carried out in accordance with the standards and requirements, so the work should be entrusted to professionals. You can do the installation in your apartment yourself. After purchasing equipment, you must act strictly according to the instructions, because working with gas equipment is quite dangerous. It is also necessary to order project documentation, and while the registration is being carried out, it is worth purchasing spare parts for the work:

- connecting chimney metal pipe;

- pipes and fittings for water and gas supply;

- shut-off valves;

- fasteners to hang the device on the wall;

- galvanized steel sheet if necessary.

Hanging the unit on the wall does not require much effort, the main thing is not to violate the distance to household objects. After the process of attaching to the wall, you need to connect the column to the water supply. To do this, perform the following actions:

- using fittings, pipes are connected to the water supply and the column;

- to connect the device you should use American ones;

- pipes must be fixed to the wall to avoid overloading the pipe;

- the mud trap is mounted horizontally on the input wiring and mounted on the wall;

- taps must be installed on the connections.

After completing all the above work, it is necessary to connect the gas pipe to the column. This requires the help of qualified workers in this industry. They must install the dispenser to the gas main and pre-set up the equipment. The user only has to perform the initial launch of the column.

To do this, open both water supply taps, and then hot water on the mixer. You should wait until the water flow evens out and then turn off the mixer. Next, you will need to insert the batteries into a special compartment and open the gas valve. If the installation of Vektor equipment was carried out in compliance with all the rules, then after opening the hot water, the device will automatically start. The homeowner will only need to adjust the optimal outlet temperature.

Attenuation: overview of popular models

Some brands of water heaters have characteristic diseases that are useful for users to know about. Here are a couple of examples.

Column "Neva 4510"

This occurs due to the jamming of the gas valve rod - the spring cannot move it to the “closed” position.

To check if this is the case, you need to remove the water-gas unit, disconnect the water part from it and try to move the rod with a screwdriver.

If this requires a lot of force, you need to replace the gas unit - this malfunction cannot be repaired (this unit in these columns is too fragile).

Column Bosch Junkers WR 13-P

The weak point of these water heaters is the thermocouple, which is heated by the igniter.

In some units, it quickly (after about 3 years of operation) begins to malfunction, as a result of which the column first goes out spontaneously, and then the igniter cannot be ignited at all - it goes out immediately after the button is released.

This problem can usually be resolved by sanding the thermocouple with fine sandpaper.

If this does not help, check to see if the pilot tube has become dislodged. In the Junkers it is not attached rigidly, and therefore can be moved during cleaning, careless manipulation, or even ignition with a match. As a result, the gap between this tube and the nozzle through which gas is supplied into it is reduced.

And through this gap air is sucked into the gas flow. Accordingly, the air content in the gas-air mixture decreases, which is why the flame on the igniter burns worse and does not reach the thermocouple. This gap needs to be adjusted. If this is done correctly, the flame on the igniter will lengthen and deviate slightly, reaching the thermocouple.

Disabling the device

It is recommended to turn off the device at night and if you do not plan to use it for a long period of time.

Do it like this:

- Close the hot water tap.

- Close the gas shut-off valve.

- Shut off the water supply to the gas device.

Recommendations for turning off if there is hard water in the water supply:

- Open hot water on the mixer.

- Turn the throttle control lever to the right until it stops (located on the left).

- Wait until cold water starts flowing.

- Shut off the gas and water supply to the device.

Methods for troubleshooting geysers

Geyser "Vector" is one of the most popular in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the Vector gas water heater, a spark does not appear and the burner does not ignite. The reasons for the problems are:

- Lack of draft in the chimney. It could simply be clogged and need to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this yourself, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. Very low pressure may indicate problems with the membrane or that the filter is clogged.

- The nutrient element is not working. Ignition is done using batteries, without which there will be no current to create a spark. You need to remove the panel, then take out the battery pack, pull them out and insert new ones.

Gas water heaters with electric ignition, such as Amina, must contain expensive alkaloid batteries. It is also necessary that the ignition electrodes are correctly positioned from the burner.

