- Conditions for normal traction

- Decorative

A classic method of heating rooms, which has been used since ancient times. In this article we will look at the standard dimensions and drawings of a fireplace stove for a room in a private house. We hope that this information will help you avoid design errors and save time and nerves.

Range of wood burning fireboxes from Saga. Fireplaces

Inexpensive fireboxes

Wood burning stove Cheminees Diffusion A 1 - French firebox with a power of 14 kW, weight 82 kg, dimensions (WxHxD) - 690x696x351 mm.

The Cheminees Diffusion A 2.2 Etanche firebox is a cast iron firebox with a power of 12 kW, the same dimensions as the previous model, without raising the glass.

Wood-burning firebox Cheminees Philippe B 1-2 with a damper - cast iron assembly body, the presence of a rotary damper to increase the fuel burning time, power 12 kW, weight 112 kg, WxHxD - 695x770x415 mm.

Wood burning firebox Cheminees Diffusion C 6 is a firebox with a nominal power of 15 kW, WxHxD - 770x880x504 mm, weight 143 kg, with the function of adjusting the combustion air supply and a flame cutter-deflector to increase the efficiency of the fireplace.

Cheminees Diffusion B 5-2 firebox with turbine - cast iron firebox with a nominal power of 10 kW, equipped with a retractable ash box, side-opening glass with a self-cleaning function, 2 two-speed fans and 2 nozzles for forced convection. Supports long burning mode.

Compliance with the exact dimensions of the fireplace is the key to its reliability. Despite the variety of appearance, purchased products have standardized sizes. For high-quality combustion and output of the derivative of the process, an oxygen influx is necessary. At the same time, its quantity should ensure that smoke is removed from the firebox exclusively into the chimney.

Calculation example

To understand the calculation method, it is worth considering it with an example - this will allow you to later calculate how many bricks are needed for a stove, but for an individual project. Regardless of the perimeter of the stove, its first row is still laid out completely - for example, 4x4 bricks, i.e. for a monolithic first row you will need 32 bricks.

To continue calculating the bricks for the stove, you need to determine the number of rows, for which the height of the room must be known. A standard single brick has a height of 65 mm, and the thickness of the seam between rows is 5 mm. As a result, it turns out that the total thickness of one row is 7 cm. With a room height of 2.8 m, 30 cm is subtracted from this value for the fire protection structure, and the calculated size of the stove is 2.5 m.

The resulting value must be divided by the thickness of one row, and in this case you get 36 rows. By multiplying the calculated number of bricks required to completely lay one row by the number of rows, the result is 1152 bricks. The design of the stove is one-third hollow, so 2/3 of the total number of bricks is calculated - and this is 768 bricks.

The next step to find out how many bricks are needed for the stove in the house is to calculate the number of bricks for the chimney. In a standard square pipe, each row consists of 6 bricks - and for a 4-meter pipe consisting of 57 rows, 342 bricks will be required. Here the calculation method is exactly the same as in the case of the main part of the furnace. Of course, this method is not suitable for determining the number of bricks in the case of round or rectangular chimneys.

When deciding how many bricks you need for a stove, you must take into account the number of bricks that will be used for cutting. This amount directly depends on the design of the stove, its location and the thickness of the wall, if the stove is built into it. For a single wall, the minimum groove width is 25 cm, so a single groove is laid out on each side of the oven. The total is 36 rows on both sides, or 144 bricks. If the stove is not adjacent to the wall, then cutting is only needed near the ceiling and roof elements. In this case, the number of bricks will vary from 30 to 50 pieces.

Where to start

First you need to decide on the location of the fireplace in the house. It is not advisable to place it opposite windows, as this will create drafts. The back wall of the fireplace can get very hot, so it is best to have it adjacent to the outside walls of the house. In wooden houses, in order to avoid fire, additional measures should be taken to eliminate this danger.

Calculation of dimensions should begin with the firebox.

They are determined as follows: the area of the room in which the fireplace is located relates to the area of the firebox as 1:50 - 1:70.

So, for a room of 20 square meters. m and a standard ceiling height (3 - 3.5 m), the area of the firebox portal will be 0.4 sq. m or 52 × 77 cm.

Similarly for a room of 15 square meters. m – 0.3 sq. m or 44 × 67 cm.

For a room of 10 sq. m – 0.2 sq. m or 36 × 45 cm.

