Heating large areas using traditional water systems with radiators is not always advisable. Not only are such projects very material-intensive, but they also do not give the desired effect. Indeed, with free convection of air, all the heat rushes to the upper zone, and the climate below remains cool. Another thing is an air-heating unit that forcibly pumps heated air in the desired direction. The method of operation of such units, as well as their varieties, will be discussed in this article.

Advantages and disadvantages

Systems operating on the principle of air heating have a number of advantages over analogues.

- Fast heating of the room. The pressure of hot air warms up the space much faster than the warm waves emanating from a radiator with water.

- Even heat distribution. Air outlet points, as well as built-in adjustable dampers, allow you to warm up different levels of the room, while the heat from convection heaters rises clearly upward. As a result, the air near the ceiling can be sufficiently warmed up, while the floors and lower part of the space remain cool.

- Economical. The operation of air heating units is less expensive than heating with water radiators or air conditioners.

The disadvantages of heating units of a centralized system include several points.

- The complexity of laying air pipes, the need to create and approve a diagram.

- Special safety requirements for the installation of electric and gas boilers.

- External units do not always have an aesthetic appearance, since most often they are designed for use in industrial premises. However, the modern market already offers models with multi-colored plastic cases that can be matched to any room design.

With proper design and installation, taking into account all the individual nuances of the living space, air heaters will become an excellent functional heating system for the home. According to reviews from Russian and foreign users, the most popular option is an air-heating unit with a water heat exchanger and a central boiler unit.

10.2. Air heating system diagrams

Figure 10.1 shows schematic diagrams of local air heating systems. Pure heating systems with complete recirculation of the air coolant can be ductless (Fig. 10.1, a) and ducted (Fig. 10.1, b). With a ductless system, internal air having a temperature tb is heated by the primary coolant in the air heater to a temperature tg and is moved by a fan into the heated room. The presence of a vertical channel for hot air causes the emergence of natural pressure, which ensures the circulation of internal air through the heater and its supply to the room. These two schemes are used for local air heating of rooms that do not require artificial supply ventilation.

| A) | b) | ||

| 1 | tG | 3 | tG |

| 2 | 4 | 2 | |

| tB | tB | ||

| V) | 7 | G) | 7 |

| 5 | 5 | ||

| tG | tУ | tУ | |

| tH | tH | tG | |

| 6 | t | 2 | 2 |

| IN | tB |

Rice. 10.1. Schematic diagrams of local air heating systems: a, b – completely recirculating; c – partially recirculating; g – direct flow; 1 – heating unit; 2 – working (serviced) area; 3 – channel with heated air; 4 – heat exchanger (heater); 5 — external air intake; 6 – recirculated air; 7 – exhaust ventilation

Electric heater installation EKU.

| An electric heating unit (ECU) is designed for heating industrial and agricultural premises; it is also used in construction for drying plaster, building materials, paint and creating comfortable conditions when performing work. During operation, the installation creates a difference in the temperature of incoming and outgoing air from +35 to +65ºС, which allows it to be used for supply ventilation and heating in recirculation mode. If necessary, in warm weather the installation can be used as a high-performance fan by turning off the electric heater; reduce the temperature difference between incoming and outgoing air by turning off ECU sections. The installation is used in enclosed spaces at an ambient temperature of -20 to +40ºС, free of flammable substances and dust. Can be installed on a platform or suspended from brackets. The electric heater installation consists of: an electric heater, an axial fan VO-06-300. |