- Oxidation of contacts. There is nothing complicated here; sometimes the contacts in the speaker block oxidize. They just need to be cleaned and put back into operation.

- Wrong regulation. If the piezo does not work, the speaker will not start working. Be sure to check the water mechanism regulator. For good operation, water should enter the system frequently, and the lever should be positioned in the right position on the edge.

- The water valve seal is worn out. If you notice that the valve is leaking, you need to replace the seal. If the measure does not help, examine the microswitch rod. If it oxidizes, it will need to be cleaned.

You can carry out identical work if the piezoelectric element in the Zanussi gas water heater does not work.

The column does not ignite, there is no spark

There may be several reasons why there is no spark and the Vector gas water heater does not ignite:

Lack of draft in the chimney.

Normal draft - - Reverse draft

The reason may be as simple as a clogged air duct. You can check the draft in a simple way - bring a lighted candle or match, or a thin sheet of paper to the air duct. If everything is in order with the draft, the flame or sheet will deviate towards the air duct. If not, you need to clean the chimney.

Low water pressure entering the device.

There can be several reasons for low blood pressure. Clogged filter located in front of the water heater water unit. In this case, you need to remove it by unscrewing the nuts and wash it. If the filter is heavily clogged with lime deposits and cannot be cleaned, you will have to replace it.

If you have low water line pressure, then you need to either install a pump or change it to a model that can operate at that pressure. The culprit may also be clogging of the mixer components. To fix this problem, it needs to be disassembled and cleaned. The fourth factor is that the heat exchanger is clogged.

It is necessary to remove the heat exchanger by unscrewing the bolts. Before doing this, you need to turn off all the taps and gas valve under the water heater. Descale it using a special ready-made chemical or regular citric acid.

Membrane failure.

It is located inside the water block. You need to remove the cover from it by unscrewing the screws. There is a rubber membrane under the cover. In working condition, it should not be torn, stretched, or deformed. If any defects are found, the membrane must be replaced. It is better to purchase silicone, as it is more durable. When replacing the membrane, you must be careful not to damage it - first you need to tighten the screws located opposite each other, then the rest.

Dead batteries.

This is the simplest and most common reason. Please note that they may sit down earlier than indicated in the instructions. Replace the batteries.

Oxidation of the battery pack contacts inside the unit itself or the wires.

It is necessary to clean the contacts.

Incorrect handle installation.

The water regulator handle is set to the extreme left position. To get a spark and turn on the water heater, the handle must be moved to the extreme right position.

Oil seal leaking inside the device.

By unscrewing the cap, you can see water dripping from the water valve. The problem is solved by replacing the oil seal with the microswitch.

stock

Insufficient mobility or oxidation of the machine rod.

In this case, it is necessary to remove the microswitch from the housing and release the fixed rod. When souring, it is necessary to clean and lubricate the rod.

The microswitch has failed.

You can determine the breakdown by short-circuiting it. In case of malfunction, the microswitch must be replaced.

The integrity of the electrical circuit between the microswitch and the control unit is broken.

It is necessary to check the contacts of the control unit connector and microswitch wires for rupture and oxidation, and if necessary, eliminate the malfunction by stripping and connecting the wires.

The solenoid valve has failed.

In this case, the valve will have to be replaced.

Solenoid valve

The control unit is broken.

Only replacing the block will solve the problem.

The most common causes of breakdowns

Let's start a review of breakdowns using the example of such simple geysers as Oasis or Neva. These are fairly simple devices, so almost any man who knows how to work with tools and has relatively straight hands can handle their repair. Here is a short list of possible faults and causes:

- Lack of traction;

- Insufficient water pressure;

- Insufficient gas pressure;

- Inoperative ignition system;

- Clogged tubes and water supply filter;

- Burner clogged;

- Malfunction of the membrane or gas block;

- Inaccurate mixing of cold water in the mixer;

- Faulty electronics or sensors.

Now we will look at how to eliminate breakdowns and causes of lack of ignition.