The depth of the firebox should be from ½ to 2/3 of the height of the portal

It is important to follow this rule, otherwise it will have an unpleasant effect during the operation of the fireplace. A depth that is too small will lead to smoke, and a depth that is too deep will lead to loss of heat transfer. The dimensions of the chimney are determined by the dimensions of the firebox

Its area should be approximately 8–15 times smaller. If you plan to make a chimney from brick, the dimensions will be 14 × 14 and 14 × 27 cm. When using a stainless pipe - 8 - 14 cm. Standard chimney height - 4 - 5 m

The dimensions of the chimney are determined by the dimensions of the firebox. Its area should be approximately 8–15 times smaller. If you plan to make a chimney from brick, the dimensions will be 14 × 14 and 14 × 27 cm. When using a stainless pipe - 8 - 14 cm. The standard chimney height is 4 - 5 m.

The overall dimensions of the fireplace are determined based on brick standards: 6.5 × 12 × 25 cm. Taking into account the thickness of the seams, the height of one row of masonry will be 7 cm. The back wall can be made in half a brick - 12.5 cm. The side walls in one brick - 25 cm.

Together with an ordering diagram (a diagram where for each row the order of bricks in it is indicated), it will allow you to determine the number of bricks needed for the job. It is worth considering that ready-made diagrams with the amount of material already calculated count each half and three-quarters as a whole brick.

For beginners, in order to avoid unpleasant surprises, it is preferable to use ready-made ordering schemes. It must be remembered that, even strictly following such a scheme, the actual material consumption may differ from the declared one.

The type of fireplace also plays a role. So, for a corner fireplace measuring 1 × 1 meter, approximately 200 pieces will be needed. red brick and 100 pcs. fireproof. For a simple fireplace with dimensions of 65 × 115 cm, the number of red bricks is approximately 250 pieces, and fireclay - 100. For a traditional large English fireplace, you will already need 300 pieces. red and 130 fireclay.

Those. lay out the fireplace according to the ordering scheme without mortar, and then, after disassembling it, proceed to the real masonry. This will avoid mistakes without lengthening the process too much.

Furnace departments

Any stove, be it Russian, Dutch, Swedish or a sauna structure, consists of several main sections. For each of them, the material should be selected separately, since certain characteristics required specifically for a specific part of the hearth are important.

Foundation

The first step is to build the foundation. Since the structure is usually located on the ground floor, the proximity of the ground must be taken into account. Therefore, a concrete slab is usually laid as the first layer, below the floor level, and a layer of waterproofing is applied to it.

Thus, we get a layer that will withstand the mass of our future structure, and also will not allow moisture and cold that come from the soil to affect it. Solid brick rows are usually laid on top of the waterproofing layer; there can be from two to four.

This is the second part of our foundation. As a rule, clinker material is used for it. This is due to the fact that it has very high strength, it is not afraid of loads, so such a base will easily support the weight of the entire stove.

Firebox

Another section of the design that raises the most questions about the selection of material is the firebox. This is the very place where firewood is laid and where the fire is made. The bricks in the firebox are directly exposed to the flame for a long time, and this happens over many years. Therefore, appropriate requirements are imposed on them.

As a rule, fireclay blocks are used to lay out the firebox. They have the highest fire resistance of all possible options, so they quietly perform their functions throughout the entire life of the fireplace.

In principle, the entire structure can be assembled from fireclay. But this is very expensive. In addition, the firebox lined with cream-colored fireclay blocks looks very advantageous when surrounded by red brick blocks, so this solution is optimal from the point of view of not only functionality, but also design.

Chimney and pipe

The chimney does not come into direct contact with the fire and does not carry a particularly high load. However, it also has certain requirements.

Firstly, it is exposed from the inside to aggressive chemicals released during combustion.

They have a detrimental effect on the condition of the building material from which the inside of the chimney is lined, so special attention should be paid to the stability of these bricks in various destructive factors

Secondly, the part of the chimney that is located above the surface of the roof of the house - that is, the pipe - is also subject to attacks from the external environment. Rain and snow, frost, wind, sudden changes in air temperature - all this significantly undermines brick blocks.

Experienced craftsmen recommend using two different materials for this section of the oven. Clinker, as the most resistant to aggressive chemicals, is used for laying out the inner layer. And on the outside, ordinary ceramic bricks are perfect, as they withstand the effects of the external environment very well. It’s not for nothing that many different structures are erected from it, including residential buildings.

