All modern heating installations using natural gas as an energy source have a high level of safety, which is achieved through the introduction of automation equipment. They monitor and manage the operation of heating units. In this material we will consider automation for gas boilers from the most famous manufacturers, which is most often installed on domestic and imported boilers.

Automatic blocks of floor-standing boilers

The vast majority of floor-standing gas boilers are equipped with automatic safety systems that operate without an external power source (non-volatile). According to the requirements of regulatory documents, automation equipment must shut off the gas supply to the burner and igniter in three emergency cases:

- Extinction of the main burner flame due to blowing out or for other reasons.

- When natural draft in the chimney channel is absent or sharply reduced.

- The drop in natural gas pressure in the main pipeline is below a critical level.

For reference. The implementation of the listed functions is mandatory for gas boilers of all types. Many manufacturers add a fourth level of safety – overheating protection. When the coolant temperature reaches 90 °C, the valve, based on a signal from the sensor, stops supplying gas to the main burner.

Various models of gas floor-standing boilers from different manufacturers use the following types (brands) of non-volatile automation:

- Italian blocks EuroSIT (Eurosit) series 630, 710 and 820 NOVA (heating units Lemax, Zhitomir 3, Aton and many others);

- Polish devices "KARE" (heat generators "Danko", "Rivneterm");

- American automatic control devices Honeywell (Zhukovsky heaters);

- domestic products, "Arbat".

Fuel supply system in the simplest AOGV devices equipped with ZhMZ valves.

The burner is hidden in the lower part of the housing. We have listed the most common brands of automation, which are often installed on water heating boilers from the same company. For example, the Zhukovsky plant equips budget versions of AOGV devices with its own ZhMZ safety units, mid-price heat generators with EuroSIT devices, and powerful models with Honeywell automatic valves. Let's look at each group separately.

SIT Group brand gas valves

Of all the types of automation found in boiler installations, EuroSIT safety units are the most popular and reliable in operation. They are recommended by companies that supply natural fuels, including for replacing old gas equipment of KChM, AGV boilers, and so on. They work without problems as part of micro-flare burners Polidoro, Iskra, Vakula, Thermo and others.

The exact names of the three models used look like this:

- 630 SIT;

- 710 MiniSIT;

- 820 NOVA.

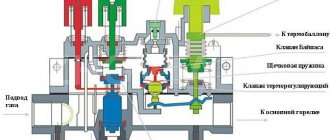

The thermocouple, main and pilot burner connection sockets are located on the bottom panel of the valve

For reference. SIT Group has ceased production of the 630 and 710 series, considering them obsolete. This has been replaced by new safety automatics for heating boilers - gas valves 820 NOVA, 822 NOVA, 840 SIGMA and 880 Proflame (battery operated). But old products are not difficult to find on sale.

In order not to bore you with the design details of automatic EuroSIT devices, let us briefly explain the operating principle using the example of a simple 630 series unit:

- When you turn the handle to the “ignition” position and press from above, you forcibly open the solenoid valve, which allows gas to flow to the pilot burner (igniter). You click the button on the piezoelectric element, which produces a spark that ignites the wick.

- By holding the main handle for 30 seconds, you allow the thermocouple to be heated by the pilot flame. The thermal balloon produces a voltage (EMF) of 20-50 millivolts, which fixes the electromagnet in the open state. Now you can release the handle.

- Set the main handle to the desired position and thus supply gas to the main burner. The latter ignites and begins to heat the heat exchanger with water from the heating system, as shown in the diagram.

- When the water reaches a certain temperature, the capillary sensor is activated, gradually closing the second valve - the thermostatic one. The supply of fuel to the burner device stops until the sensor cools down and the valve plate opens the path for gas. The igniter continues to burn in standby mode.

Note. Older automation modifications were not equipped with temperature sensors and ignition units, so matches were required to start the heat generator.

Connection diagram of the automation unit to the gas burner device.