Advantages of Vector speakers

The Vector gas water heater was created taking into account gas and water pressure in Russia.

These speakers have an attractive design and are sized to fit even into a bathroom. The company's gas equipment meets all standards and has several protection systems. This is why Vector speakers are so popular. The following advantages can be noted over other similar devices:

- Low price, allowing you to install a gas instantaneous water heater in any home or country house;

- Stylish design will fit into any interior;

- Using a geyser is very simple - there are only two regulators;

- The “winter-summer” switch on some models allows you to save fuel in the warm season;

- The presence of electric ignition eliminates the need to use matches or lighters; this function also reduces gas consumption;

- “Vector” without a chimney, which makes it possible to install it in any non-residential premises;

- The water heater operates silently;

- Thanks to the availability of any parts for sale, there are no questions about repairs.

Blockages in the system

How to clean the mesh filter was written above. The heat exchanger system should also be cleaned - scale forms on it during operation. To do this, the heat exchanger is removed and placed in water with citric acid. The container with the solution must be heated on the stove. The inside of the heat exchanger should also be washed with this solution.

In Junkers gas devices and other similar units, burners often become clogged. A large accumulation of soot and soot leads to the fact that the column will not ignite. When cleaning the heat exchanger, it is worth cleaning the burner as well. Wash the outer part of the device with a solution of citric acid. It is better to clean the inside of the burner outside.

Main characteristics

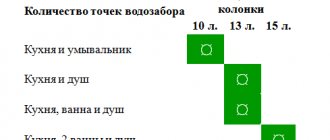

A gas water heater for running water is a technical solution based on the needs, conditions and capabilities of the consumer. The issue of hot water supply is relevant at all times. The Astra gas water heater is a worthy offer that meets the needs of the population. The device, even with a small power of 12-15 kW, is capable of heating water to 60-65 degrees, while gas consumption is moderate. A device with higher power, with a capacity of up to 12 l/min, is capable of serving two water connection points simultaneously.

It should be remembered that the installation of the Astra geyser must be carried out in full accordance with the instructions, taking into account the necessary technical parameters of its use.

Despite the fact that the equipment is a budget option, it is equipped with a complete security system. So, the column automatically turns off in the following cases:

- lack of traction;

- interruption of water supply;

- lack of flame.

The product range is quite diverse. Depending on performance and individual preferences, it is possible to provide a relatively inexpensive, uninterrupted supply of hot water at the optimal temperature. Despite the fact that this gas installation is significantly lower in cost than well-known branded equipment, it is a worthy competitor in terms of functionality and design.

When the Vector ignites late

There are several variations here too. The very first thing that needs to be done in such a situation is to open and clean the unit, especially the nozzles and jets. If this does not help, you should sequentially check the following to determine the location of the failure:

- electronic ignition unit

- traction sensor

- microswitch

- solenoid valve.

If there is no spark during ignition, but there is a crackling sound, you need to check the microswitch for functionality by short-circuiting it.

Geyser microswitch Vector

First you need to remove the casing: pull the handles towards you, remove them, and unscrew two screws from the bottom of the unit, on the right and left. Pull the bottom of the column towards you, lift the casing until it comes out of the pins at the top. The casing has been removed. There is a microswitch in the center at the bottom. When you turn on the hot water tap, the switch button will be released by a lever and come out of the recessed state, otherwise you should push it with a screwdriver and lubricate it with oil. After all this has been done, the ignition should begin.

If this does not happen, the microswitch requires replacement. When there is a spark, there is a click, but ignition does not occur; in this case, the solenoid valve does not work. It cannot be repaired; it must also be replaced. If there is no spark, no crackling or clicking, but it has been verified that the microswitch is working, you need to check the electronic ignition unit. Repairing this unit is difficult and will require replacement.

To help, we suggest that you read the article about repairing the Vector JSD20 W speaker with your own hands. In addition, additional information on replacing the rod can be obtained from this video:

Some of the listed problems can be eliminated on your own; some arise due to improper care of the unit or non-compliance with the rules of use. In any case, it should be taken into account that if the malfunction concerns gas equipment, it is better to entrust the repair to specialists, especially if the unit does not ignite and the reason is unclear.

