Features of foil material

The modern market offers a great variety of insulation materials for residential buildings. Fibrous materials have also found the widest application. And with the use of foil, which “works” by reflecting heat from its mirror coating, such insulation has the highest performance.

This heat insulator, which has a foil coating, is directly related to combined insulation materials. Its base - the base - plus a thin layer of polished aluminum foil reflects almost one hundred percent of the heat, with the base layer only absorbing about three percent.

Such an improved insulator keeps heat in the room for a very long time without releasing it outside.

Types of reflective insulation

For owners who have started construction or renovation, it is not indifferent to the name of the insulation, on one side of which foil is glued, since not all varieties are interchangeable. It is equally important to understand how to properly install insulation with foil in order to minimize heat loss. There are several types of thermal insulators with foil on the market, with different thermal insulating material as a base.

Foamed polyethylene (polyethylene foam)

The material looks like an elastic fabric 2-10 mm thick, structurally consisting of closed-porous cells. Insulation is sold in rolls; some manufacturers supply it with a self-adhesive base; The reflective layer is aluminum foil.

Polyethylene foam with foil is suitable for thermal insulation of the floor, where it is placed under the final finish (for example, laminate). For heating radiators, thin varieties of fabric are chosen as a reflective screen. Elastic material is suitable for insulating water and sewerage pipes; it will keep the pipes from freezing and at the same time protect the owners from annoying noise.

Insulation made of foamed polyethylene Source of peace-comfort55.rf

Scope of application of foil insulation

The scope of application of foil insulation is quite wide, and the material itself belongs to combined insulation. By combining the base material and a layer of polished foil, reliable thermal insulation is provided for all kinds of structures.

This type of insulation is applicable to almost any surface; the type of material is simply selected according to its intended purpose for each object. Area of most frequent use:

- Pipeline lining. Equally applicable for hot and cold water pipes.

- Insulation of air ducts, ventilation shafts.

- Insulation of ceilings and the inside of the roof.

- Insulation of walls - both external and internal.

- Fits under linoleum.

The need to insulate heating pipes

Due to the high cost of energy resources, thermal energy must be used rationally, which means that only the rooms that require it should be heated. If uninsulated pipes pass through a non-residential area, such as an attic or basement, then heat is wasted for other purposes. This circumstance leads to a decrease in the performance of the heating system and an increase in the cost of purchasing fuel.

Insulating the outer section of the heating main reduces the likelihood of the coolant freezing in the event of a sharp drop in outside temperature. True, freezing of the heat supply structure is unlikely, but traffic jams may appear.

For this reason, insulation of a pipeline laid outside a building is a prerequisite for the operation of both internal and external sections of the heating system. Correctly selected insulation thickness can ensure protection of heating network elements from various types of damage, serious breakdowns and corrosive processes.

Rules for installing foil insulation

The rules for installing foil insulation are as follows:

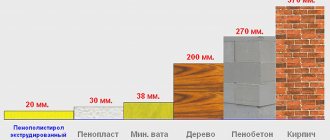

- Basically - with the exception of foiled polyethylene foam - the thickness of the material that will be used to insulate the ceiling, floor or wall is recommended from 50 mm. Of course, a thicker layer is quite acceptable, but this is not always economically justified. As a rule, ceilings need to be insulated more reliably.

- Since mineral wool absorbs moisture, once it gets wet it loses its characteristics, and in cold weather it can even turn into ice. Considering that the insulation itself does not release moisture well, it needs to be additionally insulated.

- To prevent water crystallization, the insulation must be protected, despite the fact that the foil generally should not allow moisture to pass through, but due to microdefects and damage to the aluminum layer, water can still get on the insulation.

- Even the presence of a hydro- and vapor barrier - a special fabric - steam can still get into the insulation. It is taking this circumstance into account that insulating layers are laid in such a way that moisture escapes into the space.