Types of bricks

The operation of a chimney made of refractory bricks is carried out in special conditions with temperature changes, so for its construction it is necessary to use building material of the best quality. The safety and reliability of the structure, the resistance of the structure to cracking and deformation, and reducing the risk of creating a fire hazard depend on the correct choice.

First class

Solid refractory bricks are made from high-quality clay by prolonged firing at high temperatures. The following signs are characteristic of it:

- Density of the consumable material, absence of porosity and foreign inclusions.

- Smooth and even surface without deformations, potholes, cracks and other visual defects.

- When tapped, a clear and pleasant sound appears.

- It has high frost resistance and strength.

- It has an attractive red color with a slight yellowish tint.

Second-rate

Brick is produced by insufficient firing of clay, so it is characterized by:

- Dull and short sound when tapped.

- Porosity and low density of the structure.

- The presence of various deformations and defects on the surface.

- A desaturated orange or ocher hue.

In addition, this material has low heat capacity, frost resistance and durability.

Third-rate

Third grade bricks are of low quality and have a burnt structure. They have the following features:

- Too high and ringing sound when tapping.

- Porous structure with low density.

- The presence of significant visual defects and flaws.

- Rich red and brown tint.

Burnt blocks are not able to withstand significant mechanical loads, and therefore are prone to cracking and deformation. In addition, they do not tolerate excessive heating and cooling.

For the construction of the chimney, first-grade building material grades M 150 and 200 are used.

We calculate the combustion hole

A stove, the masonry of which will be done by hand, must have the most accurate and detailed calculations of each structural element. To do this, first of all, we determine the overall dimensions of the firebox.

For example, if the room has an area of 30 square meters and the ceiling height is from 3 to 3.5 meters, then the fuel compartment will have a size of 0.6 square meters. For a space of 20 square meters, this parameter will be 0.4 or 52x77 centimeters. If the living room or bedroom has an area of 10 squares, the firebox will be equal to 0.2 squares or 36x45 centimeters.

It is equally important to take into account and correctly calculate such indicators as the height and depth of the fuel compartment. The depth of the fuel compartment will vary from one second to two thirds of the frame height

If this aspect is not observed, certain difficulties and malfunctions in the operation of this heating equipment may arise. If the selected depth is insufficient, the room may periodically become filled with smoke. If the depth is greater than the maximum indicator, this will negatively affect such an indicator as heat transfer.

To calculate the dimensions of the chimney, it is necessary to take the dimensions of the combustion opening as a basis. The chimney system must have an area that is 10 times smaller than the firebox. There are certain standards for a brick chimney, which are 140 by 140 or 140 by 270 millimeters. For stainless steel pipes, the hole diameter will average about 11 centimeters. In this case, the total height of the chimney system will be about five meters.

It is equally important to determine the dimensions of the entire oven. In this case, the size of the brick used for laying is taken as a basis (65x120x250 millimeters)

Also, when calculating, you should add such a parameter as the thickness of the seams. From this we conclude that one row will have a height of about 70-80 millimeters. The rear partition of the fireplace can be assembled not from a whole brick, but from 1/2 brick: 125 millimeters. The sidewalls must consist of solid elements: 250 millimeters.

The order of the furnace plays a key role and is the key to successful DIY construction work. Having made a drawing, you can first take into account all the nuances and subtleties of the construction, and, if necessary, make all the appropriate adjustments.

The laying of fireplaces, carried out by a beginner, should follow a ready-made diagram. However, even in this case, material consumption may vary. When purchasing, take bricks and building mixtures with a small margin!

Home stoves can have different consumption of materials, which is directly related to their type and the way they are located in the interior. For example, for a corner fireplace measuring one meter by one meter, it will take about 210 units of standard and 120 units of refractory brick. For a wall fireplace measuring 650 by 1150 millimeters, you will need 260 units of red and 120 heat-resistant bricks.

A fireplace, the dimensions of which are determined, will be guaranteed to meet your wishes, if you make sure that the calculations are correct. To do this, even experienced professionals initially lay several rows dry, that is, without masonry mortar.

Introduction

In books about stoves, descriptions or orders of stoves are often supplemented by an indication of their heat output, expressed in kilocalories. In stores, as a rule, the price tag of metal stoves indicates the power of the stove in kilowatts.

At the same time, it is quite difficult for most users to estimate these figures specifically, especially since many manufacturers are disingenuous and in the descriptions of their products (metal stoves) indicate quite fantastic parameters or simply do not say anything, which can lead to the use of an unsuitable model in a room with the specified area.