A diaphragm valve, which plays the role of a pressure regulator, is responsible for the normal supply of gas in the device. When it falls below a preset value, the fuel channel closes and an emergency shutdown of the boiler occurs. Other situations that lead to refusal include:

- The burner and the wick heating the thermocouple go out. Voltage generation stops, the solenoid valve closes the fuel passage.

- If the draft in the chimney suddenly disappears, the sensor placed in this channel overheats and breaks the power supply circuit of the electromagnet. The result is similar - the fuel supply is blocked.

- In heaters equipped with overheating sensors, the electrical circuit is broken after the water reaches a temperature of 90-95 °C.

When the gas automatic system triggers an emergency shutdown, the user is blocked from restarting the boiler for 1 minute; before that, the fuel supply will not resume. The operation of the system is clearly reflected in the training video:

Differences between models 710 MiniSIT and 820 NOVA

According to the principle of operation, these units do not differ from their predecessor - the 630 series. Changes to the 710 MiniSIT automation are purely constructive:

- 2 buttons “Start” and “Stop” are placed separately along with the solenoid valve;

- the main handle only rotates the thermostat rod and regulates the temperature of the coolant;

- the ignition unit with a piezo igniter button is built into the product body;

- The basic package of the device includes a bellows-type temperature sensor with a capillary tube;

- added gas pressure stabilizer.

In the 710 MiniSIT unit, the handle acts as a temperature regulator and switches the heater to standby mode with the pilot light on.

For reference. In the first versions of the 710 family, a spark igniter was not provided.

The latest 820 NOVA product line includes changes to improve stability, reliability and throughput. We want to highlight 2 improvements that are important from a user point of view:

- The product is equipped with a connector for connecting a room thermostat and weather-dependent automation. Now the heating unit is able to maintain the air temperature in the apartment.

Connection diagram for a remote thermostat with an external power source - A modification has appeared with its own power source - a thermogenerator mounted on a bar next to the pilot burner, as shown in the diagram. The principle of operation is similar to a thermocouple, but the magnitude of the generated EMF is much greater.

Non-volatile circuit for connecting a room thermostat

In this section, it makes sense to mention Honeywell automatic gas valves, which operate according to a similar circuit. Their main difference is their increased throughput, which allows the units to be used in high-power boilers (30-70 kW).

Polish automatic "Kare"

Few manufacturers practice installing Polish security systems on gas boilers. The reason is banal: in terms of reliability, the product is inferior to products from Italy, the USA and Germany, but the price is more expensive than domestic boiler automation.

We called the product a “system” because it consists of several blocks, although the general principle of operation remains unchanged:

- gas filter;

- valve – gas pressure regulator;

- there is a separate thermostat with a control knob;

- membrane thermostatic valve;

- piezoelectric igniter button.

Diagram of the Polish “Kare” system.

The nodes and sensors are connected to each other by capillary tubes. Essentially, this is the same SIT or Honeywell device, only broken down into separate parts. This is a plus: changing parts is more convenient and cheaper.

Products of domestic companies

As you understand, boiler automation made in the post-Soviet space does not contain any revolutionary solutions or technological breakthroughs. To implement three safety functions, the same principles are used - turning on an electromagnet with voltage (EMF) of a thermocouple, a membrane gas valve and a traction sensor that breaks the circuit.

ZhMZ safety valve diagram

It makes no sense to talk in detail about the design of blocks from the brands SABK, Orion and ZhMZ (Zhukovsky Plant). The listed products are distinguished by their simplest design, low cost and low reliability. Thermocouples burn out almost every year, and the thermostat turns off and starts the burner too abruptly, causing a loud bang that sometimes resembles a micro-explosion.

The devices work normally in the first years of operation, then they need to be monitored and promptly serviced, fortunately, spare parts are available for sale and are inexpensive. For an example of troubleshooting a typical ZhMZ automation fault, see the video:

Types of volatile systems

An autonomous gas boiler involves the installation of complex electronic devices dependent on the power supply network. These devices independently adjust the fuel supply and flame power.

Room thermostats

Volatile automation systems are represented by the following types of devices:

- room thermostat;

- daily programmer;

- programmer for a week.