Popular brands and prices

Each foil insulation has its own leaders in the sales market. Here are the top three manufacturers of polyethylene foam, expanded polystyrene, glass wool and basalt wool (based on sales volumes) and the prices for these products.

Foil polyethylene foam. Many companies produce polyethylene foam insulation with a foil side. The leaders among them are:

- “Izolon” - can be bought from 78 rub./m2 with a thickness of 2 mm and from 110 rub./m2 with a thickness of 3 mm;

- “Penofol” - the price varies from 65 rub./m2 for insulation with a thickness of 3 mm to 456 rub./m2 with a thickness of 20 mm;

- "Ekofol" - sold at prices from 37 (2 mm) to 70 (10 mm) rubles/m2.

Please note: prices are average. Listed for St. Petersburg. In other regions, they may differ slightly in one direction or the other.

In addition to the above companies, Isoflex, Jermaflex and Folgoizol receive positive reviews.

Foiled polystyrene foam. Buyers are well aware of such brands of foil foam as Penoplex, Knauf, Technonikol and others. Prices depend on the thickness of the base. Therefore, for comparison, we will give in m3, although such a comparison does not make it possible to understand the huge variability of the price range: from 2.0 to 9.0 thousand rubles. for 1 cubic meter

Foil glass wool. Most often, foiled mineral wool is purchased - the price of insulation with a thickness of 50 mm is in the range of 130-140 rubles / m2. The brands “Rockwool”, “Knauf”, “PAROC” also find their buyers. However, prices here are much higher and have a wide range, and therefore it is inappropriate to list them.

Foil basalt wool. Among foiled stone wool, the leaders are “Rockwool” and “PAROC”. Prices are high and start at 4,000 rubles/m3 and end at around 14,000 rubles/m3.

Installation features

Installing insulation is not always simple and requires certain conditions to be met. The levels of the “insulation pie” are as follows:

- The finishing itself is usually made from natural materials. Wooden lining is often used as an environmentally friendly material.

- Vapor barrier. This is a film (membrane) that protects against moisture and vapor. Its installation is carried out close to the finishing material.

- Ventilation gap. This is simply an air gap created by lathing.

- Foil insulation for walls. Laying is done so that the reflected rays return to the room in the direction of the main wall.

- Waterproofing. Also a membrane that does not allow moisture to pass through, but allows steam to pass through. Its installation is carried out close to the insulation.

- An air gap is required between the foil and the adjacent surface, and if this is not done, the insulation will not reflect infrared rays.

The heat insulator is always located between the sheathing guides, which are used as wooden beams, the thickness of which should be greater than the thickness of the insulation. This provides a ventilation gap between the finishing material and the surface of the foil.

The guide battens should be installed at a distance of 3 cm, less than the width of the insulation itself. As for waterproofing, it is attached to the wall without a gap with brackets. This is how, due to the difference between the thickness of the wool and the cells of the sheathing, the material is seated tightly, without additional fixation.

Afterwards, a vapor barrier is attached to the sheathing, and the finishing is laid on top of it.

Insulation of walls indoors

Insulation of indoor walls is done only in the most extreme cases, when there is simply no alternative. Both builders and manufacturers of all kinds of insulation materials are arguing everywhere about whether this can be done.

This solution is far from the best, and external insulation would still be a more effective and justified method.

However, it happens when the walls of an apartment, for example, cannot be insulated in any other way due to very poor access to them due to the architecture of the house. Another point is that the high-rise building is too high to financially prevent the owners from hiring industrial climbers, and therefore people take risks by insulating their homes from the inside. There is one more nuance that does not allow insulating the apartment from the outside - the house may be an architectural monument and its pristine appearance is jealously monitored by local authorities.

It's time to talk about the disadvantages of this solution:

- Shift of the so-called “dew point” inside the housing. As a result, the walls freeze to their entire thickness, and cold air at the junction of the wall and the insulator meets warm air - hence condensation. The consequences are the most unpleasant - fungus on a wet surface, reduced efficiency of the heat insulator, deterioration of the finish, etc.