Problem with Vektor gas water heater

Good evening, everyone. There was a problem with the Vektor gas water heater. It worked honestly for about 4 years, but now it’s started acting up. It runs on batteries (open the tap and go). When you open the tap, the spark fires clearly. But apparently there is no gas supply. If Gently tap something on the gas or hot water supply fittings (which come out from below), and the cold water supply too. It starts working normally. Saves for 3-5 days. I understand that our “too soft water” has soured somewhere automatic rod. I want to disassemble and clean everything. The question is actually which unit needs to be disassembled (so as not to gut everything) and treat the patient.

Disassemble the hydraulic gas switching unit. Located at the bottom center of the column. DO NOT TOUCH THE GAS PART, it has 99% nothing to do with it. I would suggest starting with replacing the batteries. Often their voltage is not enough to open the gas valves.

Thanks for the advice. We’ll clean it. As I understand it, cold water is suitable for this unit. There are no batteries for a long time. Two years ago I converted it to a power supply unit - it works from electricity, but you can also add batteries when Chubais turns off the switch

You got it right. There may be two faults:

- soured rod (lubricate, clean the metal, BUT DO NOT CLEAN THE RUBBER through which the rod passes)

- the membrane has stretched or torn. Replacement only.

Thank you very much for the consultation

Problem with gas. column Vector. I turn on the hot water, look for clicks, but there is no gas supply and the column does not light up. When the gas is turned off, I turn on the hot water, look for clicks and the column lights up, but the clicks continue and the column goes out after 10 seconds, and all this with the gas turned off.

Column Vector. It worked for 5 years, then within 3 days it began to go out, then stopped lighting up. They removed the casing and a hole burned out in the heat exchanger. We installed the same new one, the dispenser does not ignite. The batteries are new, the water pressure is good. When the water is opened, the ignition works, the microphone opens, the gas valve relay does not work. How to force open a gas valve (three wires: red-yellow-black). Is it possible that the column does not turn on due to low gas pressure?

Morriss62, if the column is new, then nothing

there is no need to do anything other than

also deliver good ones.

Morriss62 wrote: How to force open a gas valve

It's possible, but it's not necessary! It's better to change the column, because... it's new.

Changing the column is not so easy, they will say, let’s get a certificate from the gas service that installed it. I bought the speaker in Russia and installed it in Ukraine. That’s why I want to fix everything myself. If I understand the automation algorithm correctly, then when the microphone opens, voltage is supplied to the control unit, where an ignition signal and a gas valve opening signal are generated. The gas valve opens and gas flows to the burner. It turns out there are two options: either there is no control signal from the control unit to the gas valve, or the gas valve has burned out. So I want to determine what is faulty, especially since there are two speakers that do not work. Or maybe there is some general reason, for example, insufficient water pressure.

Morriss62 wrote: Is it possible that the column will not turn on due to low gas pressure?

Elementary - but more often this happens out of stupidity - 1. Forgot to open the gas tap. 2. The gas valve was not opened completely (it should be 90 degrees (no more/no less)) 3. A gas valve with excessive narrowing was used, or the gasket was installed with a small passage. The “correct” passage in a narrow place of a gas GP (in the fitting; and so that the gasket does not narrow) is at least 13 mm

Morriss62 wrote: two options, either there is no control signal from the control unit to the gas valve, or the gas valve has burned out.

Of these two, most likely the first. The second option is unlikely (I have never seen a “burnt out”), unless of course there is a manufacturing defect, etc.

but you know better! Although the pressure seems to be in order, since

Morriss62 wrote: When the water is opened, the ignition works, the microphone opens

Overheat

Most often, overheating occurs for the following reasons:

- The user dilutes hot water with cold. Due to the addition of cold water, the consumption of hot water is reduced, therefore, the heat extraction is reduced and the water in the heat exchanger overheats. Remember: you can regulate the temperature of hot water only by changing its pressure or using the regulator on the column.