A room thermostat is installed in the room where the temperature needs to be controlled. Sensors take measurements.

When the temperature drops, the thermostat reacts and sends a signal to the gas boiler. The boiler starts.

When the optimal temperature in the room is reached, the valve closes and the gas boiler stops working.

The room thermostat is connected to the unit using a cable.

Daily programmer. The functions of this device are the same as those of the thermostat, but it is possible to set programs for the day. The programmer also works with the hot water supply system. After 24 hours the cycle resumes.

The device is connected to the gas unit using a cable and via a radio channel.

Programmer for a week. Such a weekly device has more possibilities for changing the indoor climate. There are built-in modes and those that can be configured manually. The action takes place within a radius of 30 meters or more. Data can be monitored on the backlit display.

Devices can be selected by color depending on the design of the room.

Modern devices can not only control the temperature, but also carry out independent diagnostics of equipment. They control the performance of the pump and protect the gas boiler from freezing.

Weekly programmer Auraton 2030

What types of gas valves are there?

Wall unit electronics

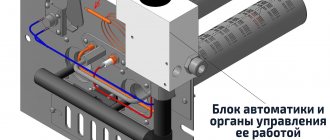

A special feature of these heat generators is electronic control of the processes of ignition, combustion and maintenance of coolant temperature. That is, wall-mounted gas boilers (and some floor-standing ones) are equipped with energy-dependent automation powered by electricity.

Important point. Despite the many bells and whistles introduced into the design of mini-boiler houses, safety functions are still in charge of the mechanics. The three types of emergency situations listed above will be processed by the equipment regardless of the presence of voltage in the electrical network.

An automatic gas boiler was created for maximum convenience for owners of apartments and private houses. To start the heater, just press 1 button and set the desired temperature. Let us briefly describe the operating algorithm of the unit and the elements involved in it:

- After these startup steps, the heat generator controller collects sensor readings: coolant and air temperature, gas and water pressure in the system, and checks the presence of draft in the chimney.

- If everything is in order, the electronic board supplies voltage to the electromagnetic gas valve and at the same time a discharge to the ignition electrodes. The wick is missing.

- The main burner ignites and gives full power in order to heat the coolant as quickly as possible. Its operation is monitored by a special flame sensor. The controller includes a built-in circulation pump.

- When the coolant temperature approaches the set threshold, which is recorded by the overhead sensor, the combustion intensity will decrease. Staged burners switch to low power mode, and modulating burners smoothly reduce the fuel supply.

- Having reached the heating threshold, the electronics will shut off the gas. When the sensor detects cooling of the water in the system, automatic ignition and heating will be repeated.

Note. In turbocharged boilers with a closed combustion chamber, the controller also starts and turns off the fan.

The instructions for the wall-mounted gas boiler indicate that the unit is designed to operate in a closed heating system, so the automation monitors the water pressure. If it drops below the permissible limit (0.8-1 Bar), the burner will go out and will not light until the problem is corrected.

Many imported boilers operate according to an energy-dependent scheme, for example, Buderus Logano, Viessmann and so on. How the installation of electronic gas equipment occurs, the master will tell you in an accessible language in the video:

replacement of ORION equipment with EUROSIT in gas boilers produced in Borino

Hello, I am asking for help in solving the problem.

There is a desire to replace ORION equipment with EUROSIT, is it possible to do this, if so, tell me how? a little more information: links (boiler, equipment), photos, reason for replacement. » > —Boiler automation: Euro SIT (Italy)

there is a desire to do this » > from this » > the reason is that the boiler with Orion automation is very noisy and the gas consumption is high. but most importantly, the thermocouple constantly burns out!

desire is good, but. The boiler is very noisy and the gas consumption is high due to a). design features of the apparatus b).design of the main burner c). setting up the automation In other words, you can change it, but it’s not a fact that it will help. Ask the owner of such miracle devices with different automation how they operate

sz23061977 wrote: the reason is that the boiler with Orion automation is very noisy and the gas consumption is high. but most importantly, the thermocouple constantly burns out!

