Operating principle of room thermostats

Temperature regulator for cellar

The room temperature controller works as follows:

- A sensor built into or removed from the thermostat housing measures the air temperature in the room;

- The sensor transmits information to the actuator;

- The actuator, depending on the temperature value, turns on or off heating devices and air conditioners connected to the controller;

- When the air temperature in the room drops to a value that was taken as the minimum during the device settings, the device turns on the heating device again.

Thus, this control equipment does not operate constantly, but cyclically, turning the heating on and off at the minimum and maximum values of the air temperature in the room. For electromechanical and mechanical thermostats this range is very small, while for electronic models it can be much wider.

How does a thermostat work in a heating system?

If you manually adjust the heating strength, there is no guarantee that the room will be heated evenly over the entire area. An automatic thermostat monitors the room and reacts when the temperature differs from the programmed parameters. When they are exceeded or decreased, it turns the heating boiler off or on.

The device operates on mains power or batteries. There are hybrid models - with two power sources. This is convenient, since during power outages the device continues to operate autonomously.

The thermostat contains metal plates with different linear expansion coefficients. They are needed for electrical contact. When they are deformed due to the difference between the set and actual temperatures, the circuit opens and the valve closes.

When the temperature rises above the set values, the contact drops, the circuit is restored, the gas supply stops, the boiler stops working, and the radiators gradually cool down. If the temperature in the radiators or the room is below the required value, then the plates close the circuit and open the valve that supplies fuel to the burner, and the device heats the coolant again.

Types of thermostats

DIY thermostat

Depending on the design and principle of operation, these devices come in three varieties: electronic, electromechanical and mechanical.

Electronic

The simplest electronic thermostat is a device consisting of the following parts:

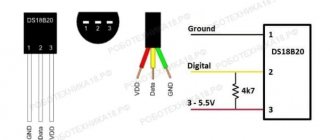

- The controller is a printed circuit board with a microcircuit. This is the key part of the thermostat, receiving information from an external temperature sensor, processing it and sending the corresponding signal to turn on or off the heating device or air conditioner;

- Monochrome liquid crystal display and control buttons - used to configure and program the thermostat to maintain the required temperature background in the room;

- Remote temperature sensor connected to the controller using a flexible thin cable;

- Contact group - clamps in which the cores of the cable connecting the thermostat to the heating device or air conditioner are fixed.

This device works quite simply: an analog signal is sent from the sensor via a cable to the controller, which is deciphered by its microcircuit, correlated with the temperature value specified in the settings, after which the controller makes a decision to turn the heating equipment on or off.

Electronic thermostat

Electromechanical

Occupying an intermediate position between electronic and mechanical, such thermostats come in two types:

- With a bimetallic plate and a contact group - inside such regulators there is a plate that, when heated to a certain level, bends, opening the contacts of the circuit that powers the heating equipment. When cooling, the reverse process occurs: the plate straightens, closes the contacts, and the heater turns on. The activation of this device is adjusted using a rotating dial with a pusher that changes the distance between the plate and the stationary contacts it closes.

- With a capillary tube - the design of such a device is the same as analogues used in water heaters and boilers.

Electromechanical room temperature controller

Mechanical

The main elements of this device are a gas-filled membrane that responds to changes in air temperature in the room, and a control mechanism consisting of two movable contacts.

The thermostat works as follows:

- As the temperature rises, the gas filling the membrane expands;

- A pusher located on one of the outer walls of the membrane opens the contacts of the control mechanism circuit, thereby turning off the heating device connected to the device.

Adjustment in such a thermostat occurs thanks to a rotating dial (wheel), which changes the distance between the membrane and the control mechanism.

Mechanical thermostat

Heating control. Part 1. Room thermostats, heat request

Thermostat with support for the OpenTherm protocol.

The OpenTherm protocol is used to exchange data between the boiler and an external logic device (for example, a room thermostat). In addition to the heat request, the boiler can be given a number of other tasks and parameters, such as, for example: coolant temperature, heat request for the DHW circuit. The boiler, in turn, sends current parameters via the protocol, among which the most useful are: the presence of a boiler error, operating status, current coolant temperature, burner status and modulation level.