- The heat exchanger is clogged with scale somewhere. This also leads to a decrease in water consumption with subsequent overheating. You can guess what happened by the clearly weakened pressure of hot water, despite the fact that cold water flows properly. To prevent such troubles, the heat exchanger must be periodically washed with special anti-scale compounds.

If the mesh filter (dirt filter) installed on the water supply in front of the column is clogged, the flow rate in this case will drop with all the ensuing consequences.

The heat exchanger is clogged with scale

With our water quality, heat exchangers in geysers become clogged with scale quite quickly and very heavily, which reduces their thermal conductivity and increases gas consumption.

The longest process in terms of time is cleaning the main tube (radiator) from deposits that arise when heating tap water. If you turn the gas knob all the way, and the water coming out is barely warm, then this indicates that the heat exchanger is clogged with ordinary scale, which does not transfer heat well.

This happens quite often if the gas water heater does not have automatic ignition (with a igniter). Scale also forms if you set the water heating temperature too high. The unit overheats, the tube (radiator) heats up to 80-850, which contributes to the rapid (a little more than an hour) formation of scale. Isn't it better to just turn off the speaker in time? Then there will be no problems, because 40-600 is enough for all washing and washing processes.

Before starting work on the heat exchanger, check the inlet tap or valve. Maybe the whole reason is that they are clogged. But if they are working properly, it is necessary to get rid of deposits in the tube.

There are two ways to solve the scale issue. We will consider both options.

Auto

The Cillit KalkEx cleaning system does its job quite well. With its help you can quickly descale any boilers. Unfortunately, it is not very accessible to ordinary users of geysers.

This is an expensive method using a special device (Cillit KalkEx) and a set of special preparations for washing. Your speaker doesn't even need to be removed from the wall. You just need to disconnect the water hoses (inlet/outlet).

The purification device is connected to the column, and it circulates the heated reagents in a closed cycle (in a circle). The scale decomposes under their influence, is washed out and drained.

Manual

Cheap, but long and labor-intensive process. To do this, it is necessary to disassemble the water heater almost completely and then wash it manually.

The following materials and tools will help us with this:

- open-end wrenches (set);

- screwdrivers (phillips and regular);

- paronite gaskets (set);

- rubber hose;

- vinegar essence or anti-scale agent.

Disassembling the gas apparatus

To remove the heat exchanger, proceed in the following order:

- First, we block the access to cold water;

- then we remove external elements that prevent disassembly (switch handles, regulators);

- remove the casing, and to do this, unscrew the screws located on the rear wall of the unit, lift and remove the cover;

- open the “hot” tap;

- unscrew the supply tube from the heat exchanger and move it aside;

Flushing the system

After the water has completely drained, we put the hose on the heat exchanger tube and raise it above the level of the column. Slowly pour the solution we prepared into the hose and leave the column for 4-6 hours.

Next, you need to open the water supply tap a little and watch the water that will come out of the column; if you see a lot of scale, then our work was not in vain - we got rid of it. If there is no scale in the outlet water, then we repeat the whole process again.

Other faults

Also, malfunctions of the water heater can be caused by the following reasons:

Ignition system failure

In speakers without an igniter (electronic ignition), the spark is generated by the batteries; perhaps they have run out.

The battery capacity is not always enough for a year, as the manufacturer promises.

In other models, a spark is produced by a piezoelectric element triggered by a turbine installed in the water supply.

If the water pressure is weak, such an ignition device will not work.

When buying a column, you need to pay attention to the minimum water pressure that it requires for normal operation. In columns with an igniter, the latter may become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself)

As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

In columns with an igniter, the latter can become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself). As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

The membrane of the water unit has exhausted its resource

This element, made of a polymer material, must have sufficient elasticity, but over time it loses it, becoming rigid, and may even crack.

It can also become overgrown with lime deposits.

Accordingly, the column will stop turning on, even if the user opens the tap completely.

