We install a thermostat for the heating system pump - see the instructions

In order to always maintain warmth and comfort in your home, you need to take care of heating your home in advance. The best option for heating a private home is water heating with a pump. Unlike a heating system with a natural circulation method, when the movement of hot water in the pipes occurs due to the different masses of hot and cold water, the forced method is more convenient and profitable.

Forced circulation is produced by water pumps for heating a house, which create a strong pressure that pushes hot water through the pipes. If you choose the right water pump for home heating, it will help save energy, increase the service life of water pipes and allow you to obtain a high level of heat transfer with little energy consumption.

The pump for drawing water into the heating system is only part of the heating system, which, in addition to the hydraulic pump, includes a radiator, filter, valve and boiler.

For high-quality functionality of any system, the presence of a control unit is a prerequisite. In heating systems, this link will be a thermostat for the heating system pump. They can be electronic or mechanical.

Only properly installed and coordinated operation of this system can provide warmth in your home.

To ensure the operation of the heating system, circulation water pumps are used to heat the house. Some manufacturers produce heating boilers with a built-in pump. This option has many advantages:

- the pump and boiler are a single unit, which improves the ergonomics and reliability of the model;

- small size, which makes it possible to install the boiler in a small area of the room;

- The boiler with a built-in pump is already ready for operation - you just need to connect the necessary communications.

The only disadvantage of this unit is its cost. But if you calculate the amount saved on installing the pump, the cost of the hydraulic system is fully recouped. Boilers that require additional installation of pumping equipment are the most common type of device. Self-assembly of a unit attracts consumers with the following factors: - Low cost of the pump. The different prices for water pumps for home heating will help you choose the right model.

- Independent dismantling of the pump in case of breakdown.

- Possibility to install the pump yourself.

Types of water pumps

Modern heating systems most often include the following types of water pumps for heating a house: with a dry rotor and a wet one.

The first type of pump is characterized by the fact that the liquid pumped in it does not come into contact with the engine.

This increases the safety of this device, since due to a special seal that ensures the tightness of the motor, complete insulation is achieved.

The solution washes all parts of the mechanism and protects them from wear, extending the life of the device. Most often, this type of pump is used for heating industrial premises.

The main characteristic of a glandless pump is that the drive structure attached to the rotor rotates due to the fluid circulation in the system. The water that flows through the pump sleeve cools and lubricates the bearings. Despite the lower efficiency compared to pumps with a dry rotor, pumps with a wet rotor are more in demand due to their low price, quiet operation, low weight and ease of installation.

Most often, such pumps are used in private houses, cottages and dachas.

You can buy a water pump for heating your home, instructions for which are included, in specialized stores.

Installing a water pump in a heating system

There are several basic rules, following which you can install pumping equipment yourself:

- for installation it is better to use a section of pipe that runs horizontally to the floor surface;

- the pump should be located at a short distance from the boiler;

- the terminal block must be located above the device;

- the mechanism must be grounded;

- location of the low-frequency filter in front of the pump.

When purchasing a water pump for heating your home, do not forget to check for instructions that describe everything in detail.

Even an ordinary craftsman can install a pump into a heating system. To do this you will need: a water heating circuit for the house, a pump, a check valve, a membrane water filtration system, a piece of pipeline and shut-off valves.

Before installing the pump, you need to thoroughly clean and flush the heating system, and also remove air bubbles.

In order for the system to be reliable and work efficiently, the joints must be treated with silicone or polymer sealant and sealed with tow.

wikiteplo.ru

Conclusions and useful video on the topic

Rules for installing heating equipment in the video:

The video explains the features of a two-pipe heating system and demonstrates different installation schemes for devices:

Features of connecting a heat accumulator to a heating system in the video:

If you know all the connection rules, there will be no difficulties with installing the circulation pump, as well as when connecting it to the power supply at home.

The most difficult task is inserting a pumping device into a steel pipeline. However, using a set of guides for creating threads on pipes, you can independently arrange the pumping unit .

Would you like to supplement the information presented in the article with recommendations from personal experience? Or maybe you saw inaccuracies or errors in the material reviewed? Please write to us about this in the comments block.

Or have you successfully installed a pump and want to share your success with other users? Tell us about it, add a photo of your pump - your experience will be useful to many readers.

Installing a circulation pump in homes with an individual heating system ensures uniform and high-quality heat distribution throughout all rooms of the house.