TECHNICAL CHARACTERISTICS OF HEATING UNITS EKU12, EKU21, EKU42, EKU64, EKU90:

| EKU-12 | EKU-21 | EKU-42 | EKU-64 | EKU-90 | |

| Analogs | |||||

| EK-12 | EK-21 | EK-42 | EK-60 | KEV-90T | |

| KEV-12 | KEV-21 | KEV-42 | KEV-60 | SFO-99 | |

| KEV-18T | KEV-24T | KEV-60T | SFOA-90 | ||

| power, kWt | 12 | 21 | 42 | 64 | 90 |

| Air capacity, m³/h. | 1000 | 1000 | 3000 | 50003000 | 11000 |

| Temperature difference between incoming and outgoing air, ºС, no more | 35 | 45 | 55 | 3565 | 2535 |

| Number of sections | 2 | 3 | 2 | 3 | 3 |

| Degree of protection | 1Р30 | ||||

| Fan | VO-06-300-3.15 | VO-06-300-4.0 | VO-06-300-6.3 | ||

| Power/number of revolutions, kW/min-1 | 0,18/1000 | 0,25/1500 | 0,25/1500 | 0,75/30000,25/1500 | 1,1/1500 |

| Voltage type, V/Hz | 380/50 | ||||

| Overall dimensions: length×width×height, mm | 735×632×510 | 735×632×570 | 755×755×625 | 780×755×625 | 900×970×855 |

| Weight, kg | 40 | 45 | 55 | 6762 | 105 |

Basic elements of the heating system

Before making air heating at home with your own hands, you need to review all the elements, components and significant details of the structure.

Devices for heating air flows

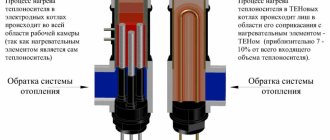

The equipment is designed to heat flows to the required temperature. Heat sources are used that heat the masses by passing them through a heat exchanger with heated steam, or heat the flows inside the heating element.

There are 4 types of heat generators used for air heating systems:

- Direct heating fuel systems, where the flows are heated due to the combustion of any fuel. This can be coal, diesel fuel, firewood; this type includes air-fired gas heating - when burned, the gas warms up the air, which is transported through air ducts throughout the premises.

- Electric units with direct heating are powerful fan heaters mounted to air ducts.

- Indirect heating units. The system involves installing a heat exchanger where hot liquid constantly circulates. The liquid is heated by any known method, and as an option, you can consider connecting the coolant from the central water supply system.

- Combined system. This is a universal option that combines several types of air heating, for example, liquid and electric options. The combined system is suitable for installation in private homes. In this case, the rooms will be heated even when the power supply is turned off.

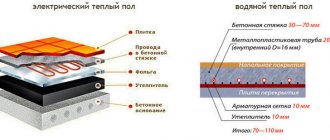

Channels for transporting air masses

Air ducts are a mandatory element of the system. Through them, the coolant enters the room and returns back for heating. Most often, a circular transportation circuit is installed, which has more functionality than single-pipe circuits.

A circular structure is made of two main pipelines made of galvanized metal. One line is supply, the second is return. Air ducts of a smaller cross-section are connected to the pipes, which are laid in the rooms. Flexible air ducts must be sealed and insulated. Aluminum tape is used for sealing, and foil heat insulators 25-30 mm thick are used for insulation. The mains also need to be insulated with foil insulation 3-10 mm thick.

Fans

Duct fans are needed for forced transportation of a flow of heated air. Installation on the supply and return lines is selected taking into account the possibility of adjustment, operation at different speeds, resistance to voltage surges, and smooth start-up. The technical parameters of the units must exactly match the specific heating system in order to maintain the pressure performance of all equipment.

Grilles and diffusers for flow distribution

All air ducts located in the room are connected to these elements. Grilles and diffusers are needed to provide air conditioning and heating systems by uniformly mixing air flows. Wall-mounted and floor-mounted models with adjustable and non-adjustable blinds are available for sale.

In-channel dampers and valves

Details are important to ensure the throughput of the entire structure. Throttle dampers are fixed in the supply lines to regulate air flows to different rooms. Valves are needed for different sections of air ducts, for example, a supply element is required to regulate the flow of air from the street.

Air preparation equipment

When setting up homemade air heating combined with air conditioning, the system must be equipped with filters. These can be carbon, mechanical or electrostatic devices that clean air flows from impurities. The scheme is also complemented by ionizers, humidifiers and other types of units.