The membrane must be inspected and if its condition is truly unsatisfactory, it must be replaced.

Control module board burnt out

This often happens with imported speakers, which are very sensitive to the quality of the power supply. They should be connected through a stabilizer.

It is also useful to know that smart speakers with electronics should not be turned off at night.

Gas water heater maintenance

To ensure that the geyser does not require repairs for a long time, it is important to periodically inspect the water heating equipment and carry out its maintenance.

To avoid the occurrence of fire hazards, it is necessary to pay attention to the condition of the ignition group and the main burner. The equipment must be promptly cleaned of accumulated carbon deposits and the heat exchanger gaps must not be allowed to become clogged with soot.

The body of the geyser is cleaned using a soap solution and detergents without abrasive substances.

Maintenance of the water heater must be carried out by specialists from the gas company and at least once a year.

A number of column cleaning activities can be carried out with your own hands, including:

- cleaning the burner;

- lubrication of moving elements;

- cleaning, replacing the water filter;

- inspection of the column for cracks and deformation;

- replacing gaskets;

- cleaning the heat exchanger;

- checking the functionality of traction sensors and water temperature.

Before each switching on of the equipment, the serviceability of the chimney system, the presence of draft and the absence of gas leaks are checked. The latter is determined by the presence of a specific odor or the reaction of a special sensor.

If any malfunction is detected, it is important to immediately turn off the column, contact a specialist or fix the problem yourself.

Application and working principle

The main working elements of the gas water heater are:

- gas-burner;

- the heat exchanger located above it is a long coiled tube in which the water flowing through it is heated.

Auxiliary components of the gas water heater include:

- Ignition device: can be electronic (generates a spark in one way or another) or have the form of a pilot burner (pilot or wick) that burns constantly. In old speakers, the igniter had to be lit with a match. In modern ones, a piezoelectric element is installed for this purpose, which the user activates by pressing a special button.

- Water-gas unit: consists of an interconnected membrane (installed in the water supply) and a gas valve (installed in the gas path). As soon as the user opens the tap and water flows through the column, the membrane bends and opens the gas valve, thus supplying gas to the burner.

- Safety automation: consists of several sensors and a special solenoid valve in the gas path, to which these sensors are connected mechanically or electrically. If deviations occur in the operation of the column, the corresponding sensor will close the valve, thereby turning off the device. In columns with an igniter, a thermocouple is also connected to this valve, heated by the igniter flame. It is triggered when the pilot burner goes out.

“Advanced” speakers also have an electronic control module.

General structure of a household water heater

A geyser is a flow-through water heating device. This means that water passes through it and heats up as it goes. But, before moving on to an analysis of how a household gas water heater works, let us recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, you must submit documents to the gas service of your region along with the appropriate application. You can read about the norms and necessary documents in our other articles, but now let’s move on to the device.

Different models of geysers differ from each other, but the general structure of a household geyser looks something like this:

- Gas-burner.

- Igniter/ignition system.

- Exhaust hood and connection to the chimney.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Gas supply pipe.

- Water node.

- Connections for water supply.

- Pipe for hot water outlet.

- Front panel with controller.

The central element of the column is a gas burner, in which gas combustion is maintained, which helps to heat the water. The burner is installed in a housing; hot combustion products are collected in it, the purpose of which is to heat water.

The housing is made of metal and completely covers the front and sides of the speaker

It is important that the material of the housing conducts heat well, because the quality of heating depends on the transmission of heat.

Structural components of a geyser located inside the housing. Closed type gas equipment is shown here

On top of the device there is an exhaust hood and a chimney through which combustion products leave the column and the room. Their design depends on whether the column is open or closed, which will be shown below.

The pipes meander like a coil inside the body, water passes through them under natural pressure and is warmed by hot gases. This entire pipe system is called a heat exchanger. At the bottom there are two pipes: on the right - for receiving cold water from the pipeline, on the left side hot water flows out.