Thermostats for heating - the basis of a “smart” heating system

It would be much easier if the same temperature remained outside at all times of the year, then there would be no need to adjust the heating. But in winter, severe frosts give way to thaws with positive temperatures and vice versa, it is clear that the heating system must adequately respond to weather surprises.

Smart heating

Heating control methods

Any problem, as a rule, has several ways to solve it; adjusting the heating operation is no exception.

The following adjustment methods can be distinguished:

- The simplest option is to install a special regulator in front of each radiator. Such thermostats for home heating can be used in all heating systems without exception, and the principle of operation is that the coolant current through the battery is regulated;

Note! In some cases, for example, in city apartments, this method of adjustment is the only one available.

- if the basis for the operation of the thermostat is data on changes in air temperature in the room (or outside), then adjusting the operation of the boiler involves changing the temperature of the coolant. In this case, the control device is located directly next to the boiler;

Thermostat for electric boiler

- “smart” circulation pumps are a bit of a stretch, but they can also be classified as heating regulators. If a conventional regulator is installed on a radiator, then the pump is located directly next to the boiler (on the pipeline supplying the cooled coolant). The adjustment process is carried out by changing the rotation speed of the pump rotor.

Of the listed methods, the first is considered the most flexible, since it allows you to change the temperature not only in a single room, but also in individual radiators. The remaining 2 methods change the operation of the heating system as a whole, that is, the temperature will change immediately in all rooms in the house.

Thermostats for radiators

Such devices are a thermal head, which is installed on a section of the supply pipe directly in front of the battery. The principle of operation is simple - when the temperature in the room exceeds a predetermined limit, the device simply slightly reduces the internal diameter of the pipe, and accordingly the volume of coolant entering the battery decreases.

Basic elements of a thermostat

The simplest manual regulator is a regular tap, in which case the adjustment will have to be done manually. But automatic models are more often used.

Types of thermostats

If we choose the principle of operation as the main criterion, then all devices of this type can be divided into mechanical and automatic. In mechanical ones, a person regulates the temperature with his own hands, constantly turning the valve; in automatic ones, after setting the device, it works on its own.

You can also classify them according to the location of the sensor.

There are 3 options:

- the temperature sensor is located directly in the thermal head (in this case, you need to especially carefully monitor the installation of the control device, because there is a heating radiator nearby);

- the sensor is located a couple of meters away - allows you to more accurately regulate the heating operation;

Thermostat with remote sensor

- the sensor is placed outside - the result is a weather-dependent heating regulator. It will instantly respond to changes in outside temperature.

Note! When using indoor temperature sensors, there is always a time gap between a change in weather conditions outside and a change in the heating operating mode. The use of external temperature sensors solves this problem.

Design, principle of operation and preparation of the thermostat for operation

Thermostats for heating radiators, operating in automatic mode, use the property of liquids and gases to expand and contract when heated/cooled. The head contains a sealed chamber (bellows), which contains the working fluid or gas.

The bellows wall is corrugated, so that when the internal volume changes, it lengthens or shortens. Due to this, the clearance in the pipe supplying coolant to the radiator changes.

Bellows device

The diagram below shows the Danfoss thermal head device. It can be seen that when the bellows is extended, the valve will partially block the supply pipe.

The diagram shows the structure of a typical thermostat

Even when using automatic devices, preliminary adjustment will be necessary.

The heating radiators are adjusted in the following order:

- first you need to ensure an unimpeded flow of coolant into the radiator, so the valve opens completely;

- as soon as the room temperature exceeds the required value by 5-7ᵒС, the valve closes completely;

- now you just need to wait until the temperature in the room drops to the required value;

- Once the temperature has become comfortable, you can slowly open the valve until the radiator begins to warm up and the murmur of water can be heard. We can assume that the thermostat for heating radiators is configured and ready for operation.

Adjusting the operation of convectors

Quite often, instead of conventional batteries, in-floor convectors are used to heat rooms. A special feature of such devices is that a fan is installed in them to improve air exchange.

One of the options for connecting convectors to a thermostat

The heater fan rotation speed regulator allows you to reduce the volume of air passing through the convector fins, due to which the temperature in the room changes. Without control devices, the fan always runs at 100% speed.

In advanced models, after the temperature in the room drops by 1.5°C, the fan turns on and, due to blowing, increases the heat transfer of the heater. Moreover, one controller can simultaneously operate several fans.

Dependence of the number of fans on the size of the heater

Boiler operation adjustment

In private homes, to change heating operating modes over a wider range, you can use devices that regulate the operation of the boiler as a whole. This will reduce the temperature of the coolant in the system and solve two problems at once: save on fuel and get the optimal temperature in the rooms.

