Before the onset of the heating season, each owner strives to prepare for the coming cold and low temperatures in his “fortress,” that is, in his home. Homeowners on the land rely on stoves and fireplaces. With proper care and operation, these structures can serve their owner for many years, while properly providing heat.

But in order for a stove or fireplace to operate smoothly and safely, you should delve into the topic and study directly the structure and those components that affect the operation of these heating systems.

First, let's look at what affects the proper operation of the fireplace . Everyone knows that the key to high-quality functioning of stoves is good traction. Poor, insufficient draft can lead to poor combustion of wood and a dangerous fire situation. In order to regulate the draft and prevent a fire, a damper is placed in the chimney, and we will look at what this is below.

A damper is a special damper that is placed in the chimney. This element is an integral and very important part of the channels that provide smoke removal. Roughly speaking, the presence of a damper determines the safe use of a stove or fireplace, since it guarantees the mandatory fire safety of the entire heating system in the house.

Main functions and characteristics of gate valve

For the heating system to function properly, good draft is necessary.

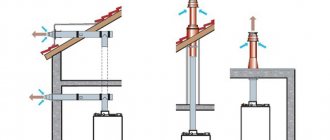

The gate valve is the main element of the chimney design with which you can regulate the movement of flue gases through the pipe. With a good level of thrust, 100% fuel combustion occurs. Lack of natural ventilation in the chimney can cause smoke in the room or fire. Therefore, a slide damper installed on top of the chimney ensures safe use of the entire heating system. Installation of such a device is carried out when heating with solid fuel or gas.

Traction adjustment is carried out using this method:

- increase – open gate valve;

- reduction – closed damper.

When the stove or fireplace stops operating, the damper closes completely. Install such a device at the beginning of the chimney. To ensure free operation of the valve, it is installed on an uninsulated section of pipe.

Different types of chimney valves

Slide dampers perform three main functions in the chimney system:

- traction level control;

- adjustment of combustion intensity;

- covering the chimney outlet.

The installation of dampers on the chimney is carried out only if the combustion process is carried out without the supply of supply air masses.

The design of gate valves depends on various indicators:

- pipe cross-section value;

- the temperature value of the flows passing through the chimney channel;

- type of heating device and outlet structure.

Gate valves are mainly made of stainless steel. This steel does not corrode and is highly durable. Stainless steel chimney dampers are resistant to chemical active formations inside the pipe and can withstand high temperatures - nine hundred degrees. They are produced with a thickness of 0.5 to 1 millimeter.

Stainless steel chimney valve

Sometimes dampers are used on chimney pipes made of cast iron alloy. The main quality of such a gate is strength and durability. But still, the material is inferior to stainless steel - due to their heavy weight, cast iron valves are installed only on brick chimneys.

When making a damper, the plate covering the chimney channel is carefully polished. The smooth surface of the product allows you to easily clean it from accumulated soot.

Features, characteristics and purpose of the gate

What is a gate valve? It is designed to control and regulate draft in the chimney system. From German, the word gate is translated as a part made of metal (the metal can be different). Any stove maker knows that good traction is the most important condition for the normal operation of the fuel system.

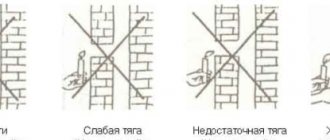

If there is not enough draft in the system, then oxygen, which is so important for combustion, does not get there. As a result, the process of ignition and combustion itself will be problematic. On the other hand, in the absence of draft, all the smoke will enter the room, which leads to negative consequences. But if the draft is good, and it is this that is provided by the rotary damper for the chimney, combustion will be effective:

- Firstly, it will be much easier to ignite the fuel.

- Secondly, the combustion process improves, the fuel burns quickly, bringing more and more heat into the room.

- Thirdly, smoke does not get inside, and the heating process is much better.

So, a gate valve allows you to improve draft and prevent negative consequences when burning solid fuel in a stove or fireplace. Experts advise installing this part when heating with any fuel, be it gas, coal or wood.