When used in small heating systems, there is little practical benefit from using such thermostats: perhaps setting a temperature schedule (the dependence of the coolant temperature on the outside air temperature), if this function is not provided by the boiler automation, and advanced monitoring of boiler parameters.

In large systems where the system is divided into several consumers, the Opentherm function turns out to be extremely useful: the operating logic of the boiler room equipment is built in such a way that each individual heat consumer sends a heat request to the boiler along with the required coolant temperature. The boiler turns on according to the task, reaches the set temperature and maintains it until the task is canceled. This approach ensures the most harmonious operation of the boiler and extends its service life, because Thanks to the correct operation of the burner modulation algorithm, the number of on-off cycles is reduced to a minimum. You can read more about the gas boiler control algorithm here.

Thermostats with dry contact and 230V output

Also, all thermostats differ in the connection method . They can be divided into 2 groups - thermostats, to which a load with a supply voltage of 230V is connected, and thermostats with a dry contact, which can be used both to open low-current networks with direct or alternating current, and for low-power loads 230V.

We can say that dry contact thermostats are universal because they can switch anything, and they are suitable for connecting to the boards of gas and other boilers, where the control signal is usually 5, 12 or 24V DC. If you see two contacts on the thermostat terminal block with the designation of an electrical breaker. networks are dry contact.

All mechanical thermostats, as well as battery-operated thermostats, are guaranteed to be dry contact.

Boiler operation control

Thermostat for incubator

A gas boiler or electric boiler can be controlled by a thermostat installed in the living room, as well as by a more complex background temperature controller - a programmer. Depending on the design of the boiler, there are three options for connecting such control devices:

- To special connectors on the boiler control board (for wall-mounted, volatile models);

- In series with the boiler thermostat with a mandatory connection to the gas valve (for non-volatile floor-standing models);

- Instead of a boiler thermostat (for floor-standing boilers).

Modern wired programmer for a gas boiler

Important! To install such regulators, select the rooms most distant from the boiler and those most visited by residents: bedroom, living room.

Thermostatic control valves

The thermostatic valve is a simple solution to the problem of obtaining a coolant at a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

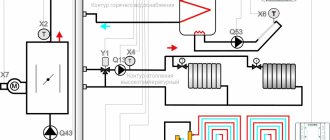

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to a heating system

Piping diagram for a solid fuel boiler using a thermostatic three-way valve:

Piping diagram for a solid fuel boiler using a thermostatic three-way valve

Piping diagram for a gas boiler using a thermostatic three-way valve:

Piping diagram for a gas boiler using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the temperature in the room by varying the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed to adjust the temperature needed in each individual room.

This idea should be considered as an addition to the thermal control installation. Also, such devices require periodic readjustment and regular performance checks (every six months when changing operating modes).

Installation and connection

Installation of a room temperature controller is carried out in several stages:

- Mount the regulator on the wall at a height of 150-160 cm away from heating radiators, various heaters, and places exposed to direct sunlight;

- Connecting to the contact group of the cable regulator - the bare and preferably soldered ends of the cable are inserted into special connectors and secured with screws;

- Laying the cable from the thermostat to the heating equipment in plastic cable channels;

- Connecting the cable to the corresponding terminals on the boiler control board, servo drive of the three-way valve on the radiator.

Recommendations for selection and installation

When choosing a room thermostat model for a gas boiler, you should be guided by the temperature limits of the device, the size of the room and the characteristics of the heating water heater.

If the renovations in the rooms have already been done, then it is worth choosing a wireless device. There is no need to lay wires for it. If the main concern is the desire to optimize the functioning of the entire heating system as much as possible, then there is no better option than a programmable thermostat. It allows you to more carefully control air temperature parameters and boiler operating modes.

When installing the regulator in question, you must ensure that the temperature sensors:

- They were located at a height of about 1.5 meters and on the internal walls;

- They were not covered by curtains, drapes and furniture;

- They were located at least a meter away from windows, doors and heating radiators.

Room-by-room installation

The air around the temperature sensors must circulate freely. Placing them in a closet or behind decor is unacceptable. Also, these sensors cannot be mounted on walls facing the street or near doors. This will result in incorrect readings due to drafts and greater cooling of the external envelope compared to internal partitions.