Devices for regulating boiler operation

Such heating regulators consist of 2 blocks:

- 1st block – consists of a temperature sensor, which can be placed both in the room and outside. Placing it outdoors has a number of advantages, in particular, it increases the speed of the system’s response to changing weather conditions;

- The 2nd block is the actual adjustment device, located in close proximity to the boiler. Both blocks are connected to each other by a metal wire.

The operating principle of the device is based on the fact that the electrical characteristics of conductors change when their temperature changes. The main working element of the thermostat is a thermocouple or thermistor.

The principle of their operation is somewhat different:

- electric heating thermostats using thermistors record changes in the resistance of the thermistor;

Relationship between resistance and temperature

- There are devices that use a thermocouple - that is, a plate soldered from 2 different metals. The types of metals are selected in such a way that a sufficiently high potential difference occurs at the junction; when the temperature of the soldering site changes, the potential difference also changes.

Dependence of current on temperature difference

This heating thermostat allows you to control the temperature over a wide range, regardless of the power of the heating system. It can be used both in private construction and in multi-storey buildings; a cascade of thermistors will allow in this case to create an intelligent heating system.

Examples of devices that regulate boiler operation

Such devices vary greatly depending on the complexity of the design, the ability to program behavior on different days and different times of day, and the accuracy of temperature control.

There are several models in order of increasing complexity and cost:

- room heating regulator VRT 40 - can be called one of the simplest devices for regulating the operation of the boiler (belongs to the class of analog electric regulators). The temperature mode is set manually, and the temperature sensor itself is located directly in the room. Apart from several temperature modes, there are no additional settings;

- automatic heating regulator Calormatic 430 - provides an order of magnitude more possibilities for temperature regulation. Refers to electronic regulators with closed logic (that is, you can only use the operating modes provided by the manufacturer). Such a device costs approximately 13-15 times more than the VRT 40 model;

Regulator with several types of operating modes

- Vzlet-RO 2 – among the heating control devices on the market, can be called the leader in flexibility and accuracy of control. In addition, the user can set an arbitrary operating mode, because this device is produced with open logic, that is, it can be reprogrammed. True, there is a downside to this - the average consumer is unlikely to want to bother with fine settings, and the price will make you think twice before purchasing.

Appearance of the thermostat

Devices like the last one on the list are most often used in industry in rooms where temperature conditions are of particular importance. In addition to simple adjustments, such devices can be used to collect statistics and even for research purposes, but conventional thermostats for heating radiators are not suitable for these purposes.

Adjusting the operation of solid fuel boilers

In a gas or electric boiler, the control unit regulates either the heating temperature of the heat exchanger (electric boilers), or the frequency and duration of operation of the gas burner (gas boilers). In the case of solid fuel boilers, the fuel combustion process cannot be interrupted every 20-30 minutes, and therefore a different principle is needed for regulating their operation.

Regulator for solid fuel boiler

The rate of fuel combustion, and therefore the intensity of thermal energy production, depends on the rate of fuel combustion, and this parameter is directly affected by thrust. The draft regulator for solid fuel boilers changes the volume of fresh air entering the combustion chamber and thus regulates the operation of the boiler as a whole.

During operation, such a device constantly monitors the temperature of the coolant (a submersible hollow sleeve is used for this), and the actual change in the position of the boiler damper is carried out through a mechanical transmission.

The diagram shows a solid fuel boiler with an installed thermostat

After installation, you need to configure the regulator; the setup instructions look something like this:

- turn the handle to set the desired temperature;

Note! If the device is installed horizontally, then you need to use the red scale, if vertically - yellow.

- after this you need to flood the boiler and bring the temperature to the required temperature;

- then the chain is put on the damper. It is important that it does not sag; the maximum free play should not exceed 1 mm.

Solid fuel boiler adjustment diagram

Such a heating thermostat will change the size of the gap through which fresh air enters. As soon as the temperature exceeds the required one, the thermostat, through a system of levers, slightly raises the chain, and with it the damper - the air flow increases, which means the combustion process proceeds more intensely.

Heating adjustment using a circulation pump

In the past, unregulated pumps were used, that is, there was no way to regulate the flow of coolant through the pipes. Nowadays, such rarities can only be found in old buildings, and in most cases they have been replaced by adjustable circulation pumps.