Automatic control systems

To simplify the coordination of the entire circuit, it is recommended to select a control unit. The choice is made according to the type of heating functionality, allows you to control the operation of devices, change the program of actions, distribute air flows across zones depending on the needs of the user.

Criterias of choice

The existence of various convector batteries forces you to carefully and even scrupulously choose them. If you focus on the products of well-known companies, preference should be given to products from Atlantic, Ballu, Electrolux. Less in demand, but quite good in terms of practical qualities, are batteries of the Scoole and Timberk brands.

Among the components of the device, special attention should be paid to such components as:

- heating block;

- control automation;

- thermostat;

- fasteners.

For gas convector batteries, the fans, valves and exhaust ducts used to extract combustion products are also important. There are models equipped with wheels that are easy to move to the desired location and then return back. Gas convectors can be installed one per room, providing efficient heating. They serve for quite a long time and heat a large area.

Electrical devices are attractive in cases where programmable operating modes and careful adjustment of the thermostat are required. They quickly warm up to the required temperature and are well protected from overheating during operation. But besides high electricity bills, there are other circumstances that exclude such a choice. Buying a convector that runs on electric current is not worth it for those who are annoyed by the clicking of the thermostat.

Anyone planning to buy an attractive device should approach such models with caution - the design is sometimes not very impressive

As for water convector batteries, they are preferred in:

- corridors;

- greenhouses and winter gardens;

- places where there is not enough space.

But such devices will not allow you to save money. If there is no one and no time to care for them, remove dust and dirt, they will also turn out to be impractical. In any case, the optimal device will be a device whose power is approximately 0.1 kW per 1 sq. m.

Important: if the walls are thin, made of high thermal conductivity material and not additionally insulated, this figure must be increased by 50%. It is unacceptable to use powerful electric convectors (more than 2 kW) in houses with old aluminum wiring

The heater power in the nursery, unlike the living room and hallway, should be with some reserve. But when the device is installed in the office, the heating needs to be reduced somewhat so that employees and visitors feel comfortable. For kitchens and children's rooms, it is best to purchase wall-mounted radiators that will definitely not be knocked over and will create a minimum of inconvenience. In other rooms, floor models are allowed, except when there are pets or small children in the house. Both of them have an amazing ability to get into unpleasant situations.

Devices that are equipped with air slots at the top heat the air better. But dust will accumulate on the heating element faster. With each startup, the “aroma” of burnt organic matter will become inevitable. And if wallpaper or soft decorative panels are located nearby, they will fade and fade, and the glue may dry out quickly.

The main advantages of air heating units of the Vulcan brand

If you need a heating unit, then you can consider one of the models described above as an option. The main advantages of these devices are:

- high efficiency of the fan heater;

- low operating costs;

- optimal air jet range;

- reduced noise level;

- high thermal power;

- full regulation of technical parameters;

- simple and quick installation and assembly.

With the help of this equipment you will be able to heat and then automatically maintain the desired level of air temperature in a room or building. In this case, the coolant will heat up to 90 °C. The Vulcan heating unit does not use air masses from the outside in its operation, since it is designed to recirculate the air that is inside the building.

As an additional feature, we can highlight the fact that the units have the ability to redistribute air masses; this is ensured by built-in axial fans and guide grilles in the form of blinds. With the help of the latter, flows can be directed to almost any part of the structure or room.

Types of water convector radiators

A convector heating radiator can be floor-mounted, wall-mounted, in-floor, base-mounted or baseboard-mounted. Their operating principle is the same. The only differences are in the location of the air intake and outlet holes.

Let's look at the features of each variety:

Wall-mounted models look very similar to traditional radiators. They are mounted on brackets under the window sill

Moreover, during installation it is important to observe the standardized distances. Wall-mounted radiators differ in size, thermal output, number of heat exchangers and the material from which they are made. Such devices are additionally equipped with Mayevsky taps, thermostats and control valves

Such devices are additionally equipped with Mayevsky taps, thermostats and control valves.