For example, they often claim that stoves are capable of heating areas of 100 square meters or more without any additional tricks. Which is basically impossible according to the laws of physics - natural convection.

Such a stove is enough to ensure that the temperature in this room is above zero, but the atmosphere in such a room can hardly be called comfortable.

Since the stove itself will have a zone of strong heating and there will be outright heat, but in the far corners the coolness will be clearly felt. And that's only half the story. Most likely, such differences will also be supplemented by condensation and dampness in the corners.

You can only get rid of these unpleasant phenomena by arranging forced air convection (fan), or by arranging forced transportation of heat directly to the problem areas of the room - in other words, by arranging a heat circuit with coolant circulation. That is, turn the stove into a boiler and heat the house with a water system.

Height adjustment

To adjust the height of the heating device, special bolts are used, which are installed on its legs, or using supports. To set the required distance from the bottom of the firebox of a brick structure to the floor, lay several rows of bricks. Basic requirements before placing the combustion chamber in height:

you need to ensure a distance to the floor of 300-400 mm; if there is a niche for firewood under the firebox, this distance may be greater; When calculating the placement of the bottom of the combustion chamber, please note that you need to take into account the design of the floor with all its components. Think about this when planning your heating system. Calculating the size of the fireplace

Fireplace size calculation

Photo

The photo shows an example of finishing a fireplace with facing bricks.

Types of figured bricks for the fireplace in the photo. The picture shows decorative bricks for the fireplace. Red solid ceramic brick for laying a fireplace in the picture.

The photo shows an example of finishing a fireplace with shaped bricks.

The picture shows fireclay heat-resistant or refractory bricks, which are used to build a fireplace insert.

Correct definition of parameters

A corner fireplace, the dimensions of which have already been calculated, can be made of any materials and have a certain lining of the hearth. Before making your choice, we recommend that you familiarize yourself with the following selection rules:

Criterias of choice

Detailed description

Decorative hearths

The dimensions of a corner fireplace largely depend on the type of hearth chosen for installation and the fuel used for its operation. If you are looking for a purely decorative solution or a firebox that will serve as an additional source of heating for a house or apartment, we recommend that you pay attention to fireplaces that operate using bioethanol or electricity.

Effective foci

Installation instructions for the finished model are always included in the basic package. The most effective fireplaces that can become the main source of heating in rooms are gas and classic wood-burning structures. If installing a gas boiler is possible both in a private and apartment building, then wood-burning fireboxes require a chimney, which is only possible in your own home. It should be noted that the installation of such installations is more complex, costly and time-consuming.

Budget materials

The chosen finish, materials for making the hearth and portal also play a big role. The most inexpensive and budget coatings are plasterboard, metal profiles, ceramic tiles, and decorative plaster. Due to their low cost, the design of portals, fireplaces or such cladding provides lower efficiency and efficiency.

Expensive coatings

The price of materials and coatings that form and provide the furnace with additional heat capacity, efficiency, and heat transfer is quite high. This category includes tiles, natural minerals, cast iron, steel

The distinctive features of the materials are practicality, durability, fire resistance, easy maintenance and environmental friendliness.

Interior decoration

Bio - fireplace.

Nowadays, fireplaces have become very popular; they are installed not only in private homes. Modern biofireplaces have made it possible to use this unit in ordinary apartments. But such structures are intended primarily for decorative purposes; today we want to talk about real ones that run on wood fuel, the installation of which requires the construction of a foundation.

It warms and dries

In a country house.

Regardless of what kind of fireplace is installed in the house, many perceive it as an attribute of room decoration and do not think about why this unit has been preserved almost unchanged from ancient times to the present day. But it is an excellent home ventilation device.

With its help, you can ventilate and dry the room, and this operation is performed in a very short time, during which more than one heating device will not be able to cope with this task. This unit is very good to use in rooms where there is no central, constant heating.

For example, by lighting a fireplace in a private house used for occasional residence, you will very quickly dry out and warm up the cottage. (See Stove-fireplace for a summer residence)

Size matters

But you need to understand that all these advantages are effective only if the sizes of fireplaces for your home are chosen correctly. It’s no secret that when arranging it, many care primarily about the appearance and location in the room. And only lastly do they pay attention to such an important fact as the size of the fireplace.

Today we’ll talk about how to correctly calculate a fireplace for your home and make a design drawing based on the existing tasks to ensure maximum efficiency.