If a conventional regulator for a heating radiator changes the coolant current in a single radiator, then changing the operating modes of the pump affects the efficiency of the entire heating system as a whole. For example, at night the rotor speed decreases, because there is no need for intensive heating.

In the photo - a pump with a thermostat

More complex models make it possible to configure the operating mode of the device by day of the week, as well as by time of day. Operating modes such as “Party”, “Vacation”, “Weekend”, etc. are available.

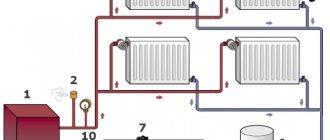

The heating system diagram provides for the installation of a pump directly in front of the boiler on a section of the pipeline with cooled coolant. If you try to install it at the outlet of the boiler, the high temperature of the coolant will significantly reduce the durability of the pump.

The diagram shows the optimal location for installing the pump

Summarizing

Heating radiators with a thermostat allow you to create a truly “smart” heating system that adapts to changing weather conditions. Meanwhile, battery regulators are far from the only way to regulate the operation of the heating system. The proposed material is an attempt to generalize existing methods of regulating heating in a house.

The video shows an example of connecting a thermostat to a boiler.

hydroguru.com

Mechanical models

The valve and thermal head are the main elements, without which it is impossible to imagine almost any thermostat. In this case, the latter performs the function of a sensitive element. These parts do not require external energy in order to function properly.

In turn, the thermal head also has several components. This is a regulator and drive, a liquid element, sometimes elastic or gas parts are found as an alternative.

Internal organization

When choosing a temperature controller, it is necessary to take into account all factors that may affect the operation of the device in the future. Its main parts are as follows:

- adjustable scale;

- ring that fixes the set temperature;

- mechanism of compensatory action;

- union nut;

- stock;

- spool;

- detachable connection;

- sensing element;

- thermostatic element;

- thermostatic valve.

Automation for heating circulation pump, UPS, thermostats, timers

Choosing a heating system option for a private or country house is a rather serious and responsible moment. If you have chosen a heating system with natural circulation, then you need to know that you will need to install a boiler that depends on electricity. However, their operation does not require an uninterrupted supply of electricity, which can be provided by an uninterruptible power supply for a heating pump. In our conditions, sudden power outages may not occur so rarely, and the energy dependence of the heating system can be a rather significant and important argument. That is why such a question as automation for the heating circulation pump and special devices for providing it with energy becomes important.

Automation for heating circulation pump

- Uninterruptable power source

- Accessories for circulation pumps

Uninterrupted power supply for the heating pump is, of course, an important point. However, you should not rush to choose a heating system until all their advantages and disadvantages have been studied. If your choice is a heating system with natural circulation of coolant, then you need to take into account that it also has some disadvantages. The main disadvantage is that if there is no automation or pump, the system may fail or, at least, will not be as efficient as it should be. Also, the absence of these components will negatively affect the amount of fuel consumed, which means that such a system will bring you considerable financial losses.

Installing a UPS for the heating pump will be an excellent solution to prevent such problems.

By installing a UPS for the heating circulation pump, you don’t have to worry if the electricity suddenly goes out, since such equipment is equipped with automation. Such equipment has a battery for the heating pump, which will ensure uninterrupted operation of the pumps and other volatile components of the heating system if the electricity suddenly goes out.

UPS for heating circulation pump

There is another method that will create all the conditions so that the components of the heating system do not lose their functionality. We are talking about a diesel or gasoline generator. This method is more reliable, but at the same time, more expensive. However, even generators have their drawbacks: some such devices can produce short-term voltage surges at the output. This may cause a malfunction of some automatic components of the boiler or heating system.

Accessories for circulation pumps

In addition to the UPS for the heating pump, we also note other components. Namely, a pressure switch, this is a kind of timer for a heating pump.

Pressure switch

Such a component is necessary for the pump in the heating system to operate automatically. The relay will turn on the pump if the pressure in the heating system drops below the set level, and if the pressure reaches the highest level, the relay will automatically turn off the pump. So, the relay controls the heating pump. The operating principle of such a component is as follows. After the consumer stops dispensing water, the pressure in the system will rise at one point to the upper level. At this moment, thanks to such a relay, the pump will turn off for a while.

If the consumer turns on the water supply, it will begin to flow under pressure, thereby the pressure level in the system will begin to decrease. It will decrease until it reaches the lowest point. At this moment, the pressure switch will turn on the circulation pump.