- When a wall freezes, it loses its ability to accumulate heat. Control over the temperature in the room becomes more difficult - the air warms up faster from radiators and from sunlight, and very quickly loses temperature when ventilated.

- There is no 100% thermal insulation due to cold bridges at the intersection of external walls and partitions inside the home.

- Increased humidity inside the house. This, along with mold and mildew, is harmful to health. To achieve good heat exchange, you have to ventilate your home very often - this increases heating costs.

- To some extent, the usable area of the house is reduced, especially if a thick layer of insulation is installed in harsh climates.

- If the renovation of the premises has already been done, you have to do it again, which is very troublesome and expensive.

- Over time, condensation will destroy the walls and spoil the finish.

To some extent, calculating the required layer of insulation and choosing the right material partially saves the situation.

And yet, sometimes such insulation measures are unavoidable, and it is still possible to ensure dry walls by protecting the places where the dew point forms from the harmful effects of moisture.

Measures:

- Use of a high-quality multi-layer membrane to provide waterproofing. At the same time, it is necessary to lay it correctly - overlapping, sealing after the joints.

- Select insulation with low vapor penetration rates. And if the wall material has a higher value, then there will be no condensation, since the moisture will come out.

- The insulation must be attached close to the wall surface. This is achieved by applying glue not in a continuous layer, but in dots or paths (beacons).

- To ensure forced ventilation, you will need to install windows equipped with air exchange valves.

- An accurate calculation of the thickness of the insulator is necessary - a reference point to average parameters will not help here, because it is necessary to take into account all the characteristics of the material used, the premises and the climatic zone.

- It is imperative to treat the walls with an antiseptic, for example, a special primer. Further work should be carried out only after the walls have completely dried.

Insulation of walls outside

Insulating the walls of a house or apartment from the outside is completely justified. There is a high efficiency of insulation, low price (insulation from the inside is usually more complex and expensive), ease of installation.

A huge number of people choose this particular method for the reasons listed above.

Perhaps the clear leader in insulating walls outside is occupied by polystyrene foam, which has an affordable price and is easy to process and install.

Balcony insulation

Such an aspect as insulating the balcony is also important, because the microclimate in the apartment depends on it. This part of the apartment is insulated using foil insulation, which has a polyethylene base. It is foamed, and then aluminum foil is glued on. The thickness of the finished combined material can be no more than 10 mm.

The canvas plays the role of a damper, reinforcement and effectively prevents heat loss.

Many people know this material under another name - penofol. It can be produced single-sided or double-sided, and its surface can be either corrugated or smooth. Additional protection may also be provided - a polyethylene film - it is applied by lamination.

Insulating a balcony without additional insulation is ineffective. That is why penofol is alternated with mineral wool or polystyrene foam.

It is easier to finish with polystyrene foam, especially if you use special glue (foam).

Insulation scheme:

- The surface must be prepared before sticking the foam.

- Next, wooden blocks should be secured on top of these layers - the finishing will be attached to them.

- The resulting “pie” is sewn up with any finishing material - for this they use plaster, siding, block house, etc.

- You cannot lay penofol overlapping - the joints must be sealed using special aluminum tape.

- When insulating the floor, guides should be placed according to the level, and foam plastic should be placed between them. Penofol is spread on the guides.

Further, there are the following installation methods:

- The floor is installed on top of penofol.

- Another sheathing is installed (second level), and then the floors are laid.

Experts advise using the second option, because with the first it is impossible to obtain the ventilation gap necessary for reflection. If this is not done, then there is no point in using penofol, since it will be of no use.

Thermal insulation of pipes

Pipes no less need insulation, no matter where they pass - above or underground. Heat losses must be reduced to a minimum, and foil insulation is successfully used for this purpose.

It is even used inside unheated rooms, country buildings, in basements, etc.