Important aspects: what to consider?

Smooth under.

When you start designing a fireplace for your home, you need to make a drawing (See Drawings of corner fireplaces) and perform calculations based on the size of the room. Firewood can be burned either in a special metal basket or on a grate, or perhaps simply on the bottom of the firebox.

Grate.

Our regular readers know that for normal combustion, in addition to fuel, a sufficient supply of air is necessary.

- in the case when the fuel burns on a flat hearth and the dimensions of the fireplace inserts are the same, combustion on the grate will be much more efficient;

- in both cases the dimensions will be identical.

The fact is that the use of a grate provides additional air flow; in this case, you can reduce the size of the firebox without losing efficiency.

Double effect - warmth plus ventilation

Since we are talking about air supply and the possibility of taking it in different ways, we should add that in some cases air can be taken not only from the room in which the fireplace is located, but also from the next room or even from the basement.

This device allows you to achieve several positive aspects at the same time:

- By taking air from the basement, you will significantly increase its ventilation, which in itself is a good result.

- If air is taken from another room of the house, a vacuum is not created in the room where the fireplace is located, and its absence does not allow cold air from outside to enter the heated room. The effect is obvious - the room warms up very quickly with minimal fuel consumption.

- If you need to ventilate a heated room, simply shut off the external air intake. In this case, the air for combustion begins to come from the room where it is located, and the room is ventilated.

Video How to choose the optimal fireplace size

Having your own fireplace is a dream for many, but its realization requires high-quality preparation and thorough implementation. Installing a fireplace yourself is not recommended for smaller rooms, since living in such a place can be quite dangerous. But if you want to create a small hearth in a room with an area of more than 20 square meters, then this can be done.

The most optimal material for creating fireplaces is considered to be brickwork, but there is a simpler solution to this issue - an electric fireplace, which can perform not only decorative, but also practical functions. However, for a suburban building this option will be more expensive and not practical.

First you need to calculate the area of the fuel portal. For the most part, it is no more than 2 percent of the area of the room in which the fireplace is installed. If the area is 15%, then the size of the portal will be approximately 0.3 “square”.

Next you need to calculate the size of the fireplace.

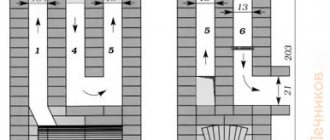

Elements of a brick fireplace

:A is the width of the portal; B - height of the portal; B is the depth of the firebox; 1 - chimney; 2 - mantel; 3 - portal; 4 - firebox; 5 - fireplace step; 6 - floor; 7 - under the fireplace;

The best proportion of height to width is considered to be two to three. The fireplace will be approximately 0.7x04, depending on what parameters the room has, whether you want to get a square-shaped fireplace or create a more elongated shape. Regarding the depth, it should not be very large or not very small. With a room size of 15 square meters, the most optimal solution would be a depth of 20-30 centimeters. More specific figures can only be obtained if you have information about the length and width of the room. To prevent heat from leaving the building completely, the chimney should be made approximately ten times smaller in relation to the area of the portal. Among other things, it is recommended to make the hole round.

Fireplace size chart

can build a high-quality corner fireplace that will work properly and look beautiful. But how can a beginner do all the work on his own

? In this article, I decided to touch on the important issues that stove makers encounter when building corner fireplaces.

This is the source of heat that we expect, even if the fireplace was built for purely aesthetic purposes. And before building a fireplace, the first thing we do is calculate all the necessary parameters of the fireplace: its size, depth, chimney height, cross-section of the smoke duct opening, firebox power, etc.

It is a mistake to think that if a fireplace is decorative, then you can use any one. A fireplace burns oxygen, and, for example, if you take a powerful fireplace for a small room, you can end up with problems with the fireplace and constantly open windows. The size of the hole for the chimney, its height and the material of the firebox and fireplace lining, the location of the fireplace and other factors play a role.

Selecting a location

When preparing for construction, the first thing you need to do is choose the optimal location. It is best to place the fireplace stove in the largest and most central room in the house. In this case, the area of the room must be at least 20 square meters. meters. It is best to install fireplace stoves near the interior walls of the room, which will provide excellent heating capabilities and simplify chimney maintenance.

When choosing the optimal location, you should take into account that installing a fireplace stove near windows or doors can lead to a fire or severe heat loss. However, when constructing a closed type structure, constant traction is ensured, which allows the structure to be installed in any convenient location.