The gate valve itself is installed directly in the chimney. It is the main traction regulator, controlling the fuel combustion process. It should be clarified that too strong thrust is also not very acceptable, since the fuel will burn intensively and consumption will increase significantly. The valve works like this: to reduce the draft and reduce the intensity of combustion inside the firebox, you need to cover it. And if you need to increase traction, then the opposite action is performed. The process is performed mechanically with human participation.

A gate valve looks like a metal plate, thanks to which the chimney can be blocked or released. It is mounted for both single-wall and double-wall boiler systems.

Note! In the case when the fireplace and stove are not in use, it is necessary to close the gate valve for the entire period.

Typically, the chimney valve is installed near the stove, in the initial section of the chimney pipe. This is approximately 1 m from the stove. This way a person can easily reach it. In addition, this area is not insulated. Experts do not recommend installing the gate on an area that is well insulated. This is especially true for double-circuit pipes. Why? The thing is that under the influence of high temperature, the metal of the inner and outer pipes expands, and the valve itself often jams and does not protrude back.

To summarize, we can consider the main tasks that a gate valve performs:

- Able to regulate the draft in the chimney, reducing or increasing it.

- Partially covers the cross section of the chimney pipe.

- The gate serves as a regulator of the flame burning intensity in the furnace.

Although the gate is small and inconspicuous, you simply cannot do without it. However, you need to understand that in the case when the combustion process in the furnace is carried out with supply air, then it is not necessary to install a gate valve.

Now regarding the material used to make the gate. Most often, stainless steel is used for this purpose, the thickness of which is no more than 1 mm. A gate valve made of this metal of this thickness will be capable of:

- withstand temperatures reaching as much as 900 degrees Celsius;

- the gate valve is resistant to corrosion;

- has a small coefficient of thermal expansion.

To make the operation of the part and the chimney itself as simple as possible, and to avoid problems with cleaning soot, you should choose a gate valve with a polished surface. The joining of seams is done using the rolling method.

The note! A regular damper can cover up to 85% of the chimney cross-section. This is the best option to effectively remove combustion products and ensure proper fuel combustion.

How does a solid fuel wood boiler work?

The boiler works as follows:

- As a result of the combustion of wood in the firebox, a certain amount of heat is released, different for different species.

- The heat is used to heat the water tank located above the firebox.

- Water circulates through a pipeline from the tank to the heating radiators and back in a closed circuit. Circulation can be either natural (when the pipes are located at a slight slope) or forced, through a circulation pump.

- Combustion products are discharged through a chimney to the street. In order for the draft to be normal, the vertical part of the chimney is made three or more meters high.

- The combustion intensity is regulated using the firebox and chimney dampers.

The heating unit is equipped with a safety system for emergency pressure relief in case of overheating. If this is not done, the boiler becomes dangerous to operate.

Advantages of gate valves

Gate valves, which make up a significant part of the range of many manufacturers of pipeline fittings, have a number of advantages, the most significant of which are given below in the form of short abstracts.

- Gate valves have a short overall length, for example, compared to cranes.

- The design of a gate valve is relatively simple, which, on the one hand, determines its ease of installation (for example, the possibility of replacement without cutting into a pipeline) and ease of operation, and on the other hand, reliability.

- Reliability indicators largely depend on the parameters of the working environment ─ its aggressiveness, temperature, concentration of mechanical impurities.

- Gate valves are unpretentious and not capricious equipment; their maintenance and repair do not require very highly qualified personnel.

- Gate valves from the best manufacturers, who use high-quality components and modern materials in their manufacture, have such important properties as durability, resistance to wear and exposure to aggressive environments.

- The service life of gate valves can be measured at three or more decades, determined by the service life of the body. For other components it is smaller, but also very impressive. For example, for rubber products - at least 5 years. The same is the average service life between major repairs of a gate valve.

- The absence of stagnant zones and the ability to self-clean allow you not to think about slag and dirt.

- An important parameter is the minimum hydraulic resistance of the medium. For example, gate valves manufactured by ARMATEK have a coefficient of hydraulic resistance of no more than 0.3 when the blade is fully open.

