If you decide to install a heated floor yourself, then you will inevitably be faced with the question of how to connect it correctly so that it is operational and heats the floor and the entire room. If you imagine this whole process, you can see that the key to the effectiveness of the system is the correct connection of the heated floor collector, which is responsible for regulating the temperature.

The collector looks like an ordinary piece of pipe with several holes on one side that serve as exits. A couple of such simple structures are actually responsible for controlling the water heated floor. Let's figure out why these outputs are needed and how to connect the underfloor heating manifold.

Features of the operation of water heated floors

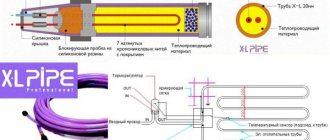

Water heated floors are used as the main or additional source of heat in private homes. The idea of this system is based on laying thermal circuits and pipelines with coolant circulating through them in the screed. The liquid is heated in a boiler and then distributed through floor loops in different rooms. The main feature of the operation of such a system is the need to maintain a low, uniform temperature across a large number of consumers. The coolant comes from the boiler heated to 60 - 70 degrees, such heat from the floors will be uncomfortable for residents. To reduce the temperature, a mixing unit is included in the system or RTL valves (reverse flow regulator) are installed.

The second feature of heated floors is associated with the uneven distribution of coolant throughout the system. The rooms have different areas, which means the contours will be of different lengths. Redistribution occurs at the collector.

What does the collector group consist of?

The collector has the form of a metal or plastic tube in which the coolant is collected and redistributed along the circuits. The collector group usually consists of two combs: supply and return, a pumping and mixing unit and additional equipment.

On the left is a pumping and mixing unit with a thermal head, on the right is a manifold comb with rotameters and a drain valve.

Collecting combs

The main differences between the supply and return combs are only in the shut-off valves. The heated coolant from the boiler comes to the supply, then the liquid is redistributed between the heating devices. The substance (water, ethylene glycol or propylene glycol) passes through the circuit, gives off heat and returns to the return comb, from where it goes back to the boiler.

Read more about choosing a coolant for a heating system in a separate article.

How it works?

The collector combs have a larger diameter compared to the pipes, because of this the coolant in the distribution block slows down its movement. Distribution occurs through pipes with a smaller flow. One comb can have up to 14 pipes, depending on the number of heating devices. Typically, the supply is equipped with adjusting devices to change the flow of underfloor heating circuits. More coolant will flow into a pipe with a higher throughput, and accordingly the heating devices will heat up more.

Shut-off valve options

To regulate the amount of coolant on the collector, ball valves, valves, flow meters (rotameters), thermostatic push-action valves or servos are used.

- Ball valves are shut-off valves with two positions: (open and closed), allowing you to stop the movement of the coolant through a separate pipe of the comb. Ball valves do not allow you to regulate the flow, so it makes sense to use them in heated floors, where the loops are approximately equal in length. They are also placed in front of collectors.

An example of a manifold with ball valves.

- The valves allow for stepwise changes in the flow diameter and require manual control of the system.

There are flow meters on the top of the supply comb, and thermostatic valves on the bottom of the return.

- Flow meter (rotameter) is a device that measures fluid flow per unit of time. It is a transparent flask with a stem inside; the mechanism of operation of the valves is similar to a regular valve.

The coolant flows along a shorter line with less hydraulic resistance - the flow meter on such loops narrows the passage, and on longer ones it widens it, due to this the floor in different rooms heats up equally.

- Thermostatic pressure valves are installed on the return comb of the underfloor heating manifold. They can close or open depending on the return temperature. The TSG valve is equipped with a Eurocone, which allows you to measure the temperature of the liquid in the pipe.

- Thermoelectric servo drive is a thermostatic head that can remotely control the operation of the comb valves. Servo drives are divided into normally closed and normally open. In the first case, in the normal position the valve is closed and opens when voltage is applied. The servo drive is connected to a thermostat, which is located in the room and responds to changes in air temperature.

The thermoelectric servo drive should not be confused with RTL valves. The first reacts to changes in room temperature, the second is adjusted to the temperature of the coolant.

Thermoelectric head with servo drive.

Device installation

The manifold for a warm water floor is mounted according to the following scheme:

- It is necessary to install a frame under the device. It is mounted directly on the wall in a horizontal position or in a specially prepared niche. When choosing a location for installation, you should be guided by the availability of free access to the device to connect the required number of pipelines. Also, a special cabinet is often used to mount the device. In this form, the device can fit into any room.

- Connection to the heating boiler. The coolant is supplied to the system from below, and the return is placed at the top. You also need to install cut-off balls in front of the frame. A circulation pump is installed behind the taps.