Dimensions of decorative fireplace

The dimensions for which a corner fireplace is determined according to the area of the room for decorative installations can also be determined based on the following tips and recommendations:

The room chosen for installation and installation of the structure must have suitable dimensions. As a rule, the dimensions of the stove should not exceed one twenty-fifth of the living room;

- Since there is no real flame burning in the hearth of false fireplaces and the structure does not heat up, it is quite possible to make it not only an addition and decoration to the interior, but also add a certain functionality. To do this, equip the frame with various racks, tabletops or shelves on which you can place books, accessories and other necessary, useful little things;

- If you want to install a purchased electric or bio firebox into a decorative portal, all calculations are made according to the existing installation dimensions. If the portal is purchased, you can find its installation dimensions in the instruction manual included with the purchase. For home-made frames, all measurements are taken by hand; choosing a hearth of suitable size in this case is quite difficult and it is quite possible to make it only to order.

You can also view photos of corner fireplaces in various interiors in this article.

How to calculate the dimensions of the combustion chamber

- To calculate such a parameter as width, you will need to add up the width of the firebox itself and its side parts, as well as add up the frame consoles;

- To calculate the height, add up the height of the firewood, mantelpieces and other decorative elements;

Step by step work

In general, you need to start work with competent and thorough design. It is imperative to arrange your own foundation, this applies to both stoves, fireplaces, and any other similar structures, so be sure to take this into account.

Attention: It all starts with the correct marking and pouring of the foundation. It must withstand the weight of the structure and the larger dimensions of the front part.

Foundation

Corner brick fireplaces should stand rigidly and should not move. The foundation is made independent. That is, it is performed separately from the foundation of the room. To correctly calculate the concrete for the foundation, you can immediately do the calculation online. It's fast and accurate. First of all, we put marks on the dimensions; they should be 10 cm larger than the structure itself.

- We take a shovel and make a hole. For an average size fireplace, a depth of about 50-60 cm will be sufficient;

- Now we take crushed stone and pour it into the hole. All unnecessary stones from the site will do;

- Now we dilute the solution. Moreover, we make it liquid, everything should spill out and there should be no voids.

- We fill in the crushed stone and now begin to tamp.

- After this, we leave the foundation to dry, this will take about a week. It is better to cover it with a wet rag, then it will be much stronger.

- If the weight of the fireplace is large, then it will be necessary to make reinforcement. To do this, a metal grate is welded and placed in the pit. After this, backfilling and filling is done. Reinforcement will significantly strengthen the foundation.

- For the foundation, it is customary to use a proportion of sand and cement of 3/3 at M300. But it’s better to add more cement. Then the strength of the foundation will be higher and this will not be a hindrance.

Laying and preparing the foundation

If we talk about individual models, special attention should be paid to the Elba firebox. This insert is installed in a home-made or store-bought portal

The line of hearths is welded from high-quality thick-walled stainless steel. The pipe is made of cast iron, and the front part is complemented by large transparent tempered glass, which has self-cleaning properties.

The compartment in which fuel combustion occurs is assembled from fireclay refractory bricks. This in turn increases parameters and indicators such as heat transfer and design efficiency. Due to high-quality materials, the service life of such fireboxes is quite long, and use is simple and comfortable. Depending on your wishes, you can choose a fireplace of certain dimensions, shape, with a corner or classic wall arrangement in the interior of the house.

This video looks at laying a simple brick fireplace with your own hands in five days:

Most owners of private houses dream of installing a stylish, romantic and cozy piece of furniture - a fireplace, the size of which largely depends on what function it will perform - heating or decorative.

A living fire is fraught not only with beauty, but also with a high probability of a fire, so laying a fireplace must be preceded by careful calculation.

Classification by manufacturing method

The systematization of bricks is related to their large number. They are all made differently. Some options will initially not be able to perform certain functions. You should know all this so as not to do unnecessary work when selecting material.

- Sand-lime brick . to distinguish such a brick by appearance. He attracts the eye with his smooth features. The reason for this is that the brick is made from fine sand and lime. Under high pressure, the mass is pressed into a special shape. The resulting building material absorbs moisture and has a low degree of strength and thermal conductivity. It immediately becomes clear that such a brick will not find its use at any stage of fireplace construction.