- Gate valves have unique technical capabilities, including fast operation and high tightness. Including tightness of the highest class A according to GOST R 54808-2011. Pipeline fittings. Standards for tightness of valves."

Technical parameters and a wide range of functionality ─ a range of sizes, pressures and temperatures that meet all needs ─ make gate valves truly universal pipeline fittings, in demand in a wide variety of technology areas.

Purpose and types of these devices

The chimney valve, or, as it is also called, a damper, is designed to regulate the draft in the chimney. The operation is performed as follows. During combustion, the valve closes a certain section of the chimney channel. By reducing or, conversely, increasing the damper area, you can control the air flow in the chimney and, accordingly, the flame strength in the heating device and draft. After the combustion process stops, the valve closes so that air currents do not carry away heat from the room. However, even in this state, the damper should not completely block the chimney: this is contrary to safety standards. The systems must be installed on almost all types of heating devices except the latest models, where the draft is adjusted automatically using a deflector.

In their shape, chimney valves must very accurately reproduce the cross-section of the pipe. There are two different design options for gate valves:

Retractable. The simplest and most reliable design. Moves only in the horizontal direction. It is most often installed in steel or brick chimneys. It is a smooth plate with holes that easily moves in the guide grooves.

Rotary or throttle.

The device rotates around its axis, as a result of which it can open or close the smoke channel. Installed in cases where the retractable damper cannot be used for various reasons.

Retractable option. During the combustion process, the gate valve opens. The ability to regulate the overlap area of the smoke channel allows you to adjust the draft. After the fire goes out, the damper closes

The throttle gate valve rotates around its axis, closing or, conversely, opening the smoke channel. Installed in cases where the use of a retractable damper is not possible

The required system option is selected based on the design features of the chimney. In addition to the type of device, the material also plays an important role. Most often used:

- Cast iron. It produces very strong, reliable and durable products. Traditionally used to make devices. The main disadvantage is their heavy weight, so such valves can only be installed on brick pipes.

- Stainless steel. Lightweight, durable and corrosion-resistant material. It does not affect the heat transfer of the heating device, therefore it allows you to achieve maximum efficiency of the stove. Steel gates are usually polished to provide a smooth surface that prevents soot from settling. Installed on any pipes.

Do I need a damper for a chimney? Two cases when you don’t even need to think about it

The gate can have 3 options for use:

Let's look at each of them in order.

It is still better to regulate combustion in a stove by supplying air to the stove. On the one hand, of course, restriction in air affects the quality of combustion itself, but with excessive restriction of thrust, nothing good happens either, and the extreme stage of this is smoldering, which is of little use at all. Therefore, if there is no excessive draft and the furnace can be adjusted using the air supply, then a damper is not needed here!

And now I want to give an example when you don’t even need to think about buying a gate!

As for me, I don’t use built-in dampers, because... I have no problems with excess draft.

That is, at the present time, some manufacturers have begun to decide the question of “whether a gate is needed” for the buyer and simply equip their products with it.

DIY installation

There are three installation methods:

- The damper is installed in the fireplace insert itself. The gate valve is installed at a distance of one meter from the heating device, which makes it easy to control the gate valve.

- The second way to install a slide damper is to combine it with other parts of the heating structure without the additional use of fasteners. This installation option is also called “pipe to pipe”.

- The third way to install a damper is to install it in ventilation pipes. In this case, a gate valve is used to prevent the fan motor from overheating when it is turned on.

Please note: the installation procedure must be carried out with the gate installation closed, and not open, in order to avoid excess pressure on the engine.

These main three methods of installing a slide damper are constantly used in the construction of chimneys or ventilation.

For example, a stove with gas heating requires a classic butterfly valve (rotary damper) or sometimes an automatic rotary damper, since it completely blocks the chimney, thanks to which the flame will not come out.

But it is not recommended to install rotary dampers when building a sauna stove, because it will allow steam to pass through when closed, and when open, the rotary damper is very difficult to clean.