Floor convectors can be installed anywhere by laying heating pipes in the floor. This type of device is suitable for studio apartments where there are no internal walls, as well as public and shopping centers.

In-floor devices are used in rooms with panoramic windows. They save space in the room and are built into a special niche in the floor. Pipes are also laid under the floor. From above, the entire structure is covered with a grille, which is located at the same level as the clean floor. Such radiators are used as an independent heat source or in combination with other heating devices.

Skirting convectors are installed around the perimeter of the room along the external walls. They have heat exchangers that are connected in series or parallel and connected to the heating system of the house. The heat exchanger is closed with a steel or aluminum housing with holes for air outlet. Such models are compact and do not spoil the interior of the room. They allow you to normalize the humidity and air temperature in the room.

Base-mounted devices are also a built-in type. They are installed inside niches made in walls, partitions, interior items or steps. The location of these convectors is planned at the stage of construction or major repairs, because it is necessary to lay pipes, prepare niches and install shut-off valves (inspection hatches are installed in this place).

Specifications

Currently, two models of Volcano heating equipment have been produced - VR1 and VR2. There are also models of fan heaters Volcano VR MINI and Volcano VR3, but they are not widely used.

Models VR1 and VR2 have a body that is resistant to temperatures and corrosive processes, which is made of special plastic that meets all control standards when testing for environmental friendliness. These copies use only reliable automation, which is very easy to operate.

The Volcano VR1 heater is a single-row device and has a power of 30 kW at maximum load. The second model has two rows, and the power indicator is increased by 2 times.

Water acts as a coolant. The maximum possible heating temperature of the working fluid for both models is 1300C with a heated air jet distance of 25 m. In the first model, namely VR1, 1.7 dm3 of water is used, and in the second - 3.1 dm3.

The maximum permissible operating pressure is considered to be 1.6 MPa.

We must not forget that the use of water under pressure as a coolant requires additional protection with a possible increase in this indicator. But the conditions are also taken into account that when temperatures drop to negative values, the heat exchanger may rupture if there is water in the system.

Features of installation and operation of equipment

Since these devices belong to the air-heating group, their power comes from a 380 V network. An electrician who has the appropriate permit to carry out technical work can be invited to connect them. The only condition before connecting is the correctly calculated power consumption, which must be taken into account to protect the wires from damage and prevent fire due to a short circuit.

Devices used in heating are connected only with steel pipes. Experts recommend using a pre-galvanized type of pipe to increase its service life, because during operation the metal may be exposed to corrosion, as well as the appearance of deposits and subsequent “overgrowth.” Pipes that are made of metal-plastic and polymers are unsuitable, because during the work they will use water heated to 1300C.

There are two installation methods:

- wall;

- vertical.

When using the wall method, it is necessary to take into account a free distance of at least 30 cm from the wall. It must be left to ensure air flow.

In workshops or warehouses where volatile, explosive or aggressive substances are stored, the use of installations using electric current is prohibited

Particular attention should also be paid when used in metalworking shops because graphite, which can be used as a lubricant, as well as fine sawdust released during operation, are capable of conducting current.

Types of air heating

There are two fundamentally different schemes for this type of heating

Air heating combined with ventilation

Heated air is transferred using elements of supply and exhaust ventilation. In this case, the operating parameter is not only the room temperature, but also the specified air exchange rate.

Heat is generated using boilers or gas heat generators. A system of air ducts is connected to them, through which warm air is distributed throughout all areas of the heated premises. The system can be supplemented with filtration, a humidifier, and a recuperator.

Air heating units

8, 366-84-44, 366-85-29

In air heating units AO2, hot water or steam at a temperature of 95-150°C is used as a coolant. The AO-2 unit heats recirculated, external or mixed air.

It can also be used as an air cooler when cold water is supplied and there is a tray for collecting condensate.