- The bypass valve is being installed. It must be equipped with a temperature limiter. Behind this unit the distribution comb is installed.

- Pipelines are being laid to the heated floor. The elements through which coolant will flow into the system are placed on top. Pipelines from underfloor heating are installed from below.

- If you intend to install the device yourself, you must connect shut-off valves that are equipped with a thermostat to the distribution comb. When installing a ready-made kit, this is not necessary.

- The collector is connected to the heating system using compression fittings. This element consists of a clamping ring, a support sleeve and an intermediate nut.

- Pressure testing of the collector. After installing all structural elements, it is necessary to check how tight the resulting system is. To do this, the unit is connected to a circulation pump. With its help, pressure is built up in the system. The water circuit is left in this form for a day. After this time, the pressure is checked. If it has not changed, then the installation was successful.

Should I assemble a collector or buy a ready-made one?

Collectors can be prefabricated, ready-welded or homemade. Let's consider their advantages and disadvantages.

Ready welded

They are usually produced in the form of supply and return combs welded together with a specified number of pipes.

Advantages

- Fast installation - no need to assemble fasteners.

- Minimum qualification requirements for an installer

Flaws

- Difficult to configure for a specific system.

- The number of pipes may not meet the needs, in which case they will have to be blocked off with plugs and not used.

- The collector can be equipped with elements that are unnecessary for a particular heating system. For example, it may have a hydraulic distributor (hydraulic arrow), which is only useful in networks with a large number of pumps.

- The return and feed combs may be welded together, making it difficult to attach separate loops to them. The pipes on factory mixers are usually located at the same distance from each other, but this is not always convenient.

Homemade

You can make a collector with your own hands from available materials: steel pipes with a round or square cross-section. To do this, holes are cut in them and pipes are welded. Couplings are made from round sections of smaller diameter.

Advantages

- Making a collector with your own hands is profitable from a financial point of view.

- You can make a drawing and manufacture an individual manifold for a specific system.

Flaws

- To perform this job, you will need skills in working with a welding machine.

- It will take more time.

- The non-separable design makes it difficult to repair and replace individual elements.

Prefabricated

Such distribution units are assembled from factory parts, which are purchased separately or as a kit. They will be discussed further.

Advantages

- There is variability when designing a collector unit for a specific heating system.

- Does not require special skills or equipment for installation.

- Possibility of separate dismantling of feed and return combs.

- High installation speed.

Flaws

- Components from different manufacturers may not fit together.

- This option usually costs more.

Distributor for radiant heating system

Let us remind you: radial wiring provides for an individual two-pipe connection of each radiator to a common distribution manifold located in a convenient location (usually closer to the center of the building).

An example of radiant heating distribution in a one-story house

To install the collector unit, the following combs are used:

- factory for TP (described above), made of stainless steel, brass or plastic;

- factory for water supply with built-in shut-off valves, made of polypropylene or metal;

- homemade manifolds twisted from brass fittings and polypropylene tees.

The type of comb you choose depends on your budget and radiator system requirements. If each battery is equipped with its own balancing valve and thermal head, then a clean manifold without valves and flow meters is sufficient. Leave the air and water discharge module.

Advice. If you have a limited budget, you can choose an inexpensive water supply manifold with taps, shown in the photo. Many homeowners do this and balance the system with radiator valves.

If you want to automate the heating operation and place all adjustments in a manifold cabinet, buy a comb for underfloor heating. Install all accessories - rotameters, valves with servo drives, air vents, room regulators. A mixer is still not needed; the coolant is supplied to the batteries directly from the boiler room.

The video below shows a combined heating manifold that distributes heat to radiator wiring and floor circuits. Both parts of the comb are installed in parallel. Please note that the master used water distributors to distribute the coolant.

How to install a rotameter on a manifold comb

Rotameters are often used on underfloor heating manifolds; they are necessary to control flow. Depending on the model, the device can be adjusted to different flow rates from 0 to 5 l/min. The setting is made only when the pump is turned on. It is necessary to remove the decorative protective cap and tighten the fixing nut into the desired position. After setting up the flow meter, the plug is installed in place.

Rotameters differ for the return comb and the feed comb. Inside the glass flask of the device there is a rod with a plate. In the non-working state, the rod plate is pressed to the zero value by a spring. The coolant is always supplied under the valve seat, since the flow opens the valve. On reverse rotameters the rod is at the bottom, and on feed rotameters it is at the top (the numbers will increase from above).

Differences between the rotameter on the feed and return combs.

If you confuse the supply and return rotameter, the coolant flow will press the rod against the seat, and the system will not work. Some devices do not allow you to record the required flow rate, but only measure its value; to distribute flows along the contours of heated floors, it is advisable to use the first option.

Mixing unit

The mixing unit can be used without a collector.