In most cases, the damper is sold together with the chimney as a complete set. But there are chimneys without it, so you can make a damper yourself by purchasing its components at various construction stores.

Please note: It is important to determine the required dimensions before purchasing. It is best to buy gate valves made of steel material

The main part of the gate installation is the shell. The gate consists of several shells.

Features of wood burning

To ensure high-quality heating, you need to know how to heat a solid fuel boiler with wood efficiently and economically. For kindling, chips are laid down, on top of which you need to place 3-5 firewood with a diameter of up to 15 cm. It is recommended to lay crumpled paper between the chips so that the wood flares up faster.

After the first fire has ignited, the firebox is filled with large firewood. To achieve the most complete and efficient burning of wood, you can place 1-2 large logs in the firebox at intervals of 30-40 minutes. In addition, this method will help reduce firewood consumption.

When the firebox is completely filled with large firewood, an ordinary modern solid fuel boiler is capable of maintaining fairly intense combustion for 3-4 hours. Long-burning boilers operate on one burner even longer. It is generally not recommended to burn such models with small wood, which does not burn completely due to increased gas emission. The optimal size of logs in diameter is 15-30 cm.

If you figure out how to properly heat a TT boiler, then the choice of firewood is of great importance. Wood moisture content should not be higher than 20%, otherwise the efficiency of the equipment will be lost. In some cases, to increase the burning time, damp wood is specially placed in the firebox, which takes longer to burn. However, it must be taken into account that this leads to increased release of tar, which settles on the walls of the firebox and on the chimney, and this causes deterioration in draft. As a result, the boiler has to be cleaned more often. In order for firewood to have an optimal level of humidity, it must be dried under a canopy for approximately 1.5-2 years before use.

If you want to increase the burning time of one bookmark, then you should not use damp firewood, but set the correct position of the gate valve and thermostat. These provisions for each TT boiler model are determined experimentally.

Tips for choosing a gate valve

It must be remembered that the correct selection of an element such as a slide damper is reflected in the future not only on the draft indicator, but also on the safety of the heating system, of which the chimney is a part. Installation of the damper is carried out on any model of fireplaces and stoves, except for the most modern ones, which have a deflector.

The main recommendations for choosing slide valves for smoke exhaust communications are as follows:

- If the heating device operates by processing gas, it is better to purchase a rotary valve model. This is due to the fact that such models exclude the possibility of completely blocking the smoke exhaust channel. Thus, the heating system will be safer. The chimney, which removes combustion products from the gas stove, must be closed by at least 40 percent during operation;

- There are heating systems that operate intermittently (periodic). A closed damper installed in such a heating structure, as a rule, allows steam to pass during supply, and an open damper contributes to the formation of a large amount of soot on the pipe, which is located below the plate;

- It is strictly not recommended to use rotating elements for installation in sauna chimneys.

A rotating device is the most suitable option for a gas-consuming system

There are 3 options for placing the damper relative to the chimney:

- Placement in the firebox of a fireplace or stove;

- Fastening according to the “pipe to pipe” principle;

- Installation in a ventilation pipe.

Let's consider the first 2 options:

By placing the valve in the furnace firebox or in the outlet pipe

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, you should install the valve strictly according to the manufacturer’s instructions.

Adjusting the draft using a slider is quite simple. By changing the position towards increasing the gap, we increase the flow of air to the fire and the flame flares up stronger. Reduce the gap - traction decreases. The valve is closed after the flame has completely died out - this way the oven cools down much faster.

Why a solid fuel boiler is an economical solution

The choice of device is primarily correct for residents of dachas and cottages not connected to centralized heating. Even if such a connection is present, this unit will help to significantly save on gas bills; solid fuel is widely available and has a low price.

On the modern market you can find suitable equipment for planning a house of any complexity, even with a fairly large area. Having studied the above recommendations on how to use and maintain the boiler, these actions will take a minimum of time.