The heating circulation pump is also controlled by a thermostat. This is a valve and a thermoelement. The thermostat for the heating pump controls its temperature. In addition, there are also components for the heating system, such as a water recirculation pump for autonomous heating.

otoplenie-doma.org

About the choice of equipment and the rules for its independent calculation

The key indicator that determines the efficiency of the circulation pump is its power. For a household heating system, there is no need to try to purchase the highest-power installation. It will only make a loud noise and waste electricity.

Mounted circulation pump

You need to correctly calculate the power of the unit based on the following data:

- hot water pressure indicator;

- pipe section;

- productivity and throughput of the heating boiler;

- coolant temperature.

Hot water consumption is determined simply. It is equal to the power indicator of the heating unit. If, for example, you have a 20 kW gas boiler, no more than 20 liters of water will be consumed per hour. The pressure of the circulation unit for the heating system for every 10 m of pipes is about 50 cm. The longer the pipeline, the more powerful the pump you need to purchase. Here you should immediately pay attention to the thickness of the pipe products. The resistance to water movement in the system will be stronger if you install pipes with a small cross-section.

In pipelines with a diameter of half an inch, the coolant flow rate is 5.7 liters per minute at the generally accepted (1.5 m/s) speed of water movement, with a diameter of 1 inch - 30 liters. But for pipes with a cross-section of 2 inches, the flow rate will already be at the level of 170 liters. Always select the diameter of the pipes in such a way that you do not have to overpay extra money for energy resources.

The flow rate of the pump itself is determined by the following ratio: N/t2-t1. In this formula, t1 refers to the temperature of the water in the return pipes (usually it is 65–70 °C), and t2 is the temperature provided by the heating unit (at least 90 °C). And the letter N denotes the boiler power (this value is in the equipment passport). The pump pressure is set according to the standards accepted in our country and Europe. It is believed that 1 kW of power of a circulation unit is quite enough for high-quality heating of 1 square meter of a private home.

Circulation pumps for home heating systems

A prerequisite when designing new heating systems in a house or upgrading existing ones is the presence of a circulation pump. It, included in a closed circuit, ensures efficient operation of the heating system.

Circulation pump: what is it and what is it for?

The circulation pump is one of the main components of a forced circulation heating system. That is, in simple terms - a pump. This is equipment designed to pump fluid for heating or air conditioning systems. The use of this device helps save up to 20–30% on energy resources compared to heating that uses natural circulation. It also distributes the heating fluid evenly across all radiators of a residential building, which helps them to warm up evenly and distribute heat evenly. The rapid movement of coolant around the house prevents it from cooling down too much, resulting in less fuel consumption required to heat it to the required temperature.

Pump design

Let's look at the design of equipment for home heating systems using the example of Wilo brand products.

Pump components

The circulation pump shown in the image above consists of the following elements:

- Frame. Can be produced in four versions: cast iron, stainless steel, bronze, with an air separator;

- Gap seal. Made from stainless steel;

- Impeller. Made from heat-resistant composite materials;

- Alloy steel bearing plate;

- Metalgraphite bearing;

- Shaft. It has two versions: ceramics or steel;

- Rotor with alloy steel shell;

- Sealing gasket;

- Monolithic rotor sleeve. Made of ferritic steel;

- Sliding bearing, ceramic;

- Stator;

- Aluminum alloy housing cover;

- Threaded plug;

- Terminal box.

Depending on the design of the heating systems of a house or multi-storey building, pumps are of two types:

- Dry - the rotor does not have direct contact with the coolant. Main characteristics: efficiency 75–80%, specific heating pipeline supply, noisy operation, can be installed to heat one multi-storey building or several, large dimensions, requires periodic maintenance.

- Wet - the rotor of the device is in direct contact with the liquid in the pipeline, and the stator is isolated by a sliding seal. It is characterized by a low efficiency of 50–60%, the coolant plays the role of a lubricant, which ensures quiet operation and small overall dimensions. Mainly used for heating systems of cottages, summer houses or private houses.

In addition, they can be equipped with electronics for automatic control, a capacitor and speed switch for manual control, and a thermostat.

How to choose a pump

When choosing a pump, we are guided by two main parameters: the pressure of the fluid flow in the pipe and the hydraulic resistance in the heating circuit. The unit is selected with a power 10–15% lower than the calculated one, so maximum equipment efficiency is achieved.

Installing a device with a power higher than required will lead to excessive energy consumption and increased operating noise.