Ideally, you should purchase room thermostats from the same manufacturer that made your existing boiler. This makes it easier to connect and configure them, and they will work together with fewer failures and last longer.

To install such a regulator, you do not need to have any special skills in electrical engineering or thermal power engineering. Remote sensors are mounted on walls. And the wires are connected via terminals on the body. You just need to avoid mixing up the wires. In the instructions for boilers and these devices, connection diagrams are described in as much detail as possible. Such a programmable device is not cheap, but it pays for itself in just a couple of heating seasons.

Advantages of using a thermostat

The main advantages of temperature controllers are:

- The ability to maintain a comfortable temperature background in the living room;

- Saving energy resources used for various types of heating equipment: gas or electricity;

- Increasing the service life of heating equipment - the use of a thermostat significantly reduces the turn-on and operation time of the boiler, which extends its service life;

- Low cost and high payback;

- Easy to install and use.

Thus, room temperature controllers are very simple, convenient and reliable devices. Maintaining a comfortable temperature background in residential premises, they not only allow you to significantly save gas and electricity, but also increase the service life of expensive boilers and other heating equipment.

Types of thermostats for gas boilers

Thermostats can be divided into three main types: mechanical, electronic and electronic wireless.

Wired models cost less, but require cable laying - it is better to install a thermostat on a gas boiler before or during renovation work in the house. Wireless models are more expensive, more functional, and more convenient.

The selection of a thermostat for connection to a gas heating system is carried out taking into account the following basic criteria:

- functionality;

- adjustment accuracy;

- thermostat cost;

- ease of use and installation.

According to functionality they are distinguished:

- simple thermostats - help maintain the desired temperature in the house;

- wireless thermostats - have a transmitter unit that is placed in another room for more precise temperature control;

- programmable - allow you to set a stable temperature regime separately for day and night, program the operation of the heating system by day of the week, which significantly reduces fuel consumption;

- with hydrostat function - help control the humidity level in the room, reducing or increasing it according to the settings.

- With an additional floor sensor - the model is used, among other things, to regulate the temperature of the coolant in the “warm floor” system.

- With an additional water heating sensor - the device is used both to regulate the temperature of hot water supply and to control the heating system.

Separately, it is necessary to say about programmers - thermostats that are more complex in terms of functionality, which are installed, among other things, to control climate systems in so-called smart homes.

There are models of Wi-Fi thermostats with voice control. Such room regulators support several foreign languages and can be controlled using a smartphone. During a power outage, the memory function is activated, which saves the programmer settings

Programmers control the operation of not only heating and water heating equipment, but also air conditioners, pumps, and other devices. Some of them help to program individual temperature conditions for each day of the week with the ability to set from 1 to 6 fixed operating points.

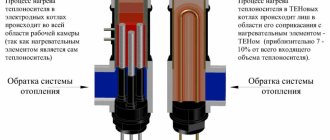

Device and principle of operation

Regardless of the design option, the thermostat device follows one general scheme and consists of 3 main modules or blocks:

- Primary temperature sensor equipped with a temperature-sensitive element;

- tuning module;

- control module.

The primary sensor determines the heating temperature of the controlled medium: air or water. When the temperature inside the measuring sensor changes, the physical parameters of the primary element change, which are transmitted to the control unit.

Important! The output signal into which the input quantity is converted can be non-electrical or electrical. Most primary sensors are electrical, operating on voltage or EMF.

After receiving the signal, the control unit processes and transmits it to the actuator, which will accordingly adjust the volume of energy carrier to heat the environment.

The following are used as actuators in heating systems:

- electromagnetic relays;

- valve of mechanical or electrical operating principle;

- digital/analog device for subsequent signal processing.

TP is capable of maintaining a certain temperature value or a set range. This indicator is affected by the hysteresis of the primary sensor.

In the retail chain today there are quite a few models of thermostats that can be equipped with additional functions, for example, starting heating using a timer and programming the device according to a given schedule. But the operation of all these devices is based on the above-mentioned principle of operation.