It would seem, what does it mean to “properly” heat a boiler with wood? What's so complicated about it, throw your firewood into the firebox before the coals cool down, and the whole process. It turns out that it's not that simple. How efficiently a boiler operates does not primarily depend on its design. First of all, the result of its work, as well as its efficiency, depends on the quality of the fuel used. Not only the type of wood is important, but also whether it is dry or damp, and the condition of the valves and chokes. The nuances of operating solid fuel boilers will be discussed in the article.

Creating a rotary gate

First, let's find out how to make the most complex version of the gate. Detailed instructions will help you get the job done quickly. We will learn how to make a valve when the stove heating has already been done, however, a gate was not provided for in it.

To make a gate, you will need the following tools:

- electric drill;

- grinder with a circle for metal;

- a tap that is needed for cutting internal threads in a hole;

- oil that needs to be used to lubricate the tap when forming the thread;

- hammer;

- welding machine and electrodes for working with stainless steel;

- vice;

- pliers;

- compass and tape measure;

- core;

- permanent marker.

The list of materials for creating a gate valve is as follows:

- stainless steel sheet, the thickness of which is from 1.5 to 2 mm;

- stainless steel tube with an internal diameter of 6 mm;

- 2 bolts, 8 mm in diameter;

- a weaving nail or a metal rod.

If you have everything you need, you can start working on creating a gate:

- First you need to measure the internal diameter of the chimney pipe. Write down these indicators. After that, a circle of the same diameter is marked on a stainless steel sheet, only 1–2 mm smaller, so that the plate can rotate freely.

- After this, the intended circle is cut out with a grinder. You need to do everything carefully so that the edges are even.

- The cut valve should fit perfectly into the chimney. To do this you need to try it on. If necessary, the plate is protected, ground and brought to the required size.

- Now you need to take a stainless steel tube prepared in advance (6 mm in diameter) and attach it to the cut out circle. It is measured with a marker according to the size of the valve. On each side it is made 3 mm smaller than the internal diameter.

- The tube is cut using a grinder. The internal hole is drilled out for threading. When drilling, it is necessary to periodically lubricate the surface of the tube inside with machine oil.

- An 8 mm thread is cut on both sides of the tube using a tap. During operation, the tool is constantly lubricated. To remove the cutting chips, after each half turn along the thread, you need to make a half turn back so that the chips come out.

- Next, three small holes are made in the valve. Make three marks in advance using a marker.

- The tube and valve are clamped in the clamp, after which it is welded to the plate through these holes. Welding begins from the central hole of the future gate valve, then one clamp is released and welded into the remaining hole.

- Two holes are marked on the chimney pipe. They must match on both sides so that the tube can pass through them freely. To do this correctly, you need to wrap the pipe with a tape measure and measure the center vertically and horizontally. All that remains is to drill these holes.

- The valve is assembled in a tube.

- Now we need to make a template for the clamp of our gate valve.

- The markings are transferred to a stainless steel sheet. A compass is used for this purpose.

- The middle for the holes of the retainer is marked, everything is cut out and drilled according to the markings.

- All that remains is to weld the finished clamp to the pipe.

That's all, the chimney damper is ready. Although this option is more complicated, with visual instructions and suitable photos everything becomes easier.

What is a gate and why is it needed?

Let's start with the definition. A damper is an adjustable, metal damper in a chimney that blocks the chimney channel. This is necessary in order to change the intensity of combustion and reduce the flow rate of flue gases. In addition, the damper prevents air from being drawn out of your home through the chimney, and also, on the contrary, does not allow external air flows to penetrate into the house. However, when the damper does not work effectively, it threatens with two problems at once: an unpleasant odor that will penetrate from the chimney into the house and high utility costs.

Typically, the chimney damper is located just above the fireplace at the entrance to the chimney. It forms a seal that prevents air flow. However, due to constant exposure to heat and moisture, the gate can become deformed, becoming a completely ineffective and useless device. But how do you know what condition your gate is in? This is quite easy to do, all you need is any bill, for example 20 hryvnia or one dollar. To find out how tightly the damper in your fireplace fits, leave a bill between the damper plates and close it tightly. Now try to get the money out. If the bill slides out easily, the slide is definitely letting a lot of air through.