- Hyperpressed brick. To prepare such bricks, screenings of limestone with the addition of cement are used. Using a certain technology, pressing occurs, as a result of which the strength of the material reaches high levels. But even under this condition, such a brick did not deserve the trust of craftsmen to be used for stove construction. The fact is that it cannot withstand the slightest deformation. If the fireplace begins to settle, the material will immediately collapse. The high density of hyper-pressed brick will lead to the fact that the mass of the fireplace will also become prohibitively large.

- Ceramic brick. Ceramic brick is already close in its performance to the material for fireplaces. It is based on clay, and all its characteristics depend on its breed and on the method of making bricks. In this matter, craftsmen have studied the properties of products from some manufacturers and know which brick to choose. However, they refrain from using this material to cover the hearth core.

- Fireclay brick. The need to use refractory bricks is dictated by high temperatures. The temperature inside the firebox exceeds 1000°C degrees. To finish the firebox, a special fireclay brick is used, which is made from clay with fire-resistant properties. To improve its characteristics, various impurities are added to the composition. As a result, the brick does not crumble even under mechanical stress. A distinctive feature is its flesh color. But it is not used for laying the entire furnace, since it is too expensive in terms of cost. They only finish the inside of the firebox and the beginning of the chimney.

Marking and preparing masonry

We spread roll insulation over the foundation. Its dimensions must correspond to the dimensions of the future fireplace.

- We make markings directly on the wall to which the stone structure will be attached. Next, we lay out the first row of bricks dry, taking into account the location of the fire-resistant elements.

- The main difference between fireplace masonry and conventional walls or other block structures is the preliminary dry masonry. It is needed to check the geometry of the available materials in order to prevent any deviations from the drawing. The sawing areas are not allowed to appear on the front or sides; they must be hidden under the solution.

- Heat-resistant bricks should be cut with a hacksaw or grinder with a diamond blade. To avoid confusion in the future, it is better to number each silicate element and its place.

or rustic unpretentiousness against the backdrop of modest charm

The etymology of the word “rustic” speaks of the most characteristic features of this style - deliberate “roughness”, “rudeness”, stylization for a rustic interior (this style is also called country). The desire of our ancestors to introduce an element of aesthetics into the arrangement of their primitive home gave rise to this architectural trend, which subsequently began to develop so widely and comprehensively.

Country style is characterized by natural details, components and materials, emphatically “rough” processing and an open shape of the hearth. The most suitable materials are: shell rock, sandstone, tuff stone, etc.

Peculiarities

The structural features of a classic fireplace suggest that air access is provided to the firebox through the fireplace window. Experts have calculated that the optimal traction force speed for a heating device of any size should be less than 0.25 m/sec. In practice, it is difficult to measure thrust speed. Until the fireplace is lit, its presence can be determined by the vibrations of the flame of a lit paper sheet. The user of a fireplace can only verify the adequacy of the traction force in practice.

Its presence or absence is also influenced by such external parameters as:

- indoor and outdoor temperatures;

- chimney condition;

- type, volume and dryness of fuel.

The main condition for the serviceability of the fireplace is to comply with the basic parameters and their relationships in the design of the heating unit. Optimal parameters of the heating design will allow you to organize high-performance operation of the device. An ideal result can be achieved if the basic requirements are met.

To avoid any violations in the device, the fireplace must meet the following tasks:

- provide warmth;

- remove smoke from the room;

- ensure the correct amount of air in the combustion chamber.

The standardization of dimensions mentioned above does not lead to the same appearance of all devices. Among all the device parameters, there are some that really affect its performance.

Certain dimensions must be implemented in projects exactly. These include:

- linear dimensions of the combustion opening;

- chimney dimensions;

- distance from the floor to the first edge of the window;

- tooth location;

- parameters of the pipe width in the area where the tooth is located.

Other parameters do not affect the operation of the device, but only determine the difference between the devices. The dimensions of the portal are often associated with the dimensions of the combustion chamber. They are associated with certain location parameters.

There is no absolute value:

The dimensions of the device are closely related to the volume of the heated room. When implementing your own project, try using the table below. It specifies the conditions for normal operation of the device. Masters use similar tables.

The data presented in the table is formed from certain values. The starting point of calculation for creating a fireplace is always the area of the room. In accordance with this value, the size of the fireplace combustion window is determined. To do this, the area of the room is divided by 50. Next, the dimensions of the furnace are determined by calculating the ratio of width and height. Calculations are expressed as a fractional value of 2/3.

With a buried combustion chamber, the gas removal rate increases.