The fan of the AO2 unit is a general-purpose axial fan with a supply voltage of 380 V.

The heaters are bimetallic, spiral-knurled. KSk water heaters are used if the coolant is hot water, and if steam is used, KPSk steam heaters are used (heat exchangers are also bimetallic, spiral-roll type VNV-113 and VNP-113 with 3-4 rows of tubes in the direction of air movement. If the coolant water, then use type VNV-113, if the coolant is steam, then VNP-113).

The air passage and air distribution valve are made of 2 mm sheet steel.

The efficiency of using the supplied heat, the size and configuration of the air flow, and the degree of comfort depend on the configuration of the valve of the AO-2 unit. As standard, the valve blades have a horizontal position, which allows you to regulate the heat flow in the vertical plane. The valve blades are made of 2 - 3 mm unformed steel and are bolted to fix the position of the blade and the direction of the outgoing air flow. Each blade is individually manually adjustable.

The base of the air heating unit AO2 has 4 mounting holes that allow you to fix the unit on the installation site or in another place.

– ambient air temperature from minus 10 to + 35°С;

– relative air humidity up to 80% at a temperature of 25°C;

– environment – non-explosive, with permissible content of aggressive gases, vapors and dust in concentrations not exceeding the values established by GOST 12.1.005-88.

The air supplied by the fan is heated, passing through the heater, and supplied to the room.

AO-2 units have high thermal performance and efficiency, which are ensured by the optimal distance between the fan and the heater, eliminating stagnant zones when air moves in the unit, as well as the use of high-quality heaters and axial fans.

air heating units

Electric air heating units (UVE) (TU 22-119-60-95, OKP code 34 4246).

| Electric air heating units (AHE) with a radial fan and a control cabinet are designed to heat air and create a microclimate in industrial, municipal, domestic, cultural, agricultural buildings, as well as retail outlets, repair shops, garages and as part of technological equipment. In this case, the environment must be non-explosive and must not contain conductive dust. The installations must be operated in conditions of a moderately cold (MCL) climate of location category 4 according to GOST 15150-69. UVE can operate in 3 modes: 1/3; 2/3; 1 installed capacity. The air heater body is made of sheet steel. The 13 mm heating element is manufactured in accordance with GOST 13268-88 with aluminum knurled fins. The materials used on the heating elements do not emit harmful substances during operation. |

UVE installations of version “01” are equipped with heaters (heaters) with a power of 2.5 kW, UVE installations of execution “02” are equipped with heaters with a power of 1.6 kW.

The control cabinet is supplied without connection to the installation. At the customer's request, the control cabinet can be mounted directly on the installation.

| UVE-15-02 | UVE-30-01 | UVE-30-02 | UVE-45-01 | UVE-45-02 | UVE-65-01 | UVE-65-02 | UVE-90-01 | |

| Installed power, kW | 15,5 | 23,6 | 29,9 | 47,2 | 45,4 | 71,5 | 61,6 | 97,5 |

| Air capacity, m3/h, not less | 2000 | 2500 | 3000 | 4000 | 7500 | |||

| Temperature difference between inlet and outlet air at minimum air supply, °C, no more | 40 | 45 | 50 | 55 | ||||

| Total aerodynamic pressure developed by the fan, Pa, not less | 500 | 800 | 1400 | 1500 | ||||

| Fan VR 305-46, no. | 3,15 | 4 | ||||||

| power, kWt | 1,1 | 2,2 | 4,0 | 7,5 | ||||

| Length L, mm | 1265 | 1280 | 1377 | 1427 | ||||

| Width B, mm | 725 | 787 | ||||||

| Height H, mm | 785 | 941 | ||||||

| Weight, kg, no more | 110 | 120 | 120 | 130 | 140 | 160 | 170 | 180 |

Upon request, units with a power of 160 and 250 kW can be manufactured.

Advantages

Air heating units Volcano VR1 and Volcano VR2 have a number of advantages when compared with conventional electric convectors, the main ones of which are:

- high heating rate;

- heat is distributed evenly throughout the entire space of the room;

- economic benefit from use;

- ease and speed of installation of equipment.