If you don't want to use money for an experiment, there is another effective way. For this you only need matches. Light it in the fireplace and extinguish it immediately. Take a close look at where the smoke from the match goes; if it goes up the chimney, it's a sign that you're losing a lot of heat.

It is known that fireplace dampers remain open most of the time, which means that heated air from the house is constantly escaping through the pipe to the street. Because of this, heating costs increase by at least 30%. Therefore, do not forget to close the damper after the fire goes out. Another problem is partially closed dampers while the fireplace is operating. This should not be done; the damper must be open so that the fire receives enough air for clean combustion.

How long does it take to heat a brick oven?

It’s better to heat it 2 times a day, in the morning at 10 o’clock, or a little earlier, depending on what time you wake up, and in the evening before bed, about 10-11 pm. But again, there may be nuances, if there is severe frost outside, the house is large and poorly insulated, then the amount of kindling for the stove can be increased up to 3 or even more times.

Interesting materials:

How many elementary particles are in an atom? How much energy does a matter generator need? How much energy does a laptop use? How much is 200 grams of butter? How much is 360 grams of flour? How many branches of Sberbank are there in Moscow? How many photos does 8GB hold? How many geometric figures are polygons? How many grams of ready-made oatmeal are in a glass? How many grams of nuts?

Adjustment

When operating heating units, an important aspect is the correct adjustment of the traction force, which affects the efficient operation and safety of the heating system. The sliding element, even with full penetration into the chimney channel, does not completely protect the bathhouse from the penetration of carbon monoxide. Closing is carried out after the end of the firebox, the firewood should have time to burn out and become covered with an ash layer.

If this is not followed, there is a risk of inhaling harmful gaseous substances. As carbon monoxide leaks out, it fills the room. It should be remembered that installing draft control devices (vane, deflector, weather vane) does not exempt you from regular cleaning of the pipe. If equipment is not cleared of soot in time, unpleasant consequences cannot be avoided.

It is necessary to carefully monitor the condition of the chimney structure and the presence of sufficient draft force.

To control traction, a formula has been developed for calculating the optimal value for the gate element, which is called the “alpha” coefficient. When setting the required value, uniform combustion of wood materials is ensured with minimal ash formation.

Selecting a location option

There are several ways to install a gate, each of which has both pros and cons. An important factor is what the chimney is made of. But modern masters prefer to use the three most common options:

- Installation in a fireplace insert.

- Fastening using the “pipe in pipe” method.

- Installation in a ventilation system.

The damper can be installed in the ventilation system

If the master has chosen the “pipe-to-pipe” installation type, then he will not need to use special fasteners to securely fix the damper with the fireplace elements. The location of the damper in the ventilation system completely eliminates the possibility of overheating of the fan motor during active operation.

Modern manufacturers offer ready-to-install chimneys that are equipped with all the necessary devices (the slide damper is no exception). In this case, the part must be used in strict accordance with the recommendations established by the manufacturer. Otherwise, you can make a chimney damper with your own hands and at a more affordable price.

There are three main options for placing the damper in the chimney:

- pipe-to-pipe fastening;

- placement in a fireplace insert;

- installation in a ventilation pipe.

Brick chimney with damper

If you place a gate valve in the outlet pipe or in the furnace firebox, that is, build this element into its design, the damper is placed on a section of pipe as close as possible to the heating boiler. This guarantees ease of control and ease of turning the valve. This is explained by the fact that the handle will not touch either the portal or the cladding area. If it is located according to the “pipe to pipe” option, no additional fastenings are required for connection with other elements of the furnace.

Typically, ready-to-install chimneys are offered, which are equipped with everything necessary, including a slide valve. In this case, it is placed in the system in accordance with the manufacturer's instructions. If it is not provided for one reason or another, it is quite possible to manufacture and install this element yourself.

Deflector for the chimney pipe (with photo)

To eliminate backdraft in the chimney, it is recommended to use a deflector.

>

Look at the photo: the chimney deflector is a mechanical fan that sucks smoke from the chimney shaft.