This is bad, since the warmth in the room cannot be expected in such an outcome. With a shallow combustion chamber, good traction force will not be achieved. Combustion products will begin to enter the room. The depth of the combustion chamber must be related to the height of the windows. Two-thirds of the latter value are proportional sizes that have been verified over the years.

To make it clearer, we give an example of the calculated indicators of a fireplace for a living room with an area of 28 square meters. meters. First, 28 needs to be divided by 50, we get 0.56. These are the parameters of the combustion window. The area of the combustion hole will be 0.61x0.92=0.5612 sq. m., the depth of the fuel chamber is (610x2) /3 = 406.7 mm. The calculated figure can be rounded: you get a fuel chamber 40 cm deep.

In addition to the firebox, a standard fireplace includes a ventilation duct (chimney).

The dimensions of the ventilation duct openings are usually 1/8, 1/15 of the dimensions of the combustion box. In this case, the length of the chimney duct is taken into account. The permissible height is 10 meters. In this case, the design should not be too low. The most optimal height of the chimney structure is 4-5 m. The device is usually supplemented with knee bends.

The required height of the chimney is achieved with a specially laid foundation. Often the pedestal is not connected to the foundation of the house. It also serves as a safety platform for the fireplace. Therefore, it is often made to protrude several centimeters beyond the hearth.

The fuel chamber is placed on a pedestal made of non-combustible materials

, the height of which can be from 30 to 40 cm. An increase in the height of the pedestal is allowed by the structural features of the chimney. In some cases, a place under the pedestal is organized for storing firewood. Calculations of the position of the firebox, as well as the pedestal itself, include the characteristics of the flooring material.

Basic structural elements and requirements for them

An outdoor fireplace, built of brick, structurally consists of the following parts:

- The base of the firebox, which is a special platform made of refractory bricks. Designed for placing fuel on it and subsequent combustion. In solid fuel fireplaces, a grate is installed on it to remove burnt coals from the combustion chamber. The location of the fireplace grate above the foundation should be at a level of 8-10 cm. The area of the base of the firebox is at least 70% of the area of the firebox.

- The mouth of the fireplace is a decorative element located on the outside of the firebox. Its height should exceed the depth of the firebox up to 2 times.

- Smoke cornice - is a vault located above the open part of the firebox.

- A mantel is a shelf that is mounted above the chimney cornice and is used to place various decorations or objects on it. Performs a decorative role.

- The fireplace table is a protective base designed to protect the foundation from the effects of high temperatures in the firebox.

- A pre-furnace platform that performs a fire-fighting role. It is located in front of the firebox and is made of fire-resistant materials. Its dimensions must meet the following requirements: protrude forward by a distance of 50 cm, be wider than the portal by 25 cm in both directions.

- The firebox is a niche in the fireplace in which fuel burns. From its front part, thermal energy flows outside the structure for heating. It can be made in the form of various shapes: rectangular, arched, trapezoidal and others.

- Chimney - designed to remove smoke outside the fireplace.

- Smoke chamber with a valve - serves to accumulate thermal energy due to the accumulation of smoke, and the valve is used to regulate the draft and the fuel combustion process.

- Ash pan - for collecting ash and subsequent disposal without stopping fuel combustion.

- Convector is a hood over the fireplace that provides a transition from the chimney ducts to the chimney.

- Deflector – protection of the pipe under significant wind loads, preventing the occurrence of reverse draft.

- A spark arrester is a nozzle on a pipe, made in the form of a head, which is designed to catch sparks and increase fire safety. It is a steel mesh with cell sizes of 3x3 mm.

Features of fireplace masonry

Before starting the construction of such a useful invention as a fireplace, the dimensions of which were determined by us earlier, waterproofing should be provided. To do this, you will need roofing felt laid in 2 layers. Laying should start from the corners. In this case, you need to constantly monitor the level. To give the structure an original look, you can lay the bottom row on the edge, and all subsequent ones - flat. External continuous rows require the use of a trowel or trowel. The smoke collector or firebox should be done manually, as this helps to detect small pebbles in the solution.

It is important to remember that when constructing a smoke collector and firebox, a fireplace stove requires removing excess mortar with a damp cloth. We must not forget that the inner wall is not plastered

The seam must be thin, otherwise it can quickly crack. Modern fireplaces require half a brick of seams to be re-tied in each row.

The lining of the firebox and the outer wall should not be connected, otherwise, due to frequent temperature changes, damage to the masonry may occur.