In order to install foil heat insulators, you do not need to have any special knowledge and skills - any construction amateur can do this.

If the insulation is made in the form of a cylinder, then such installation is even simpler: after removing the protective film covering the adhesive layer, then you should connect both halves together - the cylinder consists of two longitudinal parts.

The reflective surface of the communications protects them from the sun, if the reflector is located on the outside, and if the coating is on the inside, then heat transfer occurs towards the pipe.

Some industrial communications should not be heated in the sun for safety reasons, so we can solve this issue with the help of foil insulation.

These materials can be used for interior decoration; in addition, they are successfully used outdoors. The basis of such insulators:

- Foamed polyethylene.

- Expanded polystyrene.

- Mineral (basalt) wool.

- Stone wool (a type of mineral wool).

- Metallized foam insulation.

Bath protection

To insulate baths, roll materials are often purchased - it is much easier for an unskilled worker to work with them. Foamed polyethylene or mineral wool of medium thickness are also used.

Most often, wooden buildings are insulated, starting work from the ceiling, then moving to the walls, and the floors are insulated with foil material last.

In addition to this insulation, for the work you will also need parchment - this is for the ceiling, and it is laid in tandem with mineral wool.

Wall insulation scheme:

- A wooden sheathing is made, on which the rolled material is laid.

- Then the planks are attached to the sheathing - they secure the material. Then the ceiling covering is attached to them.

If the insulation breaks, it is sealed with special metal tape.

The absence of basalt (mineral) wool is replaced with other foil materials, if they are already available. Installation is done the same way.

The easiest installation method is using polyethylene foam. In this case, the roll is cut into strips of the required size and the ceiling is insulated. The seams are glued together with heat-resistant tape.

They do the same with walls. The only difference is that a five-centimeter overlap is required - this must be taken into account when cutting material for the entire scope of work. This measure will not allow the steam to leave the premises.

A small gap should be left between the foil layer and the inner surface of the wall.

Since steam always rises, increased attention should be paid to ceiling insulation. Many bathhouse organizers lay basalt wool in two layers, considering this measure necessary, despite the financial costs.

Outside the building

Wooden houses also need insulation, and here the best option would be to do it from the inside. If this is not feasible, external insulation is also acceptable.

To accomplish this task, mineral wool with a thickness of 5 cm is used.

What you need to prepare for this:

- Glue.

- Dowels and a gun.

- Sanding brush.

Work should begin with the arrangement of a metal cornice, which is secured with dowels. This is required for the even placement of mineral wool slabs. Next, step by step:

- Glue is applied to the inside of the wool, and the slab is pressed against the wall surface. Plastic dowels serve as auxiliary fastening.

- Level the surface using the mentioned brush.

- A windproof film is laid on top of the insulating layer.

- Next comes priming, and after that comes external finishing.

When insulating a wooden house, it is necessary to use antiseptic compounds and the corners must be treated especially carefully.

External insulation can be done using perforated foam foam - it will protect the walls from getting wet. How it's done:

- A rack structure is being built, to which sheets of this insulation will then be attached.

- The joints are sealed with metallized tape.

Next comes the arrangement of the finishing layer.

Internal wall insulation

Internal insulation of wall surfaces can also be made with penofol - this is a universal material used for all types of insulation. The recommended layer is 5 mm.

If insulation is carried out in a cold climate zone, then this insulation alone will not be enough - another additional layer of mineral wool in rolls will be required.

How to install:

- The material is cut based on the height of the walls.

- Penofol is attached using a construction stapler.

- Upon completion of installation, the joints are sealed with tape.

- A plasterboard sheet (GKL) is laid on top of the insulator.

It is possible to replace penofol with foiled basalt wool.

For roofing

To insulate the roof, mineral wool, foil-coated basalt slabs, and penofol are often used. The latter cannot always solve the problem due to its small thickness, which may not be enough to achieve the required effect in severe winter conditions. Therefore, it is used in conjunction with mineral wool, for example.