It is also necessary to look at how the gate is located - a special valve with which the draft is controlled. One damper should be located in the chimney duct, and the second, as a rule, is located either in the stove or in its door. You can try changing their position.

Modern deflectors for stoves are:

with a flat top;

equipped with an opening lid;

having a gable roof with two slopes on the pipe;

with a semicircular top.

Deflectors with a flat copper top are often located in Art Nouveau style baths.

Basically, sheets of galvanized iron are used to make deflectors, although recently you can often find deflectors on sale in which the metal is coated with enamel or even a layer of plastic.

Some models of deflectors must be inserted with the door facing the smoke collector. To do this, you need to place one edge on the wall, carefully lift the second and lower it into place. For ease of installation, the plates should be removed from the rear and side walls.

You can choose a model in a store, or you can easily make a chimney deflector yourself. Before making a deflector for a pipe, read the detailed description of the stages of work.

Before you begin directly making the deflector, you need to decide on the material from which it will be made. It can be copper, galvanized iron or stainless steel. Despite the fact that copper is a fairly expensive material, it is better to opt for this metal, as it is resistant to atmospheric conditions. This is due to the fact that the deflector is located in one of the most inaccessible places in the bathhouse, and frequent repairs will be problematic.

Before making the deflector, it is necessary to draw on cardboard a development of all the main parts, including the cap, diffuser and outer cylinder. Then you should transfer everything to metal and cut according to these patterns using special scissors. Next, you need to connect the parts to each other using rivets, bolts or welding. From a strip of metal you need to make brackets with which the cap will be fixed to the surface. A reverse cone should be attached to the cap. Having assembled the deflector onto the chimney pipe, you can proceed to installing it on the roof. First you need to fix the lower cylinder using bolts and nuts. Using clamps, you need to secure the diffuser to the lower cylinder, and install a cap with a reverse cone on it.

How to make a stove valve with your own hands?

Do-it-yourself stove chimney valve is not a problem. At home, having a grinder, a welding machine and the necessary material, you can assemble both a retractable and a throttle gate

It is very important in such a matter to maintain the accuracy of calculations. It is necessary that the valve fits perfectly into the groove and can move there freely

Retractable gate

There is nothing complicated here. The retractable gate is a retractable frame and the base itself.

- The chimney damper for a stove with a sliding frame requires the most accurate measurements. First you need to calculate the cross section inside the pipe.

- Next, based on these measurements, a frame is cut out (most often a steel sheet is taken) that will extend. A bend is made at its end for more convenient control. All ends should be carefully cleaned so that there are no unnecessary irregularities.

- Depending on the chimney, a steel sheet, strip or wire is used for the frame. But there is a method for a round chimney. Use two identical sheets of metal (thickness - 2 mm) and cut two holes in the middle according to the diameter of the pipe. The plate that will fit into the frame is cut out separately.

- Next, you need to weld the structure so that the holes for the pipe match. Between the sheets you need to leave 4-6 mm of free space.

Video instructions for making a retractable stove valve for a metal chimney:

Manufacturing of a rotary gate

For a rotary valve you will need a steel angle (30 by 30) and sheet steel 2 meters thick.

- First, measure the chimney and make a frame from the corner using these measurements.

- We cut out the part according to the measurements and try it on the pipe.

- We take a piece of pipe with internal thread and place it in the center of the workpiece. We make marks so that the edges of the pipe are 3 mm shorter than the valve itself.

- Cut off all excess.

- We make 3 holes on the valve blank and weld the pipe to them.

- The structure is ready (the installation process is described below (after the brick version).

A homemade valve in a chimney has a right to exist. The only thing is that this matter can take a lot of time due to the number of precise measurements.

Useful video instructions for making a rotary gate:

How to choose a gate?

Install gate valves on stoves and fireplaces. The exception is models with adjustable control of supply air, equipped with a deflector. For a gas stove, a rotary damper is better suited, which eliminates the possibility of completely closing the chimney and preventing the flame from escaping through the ash pan.

Helpful advice! If you choose a damper, you must constantly ensure that the gap is at least 30% of the cross-sectional area of the stove chimney.