The dampers through which warm air escapes can change in any direction, which is why the space is saturated with heat. In the process of forced airflow, which is used during operation of the device, there is a forced removal of heat from the heat exchanger, and it is many times greater when compared with convection flows.

Cost-effectiveness when using these devices is achieved due to the uniform distribution of heat. For example, to heat a warehouse with a height of 10 meters, the temperature below should reach a value of 16-180C, and at the same time the air under the ceiling will be heated to at least 300C. In order not to lose the “lion’s” share of the heat released for heating the room through the roof, it is necessary to use these units.

We must not forget that thanks to the use of equipment for heating purposes, excess moisture is eliminated in the premises, which can lead to corrosion and fungus.

The ability to turn on the units in hot weather improved its functionality. During this period of the year, it serves as a regular fan, which provides a flow of fresh air into the room, thereby creating favorable conditions.

Compared to their predecessors, Volcano VR1 and VR2 have the ability to supply warm air over long distances, and the special design of the heat exchanger used made it possible to increase heat transfer by more than 20% than previously used models.

To give an aesthetic appearance, the developers placed all the connection connectors on the rear panel, thereby hiding them from the eyes of users.

Varieties

Convectors have many varieties, which differ:

- by type of coolant (electric, gas, water);

- by type of operation (convection, infrared or mixed type);

- by installation method (floor, wall, ceiling, baseboard);

- by material of manufacture (steel, ceramic, glass, quartz);

- according to additional options (with natural convection or forced with a fan, with an ionizer or humidifier, with a dust filter and others).

When choosing a convector for your dacha or home, you should also remember about the different power of the devices. Preference should be given to one type or another based on the volume of heated air in the room. Manufacturers usually indicate the maximum number of square meters for which the device is designed.

If, for example, the room is poorly insulated, there are drafts, the windows face north, or there are other conditions that contribute to a decrease in temperature and heat loss, you should choose a convector of higher power. So, for a room of 15-20 square meters, purchase a heating device with a power of at least 2 kW. A 1 kW device can heat a very small room of up to 12 square meters. If the convector has additional options (air humidification, electronic thermoregulation), then it is worth taking into account these losses when operating the device. Accordingly, it will fit an area smaller than the declared one by about 30-40%.

Infrared

These are the most modern innovative models. Their effectiveness is increased due to the additional effect of infrared radiation. Combined type devices have 2 heating elements and can operate even if one of them fails.

They have increased efficiency and warm up the room faster than other types due to the transfer of heat by IR waves to surrounding objects. Such devices often have decorative panels and are the latest generation heating systems.

Electrical

Electric convectors work by heating the internal element (heating element) with electric current. Using such a device is absolutely safe. The heating element is protected by the insulation and shell of the convector, so at any set temperature its surface does not heat up above 50-60 degrees.

They are equipped with automatic thermostats. It is worth remembering that an electric convector consumes a sufficient amount of energy. Therefore, you need to choose the option with maximum energy saving. It is suitable for a small room or intermittent operation (between heating seasons).

Gas

The gas convector is not very popular, although it was originally designed as a more economical alternative to the electric one. It runs on liquefied gas from a cylinder. It is also convenient to use it in private households if it is possible to connect to the highway. At the same time, its installation should be carefully considered, since further dismantling and transfer of the device may cause difficulties.

In addition, a gas convector requires a flue gas removal and recovery system. Installing such a convector will require special skills. And the savings become relative, since significant heat losses will occur through ventilation to remove gases in the outer wall.

Mermen

Convectors with water as a coolant are characterized by maximum efficiency, ease of use and safety.

Water intake for heating comes from the centralized heating system. They are compact and can be hidden under the floor surface (so-called “plinth models”). Their only drawback is the small area of the heated room. It should not exceed 10-12 square meters.