Replace the boiler. Insulate the room. The problem will solve itself.

mvs wrote: Replace the boiler. Insulate the room. The problem will solve itself.

You can insulate the room, but what about replacing the boiler? It can be changed, but as they say, we are not looking for easy ways!

madmax333 wrote: desire is good, but. The boiler is very noisy and the gas consumption is high due to a). design features of the apparatus b).design of the main burner c). setting up the automation In other words, you can change it, but it’s not a fact that it will help. Ask the owner of such miracle devices with different automation how they operate

I asked if the automatic sit works quietly and there are no problems with the thermocouple.

sz23061977 wrote: you can insulate the room, but what about replacing the boiler? It can be changed, but as they say, we are not looking for easy ways!

What are we looking for? adventures on your own. neck?

sz23061977 wrote: I asked, with the sit automation it works quietly and there are no problems with the thermocouple.

Well, then new automation, probably a new main burner, new pipes connecting the blocks, tools and straight arms. And, most importantly, a tambourine for dancing, because... I'm sure this is your first. or call a specialist, give him money, he will do everything and set up the automation as needed. success

.

Automation Honeywell

Honeywell automation for a gas boiler is a very common automatic system for boiler equipment. The high quality of the Honeywell automatic system has been proven for more than a century. The fact is that the German company Honeywell was founded in 1885, and over its long history this old brand has gradually become one of the leaders in the production of various automated systems.

Rice. 3 Honeywell automatic device

If we talk about the cost of Honeywell products, prices fluctuate in a very wide range. The cheapest Honeywell automated systems for gas boilers cost approximately 40 - 60 dollars, they have a device for manually switching temperature modes.

These cheap types of Honeywell automatic equipment have a number of features:

- Automatically maintains water temperature in the range from 40 to 90 degrees Celsius;

- Automatic shutdown of the boiler installation if the gas supply stops;

- Automatic shutdown of the boiler installation if the draft disappears or reverse draft occurs;

- Honeywell's automatic device stops supplying gaseous fuel if the burner flame goes out (often an Italian gas valve 630 Eurosit is used).

Honeywell automated systems for gas boilers are available in a wide range. In addition to the above-mentioned economy class systems, you can purchase premium Honeywell systems. Gas heating using a Honeywell automated system is a good choice.

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6…12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be lower than the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5) .

Design features and advantages

Modifications of the Aton gas boiler are based on the basic version - a boiler with a sectional heat exchanger and an atmospheric burner for gravity-type heating systems with the ability to connect a circulation pump. The boiler design is determined by:

- type of automation;

- rated power;

- executable options.

Heating boiler Aton

Combustion chamber control ensures uninterrupted operation of the burners at a given power level or when switched off. The combustion chamber fittings are equipped with line pressure and combustion pressure connections. The storage product for processed products is connected to a deflector and a smoke exhaust valve.

The heat exchanger insulation is reinforced mineral wool. The generator casing is covered with a wear-resistant coating.

The Aton heating generator is included in the high utility class, in addition, with the following qualities:

- do not require connection to an external power source;

- high-tech burners;

- surfaces are coated with an anti-corrosion compound;

- single-circuit and double-circuit devices;

- original design;

- ease of maintenance;

- efficiency;

- compactness;

- strength;

- accident-free;

- modern design.

By material and type of heat exchanger

Heat exchangers can be:

- cast iron;

- copper;

- aluminum-silicon;

- made of carbon or stainless steel.

The design of the heat exchanger may also vary.

The most popular are separate heat exchangers. Heating water flows separately, and water for residents’ household needs passes separately. They are a little more expensive, but more reliable.

A bithermic heat exchanger looks like a pipe within a pipe. In the inner pipe there is DHW water, which needs to be heated, and in the outer pipe the heating coolant circulates.

The third type is a heat exchanger in which a coil is built in. The container with water is heated by the coolant flowing in the coil. An indirect heating system is good for everyone, but in the summer you will either have to heat the boiler or live without hot water.

The bithermic option is not recommended for use where there is hard water. And be prepared that every time scalding water will flow out of the tap first, and only then at the temperature you need.