The mixing unit is often included in the collector group. Its operating principle is based on combining the supply and return flows. After passing through the heated floor loop, the medium usually has a temperature of about 30 degrees; at the mixing unit it flows into the supply flow, which allows you to get a comfortable temperature of 40 degrees.

There are many options for implementing this unit: using a three- or two-way valve, using thermostatic valves, etc. Mixers can also be prefabricated or factory-made.

The mixer usually has a thermostatic valve that measures the temperature of the medium. It is equipped with an overhead or cap sleeve. The first is simply glued to the pipe, the second is inserted into the line itself.

A three-way valve with a thermal head is installed in front of the pump. It is also useful to install a coarse filter on the supply before it.

- A three-way valve is installed on the supply side; using a thermostatic head, the element allows you to control two flows. There are mixing valves and distribution valves. The first one receives two streams from different sources, combines them into one and sends them along the required highway. The distribution valve receives one flow, which is distributed through several circuits. These elements are used not only to regulate the temperature of the coolant, but also to protect the boiler to prevent idling and overheating. However, the valve installation and layout will not be the same as when used in combination with a manifold.

A mixer with a two-way valve; on the bypass it is useful to install a hidden valve under a hexagon instead of an element with a handle.

Bypass is a channel between the return and supply combs; it creates a small circle and prevents the pump from working at a dead end when one of the lines is closed.

- The two-way valve is equipped with a thermostatic head and controls the flow in only one direction. When using this element in a mixing unit, an additional bypass valve will be required. In most cases, shut-off valves are placed under the hexagon. Ball valves cannot be used on this unit due to the impossibility of precise adjustment; it is also not recommended to install a valve with a handle, since someone could accidentally mess up the entire system setting.

The mixing unit is installed after the collector. A pump is placed between the collector and the boiler, which ensures movement in a small circle. The three-way mixing valve is installed on the supply line, the distribution valve - on the return line.

Location of two-way and three-way valves in the heating system

| Task | Two way valve | Three-way valve (distribution) | Three-way valve (mixing) |

| Boiler protection | — | Innings | Return |

| Temperature regulation | Innings | Return | Innings |

The mixing unit on a two-way valve can always be distinguished from a three-way valve by the presence of a valve on the bypass.

Adjusting the operation of the mixer using the example of a two-way valve

In a three-way valve, the flow is always open: if one plug closes, the other opens. In a mixer with a two-way shut-off device, only one plug closes; it works as follows: the thermal head determined that the temperature of the medium is lower than necessary, pressed the rod, the valve opened, and a portion passed into the manifold, mixing with the liquid from the return. When the temperature has reached the required values, the thermal head begins to close: the flow from the supply decreases, the flow from the bypass increases.

- The longer the heating circuit of the floor, the more the bypass valve is closed.

The bypass valve has a hidden valve for a hex key. When setting up the system, you need to close the thermostatic valve and open the balancing valve. The rotameters are adjusted, then the valve on the bypass is gradually closed until the rotameter rod begins to show that the coolant is becoming less. Fully open the thermostatic valve and tighten the balancing valve again. As soon as the rotameter plates lower or rise when turning the key on the bypass valve, balancing stops.

Series and parallel mixing type

The sequential type of mixing is considered more correct in terms of thermal engineering.

The circulation pump works to supply water to the floor. The temperature of the outlet flow towards the boiler here is the same as at the floor.

The result is high productivity. Although the series connection scheme is more efficient, it requires careful calculation.

If you make mistakes in the calculations, it may happen that the water reaches the last room already cooled.

In a parallel connection, due to the separation of the flow lines, energy is partially lost. But the plus is that all branches of the system operate in parallel, and each of them can be turned off without damaging the heating as a whole. For this purpose, shut-off valves are installed on all bends. The parallel circuit is simpler and more suitable for non-professionals.

Do you need a hydraulic gun?

A hydraulic separator (hydraulic arrow) is a device that is usually placed between the boiler and the collector; it provides zero resistance in this area. Visually, the element is a hollow pipe with 4 pipes: on one side, two are intended for the boiler, on the other, for the collector. The question of installing a hydraulic separator arises when there is a need to install more than 4 pumps and more than 1 boiler.

The hydraulic arrow can be fixed vertically or horizontally, it does not matter. The first option is often chosen, as it simplifies the installation of the air vent in the upper part. A tap can be attached to the bottom to remove sludge.

Often in articles this device is attributed properties that it does not possess. We list the tasks for which you should not buy a hydraulic gun.

- Does not increase boiler efficiency

- Does not reduce fuel costs

- Does not protect against heat stroke

- You still need to select pumps for each circuit separately.

- Not intended for air bleeding or sludge protection.