It is not recommended to install rotary dampers on sauna stoves with periodic operation, since the damper allows steam to pass through even when closed. Sometimes the damper is sold with a chimney and is its element. If it is not provided by the manufacturer, it can be purchased at a specialized store.

Most consumers prefer to use factory-made ready-made dampers, which can be matched to any chimney design. Some bathhouse attendants make a rotary or retractable valve in the bathhouse with their own hands, which does not require special skills.

Gate valve installation

Installation of any type of damper is carried out at the first stages of installing a heating system. Installing the structure on a chimney pipe is not at all difficult. This can be done in three ways:

- Near the fireplace. The device is connected to the chimney pipe at a distance of one meter from the heating devices. This convenient installation of the damper allows you to easily monitor the operation of the gate.

- "Pipe to pipe." This method involves attaching a slide damper to a chimney pipe without the use of additional clamps. The valve is held securely due to its tight connection to the chimney pipe.

- In the ventilation duct. This installation option is mainly used to cool the fan motor.

When constructing stoves and fireplaces, the damper is most often installed using the first method. Gate valves are used for both round and square chimney pipes. Products with a rotating plate are most often installed in chimneys with a cross-section in the form of a circle.

Installing a damper in a brick oven

The gate valve is quite often used for brick kilns. It is installed during the construction of the chimney. Place the valve on the first meter of the pipe. This arrangement of the gate makes it easy to adjust the draft. To install such a gate you need:

- two rows of chimney bricks are laid;

- in the second row an opening of the required size is cut;

- a damper is installed;

- in any brick of the same row a recess is made for a rotary handle;

Next, the next rows are laid

In this case, you should pay attention to the tightness of the fit to the place where the gate is installed. All cracks should be sealed with mortar.

When using such a damper, all safety precautions must be taken into account.

During operation of the furnace, under no circumstances should the gate valve be closed. This action will lead to carbon monoxide entering the room. Some models have a special fixing element that prevents the pipe opening from being completely closed. Date: September 25, 2022

How to heat a solid fuel boiler with wood

Before you start heating, you need to properly make the kindling, but if you ignore it, smoke may begin to seep into your home. Different types of wood are better suited for different stages of the process; the size of the wood also matters in this case.

Which firewood to choose

It is recommended to burn with well-dried wood, and its varieties are worth dwelling on separately.

Birch gives a lot of heat, burns for a long time, but during the combustion process it leaves a large amount of tar on the walls of the chimney.

Alder produces one and a half times less heat than birch, but leaves virtually no soot. Well suited for kindling as it ignites easily.

Aspen also does not produce soot and produces little heat; it is also advisable to use it as kindling.

Pine burns hot, but contains a lot of resin and produces a large amount of soot. Spruce firewood burns hotter than pine firewood, while producing less soot.

Poplar, releasing a lot of heat, burns out very quickly.

Apple and pear produce a lot of heat, good coals, but knotty and difficult to prick.

Oak, ash and beech are dense and hard, and are difficult to chip. When burned, they release a lot of heat and produce little soot. Rarely found on sale.

Taking into account the above properties, firewood is selected both for kindling and for directly heating the boiler.

Correct sequence of actions

The process begins with cleaning the ash pan and subsequent kindling.

This stage can take about an hour. The purpose of kindling is to warm up the firebox and chimney to create sufficient draft. The complexity and duration of the process is determined by the shape of the chimney and the presence of horizontal sections in it. Crumpled paper, bark, and small wood chips are used as kindling. Then thin logs are placed. After they are ignited, add wood little by little until the firebox is half loaded. The vent and chimney dampers are opened wide during the kindling process to ensure good air flow. It is also recommended to open the windows in the room to increase the flow of fresh air. After the flame burns well, close the dampers halfway. After sufficient heating, full fillings begin, and the rate of their burning is determined by the type of wood and the position of the dampers.

To automate the adjustment process, thermostatic draft regulators and fans with controllers equipped with a temperature sensor are used. These devices can significantly simplify temperature control and increase boiler efficiency.