As the temperature increases, the hydraulic resistance inside the systems increases and significant noise and load on the working element appear in the operation of the pump. As a result, it is necessary to switch the unit to minimum speed using power regulators. If the product is equipped with electronics, then this process occurs in a smooth automatic mode under the control of a built-in thermostat.

You can study more detailed instructions on how to choose a circulation pump for heating.

Global pump manufacturers

One of the world's leading producers of these products is the German company Wilo. The company's products are intended mainly for heating a private house with two or more floors and are certified according to all international norms and standards. The plant uses high-tech equipment and applies advanced technologies for the assembly and production of equipment. A distinctive feature of Wilo products is the minimal amount of defects and a fairly low price.

The characteristics of the entire model range allow the pumps to be used in temperatures from –10 to +110 °C and at pressures up to 16 bar. The products have energy consumption class A and are mainly produced in the wet type.

Wilo-Yonos PICO pump

For example, Wilo-Yonos PICO, equipped with automatic control and a thermostat, helps save energy up to 90%. Permanent magnets provide a high level of resistance to blocking currents.

The stores have a wide range of this product, having approximately the same technical characteristics.

The most common brands:

- Wilo (Germany);

- Grundfos (Germany);

- Speroni (Italy);

- Elsotherm (Russia);

- Wester (UK).

According to reviews from consumers and specialists who give their preference to products of the first brand, they do not require regular maintenance, are silent in operation, durable and practical. In accordance with this, we present the main characteristics of the pump of the classic model of the RS series from Wilo:

- Pressure, m - from 4 to 6;

- Maximum flow rate, m3/hour - from 3.5 to 4;

- Operating temperature at an air temperature of 40 °C - from -10 to +110;

- Working pressure, bar - 10.

Thermostat: its purpose for heating systems

A thermostat is used to control the pump. In models with electronic control, it is already integrated into the pump itself and with its help, the rotation of the impeller is smoothly adjusted. For manually controlled models, mechanical or electronic thermostats are used.

They set the minimum and maximum temperatures at which the pump should turn on or off, respectively.

Electronic thermostat

Mechanical thermostat

Mechanical devices are attached directly to the pipe, and when using electronic thermostats, a special temperature sensor is built into the pipeline, which monitors temperature changes in the pipelines of the home heating systems and sends a signal to the thermostat.

The issue of choosing a circulation pump for installing or modernizing the heating systems of cottages and buildings should be approached carefully and small nuances and details should not be ignored. After all, the coziness and comfort of your home depends on reliable and high-quality engineering equipment.

Related video: Grundfos pumps

Solid fuel pump and boiler

The pump is connected to the system with a solid fuel unit on the return line. In this case, the pumping device is connected to the boiler circuit with a bypass and a three-way mixing valve. In addition, the latter can be equipped with a servo drive and an overhead temperature sensor.

Due to the fact that the maximum performance of heating equipment is used to its fullest extent only during the cold period, it is possible to install a heat accumulator (TA). It is able to absorb excess heat and then, on demand, release it to the heating circuit.

This battery is made in the form of a tank and is lined with thermal insulation material. On one side of the device there are two pipes intended for connecting it, and two on the other - for connecting to the radiator line.

As the liquid passes through the boiler, which operates at maximum, the coolant in the heat accumulator warms up over time to 90-110 degrees. In a large circuit, the insertion of another circulation device is required.

Depending on the degree of cooling of the liquid in the heating system, the required amount of heat from the storage device will enter through the valve.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Principle of operation

The volume of coolant changes when the temperature in the heated room changes.

The bellows also changes its volume. It is because of this that the control spool begins to move. Its movement is proportionally related to how the temperature regime changes.

The thermostat has a special valve stem that moves due to a sensing element that reacts to the environment.

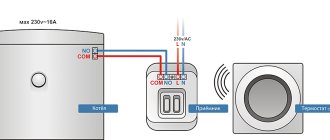

Wireless thermostat connection diagram.

At the moment, wireless thermostats have become widespread and have seriously displaced their wired counterparts. They are easier to work with; you don’t need to run wires from the thermostat to the sensor across the entire house. It is enough to simply set the address of the sensor and install it in a place with stable reception of the signal from the thermostat. As for the connection diagrams for such devices, there can be two of them:

Open circuit connection diagram.

The diagram is no different from the connection diagram for a mechanical thermostat. The boiler, pump or servo drive is turned on when current appears in the circuit.

Connection diagram based on potential (voltage).

In this circuit, when the circuit is connected, the thermostat transmits a voltage to the boiler input, which turns on the boiler, pump or servo drive.