The hydraulic arrow can worsen the operation of the system if the pumps are incorrectly selected. For example, a boiler unit is much inferior to the total power of devices on other circuits. As a result, the coolant reaches the comb already cold due to mixing with the reverse flow.

Are a manifold and mixing unit required?

In a small house, a heated floor may not take up so much, in which case the costs of a collector and mixer will not be worth it. The simplest solution would be to install a heated floor with one or two circuits, controlled by a TSG thermal head or an RTL tap. Regulation in this circuit occurs by limiting the temperature on the return flow.

The RTL valve is not intended for installation on a manifold; it has high hydraulic resistance. Due to the large size of the head, it is inconvenient to screw the element onto a distribution unit with a large number of adjacent circuits. This also makes it impossible to use built-in plumbing cabinets. It is not recommended to install RTL cranes on a circuit longer than 70 meters. The thermal head is usually placed in a plastic box that is hung on the wall.

The TSG head also limits the return flow, but has a Eurocone, so it can be installed on the return of the manifold. The actuator acts on the stem, and not on the valve itself. In this case, the head is occupied by the working valve of the manifold, because of this, installation of the servo drive becomes impossible. The absence of resistance makes it possible to install a longer circuit.

Installation nuances

The technology for attaching the collector to the wall is quite simple: the TC and radial distribution comb are suspended on mounting brackets, the loops are connected with Eurocone fittings. Pipes going to the top of the collector (usually the “return”) are passed under the bottom.

Advice. No one is forcing you to mount the distributor on brackets. If necessary, the tubes can be spread apart and mounted separately on the wall. The collector box is used in residential areas; when installing the collector in the boiler room, the cabinet is not needed.

Let's briefly list the main points:

- The size of the comb is selected according to the diameter of the pipes used in the heating loops - Ø16 or Ø20 mm. Accordingly, we take a ¾ or 1 inch distributor. The material of the product does not matter; in terms of price/quality ratio, stainless steel wins.

- If the number of comb outlets exceeds 12, assemble a collector assembly of 2 sections. When installing accessories, winding materials are not used, since the parts are equipped with rubber seals.

- A heavier common house collector is suspended on hooks, reinforced brackets, or installed on the floor. Pumps, pipes and other piping elements must not load the distributor with their own weight.

- The hottest coolant receives an indirect heating boiler. The coil and circulation pump of the water heater are connected to the comb directly, usually from the end.

- The radiator heating and TP branches are connected to the manifold through mixing units with three-way valves. A separate pump is installed on each line, selected for pressure and performance.

A heavy coplanar comb can be installed on the floor - weld metal supports

Important point. The mixing unit for heated floors can be installed in the boiler room, near the main comb. Then water at the required temperature will flow to the TP distributor.

Work progress

- We install the mixer on the return comb, if an assembled factory element is used, and tighten the union nut (American) with a wrench.

- A mixer is installed on the child’s feed using the same principle.

- We install air vents for return and supply.

- Plugs are installed at the ends opposite from the mixer; they should be tightened with a wrench.

- A drain valve is installed on the comb; it is usually located under the air vent; they are designed to bleed gases from the manifold.

- For convenience, you can screw the fitting into the comb separately and then install the tap on it.

- A pump is attached between the return mixer and the supply comb.

- The fastening element is assembled; all manufacturers have their own in the form of runners or strips. If a homemade manifold is used, then the fasteners are made from improvised materials. The holders are first mounted on the combs and only then on the wall.

- The combs should be at the same distance from each other so that they are parallel on the wall. This is not a technical requirement, but more of an aesthetic consideration. To align the combs, they are first fixed to the fasteners on one side, then the same distance is measured from the other end. This is easy to achieve in short manifolds. Typically, for many manufacturers, the standard distance between combs should be 21.5 cm.

- In practice, from the point of view of system operation, it does not matter which comb is on top. In most cases, a supply distributor is placed there, but nothing will change if you put it below. The main thing is not to confuse the supply and return rotameters.

- The plug is removed from the factory return mixing unit, the thermostatic head is screwed to it, and the measuring sleeve is inserted into the supply comb mixer.

- Two mounting strips are fixed to the wall. Fasteners and hardware are selected depending on the base material. It is advisable to fix the collector at 4 points.

- The connection is made using a Eurocone. A nut is put on the pipe, then a ring, and a thrust bushing is placed in the hole. Fixation is carried out using two keys. One fixes the hexagon, the other tightens the nut. You need to do this carefully so as not to rip off the fitting.

- The contours are drawn in increments of 100 mm.

- Installation of the circuit is completed by connecting the line to the return comb. Pipes must be placed in an insulating casing. The system is filled through drain and fill valves. The ball valves on the manifold are closed.