A filter is often installed between the water supply network and the gas water heater, which regulates the water hardness. Without a filter, the column may become covered with scale at high water temperatures. When entering the column, water passes through a water unit, which serves as a kind of “connection” between the water flow and the gas flow. We'll talk about this connection a little further.

Burning gas burner with electric ignition and flame sensor. Sensors play an important role in the functioning of equipment. We'll talk about their functions further.

Using another tube, which is also located below, the column is connected to the gas main.

There is also a front panel with a control unit. It is equipped with regulators to control gas and water consumption. Depending on the model, these can be either simple knobs that need to be turned, or liquid crystal displays, where you can see many characteristics of the column, or even the nature of its malfunction if the column does not work.

Why does the speaker go out during operation?

Another common malfunction is that the flame does not die out immediately, but after a few minutes of operation.

When figuring out the cause of the malfunction, you should pay attention to the following signs:

- duration of operation after switching on;

- whether the malfunction is eliminated when the water heater is restarted.

The main reasons that a geyser goes out during operation:

The chimney is clogged - combustion products have time to escape from the combustion chamber. A characteristic manifestation: the igniter and burner go out. The speaker turns on with a bang. Troubleshooting: cleaning and restoring the smoke channel. The supply and exhaust ventilation and the gas heater in the kitchen are turned on at the same time - while the water heater is operating, the hood must be turned off or set to a lower power. Burner extinction occurs due to the accumulation of flue gases, which cannot escape into the channel due to insufficient draft. The speaker turns off automatically after a short period of operation. The overheating sensor in a gas water heater is triggered - the block consists of two metal plates that are triggered when heated. The reason for the shutdown is the oxidation of the contacts between the control module and the fuse. You can check the temperature sensor by moving it closer to the burner. If this is the reason, the column will begin to work temporarily without failures. Protection against overheating of the geyser is an important part of the internal structure. It is prohibited to turn off and start the water heater without a module. The radiator is clogged - the heat exchanger has fins. When using the speaker for a long time, debris accumulates between the plates. A characteristic sign of a clogged heat exchanger is a change in the color of the flame to yellow. The problem can be resolved by washing the coil with warm water. At the same time, clean the igniter using a wire or a brush with coarse bristles.

Spontaneous shutdown during operation should stop. In models with piezo ignition, it is important that the wick is constantly burning. If there is insufficient draft (the reasons are given in points 1 and 2), the igniter goes out, which leads to the column turning off.

After eliminating the described disturbances related to air circulation in the room and the need for good draft, as well as replacing the overheating sensor, the water heater will continue to function normally. The speaker will stop turning off regardless of the duration of operation.

Gas block diaphragm

It is impossible to turn on the gas water heater if there is a rupture of the membrane

made of elastic and durable rubber: depending on the water pressure, it controls the flow of gas into the product.

Repair is associated with difficulties - finding a spare diaphragm, which is made of durable and elastic rubber, is very problematic in retail trade, and their cost from dealers is very high.

Advice! To replace a torn membrane, a silicone product is suitable - such a part is more reliable and lasts much longer.

In addition to the diaphragm, you should check the entire gas block of a working column; there are many parts there, and each one can break. There are many recommendations for disassembly and subsequent repairs that can be found on the Internet.

Problems with multi-zone control (errors 7**)

Ariston brand boilers allow you to divide your house into zones, each of which will have its own heating mode. If a problem occurs with one of the sections, the system accurately determines the malfunction, so repair of a specific circuit can be carried out without interfering with the remaining normally operating parts of the heating network.

Error #70X. There is a problem with the coolant supply temperature sensor in zone X. It is necessary to check the sensor contacts or replace this part.

Error #71X. The same thing, only with a sensor on the return line.

Error #72X. Overheating has been detected in zone X. First of all, you need to check the operation of the thermostat responsible for this area. It may simply be a loose contact or a broken unit. If it works correctly, then you need to change the settings.

Error No. 750. Hydraulic circuit error. The correct type of hydraulic module connected must be set (menu parameter 720). If there is no error here, then the problem is in the settings of the circuit itself.