Features of carrying out competent calculations

Despite the assurances of would-be experts, it is very difficult to independently calculate air heating. Only specialists can do this task.

The customer can only check the availability of all project items, which include:

- Determination of heat losses for each heated room.

- Type of heating equipment indicating the required power, which should be calculated based on actual heat loss.

- The required amount of heated air, taking into account the power of the selected heating device.

- Required cross-section of air ducts, their length, etc.

These are the main points for calculating the heating system. It would be right to order a project from specialists. As a result, the customer will receive several calculation options from which he can choose and implement the solution he likes best.

An air heating system is a complex structure consisting of many elements. To calculate it, it is better to involve professionals; to familiarize yourself with the components, it is worth studying the diagram in detail (+)

Operating principle of air heating

The heating system, where the coolant is hot air, is practical and easy to operate. The operating principle of such a system is based on thermoregulation. This method is used for both heating and air conditioning. The function of a heat generator is performed by various equipment - it can be an electric heater, boiler or furnace running on gas, solid or liquid fuel.

Regardless of what equipment is installed, the working algorithm is the same:

- The heat obtained by burning fuel is sent to the heat exchanger.

- The air mass, heated to a certain temperature (45-60 degrees), moves through air ducts (round or rectangular). The advantage of round air ducts is low aerodynamic drag. Thanks to their modern design, elements with a rectangular cross-section fit harmoniously into the interior.

- Warm air enters the room through special distributors that are installed at the outlet of each air duct.

The cooled air is returned to the heat generator for reheating through grilles installed in the floor or through return air ducts. On average, the air flow in the system varies from 1000 to 3800 cubic meters. meters per hour. Working pressure - 150 Pa.

Natural air circulation

The simplest option is to supply coolant through initial heating. The rising air enters the rooms through air ducts, after which it falls down and returns for reheating. The only drawback of natural circulation is the presence of a large amount of cold air masses that enter the room through windows and doors. In this case, the circulation process is disrupted and the entire system malfunctions. To create optimal temperature conditions and climate, the parameters of the main air duct must be more than 30 meters in length, and the branches - 15 meters.

How to warm up a house with air?

Air is a very effective coolant, much more convenient than water. The simplest option for such heating is a conventional fan heater. This device, consisting of a fan and a heating coil, can warm up a small room in literally a matter of minutes. Of course, for a private home you will need more serious equipment.

A gas or solid fuel boiler can be used as a heat source. An electric heater is also suitable, but this option is not considered very profitable, since electricity costs increase significantly.

An interesting and environmentally friendly heating option is the use of solar panels or a solar collector. Such systems are placed on the roof. They either directly transfer thermal energy from the sun to a heat exchanger or convert it into inexpensive electrical energy. In the latter case, the fan can also be powered from the battery.

The air is heated in a heat exchanger and supplied to individual rooms through air ducts. These are rather bulky structures made of durable metal. The cross-section of the air ducts is significantly larger than the diameter of the water heating pipe.

Gas boilers and other types of heating equipment are also suitable for air heating. The efficiency of such systems reaches 90%; they are used not only in residential premises, but also in workshops and warehouses

But radiators for air heating are not needed. Warm air simply fills the rooms through special grilles. As you know, hot gas tends to rise. Cold air will be forced downwards.

From here, cold air flows move back to the heat exchanger, heat up, enter the rooms, etc.

This diagram clearly demonstrates a recirculation-type air heating device with partial intake of outside air, as well as an air conditioner, ionizer and ultraviolet purifier

Almost all air heating systems include the installation of a fan, which blows hot air and forces it to move through the heating system. The presence of such a device makes the system dependent on electrical energy.

You can also make a system in which hot air moves naturally, without any fan. However, the efficiency of such systems usually leaves much to be desired, since the rooms in this case warm up too slowly.

A convincing argument in favor of organizing an air heating system is to eliminate emergency leaks and flooding with resulting property damage. In addition, if the air ducts are damaged, the automation will stop the system.